Prev Page--Recharge || Next Page--Chemical Character

Ground Water, continued

Recovery of Ground Water

Principles of Recovery

When water is pumped from a well the water table in the vicinity of the well is lowered to form a depression resembling an inverted cone. This depression of the water table is called the cone of depression or cone of influence, and the vertical distance that the water table is lowered is called the drawdown. The cone of depression expands and deepens as water travels toward the well from successively greater distances, until it intercepts sufficient recharge to balance the pumping. In any given well, the greater the pumping rate the greater the drawdown; the water level drops rapidly at first, then more slowly. When pumping ceases the water level rises rapidly at first, then more slowly for some time, until its original level is approached or reached.

Dug Wells

Dug wells are wells that have been excavated, usually by hand with pick and shovel. Dug wells in Cheyenne County are most common in areas where ground-water supplies are limited. In such areas wells of large diameter are dug to provide a reservoir for water. In Cheyenne County most dug wells extend through the water-bearing beds and a few feet into the Pierre shale. They are cased with concrete, iron, galvanized iron, or rock. Several dug wells in Cheyenne County are uncased because they are dug mainly in loess, which stands in vertical walls without caving. As most of the dug wells tap poor water-bearing material they have a small yield. Several irrigation wells and the St. Francis municipal wells were dug to the water table, then drilled deeper.

Bored Wells

Bored wells are made by post-hole diggers or hand augers. They are common in South Fork Valley where the water table is shallow. Bored wells are usually cased with 5- or 6-inch galvanized-iron casing.

Drilled Wells

Most of the domestic and stock wells were drilled by cable-tool drills. The cable-tool or percussion method uses a heavy bit which is lifted and dropped at regular intervals to produce a cutting action at the bottom of the hole. The crushed material in the well is mixed with water added during the drilling and is removed by means of a bailer. The hydraulic-rotary method also is used for the drilling of domestic and stock wells. In this method cutting is done by rotating in the hole a cutting bit at the end of a hollow drill pipe. Cuttings are removed by circulating muddy water under high pressure down through the drill pipe and up through the annular space between the pipe and the hole. The cuttings are brought to the surface as fragments suspended in the mud. The drilling mud prevents caving of the hole by plastering the walls.

The hydraulic-rotary method and the reverse-rotary method are used in the construction of wells of large capacity. In the reverse-rotary method the direction of flow of water is reversed, the cuttings being carried up through the drill pipe. In Cheyenne County the most common method of constructing wells of large diameter and large capacity is to dig down to the water table by hand and to deepen the well beneath the water table by drilling or by means of a sand pump: In the sand-pumping method, casing is placed in the dug part of the well and forced downward as sand and water are removed from the bottom of the well with a bailer. This method is most effective in deposits of uncemented sand and gravel such as in the alluvium of South Fork. The municipal wells at St. Francis were constructed in this manner.

Most of the drilled wells in Cheyenne County obtain water from unconsolidated or partially consolidated deposits of Pleistocene or Pliocene age. Wells in these deposits are ordinarily cased from top to bottom with steel, iron, or galvanized-iron casing to prevent caving. The casing below the water table is perforated or a well screen is used to allow the free passage of water into the well. The size of the openings in the screen or perforated casing is an important factor in the construction of a well. If the openings are too large, the fine material may filter through and fill the well; if the openings are too small, they may become clogged so that water is prevented from entering the well freely. A common practice is to select an opening size that will pass 30 to 60 percent of the particles of the sizes making up the finer-grained water-bearing material. The coarser particles that remain around the screen form a natural gravel packing which increases the effective diameter and thus the specific capacity (yield per foot of drawdown) of the well.

Gravel-packed wells are generally effective for increasing yields of wells penetrating mainly fine sand, and the gravel packing of wells has been practiced to some extent in the construction of irrigation wells in Cheyenne County. In drilling a well of this type in this area a hole of large diameter is first drilled and cased with unperforated casing. A smaller well screen or perforated casing is centered in the hole opposite the water-bearing beds, and enough unperforated casing to reach the surface is added. The space between the two casings is filled with sorted gravel, preferably of a grain size just slightly larger than the openings in the screen or perforated casing, and also just slightly larger than the particles of water-bearing material. The outer casing is then withdrawn, uncovering the screen and allowing water to flow from the water-bearing material through the gravel packing. The envelope of gravel placed around the screen increases the effective diameter of the well, prevents the movement of fine sand into the well, and increases the production of sand-free water. The drawdown is generally reduced appreciably because the friction of water entering the well is reduced. The character of the water-bearing material usually determines whether construction of gravel-packed wells is advisable. If the material is coarse and well sorted, as is generally the case in the alluvium of South Fork Valley, gravel-walled wells are not necessary. Where wells are to be drilled in the poorly sorted fine-grained materials of the Ogallala formation in the upland areas of Cheyenne County, gravel packing may be beneficial. For a more detailed discussion of well construction and development the reader is referred to publications by Rohwer (1940), McCall and Davison (1939), and Bennison (1947).

Methods of Lift and Types of Pumps

Most domestic and stock wells in Cheyenne County are equipped with cylinder pumps. Many use windmills for power, but some are operated by hand and some are equipped with pump jacks operated by gasoline engines or electric motors. A few wells are equipped with electrically driven jet pumps. The spread of rural electrification in the county has increased the number of electric pumps in use. Some wells are equipped with the force type of cylinder pump which is used to pump water for considerable distances or to considerable heights. Most of the cylinder pumps are of the lift type, which discharge water at the surface or in near-by storage tanks or cisterns.

Irrigation wells in Cheyenne County are equipped with either horizontal centrifugal or deep-well turbine pumps operated by stationary gasoline, butane, or diesel engines, or by tractors. Horizontal centrifugal pumps can be used only where the depth to water plus the drawdown does not exceed the working suction limit. These pumps are usually set in pits dug nearly to the water table. A common type of irrigation pumping plant in South Fork Valley consists of two or more wells connected to a centrifugal pump by a suction pipe laid in the ground just above the water table. An installation of this type is called a battery of wells. Deep-well turbine pumps are used in the irrigation wells in the uplands and in some of the wells in South Fork Valley.

Several types of electrically operated pumps are used in the municipal wells at St. Francis and Bird City. St. Francis has two deep-well turbine pumps, one centrifugal pump, and a piston-type suction pump. Bird City has two turbine pumps and a plunger-type cylinder pump. The railroad well at St. Francis has a piston-type suction pump.

Utilization of Ground Water

During this investigation information on 361 wells and 1 spring was obtained. Only a small percentage of the domestic and stock wells was visited, but records were made for all public-supply wells and for the railroad well at St. Francis. Most of the irrigation wells were visited also. Records of wells are listed in Table 6 and the principal uses of water are described below.

Domestic and Stock Supplies

Nearly all the domestic water supplies of Cheyenne County are from wells. Springs supply a small amount of water for domestic use. In parts of Cheyenne County ground-water supplies are lacking or contain excessive amounts of minerals and water for cooking, drinking, and washing, must be hauled. Tn general, ground water in Cheyenne County, although moderately hard, is suitable for most domestic uses.

Most stock-water supplies are also from wells but water from springs, streams, stock ponds, and undrained depressions is used to some extent, especially in areas where wells are difficult to obtain.

Public Supplies

Public water supplies at Bird City and St. Francis are obtained from wells. Data on the Bird City and St. Francis municipal wells are given in Table 6.

Bird City--Bird City obtains its water from three wells in the city park which penetrate the Ogallala formation. These wells are reported to range from about 230 to 260 feet in depth and individual yields are estimated to range from 55 to 125 gallons a minute. The wells pump directly into the mains and the excess is stored in an elevated tank holding 50,000 gallons. The maximum daily consumption in 1950 was 228,000 gallons on June 12. On some days the consumption was as low as 30,000 gallons. The average daily consumption is about 80,000 gallons. The quality of water used in Bird City is indicated on Table 3 (well 3-38-36 bad).

St. Francis--St. Francis, the county seat of Cheyenne County, obtains its water supply from four wells deriving water from the alluvium of South Fork. The wells range in depth from about 25 to 30 feet and all are drilled through the entire thickness of the alluvium into the Pierre shale. They are near the power plant and pump directly into the mains, the excess going to an elevated water tank in the southern part of town. The capacity of the tank is 225,000 gallons. The maximum yield of each well is about 300 gallons a minute. The average daily consumption is about 500,000 gallons, but during dry periods when gardens and lawns are irrigated the daily consumption is much greater. An analysis of a composite sample of water from the St. Francis municipal. supply is included in Table 3 (well 3-40-2ldcd). The water is not treated.

Industrial Supplies

The Chicago, Burlington and Quincy Railroad at St. Francis has one well used principally for filling locomotive boilers. No data concerning the yield of the well and the amount of water used by the railroad are available.

Irrigation Supplies

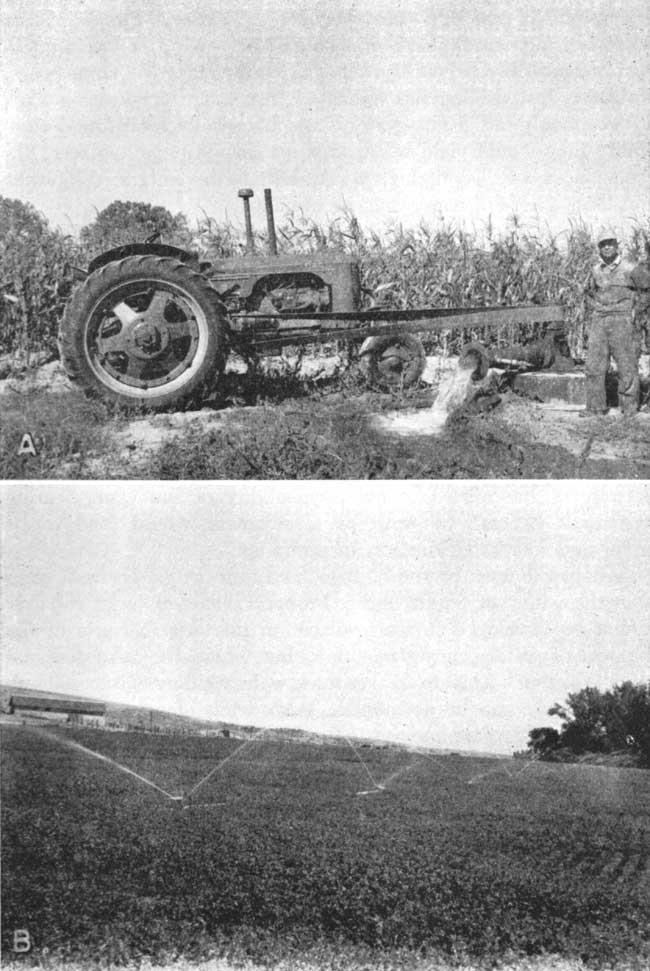

Irrigation, both from South Fork and from wells, was practiced on a small scale in Cheyenne County many years ago (Hay, 1895, p. 586; Wolff, 1911) and is still practiced to a small extent. Although 27 of the wells visited were classified as irrigation wells, very few pumped an appreciable amount of water in 1950. Some of the wells had not been used for several years. The main crops irrigated in 1950 were corn, alfalfa, and milo maize, the total acreage being a few hundred acres. The amount of water used for irrigation in Cheyenne County is small. A few wells equipped with windmills are used to pump small amounts of water for irrigating gardens. Yields of irrigation wells tested ranged from 150 to 900 gallons a minute. A typical irrigation well and an irrigation sprinkling system in Cheyenne County are shown on Plate 5.

Plate 5--A, Irrigation well 1-38-19adc in South Fork Valley, pumping 400 gallons a minute. B, Irrigation sprinkling system irrigating alfalfa in South Fork Valley, sec. 29, T. 3 S., R. 40 W.

Possibilities of Further Development of Irrigation Supplies

Further development of irrigation supplies from wells in Cheyenne County depends upon the thickness of the water-bearing materials and their permeability, and the amount of recharge to the ground-water reservoir. Figure 9 indicates that, in general, there is little saturated material north of South Fork and the chances of developing irrigation wells north of the river, except in the immediate vicinity of the river, are very poor. South of the valley the water-bearing deposits reach a maximum of nearly 180 feet in thickness and possibly irrigation wells can be developed in some areas. However, test drilling has indicated that the water-bearing beds are commonly rather fine-grained, and because of their low permeability they would yield water to wells slowly in most places. In some places beds having high permeabilities are penetrated by wells and large yields of water may be obtained.

The feasibility of further development of irrigation supplies from wells depends upon the availability of ground water as discussed in the preceding paragraph, the cost of drilling and pumping, the types of soil, the topography, the kinds of crops raised, the market and price conditions, and other factors beyond the scope of this report. The cost of drilling and pumping is determined to some extent by the depth to water level. Depths to water level in areas in Cheyenne County where an adequate supply of ground water for irrigation might be obtained range from less than 10 feet in areas along South Fork to more than 200 feet in the vicinity of Bird City. Because of the relatively low permeability of the water-bearing formations beneath the uplands, drawdowns would tend to be large, thus increasing the cost of pumping.

Perhaps the most promising area for future irrigation from wells is in the valley of South Fork. Probably wells of large capacity cannot be developed in many places in this area because of the thinness of water-bearing materials, but where the saturated material is as much as 20 to 30 feet thick wells yielding 300 to 400 gallons a minute can be developed. Also, wells along the river are shallow and therefore inexpensive to drill and economical to operate. Large yields from wells probably can be obtained in many areas in Cheyenne County where the aquifer is thick, although in these areas the water table is generally 100 feet or more below the surface. More wells may be drilled in such areas if future economic conditions are suitable.

Prev Page--Recharge || Next Page--Chemical Character

Kansas Geological Survey, Geology

Placed on web Aug. 8, 2008; originally published April 1953.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/General/Geology/Cheyenne/05_gw3.html