Prev Page--Structure || Next Page--Invertebrate Faunas

Mineral Resources

Coal

General Statement

All of the economically important coal beds in the southeastern Kansas coal field occur in the Cherokee shale. The thickest coal bed in the field is the Weir-Pittsburg bed, which is near the middle of this shale unit. There are seven to nine thin coal beds below it in the Cherokee shale, uncertainty in number being due to lack of determination of continuity owing to the thinness of the beds in this area; some have been mined locally, mostly by surface stripping. The Cherokee shale contains six coal beds in the stratigraphic interval of about 120 feet from the Weir-Pittsburg coal up to and including the coal just above the Ardmore limestone. Of these six beds the Mineral and Bevier coals have been extensively mined commercially and two others have been worked at a few places where the coal thickens locally. The Fort Scott coal near the top of the formation is the only coal in the upper 100 feet of the Cherokee shale in Cherokee and Crawford counties. In southeastern Labette County there are a few thin, local beds between the Ardmore limestone and the top of the Cherokee; these beds probably continue southwestward into Oklahoma.

For a graphic summary of the coal beds the reader is referred to figure 2, which shows the relative position of the beds and the approximate intervals from them to other coal beds and recognizable stratigraphic units.

Many of the coal beds to be discussed in this report have not been named in the literature. Most of the beds have local names, but such names are sometimes extended laterally only a few miles, and in some cases several local names are used in different localities for the same bed. It therefore seemed desirable at this time to exercise considerable care in the selection of names for the coal beds of this area. At the suggestion of the State Geological Survey of Kansas, the authors sent that Survey a list of the tentative names which we were proposing for the coal beds of southeastern Kansas. A conference on southeastern Kansas nomenclature, which included members of the Kansas Survey and a member of the Missouri Geological Survey, considered the questions involved in the naming of the various coal beds and stratigraphic units and, through correspondence, agreement was reached on the terminology to be used. Further discussions of the naming of individual coal beds will be given at their appropriate places in the following descriptions of the beds.

(NOTE: Those attending the meeting at Lawrence, Kan in March 1936, were R. C. Moore, K. K. Landes, C. M. Young, G. E. Abernathy, and N. D. Newell. A second meeting in April included the same members and also F. C. Greene.)

Riverton coal bed

In a previously published statigraphic section (Pierce and others, 1935) the authors called the coal below the Little Cabin sandstone the "Little Cabin coal." In order to conform with usage to be adopted by the Kansas Geological Survey, however, it will here be called the Riverton coal, from the village of that name in southeastern Cherokee County. The Riverton coal is normally 15 to 20 feet above the base of the Cherokee shale. In places it is overlain directly by the Little Cabin sandstone, but elsewhere a foot or two of gray shale intervenes. The Riverton coal is from 3 to 14 inches in thickness and seems to be of good quality, but it is not of sufficient thickness to be mined commercially. It was observed at several places along the crop in southeastern Cherokee County and is probably fairly persistent in a northeasterly direction following the trend and strike of the Little Cabin sandstone, but outcrop and drill-hole data were not sufficient to determine with certainty the lateral continuity of the coal. As stated earlier, the Riverton coal may be absent due to erosion and its horizon occupied by the Little Cabin sandstone in some areas. Little is known about the extent of the coal to the northwest where it is concealed beneath younger rocks, but judging from the seeming lenticularity of the Little Cabin sandstone in that direction and the probable orientation of the shore line of the Cherokee sea in a northeasterly direction, the sea lying to the northwest, it is likely that the Riverton coal is even more lenticular and discontinuous to the northwest than along its outcrop. In the NE SE sec. 33, T. 32 S., R. 25 E., 10 inches of coal was measured in a small draw and a quarter of a mile to the northwest are some old strip pits, probably in the Riverton coal.

Local coal beds from 50 to 175 feet above the base of the Cherokee shale

The interval from 10 feet or more above the Little Cabin sandstone to 20 feet or more below the base of the Bluejacket sandstone, comprising about 125 feet of strata, contains four or five coal beds. The exact number of coal beds could not be determined because single exposures do not show more than one or two coal beds, and this part of the Cherokee does not contain distinctive beds which can be used as stratigraphic ties between individual outcrops and thereby build up a reliable detailed section. The individual coal beds have not been mapped, but places where the coal has been stripped are indicated on the map (Pl. 1). The greater part of the strip mining of these beds has been done in T. 31 S., R. 25 E., the eastern part of T. 32 S., R. 24 E., and T. 32 S., R. 25 E. Considerable stripping has been done along Taylor Branch, west and southwest of Opolis. The thicknesses of these local beds vary from a few inches to 16 inches. In a highway borrow pit just west of Taylor Branch and on the south line of sec. 14, T. 31 S., R. 25 E., there is 16 inches of coal (upper 1 inch dirty coal) overlain by greenish-gray shale and underlain by hard gray clay. A mile down the creek, near the south line of section 23, there are two coal beds which are probably lower than the one just mentioned. The upper one of the two is not completely exposed; where measured it was 8 inches thick. Its total thickness is unknown, however, because the top has been eroded. About 3 feet below this coal is another which has been mined from the bed of the creek. It is reported to be from 3 to 6 inches thick. A drill hole near this locality shows that this bed is about 85 feet above the base of the Cherokee. There are other small strippings and coal outcrops for several miles down the creek.

Several thin coal beds have been stripped along a tributary of Cow Creek in secs. 7, 17, 18, and 20, T. 32 S., R. 25 E. In a strip pit in the NW NE sec. 20, 15 inches of coal was measured. In the E/2 of the SW sec. 18, a coal bed from 18 to 20 inches thick has been stripped. About 10 feet above this is a bed of weathered coal a few inches thick. In the NW NW sec. 18 there are also two coal beds, perhaps the same beds as just mentioned. The thickness of the coal that has been stripped was not determined, but about 8 feet above it is another bed from 12 to 15 inches thick, the upper half of which is dirty.

The Meyer mine, in the NE sec. 30, T. 32 S., R. 25 E., is worked from a shaft 70 feet deep. The coal is reported to be from 3 to 3 1/2 feet thick, which is twice as great as any of the other coal beds in this part of the Cherokee shale. The mine was closed at the time of the field examination, so there was no opportunity to examine the coal. The coal is seemingly between 40 and 90 feet above the base of the Cherokee. A line of drill holes, at intervals of 600 to 1,000 feet apart, extending from the southwest corner sec. 29, T. 32 S., R. 25 E., to the center of the north line of that section, show a sharp trough; the altitude of the base of the Cherokee drops from 780 feet to 710 feet. Shale exposures in the southwest quarter of the section adjoining on the north show a south dip of about 1 degree. The trend of the trough is not known, but if it were assumed to be at a right angle to the line of drill holes, and were extended southeastward, it would pass through the area where the Meyer coal mine is located. In view of this indication of a northwest-trending structural depression, shown on the structure map (Pl. 5), it is possible that the coal at the Meyer mine may be the Weir-Pittsburg bed. It seems more likely, however, that it is a bed below the Weir-Pittsburg that locally is considerably thicker than normal.

Columbus and Rowe coal beds

The coal which underlies the Bluejacket sandstone was called the Columbus coal by Crane (Haworth and Crane, 1898), from the town of that name in central Cherokee County.

The Columbus coal occurs in the Timbered Hills area, 2 miles southwest of Crestline, and east and south of Columbus. The outcrop of this coal was not mapped, but its location conforms approximately with the outcrop of the base of the Bluejacket sandstone which is shown on Plate 1. The coal, however, is not a continuous bed throughout the extent of the Bluejacket sandstone. The largest strip pit in the Columbus coal is about a mile northeast of Columbus, in the SE sec. 7, T. 33 S., R. 24 E. A steam shovel is used to remove the overburden consisting of about 6 feet of soil, underlain by 4 feet of sandstone, a thin irregular bed of soft coal about 3 inches thick, and 9 feet of shale. The Columbus coal is reported to be from 6 to 14 inches thick; two measurements along the working face showed thicknesses of 10 and 12 inches. There are many other places where the Columbus coal has been mined from small strip pits, but most of them are now partially filled and the coal is not exposed. In a road cut about 1,700 feet east of the center of sec. 18, T. 33 S., R. 24 E., the following section was measured:

| Section of Columbus coal and associated beds east of Columbus | Feet |

|---|---|

| Soil | 1 |

| Sandstone (Bluejacket) | 7 |

| Shale, lower part dark and fissile | 7 |

| Coal (Columbus) | 1 |

| Clay, gray | 5+ |

The Columbus coal has been worked from small slope mines in sec. 24, T. 33 S., R. 24 E., and the SW sec. 19, T. 33 S., R. 25 E. The coal is about 10 inches thick and is either overlain directly by a hard, thick bed of sandstone, or has a foot or two of shale intervening.

The Rowe bed is named from the Rowe school at the northeast corner of sec. 34, T. 30 S., R. 25 E. Although the Rowe coal is from 10 to 15 feet below a bed of sandstone, this bed cannot be identified as Bluejacket sandstone, since the latter could not be traced into southeastern Crawford County and thereby furnish a means of correlation. The records of drill holes that begin above the Weir-Pittsburg coal and extend some distance below, likewise could not be used for precise correlation, for the Rowe coal could not be identified in the logs. Consequently the stratigraphic relation of the Columbus coal to the Rowe coal is unknown, but they are thought to be at approximately the same horizon. The Rowe bed is unique, in that it contains a persistent shale parting that serves for identifying and correlating this coal. In the local area of outcrop, shown on Plate 1, the Rowe bed consists of 14 to 16 inches of coal at the top, a gray clay-shale parting about 2 inches thick, and 3 1/2 to 4 inches of coal at the base. The following section was measured at the Ridge Coal Co. strip pit:

| Section of Rowe coal and overlying beds in the NW sec. 35, T. 30 S., R. 25 E. | Feet | Inches | |

|---|---|---|---|

| Soil | 3 | ||

| Sandstone, light gray, micaceous | 10 | ||

| Shale, bluish-gray | 8 | ||

| Shale, gray, with ironstone bands | 2 | ||

| Coal, usually much thinner or absent | 1 | 4 | |

| Shale, yellow | 5 | ||

| Shale, bluish-gray, hard | 6 | 6 | |

| Rowe bed | |||

| Coal | 1 | 4 | |

| Clay-shale, gray | 2 | ||

| Coal | 4 | ||

The Rowe bed has been mined from a drift near the center of the east line of sec. 27, T. 30 S., R. 25 E. Here the underclay beneath the coal has been mined to a limited extent along with the coal for pottery clay. The same coal has been stripped in the section to the east in the NW SW sec. 26. The largest strip pit on the Rowe coal is in the NW sec. 35, T. 30 S., R. 25 E., where a small steam shovel is used to remove the overburden. The Rowe bed has been mined from drifts along the south side of the creek in the S/2 sec. 35. The coal extends on southward into T. 31 S., R. 25 E., but could not be definitely traced much beyond the north line of the township, because of structural irregularities and steep local dips in the Cherokee shale.

Coal between the Columbus and Weir-Pittsburg beds

Within an area bounded by Girard, Pittsburg, Columbus, and Monmouth, the logs of drill holes that either go below or start below the Weir-Pittsburg coal show one, and in some places two coal beds, less than 40 feet below the Weir-Pittsburg bed. The coal is from 3 to 12 inches thick and is apparently very lenticular. None of this coal has been mined and, so far as known, is nowhere thick enough for commercial mining.

Weir-Pittsburg coal bed

Weir-Pittsburg bed was named from two of the early coal-mining towns located near the outcrop of the bed. It is also locally known as the Cherokee coal. The extent of the bed is well known from extensive underground mining and surface strippings. The outcrop of the coal has been traced for a distance of about 50 miles, beginning 1 1/2 miles east of Arcadia in the northeast corner of the area and extending southwestward to within 2 miles of Columbus. That part of the Weir-Pittsburg bed lying in Missouri was mapped by automobile reconnaissance; the outcrop of the coal can be determined with fair approximation from the location of strip pits.

The Weir-Pittsburg bed lies near the middle of the Cherokee shale. In the northern part of the field it is about 175 feet above the base of the Cherokee, but toward the southern part this interval increases to 250 feet. The interval from the top of the Cherokee to the Weir-Pittsburg coal is fairly constant in most of the field, ranging from 200 to 225 feet. Just southwest of Mulberry, however, in the northeastern part of the outlier of the Fort Scott limestone, on the hill known locally as Breezy Hill, the interval from the top of the Cherokee to the Weir-Pittsburg coal is only 165 feet. Drill logs show that this thinning takes place in the interval between the Ardmore limestone and the top of the Cherokee shale; normally this interval is about 100 feet, but here it is only 65 to 70 feet.

The Weir-Pittsburg coal is the only coal bed in the field over 2 1/2 feet in thickness. It is overlain by 20 to 30 feet of finely laminated gray shale. The shale usually contains a sandy zone about 3 feet thick near the middle, and in some places this zone grades laterally into a thick and prominent sandstone (see Pl. 3-C).

The thickness of the coal is about 2 feet 10 inches in the northern part of the field and 3 feet, 8 inches in the southern part. These thicknesses are averages for the field as a whole, for although the bed maintains a uniform thickness for many miles, the coal content varies considerably owing to "horsebacks" and "clay veins" which displace the coal. The "horsebacks" and related features are discussed in detail by Crane (Haworth and Crane, 1898). The workable limits for underground mining of the Weir-Pittsburg bed are fairly well known. Arcadia is near the northern end. The southern limit does not extend much beyond a line drawn from Columbus to Mineral, for beyond this point the coal thins to less than 2 feet. The northwestward limit of workable coal in the Weir-Pittsburg bed is known approximately from mine workings and numerous drill records and is indicated on Plate 7 by the 2 1/2-foot thickness line extending from Mineral to the northeast corner of Crawford County. Young (Young and Allen, 1925) believes that this western limit as now known has been determined by some factor other than thinning of the coal and suggests two possibilities: (1) Stream channels which cut out the coal in a narrow belt, and (2) either faulting or a change in dip which has changed the bed from its normal position. The structure map (Pl. 5) shows that this latter possibility need not be considered. From a study of the stratigraphy of the strata overlying the Weir-Pittsburg coal and the regional extent and character of the coal bed, the writer interprets the western workable coal limit as due to thinning near the margin of the basin in which the coal was deposited with the Cherokee sea lying to the west and land to the east.

The Weir-Pittsburg bed thins rapidly north of Arcadia. In Vernon County, Missouri, it is called the "Weir-Pittsburg lower," and in the southwestern part of that county is 5 to 9 inches thick; in the northern and western parts of the county drilling shows this coal (Greene and Pond, 1926) to be very thin or absent.

A line drawn through points where the thickness of the Weir-Pittsburg coal is reported as 2 1/2 feet is shown on Plate 7. The thickness of the coal is determined from drill-hole data and mine workings. West of this line the average thickness of the coal is reported to be less than 2 1/2 feet and east of it the average thickness is reported as 2 1/2 feet or more. This line may be regarded as the approximate western limit of workable coal at the present time. The "workable thickness" of a bed mined by underground methods, however, is dependent upon economic and other conditions, as well as the thickness of the coal, and for that reason may change from time to time. Of course, where the coal can be mined by stripping the overburden, the workable limit may be much less, and consequently some areas that are not workable by underground methods may be mined by stripping if the overburden is not too great.

The mined-out areas on the Weir-Pittsburg bed are shown on Plate 7. On this map the coal which has been mined from shafts is differentiated from the coal that has been stripped. It is now practically impossible to determine accurately the extent of underground workings, for several years ago many of the maps of abandoned mines were destroyed in a fire. The extent of the mine workings has been taken in large part from a map prepared by the Central Coal & Coke Co. in 1929. The mine workings since that time have been incorporated in the present map, together with some revisions. A few of the areas, which have not been mined, contain good coal, but for the most part they contain either thin or "faulty" coal. In this area, the term "faulty" is commonly used to describe coal which is of irregular thickness, has numerous horsebacks and clay veins, and is oftentimes rashy or impure at the top.

Plate 7--Map of the Weir-Pittsburg coal bed in southeastern Kansas and adjoining part of Missouri, showing the coal outcrop, amount of overburden, and areas which have been strip mined and shaft mined. [A larger Acrobat PDF version of this plate is available.]

The amount of overburden on the Weir-Pittsburg bed is also shown on Plate 7. The Mineral coal bed lies about 75 feet above the Weir-Pittsburg bed; so the depth to the Weir-Pittsburg coal in the area between the Mineral coal outcrop and the Weir-Pittsburg coal outcrop is from 0 to 75 feet, the depth increasing from east to west. Similarly, the base of the Fort Scott limestone is about 200 feet above the Weir-Pittsburg coal, so the depth to the Weir-Pittsburg bed in the area between the base of the Fort Scott and the Mineral coal is from 75 to 200 feet. The depth to the Weir-Pittsburg bed in the area underlain by the Fort Scott limestone is 200 feet or more.

Extensive core drilling of two areas in southwestern Labette County has proved that a coal bed up to 4 1/2 feet in thickness lies from 425 to 625 feet below the surface. This bed is from 260 to 275 feet below the top of the Cherokee shale. The log shows that the upper 100 feet of the Cherokee is barren of coal, but below that is a succession of coal beds and a limestone bed, all of which has a striking similarity to the stratigraphic section in Crawford and Cherokee counties. The thick coal may be the approximate stratigraphic equivalent of the Weir-Pittsburg bed, but it may not be continuous with the Weir-Pittsburg bed. Possibly it was formed in a separate coal basin in which the period of coal formation was more or less contemporaneous with the period of coal formation in Crawford and Cherokee counties.

Pilot coal bed

The term "Pilot coal" is applied to the thin coal above the Weir-Pittsburg bed by many of the coal drillers, for it is a guide in prospect drilling for the Weir-Pittsburg coal. It is also known locally as the "Sun bed." At surface outcrops it is overlain by a distinctive series of beds which readily identify it from the other Cherokee coals. The coal is from 3 to 7 inches thick overlain by 12 to 20 inches of dark shale, which is followed by a 3-inch bed of ironstone, limestone, or a peculiar red, porous "clay." The following sections show the characteristic types of lithology in the strata above the Pilot coal:

| Section of Pilot coal and overlying beds measured 1,000 feet east and 200 feet south of the NW corner sec. 13, T. 28 S., R. 25 E. | Feet | Inches |

|---|---|---|

| Clay-shale, light gray with reddish specks | 8 | |

| Sandstone, thin-bedded | 6 | |

| Shale, bluish-gray, with gray disc-shaped concretions | 9 | |

| Ironstone, dark gray, dense, weathers yellow with rouge-red streaks | 2 | |

| Shale, dark gray | 8 | |

| Limestone, hard, black, fossiliferous | 2 | |

| Shale, black, slaty | 1 | 10 |

| Coal, Pilot bed | 7 |

| Section of Pilot coal and overlying beds measured in strip pit in SW SW sec. 17, T. 32 N., R. 33 W., Barton County, Missouri | Feet | Inches |

|---|---|---|

| Sandstone, buff, laminated | 5+ | |

| Shale, dark gray, laminated, with rusty yellow disc-shaped concretions | 4 | |

| "Clay"?, dark red, contains cavities and numerous gastropods | 4 | |

| Clay-shale, red to black | 1 | 1 |

| Coal, weathered, Pilot bed | 3 |

The Pilot bed is not of sufficient thickness in Kansas to be of economic value. It was noted at many places in northeastern Crawford County, but seems to be less continuous in the southeastern part of the county and in Cherokee County. Most of the logs of drill holes in both counties, however, show a thin coal at its approximate horizon. The Pilot coal lies from 8 to 30 feet above the Weir-Pittsburg bed; in northeastern Crawford County the interval is usually about 20 feet.

The Pilot bed is correlated with the Walker coal (Greene and Pond, 1926) of Vernon County, Missouri.

Coal between the Pilot and Mineral beds

Practically all of the logs of the drill holes available to the authors record a thin coal bed from 25 to 40 feet above the Pilot bed, and from 15 to 20 feet below the Mineral bed. The only exposures of this coal that were noted are along the west line of the NW sec. 14, T. 28 S., R. 25 E. There the coal has a maximum thickness of 8 inches and is underlain by gray clay and overlain by gray-brown shale containing small concretions. The thickness of the coal, according to drill logs, is from 3 to 12 inches.

Mineral coal bed

The Mineral coal bed is named from the town of Mineral, in northwestern Cherokee County, where it is extensively mined and exposed in strip pits. This bed has been referred to as the "Weir-Pittsburg Upper" and "Lightning Creek" in published reports, and locally has been variously termed the "Mineral," "Baxter," "22-inch vein," "top vein," and "upper seam." Haworth and Crane (1898) called it the Weir-Pittsburg upper coal, but because of lack of sufficient drill-hole data and strip-pit exposures at that time, the name was not always applied to the same coal bed. For example, in their record of a prospect hole near Mineral City (Haworth and Crane, 1898), the coal bed 3 feet 11 inches thick that is 122 feet below the surface is said to be the Weir-Pittsburg upper, but according to our data it should have been called the Weir-Pittsburg lower. The Weir-Pittsburg upper coal was described as "maintaining an average vertical distance of 30 feet" above the Weir-Pittsburg bed, whereas we have found that the average interval is more than twice that amount. Later reports (Young and Allen, 1925; Moore and Landes, 1927; U.S. Bureau of Mines, 1929) on Kansas coal use the name Lightning Creek coal for the bed, but inasmuch as the bed which was called Lightning Creek does not crop out on that creek and the coals that do crop out there are younger, it is advisable to discontinue the use of that name.

The outcrop of the Mineral bed, as shown on Plate 1, trends northeastward from a point about 2 miles northwest of Sherwin Junction, in Cherokee County; it passes near Carona, is about a mile west of Weir and Pittsburg, then trends eastward to within a mile of the Kansas-Missouri line, where it swings northward to a point less than 2 miles south of Mulberry. There the coal thins and could not be traced around the east side of Breezy Hill. Drill records, however, show its continuation under the west side of Breezy Hill. Northwest of Mulberry the coal is again of normal thickness and its outcrop extends on northward to the northeast corner of Crawford County. Several outliers of the Mineral bed in the northeastern part of Crawford County and in Missouri are also shown on Plate 1. The Mineral bed could not be traced in the area between Sherwin Junction and Neosho River. To the west of the Neosho, in Labette County, a coal is mapped which occurs at approximately the same horizon as the Mineral bed, and to simplify the terminology the same name is applied.

The Mineral coal lies between 65 and 80 feet above the Weir-Pittsburg coal, and is approximately 150 feet below the top of the Cherokee shale. Drill records show that the interval between the Mineral and Weir-Pittsburg coals increases to the northwest, but on the average the increase is not more than 2 to 3 feet to the mile. The Mineral coal is in many places overlain by a caprock of black fossiliferous limestone, from a few inches to a foot in thickness. The limestone is not a continuous bed; where it is not present the coal is overlain by black shale. In strip pits the Mineral coal can usually be identified by its relation to the Fleming coal bed which occurs a few feet above it (see Pl. 8-A).

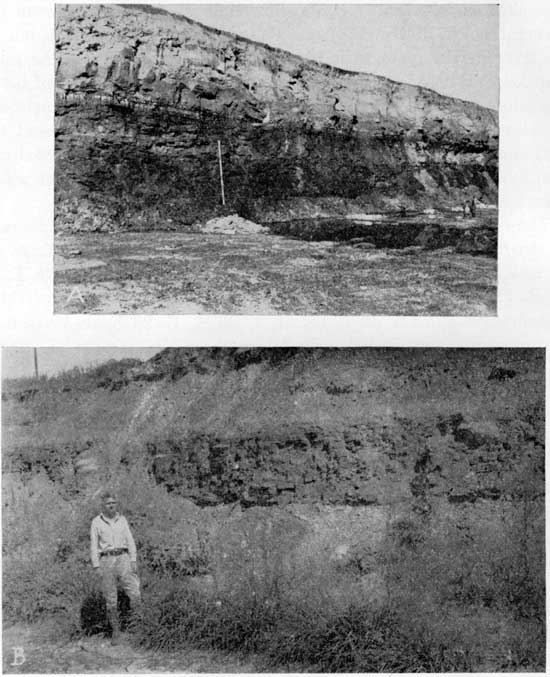

Plate 8--A, View showing the rocks overlying the Mineral coal in the wall of a strip pit in the SW sec. 34, T. 30 S., R. 24 E. Base of 13-foot stadia rod is 3 feet above the top of Mineral coal and the Fleming coal, 3 inches thick, is 4 feet below top of rod. The coal about 4 feet above top of rod is the Croweburg bed. The thick sandstone which overlies it is of local extent; B, View of typical succession of beds overlying the Croweburg coal, exposed in strip pit in NE sec. 3, T. 29, S., R. 25 E. Man stands near top of Croweburg coal (concealed).

The coal is usually between 17 and 24 inches thick. The average of two measurements in a strip pit in the NE sec. 34, T. 28 S., R. 25 E., is 17 inches; three measurements in a pit in sec. 23, T. 29 S., R. 25 E., gave an average of 19 1/2 inches; the average of three measurements in the pit in sec. 4, T. 30 S., R. 25 E., is 19 inches; two measurements in the strip pit in the SW sec. 34, T. 30 S., R. 24 E. averaged 24 inches; one measurement in sec. 20, T. 31 S., R. 24 E., shows 26 inches of coal; the average of two measurements in the pit in the NW sec. 9, T. 32 S., R. 23 E., is 20 1/2 inches. A few clay rolls and horsebacks were observed in the Mineral bed, but they are not nearly as numerous as in the Weir-Pittsburg bed and do not seriously affect mining operations.

In recent years the Mineral bed has become increasingly important as a commercial coal bed. It has been strip-mined at numerous places, extending southwestward from the northeastern part of Crawford County and into Cherokee County as far as Mineral (see Pl. 1). There are also a few small strip pits in southeastern Labette County. A few shaft mines have been opened on the Mineral bed in the vicinity of Mineral and Cherokee, but the coal is not thick enough for extensive underground mining.

Greene (Greene and Pond, 1926) correlated the Rich Hill coal of Missouri with the coal bed between the Pilot and Mineral beds of Kansas. His Kansas section, however, was measured near Mulberry where the upper half of the Cherokee is abnormally thin and the sequence of beds is not typical. The writer correlates the Rich Hill coal of Missouri with the Mineral bed, because it bears the same relationship to the older (Greene and Pond, 1926) and younger coals as do the coals described in Vernon County, because similar strata overlie both coals, and because the average interval from the top of the Cherokee shale to the coals is practically the same, being 146 feet for the Rich Hill coal, and between 145 and 150 feet for the Mineral coal.

Fleming coal bed

The Fleming coal is so named from exposures in strip pits just north of the village of the same name, which is in southern Crawford County between the towns of Pittsburg and Cherokee. The coal which has been strip-mined at Fleming is the Mineral coal, but the Fleming coal is exposed in the walls of the strip pits. In a previously published section (Pierce and others, 1935), the authors called this coal the "Mineral Rider" because of its association with the Mineral coal. Locally it is known as the "Bastard bed" and is exposed in many other pits where the Mineral coal is stripped. It is from 7 to 20 feet above the Mineral coal; in northeastern Crawford County it averages about 9 feet above the Mineral coal, in east-central Crawford and southern Crawford County it averages 12 feet above, near Fleming it is 14 feet above the Mineral coal, and in the vicinity of Mineral the average interval is 19 feet.

The Fleming coal is extremely variable in thickness. In the walls of many strip pits, it can be seen to thin from 6 inches to only a trace of coal. In Crawford County it is from 0 to 10 inches thick, but in the vicinity of Cherokee and Mineral it is usually about a foot thick and locally attains a thickness of 18 inches. A notable characteristic is the lack of a distinct difference between the strata above and below the coal, both usually being medium gray shale (see Pl. 8A). The Fleming bed is strip-mined in a part of the Commercial Fuel Companies mine No. 2, in the NE sec. 20, T. 31 S., R. 24 E. The coal mined here is from the Mineral bed, except for a small area in the northern part of the pit, where the Mineral coal is reputed to be thinner and has a greater overburden. In this part of the pit the Fleming coal slopes down into a synclinal depression, and coincident with this increasing depth there is a thickening of the coal and also a change in the strata above and below the coal (see fig. 7). The depression or syncline, however, does not appear to be reflected in the coal below. The Fleming coal reaches a maximum measured thickness of 20 inches in this depression.

Figure 7--Diagrammatic sketch of a depression in the Fleming coal, showing the relation of the coal bed to the strata above and below. North wall of strip pit in NE sec. 20, T. 3,1 S., R. 24 E.

Drill holes in sec. 31, T. 32 S., R. 22 E., and adjoining sections show that there are several coal beds present below the surface, varying in thickness from a few inches to 2 feet. The coal beds recorded in these holes are correlated with the Croweburg, Fleming, and Mineral beds. The bed which is correlated with the Fleming coal is thick enough for commercial strip mining at some places in this vicinity.

The Fleming bed is correlated with the Middle or Two-foot coal of Vernon County, Missouri.

Croweburg coal bed

Locally the Croweburg coal bed is known as the "Fireclay bed"--a descriptive term applied by some of the drillers of prospect holes because it is overlain and underlain by several feet of material which they call "fireclay." In restricted local areas it is also called the "Huntsinger bed" and the "mud seam." Inasmuch as the Kansas Geological Survey wished to apply a geographic name, Croweburg was finally adopted. The exposures from which it is named are in strip pits about a mile east of Croweburg, particularly in the SE sec. 34, T. 28 S., R. 25 E., and the NE sec. 3, T. 29 S., R. 25 E. In the pits east of sec. 34, Mineral as well as Croweburg coal has been stripped, and in the NE sec. 3 some Bevier coal has been strip-mined to the east of the Croweburg coal strip pit.

The outcrop of the Croweburg coal extends from the northeast corner of the area to the southwestern part and lies between the Mineral coal outcrop and the Ardmore limestone. Plate 1 shows the outcrop of the Croweburg coal in T. 28 S., R. 25 E., and in T. 34 S., R. 21 E. Although the outcrop is not shown in the intervening area, the coal was actually observed at many places, and drill records likewise show it to be present. The Croweburg coal lies 17 to 35 feet, averaging 25 feet, above the Mineral coal.

The Croweburg coal is overlain by 3 to 8 feet of shale, the upper half light gray and the lower half somewhat darker in color. Above this unit is 2 1/2 to 5 feet, averaging 3 feet, of fissile black shale,, containing black siliceous limestone concretions, many of which are 18 inches in diameter, and some 3 feet in diameter were noted. Small phosphate nodules, about three fourths of an inch in diameter, are common in the black shale. Some of the larger concretions and many of the smaller ones contain nuclei of fossils. The large concretions have the shape of flattened spheres, whereas the small ones may be round, flattened, or several may be grouped together like peanut brittle. The succession of strata just described--that is, a coal overlain by gray shale, and then a black shale with concretions--furnishes an excellent means of identifying the Croweburg coal, for none of the other coals in the Cherokee shale have a similar succession of strata associated with them. A typical view of the black shale unit with the concretions is shown on Plate 8-B. At two localities--one in the SE NE sec. 8, T. 31 S., R. 23 E., and another near the center of the N/2 sec. 17, T. 35, S., R. 21 E.--the black shale was observed to rest directly on the Croweburg coal. This relationship is illustrated in figure 8.

Figure 8--Sketch showing an unusual relationship of the Croweburg coal to the black shale above it, as exposed in a strip pit near the center of the N/2 sec. 17, T. 35 S., R. 21 E.

The Croweburg coal is 10 to 18 inches, averaging 12 inches in thickness. It has been mined at several strip pits in northeastern Crawford County and southeastern Labette County and at places between these areas, such as along Deer Creek in T. 32 S., R. 22 E., as shown on Plate 1.

The Croweburg coal is correlated with the one-foot coal of Vernon County, Missouri. There is no doubt as to this correlation, for the black shale unit with the concretions occurs above both coals, and the relations of the coals to the Ardmore limestone above and the other coal beds below are also similar.

Bevier coal bed

The Bevier coal was so named from the town where it was first developed, in Macon County, north-central Missouri (Gordon, 1893). It is from 4 to 5 feet thick in northern Missouri, where it has been extensively mined, and is one of the most important coal beds in the state. Since it is at the insistence of the Kansas Geological Survey that the name Bevier be extended into southeastern Kansas--a distance of nearly 200 miles from its type locality--the authors wish to qualify any implication of horizontal continuity with the Bevier of northern Missouri which may be suggested. (The observed distinctive cyclic relationships of this coal, whether physically continuous with the Bevier coal of west-central Missouri or not, amply support use of this name in southeastern Kansas.--R. C. Moore.) They are inclined to agree with the generalized cross section by Green (1933), which depicts graphically his interpretation that southwestward from the type locality of the Bevier coal the bed is discontinuous, but where present it occurs at approximately the same stratigraphic horizon. In the authors' previously published section this coal was called the "Ironclad"--a local term used because the coal is underlain by a very hard limestone (Ardmore) and in places is capped by a hard, impure, dark, crystalline limestone, and in places by abundant pyrite. It is also known locally as the "Drywood seam" in northern Crawford County; the "Pioneer seam" in the area being mined by the Pioneer Coal Co., in T. 28 S., R. 25 E.; and the "Limestone seam."

The Bevier coal lies just above the Ardmore limestone and its outcrop is practically coincident with that of the Ardmore. It crops out around Bone Creek and the West Fork of Drywood Creek, and extends southward from a point 2 miles west of the northeast corner of Crawford County to near Mulberry. There the line of outcrop trends southwestward, passing near the towns of Dunkirk, Capaldo, Cherokee, and Mineral. Between Mineral and Lightning Creek its line of outcrop is very irregular and discontinuous. Because of small structural deformation of the strata in this region of low relief, there are numerous places where the Bevier coal crops out at the surface in the area lying to the northwest of the principal line of outcrop. The largest of these is along Lighting Creek, extending from a point a mile west of Monmouth to within 2 miles of Sherman.

The Bevier coal could not be traced across Neosho Valley. Apparently the coal becomes discontinuous in the area, along the lower part of Lightning Creek, for on the west side of the Neosho River there is no coal just above the Ardmore limestone, but local beds do occur somewhat higher--in the part of the Cherokee shale that to the northwest is noncoal-bearing.

The Bevier coal is normally 80 to 100 feet below the top of the Cherokee shale, and the average interval is 100 feet. The one exception to this--which was mentioned earlier--is southwest of Mulberry, in the vicinity of the outlier of Fort Scott limestone on the hill known locally as Breezy Hill, where the interval from the Bevier coal to the top, of the Cherokee decreases to 65 feet. The Bevier coal is underlain by 6 to 12 inches of gray clay, and below that is the Ardmore limestone. It is overlain by several feet of dark-gray to black shale, which usually contains from one to four thin beds of dark, impure limestone. The Ardmore limestone below and the thin limy beds in the shale above serve as identification for the Bevier coal.

The Bevier coal has an average thickness of 18 inches along the outcrop in Crawford County. In the S/2 T. 32 S., R. 22 E., in Cherokee County, it is thinner and could not be definitely traced in the logs of drill holes. In this area where it is thinner, another thin coal bed is recorded about 10 feet above the horizon of the Bevier coal. The Bevier coal does not extend into Labette County, but coal beds occur above the Ardmore limestone, whereas in Cherokee and Crawford counties the interval between the Bevier and Fort Scott coals is barren.

The Bevier coal has been strip-mined in Tps. 27 and 28 S., R. 25 E., sec. 25, T. 29 S., R. 24 E., the north-central part of T. 30 S., R. 24 E., and from numerous small pits in T. 31 S., Rs. 22 and 23 E., and the north half of T. 32 S., R. 22 E., as shown on Plate 1.

The Bevier coal of Kansas is correlated with the Williams coal of Vernon County, Missouri, because of its position in the Cherokee shale with similar identifying strata above and below the coal. Greene (Greene and Pond, 1926) states that the Williams coal is probably the Bevier coal of northern Missouri.

Stice coal bed

The Stice coal is named from the Stice school, in the NE corner sec. 33, T. 33 S., R. 21 E. The outcrop of the bed was mapped in the south-central part of T. 33 S., R. 21 E., the west-central part of T. 34 S., R. 21 E., and the southeastern part of T. 34 S., R. 20 E., as shown on Plate 1.

The Stice coal is 15 to 25 feet above the Ardmore limestone. The interval between the two consists of thin beds of sandstone, shale, and black shale, with locally two coal beds from 2 to 6 inches thick. Where measured, the Stice bed is from 13 to 15 inches thick and is overlain by 6 to 12 inches of black, fossiliferous limestone. It has been strip-mined in secs. 27, 33, and 34, T. 33 S., R. 21 E. and at several places along Turkey Creek (see Pl. 1).

Local coal beds in the upper part of the Cherokee shale

Thin coal beds were noted between the Stice coal and the top of the Cherokee shale in southeastern Labette County. The coals, however, are thin and apparently lenticular, for individual beds could not be traced. One of these local beds is exposed in a small strip pit near the south line of the SW SW sec. 5, T. 35 S., R. 21 E. The coal is 7 to 12 inches thick and is about 34 feet below the top of the Cherokee shale. This bed has also been stripped in a small area near the center of the NW sec. 8, T. 35 S., R. 21 E.

Fort Scott coal bed

The name Fort Scott coal has long been applied to the coal a few feet below the base of the Fort Scott limestone, although it is actually in the Cherokee shale. It is also known as the "Red coal," and in northeastern Crawford County is locally called the "Bunker Hill coal."

The Fort Scott coal occurs in the northeastern part of the area and extends southward to Arma. Between Arma and Girard the coal is discontinuous, and south and west beyond the south line of T. 29 S., R. 24 E., no coal was observed at the horizon of the Fort Scott coal, although a few of the drill holes log a trace of coal.

The Fort Scott coal is from 3 to 5 feet below the top of the Cherokee shale. The interval between the Fort Scott coal and the Fort Scott limestone consists of black, slaty shale, containing in many places small phosphatic nodules and some large siliceous and pyritic limestone concretions. Silicified tree stumps were found near the base of the black shale in several localities, namely, center N/2 N/2 sec. 21 and NW sec. 29, T. 29 S., R. 24 E., Kansas, and on top of a small hill just west of Oskaloosa, Missouri, in sec. 7, T. 33 N., R. 33 W. One stump with definitely recognizable root remnants was found in NE SW NW sec. 29, T. 29 S., R. 24 E., and a thin coating of coal covered a portion of the main roots. The coal is underlain by a foot or two of clay-shale, and below that is the Breezy Hill limestone.

In northeastern Crawford County--that is, in that part north and east of Franklin--the Fort Scott coal is from 8 to 12 inches thick. The average thickness in T. 28 S., R. 25 E., and in the vicinity of Cato is 8 inches; at Breezy Hill, southwest of Mulberry, the average thickness is 12 inches. In T. 29 S., R. 24 E., it is from 0 to 6 inches thick, and to the south and west of this township the Fort Scott coal is absent, except for a few places where the coal may be present locally with a thickness of a few inches.

The Fort Scott coal has been strip-mined in secs. 25 and 26, T. 27 S., R. 24 E., and at numerous places along the base of the Fort Scott limestone in T. 28 S., R. 25 E., and at Breezy Hill in the NE T. 29 S., R. 25 E. (see Pl. 1 for location of strip pits).

Coal in Fort Scott limestone

In Bourbon County, Kansas, which lies to the north of Crawford County, and in Vernon County, Missouri, the shale unit between the upper and lower members of the Fort Scott contains a coal bed from 0 to 2 feet thick. In the area of this report, however, no coal was observed in this interval and the drill records examined likewise do not record any coal.

Coal in the Labette shale

Several thin coal beds were observed in the Labette shale, but none of them have been mined in southeastern Kansas, as they are too thin for commercial value. The generalized section shown in figure 2 shows the approximate position of three of these thin beds. In addition, a few drill holes in the extreme northern part of Crawford County record a few inches of coal about 7 feet above the base of the Labette shale.

Physical and Chemical Character of Coal

The coal in the southeastern Kansas field is all of bituminous rank. It is somewhat, friable, but is practically nonslacking and has a bright appearance. Some pyrite is present in the coals, but much of it is removable by sizing and washing operations. Calcite commonly occurs as film-like veins along joints and fractures. The Weir-Pittsburg coal is the only bed mined that carries a large amount of clay. This is present as clay veins and "horsebacks," and in some areas may average as much as 10 percent of this coal bed. In some places a "rash," consisting of a mixture of shale and clay with streaks of coal, occurs above the Weir-Pittsburg coal.

The quality of coal is represented analytically by two methods of analysis--"proximate" and "ultimate." Moisture, volatile matter, fixed carbon, and ash are determined in a proximate analysis. In ultimate analyses the percentage of the chemical elements that form the combustible and volatile matter of the coal is determined, these elements being carbon, hydrogen, oxygen, sulfur, and nitrogen. The softening temperature is defined as the temperature at which a cone of the ash, when heated in the test furnace in a slightly reducing atmosphere, has fused down to a spherical lump.

Sampling of coal in strip pits is necessarily somewhat modified from the standard method used in sampling shaft mines. The standard procedure is followed as closely as possible, but in strip mines it is usually impossible to obtain a face sample of the coal immediately after the overburden has been removed. In order to keep the samples on a comparative basis, the following precautions were observed: The overburden on the coal had been removed less than 24 hours, the face of the coal bed had not been exposed over six hours, and a fresh exposure was made by channeling back in the exposed face. As soon as the samples were taken, they were immediately sealed in air-tight cans. Most of the pits were sampled a second time, so that a fresh sample could be obtained from a different part of the pit.

All of the following analyses, except those of the Weir-Pittsburg coal, are of samples collected by the senior author during the field season of 1934 as part of the project supported by funds from the Public Works Administration. All of the analyses in Table 1 were made in the laboratory of the United States Bureau of Mines, at Pittsburgh, Pa. They are arranged in the order of the statigraphic position of the coal beds.

Table 1--Chemical analyses of samples of coal from the southeastern Kansas coal field.

| Coal Beds | County | Locality and mine |

Location in mine |

Sample | Proximate | Sulphur | Calorific value | Softening temp. of ash, °F |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Condition (1) |

Lab. no. | Moisture | Volatile matter |

Fixed carbon |

Ash | Calories | British Thermal Units |

||||||

| Fort Scott | Crawford | SE sec. 26, T. 27 S., R. 24 E., W.H. Moberly | North side of pit | 1 | B-2661 | 2.3 | 41.7 | 47.2 | 8.8 | 3.9 | 7511 | 13,520 | 2060 |

| 2 | 42.7 | 48.3 | 9.0 | 4.0 | 7689 | 13,840 | |||||||

| 3 | 47.0 | 53.0 | 4.4 | 8450 | 15,210 | ||||||||

| Fort Scott | Crawford | SE sec. 26, T. 27 S., R. 24 E., W.H. Moberly | East side of strip pit (250 ft SE of B-2661) | 1 | B-2662 | 2.4 | 40.2 | 48.9 | 8.5 | 3.9 | 7511 | 13,520 | 2060 |

| 2 | 41.2 | 50.1 | 8.7 | 4.0 | 7689 | 13,840 | |||||||

| 3 | 45.1 | 54.9 | 4.4 | 8422 | 15,160 | ||||||||

| Fort Scott | Crawford | Near center west line sec 18, T. 28 S., R. 25 E., Martin & Black | Northwest side of strip pit | 1 | B-2671 | 3.8 | 39.1 | 46.3 | 10.8 | 3.9 | 7122 | 12,820 | 2060 |

| 2 | 40.7 | 48.1 | 11.2 | 4.0 | 7406 | 13,330 | |||||||

| 3 | 45.9 | 54.1 | 4.6 | 8344 | 15,020 | ||||||||

| Bevier | Crawford | Center, south line NW sec. 16, T. 28 S., R. 25 E., Pioneer Coal Co. | 1 | B-2669 | 3.4 | 37.6 | 50.6 | 8.4 | 2.8 | 7361 | 13,250 | 2140 | |

| 2 | 38.9 | 52.4 | 8.7 | 2.9 | 7622 | 13,720 | |||||||

| 3 | 42.6 | 57.4 | 3.1 | 8350 | 15,030 | ||||||||

| Bevier | Crawford | Near center SW sec. 16,T. 28 S, R. 25 E., Pioneer Coal Co. | 800 ft south of B-2669 | 1 | B-2670 | 4.6 | 36.9 | 48.6 | 9.9 | 2.4 | 7189 | 12,940 | 2180 |

| 2 | 38.7 | 51.0 | 10.3 | 2.5 | 7539 | 13,570 | |||||||

| 3 | 43.1 | 56.9 | 2.8 | 8411 | 15,140 | ||||||||

| Bevier | Crawford | SE sec. 4, T. 30 S, R. 24 E., Eagle-Cherokee Coal Mining Co. | 1 | B-2657 | 4.3 | 35.4 | 46.4 | 13.9 | 2.3 | 6822 | 12,280 | 2560 | |

| 2 | 36.9 | 48.6 | 14.5 | 2.4 | 7128 | 12,830 | |||||||

| 3 | 43.2 | 56.8 | 2.8 | 8339 | 15,010 | ||||||||

| Bevier | Crawford | Sec. 4, T. 30 S., R. 24 E., Eagle-Cherokee Coal Mining Co. | North runway, west strip face, 0.25 mi north of B-2657 | 1 | B-2658 | 3.4 | 34.3 | 49.6 | 12.7 | 2.4 | 7056 | 12,700 | 2490 |

| 2 | 35.5 | 51.3 | 13.2 | 2.5 | 7306 | 13,150 | |||||||

| 3 | 40.9 | 59.1 | 2.9 | 8411 | 15,140 | ||||||||

| Bevier | Labette | NE sec. 33, T. 33 S., R. 21 E., Vanduker Coal Co. | North strip face, west end of pit | 1 | B-2663 | 3.7 | 40.1 | 47.7 | 7.8 | 3.1 | 7406 | 13,330 | 2310 |

| 2 | 42.4 | 49.5 | 8.1 | 3.2 | 7694 | 13,850 | |||||||

| 3 | 46.1 | 53.9 | 3.5 | 8372 | 15,070 | ||||||||

| Bevier | Labette | NE sec. 33, T. 33 S., R. 21 E., Vanduker Coal Co. | East end of pit, north strip face | 1 | B-2664 | 3.5 | 42.0 | 48.6 | 5.9 | 3.1 | 7589 | 13,660 | 2070 |

| 2 | 43.5 | 50.4 | 6.1 | 3.2 | 7861 | 14,150 | |||||||

| 3 | 46.3 | 53.7 | 3.4 | 8372 | 15,070 | ||||||||

| Fleming | Cherokee | Near north line, NE sec. 20, T. 31 S., R. 24 E., Commercial Fuel No. 2 | 1 | B-2653 | 2.8 | 39.3 | 47.3 | 10.6 | 2.3 | 7272 | 13,090 | 2330 | |

| 2 | 40.5 | 48.6 | 10.9 | 2.4 | 7483 | 13,470 | |||||||

| 3 | 45.4 | 54.6 | 2.7 | 8400 | 15,120 | ||||||||

| Mineral | Crawford | NE sec. 34, T. 28 S., R. 25 E., A.B. McKay Coal Co. | West strip face | 1 | B-2659 | 4.8 | 33.9 | 49.5 | 11.8 | 3.5 | 6961 | 12,530 | 1980 |

| 2 | 35.6 | 52.1 | 12.3 | 3.7 | 7306 | 13,150 | |||||||

| 3 | 40.6 | 59.4 | 4.2 | 8339 | 15,010 | ||||||||

| Mineral | Crawford | Near center east line sec. 34, T. 28 S., R. 25 E., A.B. McKay Coal Co. | 700 ft SE of B-2659 | 1 | B-2660 | 4.3 | 34.3 | 48.0 | 13.4 | 4.6 | 6833 | 12,300 | 2030 |

| 2 | 35.8 | 50.2 | 14.0 | 4.8 | 7139 | 12,850 | |||||||

| 3 | 41.6 | 58.4 | 5.6 | 8300 | 14,940 | ||||||||

| Mineral | Crawford | SW sec. 23, T. 29 S., R. 25 E., Clemens Coal Co. No. 23 | West strip face, 600 ft NW of B-2656 | 1 | B-2655 | 4.4 | 34.2 | 48.8 | 12.6 | 4.8 | 6900 | 12,420 | 2000 |

| 2 | 35.8 | 51.0 | 13.2 | 5.1 | 7222 | 13,000 | |||||||

| 3 | 41.3 | 58.7 | 5.8 | 8311 | 14,960 | ||||||||

| Mineral | Crawford | SW sec. 23, T. 29 S., R. 25 E., Clemens Coal Co. No. 23 | West strip face | 1 | B-2656 | 5.1 | 34.7 | 48.7 | 11.5 | 3.6 | 6939 | 12,490 | 1990 |

| 2 | 36.6 | 51.3 | 12.1 | 3.8 | 7311 | 13,160 | |||||||

| 3 | 41.6 | 58.4 | 4.4 | 8317 | 14,970 | ||||||||

| Mineral | Crawford | SW sec. 34, T. 30 S., R. 24 E., Pittsburg-Midway No. 17 | West strip face, near center 1/4 section | 1 | B-2665 | 4.4 | 33.5 | 45.7 | 16.4 | 3.3 | 6628 | 11,930 | 2050 |

| 2 | 35.1 | 47.7 | 17.2 | 3.5 | 6933 | 12,480 | |||||||

| 3 | 42.4 | 57.6 | 4.2 | 8378 | 15,080 | ||||||||

| Mineral | Crawford | SW sec. 34, T. 30 S., R. 24 E., Pittsburg-Midway No. 17 | 300 ft north of south end of pit, west strip face | 1 | B-2666 | 4.0 | 35.8 | 49.3 | 10.9 | 4.9 | 7050 | 12,690 | 2050 |

| 2 | 37.3 | 51.3 | 11.4 | 4.0 | 7344 | 13,220 | |||||||

| 3 | 42.1 | 57.9 | 4.6 | 8289 | 14,920 | ||||||||

| Mineral | Cherokee | 700 ft west, 15 ft south of NE sec. 20, T. 31 S., R. 24 E., Commercial Fuel No. 2 | Small drift into north side of strip pit | 1 | B-2652 | 5.1 | 33.2 | 46.8 | 14.9 | 3.6 | 6700 | 12,060 | 2020 |

| 2 | 35.0 | 49.3 | 15.7 | 3.8 | 7061 | 12,710 | |||||||

| 3 | 41.5 | 58.5 | 4.5 | 8372 | 15,080 | ||||||||

| Mineral | Cherokee | SW NW sec, 9, T. 32 S., R. 23 E., Pittsburg-Midway No. 15 | NW strip face, near center of 40 acre trract | 1 | B-2667 | 3.6 | 34.3 | 50.5 | 11.6 | 3.4 | 7150 | 12,870 | 1960 |

| 2 | 35.3 | 52.5 | 12.0 | 3.5 | 7417 | 13,350 | |||||||

| 3 | 40.4 | 59.6 | 4.0 | 8422 | 15,160 | ||||||||

| Mineral | Cherokee | NW sec. 9, T. 32 S., R. 23 E., Pittsburg-Midway No. 15 | 400 ft. southwest of B-2667 | 1 | B-2668 | 2.9 | 35.1 | 51.5 | 10.5 | 2.8 | 7283 | 13,110 | 2050 |

| 2 | 36.2 | 53.0 | 10.8 | 2.9 | 7506 | 13,510 | |||||||

| 3 | 40.6 | 59.4 | 3.2 | 8411 | 15,140 | ||||||||

| Weir-Pittsburg (2) | Barton, Mo. | W2 sec. 30, T. 33 N, R. 33 W., Carney-Cherokee No. 2 | (Shaft mine) | 1 | 75557 | 6.1 | 30.6 | 50.2 | 13.1 | 5.0 | 6783 | 12,210 | |

| 2 | 32.6 | 53.5 | 13.9 | 5.3 | 6833 | 12,300 | |||||||

| 3 | 37.9 | 62.1 | 6.2 | 8394 | 15,110 | ||||||||

| Weir-Pittsburg (3) | Crawford | Sec. 11, T. 29 S., R. 24 E., Central Coal and Coke No. 51 (shaft) | Average of A2343 and A2348 (inclusive) | 1 | 7.4 | 32.0 | 51.2 | 8.4 | 2.6 | 6871 | 12,668 | 2060 | |

| 2 | 34.4 | 56.4 | 9.0 | 2.8 | 7250 | 13,678 | |||||||

| 3 | 37.9 | 62.0 | 3.1 | 8155 | 15,038 | ||||||||

| Weir-Pittsburg (3) | Crawford | Sec. 18, T. 29 S., R. 25 E., Western No. 16 | 2000 ft SW of shaft in mine | 1 | 17032 | 6.7 | 33.6 | 47.9 | 11.8 | 5.3 | 6728 | 12,110 | 1970.0 |

| 2 | 35.9 | 51.4 | 12.7 | 5.6 | 7210 | 12,978 | |||||||

| 3 | 41.2 | 58.8 | 6.5 | 8256 | 14,861 | ||||||||

| Weir-Pittsburg (3) | Crawford | SW sec. 13, T. 29 S., R. 24 E., Wear No. 21 | Average of 30293 to 30295 (inclusive), (shaft mine) | 1 | 3.8 | 34.3 | 50.1 | 11.8 | 4.7 | 6941 | 12,494 | 2120.0 | |

| 2 | 35.6 | 52.0 | 12.3 | 4.9 | 7214 | 12,986 | |||||||

| 3 | 40.6 | 59.4 | 5.6 | 8227 | 14,809 | ||||||||

| Weir-Pittsburg (3) | Crawford | SW sec. 12, T. 30 S., R. 25 E., J.J. Stephenson | Strip face | 1 | 23241 | 6.3 | 35.3 | 51.9 | 6.5 | 3.7 | 7339 | 13,210 | 2020.0 |

| 2 | 37.7 | 55.3 | 7.0 | 4.0 | 7839 | 14,110 | |||||||

| 3 | 40.5 | 59.5 | 4.3 | 8428 | 15,170 | ||||||||

| Weir-Pittsburg (3) | Crawford | NE sec. 14, T. 31 S., R. 24 E., Central Coal and Coke | Strip face, 1,000 ft from outcrop | 1 | 23240 | 6.8 | 32.9 | 52.0 | 8.3 | 3.1 | 7078 | 12,740 | |

| 2 | 35.3 | 55.7 | 9.0 | 3.3 | 7600 | 13,680 | |||||||

| 3 | 38.9 | 61.2 | 3.6 | 8344 | 15,020 | ||||||||

| Weir-Pittsburg (3) | Crawford | Sec. 6, T. 31 S., R. 24 E., Hamilton No. 9 | Average of A2473 to A2476 (inclusive), (shaft mine) | 1 | 6.6 | 33.4 | 50.5 | 9.2 | 2.2 | 6972 | 12,550 | 2147.0 | |

| 2 | 35.8 | 54.0 | 10.1 | 2.4 | 7461 | 13,430 | |||||||

| 3 | 39.8 | 60.1 | 2.6 | 8308 | 14,955 | ||||||||

| Weir-Pittsburg (3) | Cherokee | Sec. 28, T. 31 S., R. 23 E., Mayer No. 9 | Average of 27222 to 27225 (inclusive), (shaft mine) | 1 | 5.6 | 34.0 | 51.6 | 8.2 | 3.1 | 7126 | 12,997 | 1950.0 | |

| 2 | 36.0 | 55.3 | 8.7 | 3.3 | 7654 | 13,777 | |||||||

| 3 | 39.5 | 60.5 | 3.6 | 8386 | 15,095 | ||||||||

| Columbus | Cherokee | Sec. 7, T. 33 S., R. 24 E. | Center west strip face, 1,400 ft north, 2,100 ft. west of SE corner of Sec. 7 | 1 | B-2654 | 4.5 | 29.7 | 49.6 | 16.2 | 6.0 | 6533 | 11,760 | 2010.0 |

| 2 | 31.0 | 52.0 | 16.9 | 6.3 | 6844 | 12,320 | |||||||

| 3 | 37.4 | 62.6 | 7.6 | 8244 | 14,840 | ||||||||

| "Local" | Cherokee | NE NE sec. 18, T. 34 S., R. 24 E., Best Coal Co. | North strip face, east end pit, 300 ft SW of center of 40 acre tract | 1 | B-2673 | 5.4 | 31.3 | 47.2 | 16.1 | 7.5 | 6372 | 11,470 | 2050.0 |

| 2 | 33.1 | 49.9 | 17.0 | 8.0 | 6733 | 12,120 | |||||||

| 3 | 39.9 | 60.1 | 9.6 | 8117 | 14,610 | ||||||||

| "Local" | Cherokee | NE sec. 18, T. 34 S., R. 24 E., Best Coal Co. | 100 ft west of B-2673 | 1 | B-2672 | 5.2 | 31.3 | 47.3 | 16.2 | 7.0 | 6389 | 11,500 | 2010.0 |

| 2 | 33.0 | 49.9 | 17.1 | 7.4 | 6744 | 12,140 | |||||||

| 3 | 39.8 | 60.2 | 8.9 | 8133 | 14,640 | ||||||||

1. The form of analysis is denoted as follows:

3. From U.S. Bureau of Mines Technical Paper 455 |

|||||||||||||

Table 2 contains the averages of the analyses from Table 1. Generalizations from such a small number of analyses must be regarded as tentative and subject to change; however, it seems appropriate to point out the decrease in volatile matter and the increase in fixed carbon in coals that are successively lower stratigraphically in the Cherokee shale.

Table 2--Average chemical analyses of southeastern Kansas coals by beds.

| Coal Bed | Number of analyses averaged |

"As received" analyses | "Moisture and ash free" analyses | Softening temperature of ash, °F |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | Volatile matter |

Fixed carbon |

Ash | British thermal units |

Sulfur* | Volatile matter |

Fixed carbon |

British thermal units |

Sulfur* | |||

| Fort Scott | 3 | 2.8 | 40.3 | 47.4 | 9.3 | 13,286 | 3.0 | 46.0 | 54.0 | 15,130 | 4.5 | 2060 |

| Bevier | 6 | 3.8 | 37.8 | 48.6 | 9.8 | 13,026 | 2.6 | 43.7 | 56.3 | 15,077 | 3.1 | 2458 |

| Fleming | 1 | 2.8 | 39.3 | 47.3 | 10.6 | 13,090 | 2.3 | 45.4 | 54.6 | 15,120 | 2.7 | 2330 |

| Mineral | 9 | 4.3 | 34.3 | 48.7 | 12.6 | 12,488 | 3.8 | 41.3 | 58.5 | 15,029 | 4.5 | 2014 |

| Weir-Pittsburg** | 8 | 6.1 | 33.3 | 50.7 | 9.9 | 12,622 | 3.7 | 39.5 | 60.4 | 15,007 | 4.4 | 2044 |

| Uncorrelated beds below Weir-Pittsburg | 3 | 5.0 | 30.7 | 48.1 | 16.1 | 11,576 | 6.8 | 39.0 | 60.9 | 14,696 | 8.7 | 2023 |

| * From ultimate analyses. ** Average for Weir-Pittsburg bed is figured from analyses in U. S. Bureau of Mines Technical Papers Nos. 366 and 455. |

||||||||||||

Production of Coal

Historical records (Crane, 1898) of the development of the coal resources of southeastern Kansas are incomplete. One of the earliest known workings was in the Weir-Pittsburg coal bed, some time between 1850 and l860, when residents of Missouri mined coal from this bed and hauled it by horse and wagon to Granby, Mo., and other places for use in blacksmithing. In the autumn of 1866, a blacksmith from Granby, with the assistance of W. H. Peters, a resident of the southeastern part of Cherokee County, mined coal at the outcrop of the Weir-Pittsburg bed near the site of the present town of Weir City. In 1868, Professor Wilbur of Chicago, was commissioned by a company of that city to report on the prospects of coal in the "Cherokee Neutral Lands," which consisted of an area of 25 by 50 miles, including all of Cherokee and Crawford counties and the southern part of Bourbon County, Kansas. He reported the existence of coal in large quantities in a narrow strip of country between Weir and Pittsburg, and found the coal (the Weir-Pittsburg bed) to be about 4 feet thick, but in places much thinner.

Between 1860 and 1870 a small amount of coal was mined by stripping along the west side of Brush Creek, in eastern Cherokee County. This was probably not far up Brush creek from Spring River, and the bed mined may have been the Riverton coal.

The district extending northeast from Weir was of importance to the railroads, for here was coal satisfactory for locomotive and stationary steam plants, easily mined and, from a geographic standpoint, well located. The first railroad to enter the field was the Missouri River, Fort Scott & Gulf Railroad (later the Kansas City, Fort Scott & Memphis, now a portion of the St. Louis-San Francisco system), which was completed to Baxter Springs in 1870. Soon after the opening of this road a company was formed in Fort Scott primarily for the purpose of mining coal for this railroad.

The Weir-Pittsburg coal bed was mined in the vicinity of Scammon, then known as Stilson, and hauled by team to the railroad stations, the earliest production being from strip mines along the outcrop. In 1874, Scammon Brothers put down a shaft north of Scammon and produced a considerable amount of coal. Following the success of this venture, other shafts were put down to the Weir-Pittsburg bed, development continuing toward the northeast, and also from the outcrop toward the deeper coal.

In 1878 and 1879 Moffet & Sargent, of Joplin, Mo., built the Joplin & Girard railroad from Joplin to Pittsburg, to obtain coal from the Kansas fields. The city of Pittsburg was founded at this time and, until the erection of zinc smelters brought other business, it remained purely a coal-mining town.

Present transportation facilities in this coal district are excellent. The following large railroad systems have mine tracks in this district: Atchison, Topeka & Santa Fe; Kansas City Southern; Missouri, Kansas & Texas; Missouri Pacific; and St. Louis-San Francisco. The Joplin & Pittsburg electric line also passes through the coal field, and hauls coal to the trunk railroads.

The earliest figures for the production of coal in Kansas, by counties, begin in 1885 (annual reports of the State Inspector of coal mines). Prior to that date, production figures are for the state as a whole. The accompanying graphs (figs. 9, 10, and 11) were made from the reports of the Kansas State Mine Inspector, supplemented by reports of the United States Geological Survey and the United States Bureau of Mines.

Figure 9--Coal production, Cherokee County, Kansas. Compiled from reports of the Kansas State Mine Inspector, supplemented by statistical reports of the U. S. Geol. Survey and the U. S. Bureau of Mines.

Figure 10--Coal production, Crawford County, Kansas. Compiled from reports of the Kansas State Mine Inspector, supplemented by statistical reports of the U. S. Geol. Survey and the U. S. Bureau of Mines.

Figures 9 and 10 show the tonnage of coal produced from 1885 to 1934 in Cherokee and Crawford counties--the principal coal-producing counties of the state. Where the data are available, the amount mined by shaft or underground methods is shown separately from that mined by surface stripping; the total annual production from both types of mining is also shown. Total production in Cherokee County reached its maximum in 1904, then declined somewhat until about 1910. In 1913 it rose rapidly to near its previous high, but since that time has declined rapidly except for a few periods of increase-notably between 1922 and 1925, when strip-mined coal increased from 150,000 to 700,000 tons. Strip-mined coal did not constitute an important part of the total production until about 1920, but since 1924 has become the predominant factor. Total production in Crawford County has exceeded Cherokee County since 1888. Production in Crawford County reached a maximum in 1918, when nearly 6 million tons were mined. In the ensuing four years production declined to less than 2 1/2 million tons. Production increased again in 1923, only to decline gradually to about 1 1/2 million tons in 1933. The amount of coal mined by shaft methods is decreasing, the tonnage for 1934 being less than one-seventh of that of the peak year of 1918. On the other hand, the tonnage of strip-mined coal in Crawford County has increased almost continuously since 1921. It surpassed the tonnage of shaft-mined coal in 1931, and the increased total production of 1934 over 1933 is due almost entirely to the increased production of strip-mined coal. The combined coal production of the three counties, shown in figure 11, is essentially an integration of the production of Cherokee and Crawford counties, for Labette County production represents less than one-half of one percent of the total. The total annual production for the area reached a maximum of over 7,250,000 tons in 1918, declined to about 1,830,000 tons in 1931, and in 1934 was about 2,300,000 tons. Strip-coal tonnage first exceeded shaft-coal tonnage in 1931, and in 1934 strip-coal tonnage was nearly three times that of shaft coal.

Figure 11--Coal production, Cherokee, Crawford, and Labette counties, Kansas. Compiled from reports of the Kansas State Mine Inspector, supplemented by statistical reports of the U. S. Geol. Survey and the U. S. Bureau of Mines.

From table 3 it may be seen that this district has produced about 88 percent of the total output of the state. In 1934, 91 percent of the state's production came from southeastern Kansas.

Table 3--Total coal production* in Cherokee, Crawford, and Labette counties, Kansas, 1885 to 1934, and total Kansas production 1869 to 1934 and 1885 to 1934.

| Counties | Shaft mines | Strip mines | Total |

|---|---|---|---|

| Cherokee | 49,890,114 | 7,097,271 | 56,987,385 |

| Crawford | 117,783,184 | 11,441,922 | 129,225,106 |

| Labette** | 172,346 | 172,346 | |

| Totals | 167,673,298 | 18,711,539 | 186,384,837 |

| Kansas (total production) | 1885-1934 | 213,117,707 | |

| Kansas (total production) | 1869-1934 | 220,719,336 | |

| *Short tons. Compiled principally from annual reports of Kansas State Mine Inspector. **Records not available for years 1886, 1888, 1898, and 1900-1923, inclusive. |

|||

Domestic and commercial usage of gas and oil as fuels has been a serious factor in reducing the production of coal. Young (1925) has estimated that oil alone has replaced coal to the extent of more than 1,162,000 tons per year.

The potential coal production of the country as a whole is far in excess of demand. Consequently, southeastern Kansas coal meets keen competition with coals from other areas. Because more than 75 percent of the Weir-Pittsburg coal bed, in excess of 2 1/2 feet thick, has been mined by shaft and strip methods, future production in this district will come mainly from stripping operations in the somewhat thinner, higher coals, particularly the Mineral and Bevier beds, and from the development of deep-shaft mines in the vicinity of Edna and Angola in Labette County.

Mining Methods

(NOTE: Much of the data on mining methods is summarized from Young, 1925.)

Two types of mining are employed in southeastern Kansas, namely, open pit or strip mining, and underground workings. Choice of the system used is dependent upon its adaptability to local conditions. Open-pit mining is used where the overburden is not too thick, which is usually at or near the lines of outcrops of the coal beds.

A small percentage of coal is mined by drift and slope workings, but the largest amount of underground working is accomplished by shaft mining, the deepest shaft being about 240 feet deep. Some of the earliest underground mines were worked by the single-entry method, which was soon abandoned for the double-entry method, because of difficulties in ventilating more than a few rooms. At present all underground mines use some form of the room-and-pillar method.

Most of the coal has been mined by "shooting off the solid," that is, the coal is not undercut before it is shot. This, of course, results in a high percentage of fine sizes of coal and less of lump coal. In recent years undercutting machines have been used in some of the larger mines with fair success, but undercutting has not been widely adopted in this field. In mining a 3-foot seam of coal, it is difficult to shoot out the coal in a deep cut so that the depth of the cut is limited to about 5 feet. In addition, the numerous clay veins, "horsebacks," and lumps of pyrite interfere with the normal functioning of an undercutting machine.

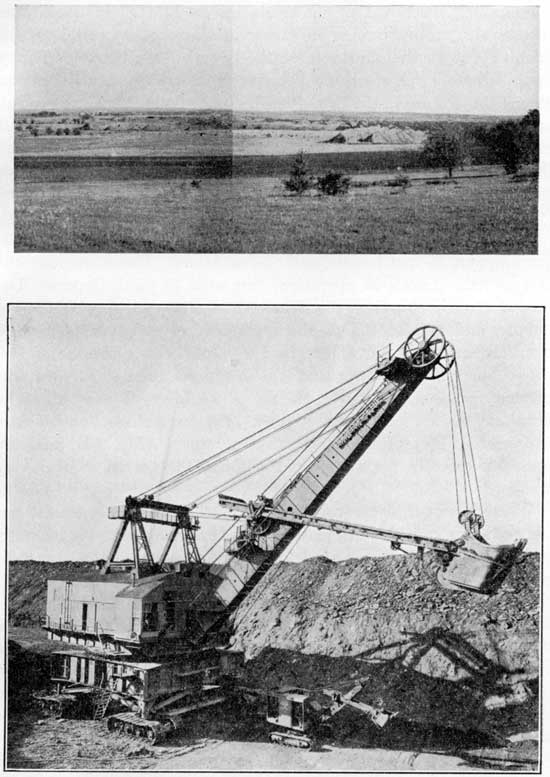

Open-pit or strip-mining methods are well adapted to the southeastern Kansas coal field, where a combination of gently dipping coal beds and low topographic relief results in large areas of relatively shallow coal (see Pl. 9-A). Early work was by hand-stripping--that is, by plowing, and removing the overburden by horse-drawn scrapers. Such methods are profitable only where the overburden is not more than a few feet thick, and production of coal by hand-stripping for marketing in competition with other coals has almost entirely ceased. Present workings of this type are usually cooperative among farmers for the purpose of obtaining their own domestic fuel.

Plate 9--A, View of an area of about 600 acres that has been stripped for the Bevier coal. The coal is about 20 inches thick. View looking south from near the center of south line sec. 9, T. 28 S., R. 25 E.; B, Type of electric shovel used in removing overburden from the coal in the southeastern Kansas coal field. Note ordinary steam shovel below boom.

The first application of a steam shovel to stripping the overburden from a coal bed was made in this district. In 1876, J. N. Hodges and A. J. Armil started stripping operations near Pittsburg, Kan., and in 1877 they leased a small steam shovel for removing overburden. Removal of materials up to 12 feet in depth was successful, but overburden in excess of this amount could not be handled due to the shortness of the boom of the shovel. Thirty years later a large steam shovel, developed by the Marion Steam Shovel Co., for use in the Danville, Ill., coal district (Young, 1925), was successful, and similar equipment was installed in southeastern Kansas in about 1912. These large shovels were of the revolving type and moved on short lengths of movable track. The capacity of these first shovels was between 2 and 3 cubic yards, but with the development of larger types, steam shovels with a capacity of 6 to 8 yards were obtained.

The first large electric shovel employed in the district had a 6-yard dipper, 58-foot handle, and 85-foot boom. There are now several electric shovels in operation, two with 16-yard dippers. The largest electric shovel in the district has a 16-yard dipper, 73-foot handle, and 110-foot boom and is capable of stripping 60 feet of overburden. This shovel weighs 1,800 tons, the generator on the shovel has 900 horsepower, and it is so equipped that a 22-yard dipper may be used. However, the use of the larger dipper will make necessary the use of a shorter boom. The large electric shovels are equipped with caterpillar-type crawling trucks (Fig. 9-B) and are operated directly upon the coal without the necessity of laying tracks.

Where the overburden consists of soft shales or shaly sandstones the shovel is capable of removing these materials, without blasting, but when hard shales or sandstones are encountered they must be blasted. The usual practice is to drill a hole with a churn drill to the desired depth, "spring" the hole with dynamite, and then blast with black powder. In addition to this type of blasting, there is the practice of drilling a horizontal hole, about equal in length to the working width of the pit, into the working face of the pit a few feet above the top of the coal and blasting with dynamite and powder. The combination of these types of blasting enables the shovel to uncover the coal more rapidly and easily.

The coal is loosened before loading, either by hand, using wedges or points, or by drilling holes by electric or compressed air hand drills and shooting with a small charge of explosive.

At some strip pits the coal is loaded into small cars running on track laid on the pit floor or into automobile trucks which haul it out of the pit on an inclined roadway. At other strip pits the coal is loaded into the box of a so-called bank machine that hoists the coal out of the pit and dumps it into cars that run on a track laid at the top of the bank along the working face of the strip pit.

The loading is accomplished by steam or electrical shovels that operate with a horizontal boom, the dipper being forced out horizontally, passing along the top of the underclay and picking up the coal with very little breaking.

For a given size of shovel the width of a pit varies with the thickness of the overburden, the stripped width becoming narrower as the depth of the coal increases.

Although much of the coal produced is run of mine coal, including that used in the domestic market, a considerable proportion of the coal shipped is now being size-graded. The sizing and cleaning of coal is now one of the most important steps in producing coal for market. In the early years of the district a large percent of the coal was screened in the mine, the fine coal being thrown back into the mine and not hoisted. With the development of the coal field, size-grading of mined coal passed through successive stages of development. Discontinuance of screening coal in the mines led, first, to the use of bar screens in the mine tipple, then rotary screens, and finally to the use of shakers and re-screening arrangements. In the last few years still more modern methods have been installed for size-grading and cleaning of coal, and today several of the larger companies use some combination of washing and mechanical sizing. A few years ago four sizes of coal were shipped--slack, pea, nut, and lump. At the present time the modern plants produce some 15 different sizes, ranging from size zero to 8-inch coal. Pyrite is removed by floating the coal in a heavy liquid, consisting of a mixture of clay and water. The heavier iron sulfide sinks and some of the coal that contains masses of pyrite likewise sinks and is thrown out as waste. Norton washers are used at several plants for cleaning the coal, and at the Pittsburg and Midway plant both the Norton washers and a cone type of washer are used. In the washing operations a large part of the pyrite and clay is removed which otherwise would be included in the coal and reduce the heat value per ton and increase the ash content.

Uses and Markets

A large amount of the coal mined in southeastern Kansas is used for steam raising. Although a considerable number of oil-burning locomotives are in use, the railroads are still the largest single consumers of coal from this district. Large quantities of steam coal are used by the power stations, packing plants and other industries in the surrounding territory, especially in the vicinity of Kansas City, Mo. Some of the other uses are for domestic and industrial heating, brick and cement plants, and miscellaneous industrial purposes.

The largest market of this coal field is Kansas City, Mo., where most of the large coal companies maintain sales headquarters. The market area open to coal from this district includes approximately: western Missouri, eastern and central Kansas, northeastern Oklahoma, eastern Nebraska, and a portion of western Iowa. Some coal is shipped beyond these limits, but the areas mentioned indicate the general district of distribution.

Southeastern Kansas coal competes with other coals on all sides of its market areas. Profitable mining and marketing of the thin seams of coal from this district depend upon very efficient operations, in the face of competition from other districts. The growth of the strip-mining industry may be directly attributed to this need of highly efficient, low-cost operations in the southeastern Kansas field.

Commercial coke was last produced in 1912. The coke industry in the southeastern Kansas area was never of great importance as a market for local coal. The principal use of coke was in zinc smelting, but this use has been replaced by slack coal or gas. Maximum production was reached in 1902 when 20,902 tons of coke, using 35,827 tons of coal, were produced. All of the coke was made in beehive ovens.

Coke made from the coals of this district had several drawbacks. It was rather porous, had thin cell walls, and highly fractured structure, which gave it a low crushing strength. In addition, this coke contained a high percentage of sulfur, and unless it was washed for the removal of sulfur, it was not practical for metallurgical use.

Petroleum and Natural Gas

There was not an opportunity to make a detailed study and analysis of the oil and gas possibilities of the area, except for the preparation of a structure map made in connection with the coal investigation (see Pl. 5). The small gas wells which occur within the area are not grouped in any particular field and the coal investigation covered only a part of the McCune oil field. Consequently, only a few statements concerning petroleum and natural gas can be made at this time.

Oil is produced in small quantity from the McCune oil field. This field is from one-fourth of a mile to half a mile wide and is about 3 miles long. The south end of the field is near the southeast corner of sec. 1, T. 31 S., R. 21 E.; the field extends north of this point for a mile, then trends north-northeast for about 2 miles. Production comes from a sandstone 15 to 25 feet thick that is from 175 to 200 feet below the top of the Cherokee shale. This sandstone is about 75 feet above the Bluejacket sandstone and is also slightly above the horizon of the Weir-Pittsburg coal.

A number of wells in the vicinity of Oswego produce small quantities of gas, some gas being obtained from a sand 320 to 420 feet below the top of the Cherokee, and also from near the base of the Cherokee shale. Gas in small quantities is obtained from numerous other wells, located mostly in Labette County.

Clay and Shale for Ceramic Industries

Building and paving brick, sewer pipes, conduits, and pottery are manufactured in this area. At Pittsburg, tile and brick are manufactured from a sandy shale occurring in a portion of the Cherokee shale below the Weir-Pittsburg coal. The raw material is mined from an open cut, and run-of-pit material is used in the brick plant.

A brick plant at Weir uses a slightly sandy shale that lies below the Weir-Pittsburg coal. At this locality the coal is only a few feet below the surface of the ground, and is considerably weathered.

Some of the better underclays are used at Pittsburg in the manufacture, on a small scale, of various kinds of pottery.

Road Metal

Four main types of materials are used in this area for road surfacing, namely, the black shale immediately below the lower member of the Fort Scott limestone; shale from mine dumps; chats, which are the tailings from mills in the zinc-lead district; and chert gravel from deposits along the Neosho River valley. In a few places the Fort Scott limestone is crushed and used for road metal.

Roads on which the black shale is used are dusty and seldom are smooth. The same disadvantages apply to roads surfaced with shale from mine dumps.

The chats consist of crushed rock--mainly chert--from which the zinc-lead ores have been removed. This material is very abundant, easily handled, and with proper usage makes excellent road material.

Prev Page--Structure || Next Page--Invertebrate Faunas

Kansas Geological Survey, Geology

Placed on web July 27, 2011; originally published Sept. 1938.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/24/06_mine.html