Prev Page—Contents || Next Page—Stratigraphy

Introduction

A preliminary report on the McLouth field (Lee, 1941), published by the State Geological Survey of Kansas, describes the development of the field prior to August 15, 1941. The present report discusses geological developments and production information of the field to April 1, 1943. The investigation that yielded these reports was undertaken by the State Geological Survey of Kansas and the Federal Geological Survey and represents part of a cooperative project having as its purpose the study of the relationship of oil and gas to stratigraphy and structure in the Forest City basin in Kansas. Another result of this cooperative investigation is a more general report on the stratigraphy and regional structure of the Forest City basin in Kansas which has been published as Bulletin 51 of the State Geological Survey. The work on the Pennsylvanian rocks of the McLouth field was done mainly by Thomas G. Payne who contributed the chapters on the stratigraphy of the Pennsylvanian, on the lithology, thickness, and lithologic zones of the McLouth sand, and on the environment and paleogeography during its deposition. The nomenclature and classification used in this report follow the usage of the State Geological Survey of Kansas. The use of adjectival endings on series names is not the preference of the senior author.

Location and Topography

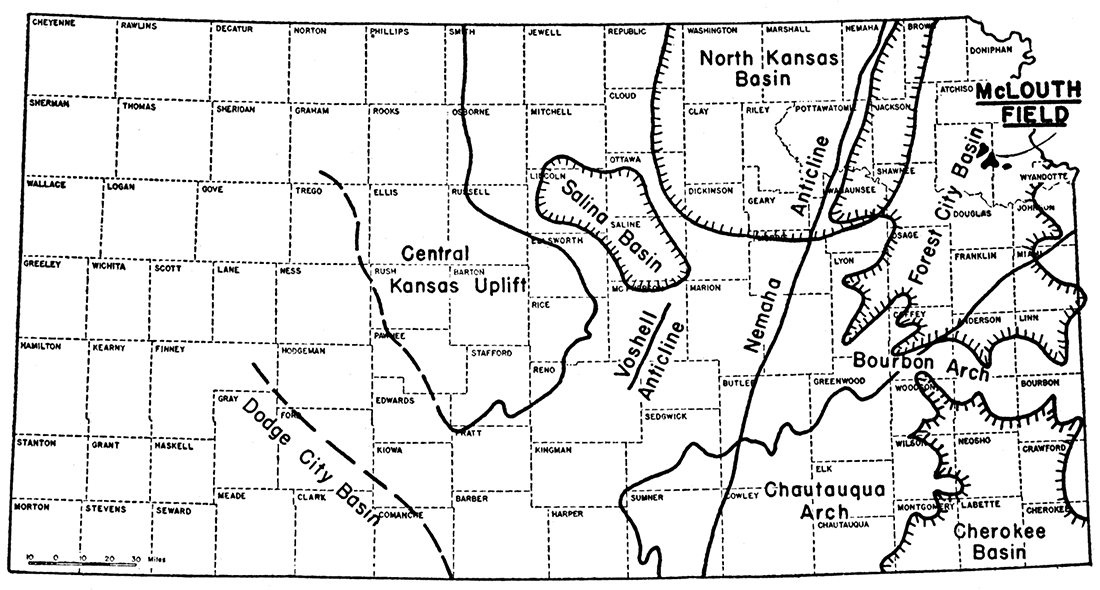

The McLouth gas and oil field is situated in northeastern Kansas between Kansas City and Topeka, 15 miles north of Lawrence (fig. 1). The field is named for the village of McLouth, in southeastern Jefferson county, on the southwestern edge of the original gas pool. On April 1, 1943, the field included three pools in Jefferson and Leavenworth counties-the McLouth, the North McLouth, and the Ackerland pools (see pl. 3). These pools include parts of 21 sections in the southern part of T. 9 S., R. 20 E., the north half of T. 10 S., R. 20 E., and a small area in the northwestern corner of T. 10 S., R. 21 E. On April 1, 1943, the area of the three pools from which oil and gas were being produced was 4,610 acres, of which 550 acres yielded oil. At that date there were 90 gas wells and 21 oil wells.

Figure 1—Map of Kansas showing McLouth gas and oil field and outlines of principal structural features of Kansas. The Chautauqua arch is indicated by pre-Chattanooga outcrops of top of Simpson sandstone (after McClellan, 1930); trends of Nemaha and Voshell anticlines and position of Salina basin are indicated by thickness of Mississippian rocks (Lee, 1939); Central Kansas uplift is shown by absence of Mississippian limestone (Lee, 1939); outline of Forest City basin from thickness map of pre-Hertha Pennsylvanian rocks (this report); outline of Cherokee basin from thickness map (Bass, 1936); North Kansas basin from thickness map of Chattanooga shale (Lee, 1940) ; and Dodge City basin after McClellan (1930). The development of all these structural features was not contemporaneous. The Chautauqua arch and the North Kansas basin are the oldest structural features outlined on the map, and the Forest City basin and the Cherokee basin are the youngest,

The field is near the southern boundary of the submaturely to maturely dissected till-plains section of the Central Lowland physiographic province. The upland area of the field ranges in altitude from approximately 1,100 feet to a maximum of nearly 1,200 feet in the southwestern part, and is mantled by Pleistocene glacial deposits of till, sand, and gravel. This upland plain has been dissected, especially in the northern and eastern parts of the field, by the headwaters of northeastward and eastward-flowing tributaries to Stranger creek, which flows southward and joins Kansas river. The well altitudes in this dissected and topographically lower portion of the field range from 969 to nearly 1,100 feet. Thus, the topographic relief of the producing area is roughly 225 feet.

The McLouth field lies on the southeastern side of the Forest City basin, a low broad structural feature whose central area lies in northeastern Kansas and whose margins extend into the adjoining parts of Nebraska and Missouri and into Iowa. The basin was formed by regional warping of the pre-Pennsylvanian rocks, and it was originally both a topographic and a structural feature in which the earliest Pennsylvanian rocks of this part of Kansas were deposited. The McLouth field is approximately 40 miles southeast of the deepest part of the basin and 50 to 60 miles east of the Nemaha anticline which confined the basin on the west.

History of the Field

The geological work which led to the development of the field was done in April, 1939, by Huntsman Haworth and C. B. Taylor, consulting geologists of Wichita. Gas was discovered in the McLaughlin and Sons No. 1 fee well, in the NE NW sec. 4, T. 10 S., R. 20 E., early in November, 1939. This gas was found in what is called the McLouth sand, an irregular body of sandstone and shale at the base of the Cherokee shale which is the oldest Pennsylvanian rock in Kansas. This well was originally gauged at 8 1/2 million cubic feet of gas per day from sand at a depth of 1,426 to 1,440 feet. As there was no market for the gas, the well was deepened to explore the possibilities for oil production. An increase in gas was reported at depths from 1,450 to 1,475 feet, Casing was set and cemented at the top of the Mississippian rocks at a depth of 1,475 feet. Small amounts of oil and gas were reported at the top of the Mississippian, and heavily oil-stained porous limestone and dolomite were encountered in four other zones in the Mississippian beds between 1,475 and 1,645 feet below the surface (170 feet below the top of the Mississippian). Water was reported at depths of 1,635 and 1,650 feet.

Limestone of Middle Devonian age ("Hunton") was encountered at 1,875 feet and drilled to 1,915 feet below the surface. Shows of gas were reported in the Devonian, but efforts to shut off the water that filled the hole proved unsuccessful. Drilling was stopped at 1,915 feet and the well was plugged back to the base of the Pennsylvanian where gas was later produced from the McLouth sand.

The second well in the field, Young and Longwell No. 1 McLeod, in the S2 NW SW sec. 4, T. 10 S., R. 20 E., was started on April 7, 1940. This well penetrated the same sequence of Pennsylvanian rocks as the discovery well except that the gas sand was represented by impervious silty and sandy shale with thin streaks of dense oil-stained sandstone. Prompted by the encouraging shows of oil in the discovery well, the operators deepened the second well to test the Mississippian limestones. Some free oil was found in the top of the Mississippian rocks at a depth of 1,469 feet, and many samples of dolomite and limestone to a depth of 1,594 feet were oil stained. Between depths of 1594 1/2 and 1,596 feet, the well filled 1,200 feet with black oil of 20.7° Bé. gravity. Seventy-two barrels of oil were pumped from the well during the first 24 hours of a test and 32 barrels were pumped during the ensuing 30 hours, but production from this well declined rapidly.

The discovery of oil in the Mississippian limestone in the second well in the field, although not in itself of great importance, led to the deeper drilling of many other tests which have revealed the structural relations of the pre-Pennsylvanian rocks to those of the Mississippian. The Young and Longwell No. 1 McLeod well (the second well) also revealed pre-Pennsylvanian faulting which is indicated by the local absence of certain limestone beds and by the shortening in this well of the upper part of the Mississippian section.

Two other gas wells were drilled shortly thereafter, one of which, the McLaughlin and Sons No. 1 Dark well in the NW SW NW sec. 4, T. 10 S., R. 20 E., was gauged at over 13 million cubic feet of gas per day. The other, the McLaughlin and Sons No. 2 Dark well, offsetting the No. 1 Dark well, was gauged at 3.8 million cubic feet per day. The fifth well, Stark No. 1 Ragan, in the N2 NW NE sec. 4, was favorably located near the crest of the surface anticline, but found the McLouth sand composed of impervious sandy shale and thin streaks of impervious sandstone. The Mississippian producing zone contained water. This location had been considered for the first well; if chance had not directed the first test to another location, the anticline would have been abandoned and the surrounding areas condemned.

At this time, gas production seemed to be so spotty that a pipeline connection seemed unwarranted. However, owing largely to persistent drilling by D. W. McLaughlin and his associates in spite of the disappointing results from some of the early wells, sufficient gas reserves were developed to insure the construction of 10 miles of pipe line to the Cities Service main line at Tonganoxie. The pipe line was connected on March 18, 1941.

Expansion of the field resulted in a series of important developments. In May, 1941, the Longwell No. 1 Bankers Life well, in the NW SW sec. 3, T. 10 S., R. 20 E., discovered oil in the McLouth sand in the depressed area south of the fault (fig.8.). This and other wells later drilled in this section revealed a small oil pool on a faulted anticline, the crest of which had been lowered by the fault below the gas sand on the upthrow side. In July, 1941, the discovery of gas in the Anderson No. 1 Woodhead well, in the NE SW sec. 32, T. 9 S., R. 20 E., outside the area of structural closure of the surface rocks, led to the hypothesis that porosity of the sand body rather than structure was the controlling factor of accumulation. This conclusion is now known to have been erroneous, for, as will be shown later, the structure at the surface imperfectly reflects the structure in the deeper rocks.

The Anderson No. 1 McLeod-Wisdom well, in the SW NW sec, 29, T. 9 S., R. 20 E., drilled in July, 1941, opened the North McLouth gas pool, which at that time was believed to be an extension of the original pool. However, a number of holes drilled later revealed a sharp intervening syncline conforming in trend to the shallow structural trough shown on Haworth and Taylor's map of the surface structure (pl. 2). The Ackerland gas pool was opened in October, 1941, by the Mosbacher et al. No. 1 Bell Estate well, in the NW NE NE sec. 12, T. 10 S., R. 20 E., 2 1/2 miles west of the village of Jarbalo in Leavenworth county. Development of this pool was retarded for a time because the well made only slightly more than 1 million cubic feet of gas per day. More productive wells were drilled later. The pool, although small, was still being extended toward the east on April 1, 1943.

Another interesting well, the Anderson No. 1 Dick well in the SE SW sec. 17, T. 9 S., R. 20 E., found oil in the McLouth sand in the North McLouth pool in October, 1941. The Mosbacher No. 1 Dolman well, in the NW NW SE sec. 27, T. 9 S., R. 20 E., drilled in September, 1941, found the McLouth sand impermeable but had a show of gas in the St. Louis limestone at the top of the Mississippian. This limestone was acidized and the flow was increased to a reported 2.8 million cubic feet of gas per day.

The Apperson No. 1 Bower well, in the SE SE NE sec. 5, T. 10 S., R. 20 E., a rotary well on the crest of the McLouth anticline, was drilled to the Arbuckle limestone in the autumn of 1941. This well is structurally the highest well in the pool in the Mississippian limestone. The Mississippian producing dolomite was cored in this well, revealing a spongy condition in the cores recovered (pl. 5). The top of the Devonian ("Hunton") was also cored. This core consisted of sucrose dolomite which was heavily stained with oil, but it lacked porosity adequate for oil accumulation. After drilling to the Arbuckle limestone, the hole was plugged back to the pay zone in the Mississippian and a good oil well was developed. Traces of oil in the upper zone of the "Hunton" in this well and traces of oil in the lithographic limestone at the top of "Hunton" in the McLaughlin No. 1 Thorpe well, in the NE NE sec. 27, T. 10 S., R. 20 E., which had been drilled earlier, indicate that oil pools probably will be discovered in the Devonian at places where both porosity and structure are favorable. The Jackson No. 1 Shughart well, in the SW SW sec. 6, T. 9 S., R. 20 E., drilled in December, 1941, found porosity in oil-stained dolomite in the upper Devonian rocks, but the well was unfavorably located structurally.

Three wells in secs. 28, 29, and 32, T. 8 S., R. 20 E., drilled by McLaughlin and Sons during 1942, failed to yield commercial production but demonstrated the occurrence of structural features in the southern half of T. 8 S., R. 20 E. which give promise of a northern extension of the McLouth field.

On December 20, 1941, 32 rigs were operating in the McLouth field. At the end of January, 1942, only 14 rigs were operating and by the first of March, 1943, only 6 wells were being drilled. During the summer of 1942 the number of wells being drilled at one time rarely exceeded 14 and frequently fell below 10. On April 1, 1943, only 8 wells were being drilled.

Drilling and Operating Practices

Spacing of Wells

It has been the practice to space each gas well on a 40-acre tract, but there are several gas wells on town lots at the north edge of the town of McLouth, in the NE NW sec. 8, T. 10 S., R. 20 E., where at one time it seemed that a town-lot drilling campaign might develop.

Oil wells were originally drilled on 10-acre tracts. The six oil wells in the SW sec. 3, T. 10 S., R. 20 E. and a few gas wells in secs. 4 and 5 were irregularly spaced because of the irregular shape of land subdivisions. Limitations prescribed by the Office of Production Management for the drilling of oil wells to the Mississippian dolomite in secs. 4 and 5 have complicated the spacing of oil wells in these sections. Conservation Order No. M68, dated December 23, 1941, restricted the drilling of gas wells to one in 640 acres and oil wells to one in 40 acres. Provisions for obtaining exceptions to the conservation order later were promulgated and relief was secured which permitted the resumption of drilling. Regulations as of April 1, 1943, permit the spacing of gas wells on 40-acre tracts as before the conservation order, but the spacing of oil wells is restricted to 20-acre locations at a distance of at least 660 feet from oil wells and 330 feet from gas wells and property lines.

Depths to Producing Zones

Most of the wells reach the gas sand at depths between 1,400 and 1,550 feet; because of structure and topography, however, extremes of depths as shallow as 1,365 feet and as deep as 1,625 feet have been drilled. The oil zone in the Mississippian dolomite is reached at depths of 1,596 to 1,682 feet in the McLouth oil pool depending upon the local topography and structure.

Drilling Practices

The wells in the field have been drilled with drilling machines of various makes; standard tools were used in a few wells. Rotary tools were used in drilling only one well. This well, the Apperson No. 1 Bower well, in the SE SE NE sec. 5, T. 10 S., R. 20 E., was drilled to a depth of 1,955 feet with rotary tools. At this depth, circulation was lost in a crevice or cavern in the Devonian limestone. Standard tools were then installed and the well was completed at 2,288 feet in the Arbuckle limestone. This experience and the shallow depth of the producing zones discouraged the use of rotary equipment.

Wells to the McLouth sand require an average drilling time of 18 to 20 days. A few wells were drilled in 10 days but many have required a much longer period because of fishing jobs, caving-shale, water, and in some cases inadequate equipment. The average contract price is $1.35 per foot exclusive of pipe which is furnished by the operator.

Three to four strings of casings are run. Ordinarily, one to three joints of 10-inch surface pipe are set and a string of 8 1/4-inch pipe is run through the Hertha limestone, which is penetrated at depths of 800 to 1,000 feet. In many wells this is followed by a string of 6 5/8-inch pipe cemented at the top of the gas sand. Where caving-shale or water-sand is encountered in the Cherokee shale, however, 6 5/8-inch pipe is run at depths ranging from 1,100 to 1,400 feet. Where 6 5/8-inch pipe is set in the Cherokee shale, 5 3/16-inch pipe is cemented on top of the gas sand. In some gas wells 2-inch tubing is run. In oil wells in the McLouth sand, 2-inch tubing is run; in oil wells in the dolomite zone, 2 1/2 to 3-inch tubing is used.

It is not the practice to shoot gas wells in the McLouth sand. Oil wells in the McLouth sand, however, have been shot with 40 to 60 quarts of nitroglycerine. The first oil well in the dolomite zone was acidized, but the great increase in water discouraged the acidization of other early wells in the dolomite. The development of the field revealed that the discovery well in the dolomite was an edge well and that the Mississippian limestone in this well was faulted. Late in 1942, one of the oil wells higher on the structure was acidized and an important increase of oil resulted. Since that time all but one or two of the dolomite wells have been acidized with 1,000 to 2,000 gallons of acid. Acidizing doubles or triples the initial production of oil, but it also increases water production. The amount of water accompanying the oil in the dolomite wells of the McLouth pool varies greatly. In many wells more water than oil is pumped. The average production of water on April 1, 1943, was reported to be about 60 percent of the fluid pumped, The water is run to earthen evaporating ponds.

The Mosbacher No. 1 Dolman well, in the NW SE sec. 27, T. 9 S., R. 20 E., an edge well, encountered gas in St. Louis limestone. The open flow is reported to have been gauged at 360,000 cubic feet per day before acid treatment. The flow of gas increased to 759,000 cubic feet per day after a first acid treatment and to 2,800,000 cubic feet per day after a second acid treatment. The amount of water, however, also increased and the well was never put on production.

All of the oil wells of the field are equipped with individual pumping units. A few of the oil wells made brief initial flows but the first successful oil well, the Young and Longwell No. 3 McLeod well, in the NE SE sec. 5, T. 10 S., R. 20 E., a well producing from the dolomite, was unique in that it flowed by heads for several months. Very little gas accompanies the oil. Gas used for pumping wells which produce oil from the dolomite is drawn from nearby gas wells. Enough gas to operate the pumps accompanies the oil in wells in sec. 3 producing from the McLouth sand. The oil is heated to 150° F. and chemically treated in the field to separate the water.

Disposal of Gas and Oil

Gas from the McLouth area is piped from the field through two pipe lines, both of which have Cities Service connections. The first, a 6-inch line connected March 18, 1941, is owned by the A and B Pipe Line Company of Wichita. The second, an 8-inch line connected December 16, 1941, is owned by Walter S. Fees of Iola, Kansas.

The A and B line runs southeast from the field to Tonganoxie, Kansas, where it delivers gas to the Cities Service pipe line at a pressure of 300 pounds per square inch. The Cities Service line runs northeast from Tonganoxie, and supplies the cities of Leavenworth and Atchison, Kansas, and St. Joseph, Missouri. The Fees line runs slightly northwest from the field and delivers gas at a pressure of 170 pounds per square inch to a former distributing line of the Cities Service Company built north from Topeka to supply the towns of Oskaloosa and Valley Falls. The direction of flow in this line is now reversed and McLouth gas is now conducted through Oskaloosa to Topeka, where most of the gas from the Fees line is consumed. The average field pressure had declined before April 1, 1943, to less than 150 pounds per square inch in all pools (fig. 20), and compressor plants are now operated by both companies to maintain pipe-line pressures.

The A and B Pipe Line Company pays 7 cents per thousand for gas at the wells; the Fees pipe line pays 7 1/2 cents per thousand. The Cities Service is reported to pay the pipe-line companies 12 cents per thousand delivered in Tonganoxie and at the line near Oskaloosa. The volume of gas is computed at 2 pounds above atmospheric pressure and at a temperature of 60° F.

The Marson Oil Company of Kansas City buys most of the oil from the field. It is transported by truck mainly to Kansas City where it is used as fuel oil without further treatment. The oil was sold at 85 cents per barrel at the well until early in 1943 when the price was raised to 95 cents per barrel. About 5,000 barrels of oil were disposed of locally and in adjoining counties for road surfacing. Minor amounts of oil have been utilized as fuel for drilling operations.

Study of the Field

The McLouth field is unique in that it is the only gas field in northeastern Kansas in which the relation of the structure of the gas sand in the Pennsylvanian to that in the underlying Mississippian rocks is known. This came about through the discovery of oil in the Mississippian rocks early in the development of the field. Most of the wells are drilled into the McLouth sand; if this proves to be dry, the wells are deepened to test the porous zone in the Mississippian rocks. The conditions revealed by a study of the data from the upper part of the Mississippian, which will be discussed later in this report, have an important bearing on the development of future deep production in northeastern Kansas and give hope for production in the deeper rocks below other gas pools in Pennsylvanian rocks in places where the accumulation of the gas was controlled by structure.

Only six wells in the field have been drilled below the middle beds of the Mississippian limestones so that the relation of the surface structures to the important oil-producing zone at the top of the Devonian limestone is still undetermined.

Examination of Samples

In the course of this work, nearly complete sets of samples have been collected from all wells in the field. Samples were usually taken at 5 to 10-foot intervals. In some wells the taking of samples at intervals of 15 to 30 feet or more has interfered with the accurate determination of the depth to key horizons. Samples of the McLouth sand ordinarily were taken at 5-foot or smaller intervals, but no satisfactory samples of the producing gas sands have ever been caught. The water used in drilling the gas wells is blown out of the hole by the gas and the wells necessarily are drilled in dry. Consequently, the gas sands become pulverized and are ejected as fine angular quartz dust which does not represent the character of the reservoir sand. Samples of the sand from oil wells, wells yielding water, and wells in which the sand is argillaceous or clogged with desiccated oil or tar, however, have been studied. Chunk samples recovered from oil wells in the McLouth sand have been of value in the study of the lithologic character of the sand (pl. 8) , but these samples probably represent the less porous parts of the McLouth sand.

Many of the depths to key horizons used on the contour maps are not in accord with the drillers logs. Some of these differences are due to corrections resulting from sample examination. Others are due to the correction of drilling depths by steel-line measurements. Corrections are, for the most part, of only a few feet and rarely over 10 feet, but corrections up to 25 feet were made in a few wells. In well logs where the correction of depth occurs below. one of the key horizons the depth of the key horizon has been adjusted proportionally to the distance up the hole to a previous check measurement. The shorter the distance between the key horizon and the correction point, the more nearly does the adjustment equal the correction. Unfortunately, it is probable that in a few cases depths were corrected without notation in the log book. The depths to key beds in all wells in the McLouth field are given in table 1 with corrected depths where these differ from the drillers log.

Well Names

Table 27 gives a list of wells drilled in the McLouth field and on its borders. Much difficulty has been encountered in naming the wells. Many of the wells were drilled as joint enterprises with two or often several owners. It is obviously impossible to name all those interested as owners and it has been. the practice to name the wells for the operator who seemed to hold the dominant interest at the time the well was started, and to continue this name even when there were later changes in the dominant ownership of the well and lease. Where such changes in ownership have attained current usage, the new name has been added in parentheses. For instance the Magnolia leases were subleased in part to Hatcher and Fisk and in part to others with the condition that the lease should revert to Magnolia in case oil were discovered. Thus, the name Magnolia in parentheses has been added in some cases.

The transfer of fee interests has been equally confusing. The authors have preferred to continue the use of the established name under which the well was drilled rather than to add confusion by changing the lease name. However, where current usage has adopted the name of the new fee owner, this name has in some cases been placed in parentheses. Thus, Longwell and others drilled an oil well on land leased from the Bankers Life Company, but the land was thereafter transferred to Bessie McLeod. The name Bankers Life was continued in naming wells subsequently drilled, but the name of the new fee owner has been placed in parentheses. Many changes in both fee and lease ownership have been ignored, however, to avoid confusion of nomenclature and because changes in ownership could not always be verified.

Acknowledgments

The study of an area like the McLouth field with divided ownership of leases can be prosecuted only with the cooperation of a large number of people upon whose continuing help the assembling of the data depends. This cooperation has been given fully by drillers, contractors, geologists, and operators.

It is a pleasure to acknowledge the help of all the operators in the field, particularly that of D. W. McLaughlin in securing the interest and cooperation of other operators in the early development. Especial thanks are tendered to the drillers and contractors who saved and labeled the samples, and whose careful logs in many instances have given more accurate determination of stratigraphic breaks than is possible from a study of samples alone.

The original map of the field by Haworth and Taylor showing the structure as indicated by the surface rocks is here published by permission of Huntsman Haworth to whom the writers are indebted also for altitudes, detailed information on current developments, and for the use of other structure maps in outlying areas (pl. 2.). The personal contacts established by James C. Clark, Gene Maxwell, and Hugh Crain in collecting samples and other information in the field have contributed in no small measure to the successful prosecution of the enterprise.

The writers are indebted to L. L. Armstrong of the A and B Pipeline Company for production figures, well pressures, and gas analyses; and to Walter Fees of the Fees Pipeline Company for data on gas production. Data on oil production have been contributed by George B. Willhoite of McLaughlin and Sons, Ray Anderson, the Magnolia Petroleum Company, and the Marson Oil Company.

Analyses of oil from the Falls City pool made by the Bureau of Mines at Bartlesville were provided by Edward A. Huffman, District Geologist for the Skelly Oil Company. Samples of oil from the McLouth pool were analyzed by J. G. Crawford of the U.S. Geological Survey. N. W. Bass contributed a discussion of the Hempel analyses of oils from McLouth and Falls City. W. F. Earl of the Ohio Oil and Gas Company assisted by contributing samples and in other ways.

Most of the work on the Pennsylvanian samples was done by Thomas G. Payne, co-author of the report. Ada Swineford ably continued the examination of the Pennsylvanian cuttings after the transfer of Payne to other work. Miss Swineford is responsible also for the tedious compilation of well data and for the production and other charts. The drafting of the illustrations was done by Dorothea Weingartner, Eileen Martin, and others under their direction. The manuscript was edited by H. D. Miser, John C. Frye and Edith Lewis to whom thanks are tendered.

Prev Page—Contents || Next Page—Stratigraphy

Kansas Geological Survey

Comments to webadmin@kgs.ku.edu

Web version July 2019. Original publication date June 1944.

URL=http://www.kgs.ku.edu/Publications/Bulletins/53/02_intro.html