Prev Page--Oil Production || Next Page--Environment

History

The beginning--Fairport oil field, 1923

The history of the Gorham oil field begins with the discovery of the nearby Fairport oil field November 23, 1923. As described in an early report (Allan and Valerius, 1929), the Fairport discovery well was 120 mi (192 km) west and north of the nearest oil production, the Covert-Sellers oil field in Marion County. Development of the Fairport oil field was rapid. Demand for crude oil was strong and the price was firm, $1.60 to $2.00 a barrel. Excellent oil wells with few dry holes were drilled along the "Fairport ridge." The oil field grew to be 4 mi (6.4 km) long and 0.5 mi (0.8 km) wide. By October 1926, 99 oil wells, each with its wooden derrick, were evenly spaced on regular 100-acre (4-hectare) spacing, 660 ft (198 m) apart. Production in 1926 was 1,847,785 BO or an average of 51 BOPD per well for the year.

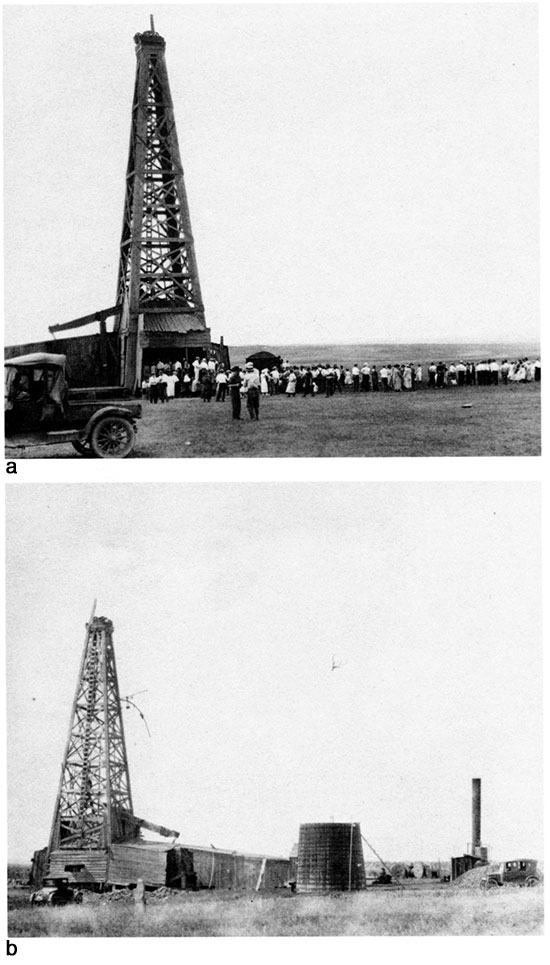

Figure 19a--Carrie Oswald No. 1, November 23, 1923, the discovery well of the Fairport oil field and of oil in the west ranges of Kansas. It was located 120 miles west of the nearest oil production. Local interest was high as shown by the 102 Sunday visitors. Figure 19b--Carrie Oswald No. 1, a second view showing the cable-tool standard rig, the wood derrick, belt house, water-storage tank, and coal-fired steam boiler. Photographs courtesy Russell County Historical Society.

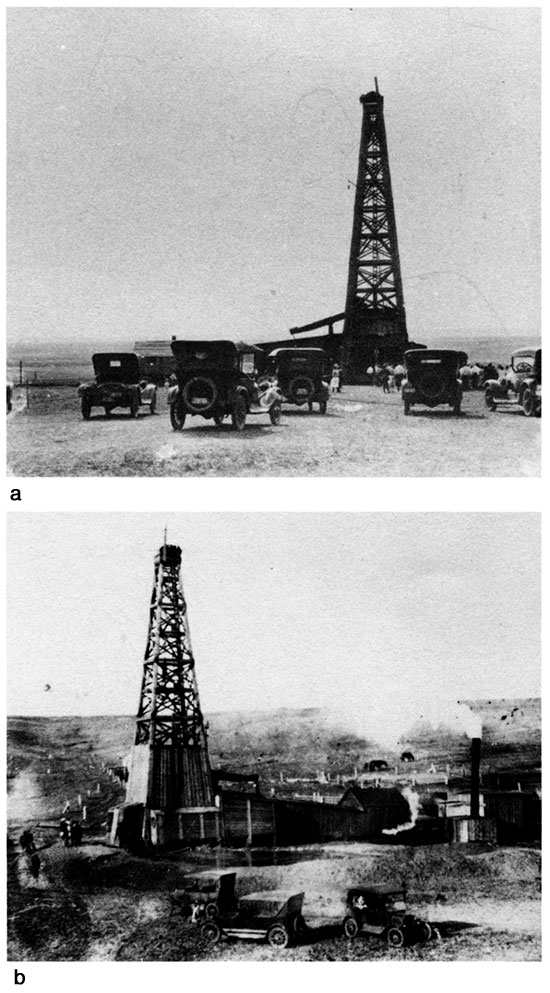

The famous discovery well of the Fairport oil field, the Carrie Oswald #1 in the SW SW SE sec. 8, T. 12 S., R. 15 W., is located 9 mi (14.4 km) north of Gorham. Interest was high among the local land owners. The much-reproduced photograph (fig. 19a) of the Carrie Oswald #1 on the Sunday afternoon after Thanksgiving shows 102 visitors in clean white shirts or long skirts. In the right foreground the discoverer, M. M. Valerius (hat in hand) is standing with the senior Mr. and Mrs. Oswald and friends. A second view of the Carrie Oswald #1 (fig. 19b) better illustrates the cable-tool standard rig with its derrick, enclosed derrick floor, belt house, water-storage tank, steam boiler, and coal pile, the latter partly concealed by an automobile. All the early wells in the Fairport oil field were drilled with similar equipment, characterized by the wooden derricks that were left in place on the producing oil wells. Figs. 20a and 20b are two additional views of standard rigs drilling in the Fairport oil field. Most of the automobiles belonged to the many visitors. The 102- well Fairport oil field of 1928 (before merging with Fairport North and Fairport South oil fields) was the last major oil field in Kansas to be drilled entirely with cable tools.

Figure 20a--Fairport oil field, 1923, with visitors' automobiles. Figure 20b--Fairport oil field; photographs courtesy Russell County Historical Society.

Exploration by surface geology

Among the oil companies, the completion of a 200 BOPD wildcat well 120 mi (192 km) from production caused much excitement. It was known that the discovery of the Fairport oil field was not due to random drilling but to careful surface mapping of an anticline based on excellent outcroppings of Cretaceous rocks in the river valley and canyon country around the town of Fairport. Following the discovery of the Fairport oil field, oil companies sent many geologists into the area to do field mapping of surface rocks in search of other anticlines. From 1923 to 1926, geologists were a common sight as they swarmed over the area in their Model "T" Fords, wearing broad-brimmed World War I hats, high boots, or leather puttees and knee-length army pants. They squinted through their alidades (fig. 21), making plane-table structure contour maps. The "post rock" or Fence-post limestone quarried by pioneer settlers in the then-treeless prairie for use as fence posts was a reliable correlation bed. Such mapping by J. S. Irwin and F. F. Hintz "led to the discovery of the Gorham structure and the drilling of the first well on it by the Producers and Refiners Corporation" (Hintz, 1928). Unfortunately, the first "well" wasa dry hole in the SW NW SE sec. 9, T. 14 S., R. 15 W.

Figure 21--Empire Gas and Fuel Company surface geologists, about 1918. The plane tables and alidades were used for surface mapping of rock outcrops; photograph courtesy Kansas Independent Oil and Gas Association (KIOGA).

As shown on the structural contour map of the Cretaceous Fence-post limestone (fig. 16) by the heavy lines following the pattern of the outcrop of the "post rock" in the canyon areas of the north part of the map, control for surface mapping was excellent, detailed, and continuous. Along the south edge of the map, the heavy lines show that the control was also excellent in the hills on the southern portion of T. 14 S., R. 15 W., south of Big Creek. In the midportion of the mapped area, only scattered small outcrops occur. There are no outcrops at all in the flat wheat fields occupying much of the area of fig. 16.

Exploration by core drill

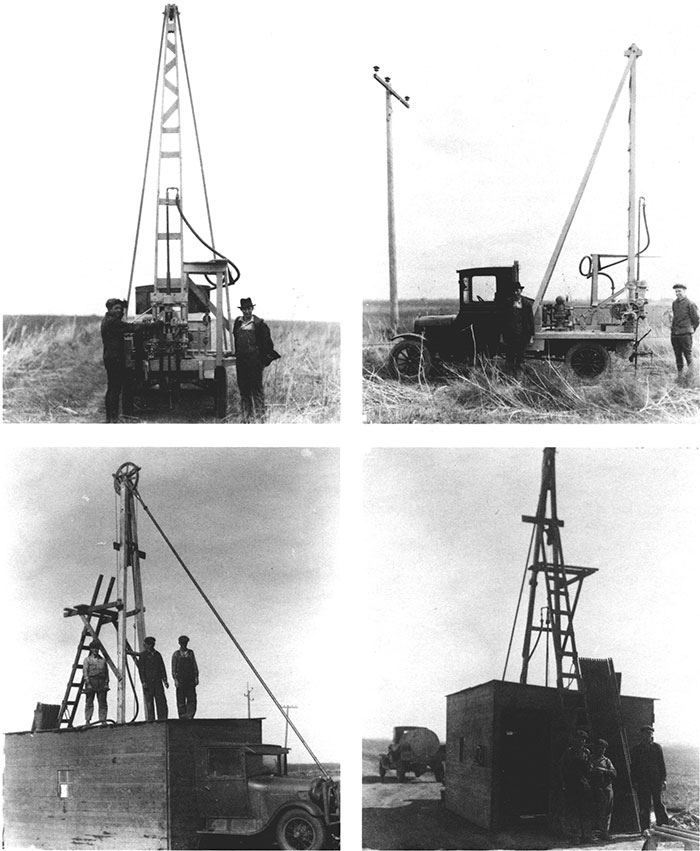

Surface geologists could not map in flat wheat fields. Tom Allan (personal communication, 1975; deceased, 1985) was a resident of Russell, Kansas, in 1925 and field geologist for the Midwest Exploration Company. He had the idea that shallow test holes drilled in wheat fields with a "core drill machine" would permit mapping of the structural position of the buried post rock and other marker beds. In an innovative move he went to the Mesabi Iron Range in Minnesota in 1924, and hired an expert in coring and setting diamonds in drilling bits. These donutshaped drilling bits studded with commercial diamonds scratched away the rock leaving a "core" or cylinder of undisturbed solid rock in the "hole" of the donut-shaped bit. In Russell, he had a drill mounted on a truck making the historic first "core drill machine" in Kansas and perhaps the entire midcontinent. Photographs (figs. 22a, b, c, and d; reproduced by courtesy of the Russell County Historical Museum) show his "core drilling machine" from all angles. The shed served not only for shelter but for privacy from rival oil company scouts when the recovered core was removed from the core barrel.

Figure 22a-d--Four views of the "core-drilling machine," assembled by Tom Allan for Midwest Exploration Company, 1924, Russell, Kansas. This is possibly the first core drill used in the midcontinent oil fields. The shed served not only for shelter but for privacy from rival oil company scouts when the core was removed from the core barrel; photographs courtesy Russell County Historical Society.

Discovery of the Gorham oil field, 1926

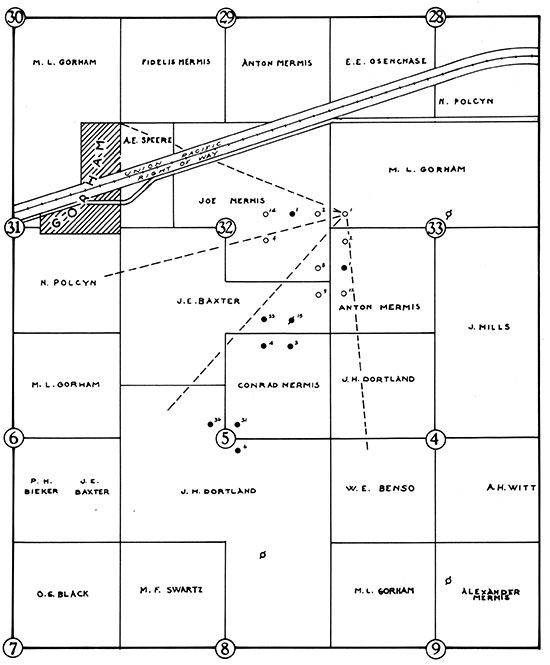

Using his core-drilling machine, Tom Allan cored the holes mapped in fig. 16. After he examined and correlated the cores, he mapped the Gorham anticline as shown and staked the location for the Midwest Exploration Company's Dortland No. 36 in the C SE SE NE sec. 5, T. 14 S., R. 15 W. (arrow, fig. 16). The well was commenced (spudded) on August 8,1926, and completed October 15, 1926, as the discovery well of the Gorham oil field. It produced 120 BOPD of 37° gravity oil from a depth of 3,057 ft (917 m) in the "Oswald" formation. The Cretaceous map (fig. 16), itself a "historic map," is redrafted directly from a copy of the original map used in the discovery work and given to the author by Tom Allan in 1975. Supplementing Allan's original work and included in fig. 16 is outcrop information from contemporaneous surface-geology maps prepared by three other rival oil companies. The maps also show two early dry holes. The first is the Producers and Refiners Corporation #1 Mermis, previously mentioned, drilled in April 1925, in the SW NW NE sec. 9, T. 14 S., R. 15 W. The second is the Keyes Petroleum #1 Sloan in the SE SW SE sec. 20, T. 13 S., R. 15 W., which was spudded August 23, 1925. Fig. 14, therefore, shows the complete development of the Gorham area at the time of the discovery, October 15, 1926.

Gorham oil field, 1926-27

The completion of Midwest's Dortland #36 as the discovery well of what came to be the greater Gorham oil field did not create much excitement. The well produced from the same formation that was producing in the Fairport oil field, the "Oswald lime" (now Lansing-Kansas City). People living locally were accustomed to oil-well drilling. They had seen 99 oil wells drilled in the Fairport oil field and watched it produce over three million barrels of oil in three years. There was less demand for oil; the price of oil had declined to $1.28 a barrel and there was no pipeline. (The Fairport oil field pipeline was not available as it went north to the Southern Pacific railroad at the town of Paradise.) "Development progressed very slowly, only four producing wells being completed by the end of 1927. No dry holes have been drilled," according to Kesler (1928).

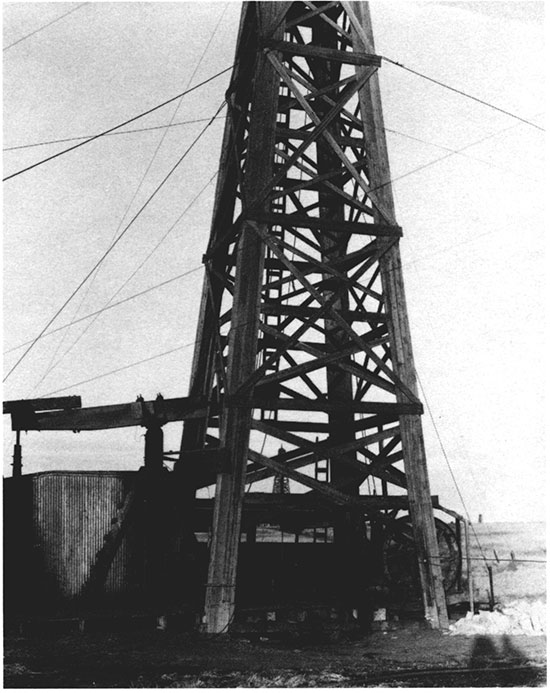

Drilling with standard cable tools

Wells were drilled in the Gorham oil field in the 1920's, 1930's, and early 1940's with cable tools, usually powered by steam. As many as 60 days were required to drill each well to a depth of 3,300 ft (990 m). A heavy drill bit and tools, hung on a cable (hence the term "cable-tool drilling"), were lifted up and down, pounding a hole in the rock. Cuttings were removed in a "bailer," an elongated bucket (to 30 ft [9 m] in length) with a hoop-shaped handle or bail at the top. Wooden derricks similar to those used in the Fairport oil field were used for the first wells, but no identifiable photographs were available in the Russell County Historical Museum. Fig. 23 is a closeup of a 1926 wood derrick left in place over a producing oil well. Each wood derrick was erected by rig builders, the most skilled and highest paid oilfield workers. Working high above the ground and hanging on with one arm, rig builders did most of their construction work one-handed. The boards were attached by metal spikes that were started in the wood with a strong shove of a gloved hand that held both the spike and the heavy rigbuilder's hatchet; the rigbuilders then drove the big spike completely into the wood with three blows (John T. Heisler, Jr., whose father operated an oil-field lumber-supply company at Russell, personal communication, 1986 and later). By 1928 (cover photograph), bolted steel derricks were in use.

Figure 23--Close-up view of wooden derrick and cable-tool equipment left on location after drilling to total depth to be used for pumping oil, Fairport oil field, approximately 1925; photograph courtesy Russell County Historical Society.

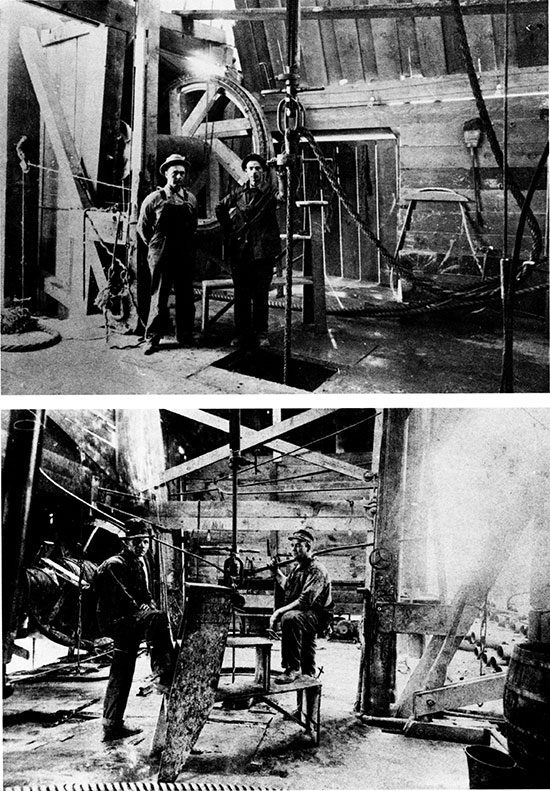

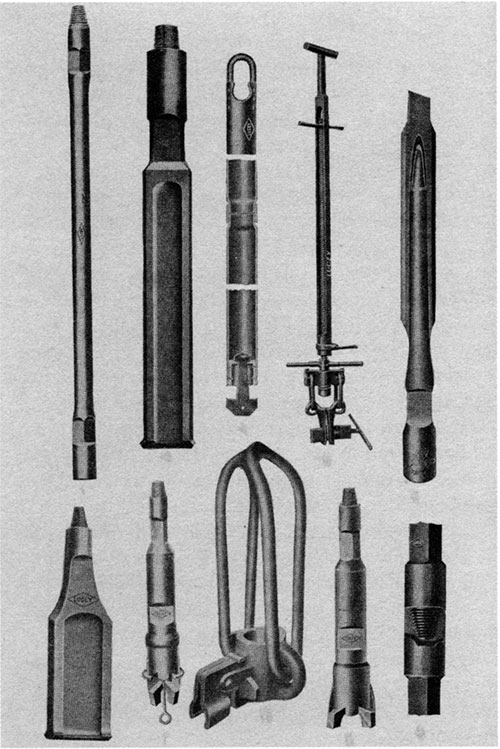

After the well was spudded (meaning actual drilling had commenced), the cable-tool drilling rig was manned by two crews of two men each. They worked around the clock, seven days a week, dividing the day into two tours (pronounced as "towers") of 12 hours each. The driller was in charge and the tool dresser was his assistant. The heavy metal drilling bits were "dressed" (sharpened) by heating them red hot in a forge just off the derrick floor and forging (pounding) the red-hot tools in shape with heavy sledge hammers. During forging, the bits were calipered (measured) by a round ring gauge to ensure that the bit would pass through the casing (pipe) in place in the hole. Cable tools are discussed more fully in the Kansas oil-field history book Discovery (Miner, 1987, p. 64-70). Figs. 24a and bare from that reference. They show interior views of the cable-tool derrick floor. The large cable, from which cable-tool drilling received its name, is shown in the hole in both pictures. Steam from a sharpened bit being quenched after forging obscures part of the lower photo. Representative tools used in normal drilling are shown in fig. 25 (Moore, 1917). The "bailer" (#4) is not shown for its full length. Bailers were 8-3O ft (2.4-9 m) long with a trip valve on the bottom and a bail on the top.

Figure 24a--Interior view, cable-tool drilling equipment, showing the cable (vertical) from which a heavy bit, auger stem, and jars were suspended. A hole was drilled by lifting and dropping the bit, pounding on the rocks. Figure 24b--Interior view, cable tools. Steam from quenching a newly forged (sharpened) bit obscures the right portion of the picture. Both photographs are courtesy KIOGA.

Figure 25--Tools used in cable-tool drilling (Moore, 1917, plate VITI).

Drilling was accomplished by raising and lowering the cable; attached to the cable were jars, drillstem, and a heavy bit that pounded and pulverized the rock. When enough hole had been made-that is, when sufficient rock had been crushed to impede progress-the bit was pulled from the hole and the bailer run to bottom to remove rock cuttings and fluid. Testing of fluids, called "bailing," was done by repeated runs of the bailer. The results were logged as 4 BWPH, for example, meaning 4 bailers of water per hour, not 4 barrels of water per hour. A bailer could hold either more or less than one barrel depending on its diameter. For example, three bailers each 30 ft (9 m) long have the following capacity in oil-field barrels of 42 U.S. gallons:

| bailer 4-inch interior diameter | 0.465 barrels |

| bailer 6-inch interior diameter | 1.050 barrels |

| bailer 7-inch interior diameter | 1.428 barrels |

Recovery of tools or objects lost in the hole was called "fishing" and required specially designed "fishing tools" not shown.

Advantages and disadvantages of cable-tool drilling

Cable-tool drilling was the only method used at the EI Dorado oil field in 1918, the Fairport oil field in 1923, and at the discovery of the Gorham oil field in 1926. Advantages of cable-tool drilling include excellent short samples (when saved) of rocks in the interval drilled, immediate response when fluid was encountered, and direct detection of "oil shows" by odor, sight, and actual recovery of oil in measurable amounts in the bailer. Cable tools began to be displaced by rotary rigs in the late 1920's in the midcontinent but continued in use for full-hole drilling in the Gorham oil field and in Russell County throughout World War II (1941-45), long after they were obsolete elsewhere. In those years, when labor and materials were in short supply, cable-tool drilling was advantageous because cable tools could be operated by a two-man crew. Old drilling units were available and could be repaired with parts salvaged from junk tools. Although casing was in short supply, most of the various sizes of pipe used in the many strings of casing could be "pulled" (recovered) and reused.

The disadvantage of cable-tool drilling included the slow drilling-up to two months to drill a 3,300-ft (990 m) hole--and the depth limitation. Each time an aquifer was drilled, the hole filled with water (the "HFW" of drillers logs). Drilling could not be continued because the water in the hole slowed the dropping of the bit, pulverizing the accumulated cuttings, without making new hole. This situation required. the setting of casing inside previously set casing, thus reducing hole size so that sometimes the cable-tool rig "ran out of hole" before the objective was reached. The disadvantage of depth limitation was overcome in Russell County by starting with a larger hole size, 24-inch diameter or more. Probably the greatest disadvantage, and the one that most affected the oil-field history of the Gorham oil field, was that cable-tool holes were drilled to find oil and when oil was "struck" (found), drilling was discontinued without knowledge of what might be encountered deeper. It was dangerous to continue drilling with a hole full of oil because of the fire hazard (see description of an oil-field fire, p. 63-64). Thus well after well was drilled into a relatively shallow pay zone such as the upper part of the Lansing-Kansas City, only to require deepening years later (often by another owner) into a deeper pay zone such as the lower Lansing-Kansas City, the Arbuckle, or the Reagan Sandstone. For example, the Sullivan oil field was discovered with considerable fanfare by Hartman and Blair in sec. 2, T. 145., R. 15 W. in February 1935. Production was from oil encountered by cable-tool drilling near the top of the Lansing-Kansas City, 3,060-3,070 ft (918-921 m). The property was sold in 1943, leaving the prolific deeper "Gorham sand" pay, 3,316-3,319 ft (995-996 m), to be produced in 1949 by Murfin Drilling Company, the purchaser. Such experiences were common. For several years, about 5% of the drilling rigs active in the Gorham oil field were re-drilling old wells, cryptically designated by scouts in their hastily handwritten notebooks as OWWO or OWDO meaning "old well worked over" or "old well drilled deeper."

Another disadvantage of drilling with cable tools was that when oil was "struck," wells that flowed oil or gas could not be controlled. The much-photographed "gushers" of the early oil fields were glamorous but dangerous, uncontrollable flowing wells. In the Gorham oil field in 1935, when the Roubach No. 1 "struck oil" in the Topeka fracture zone, the well was a "gusher" flowing out of control for five days as described on p. 60-62.

Information from cable-tool drilling

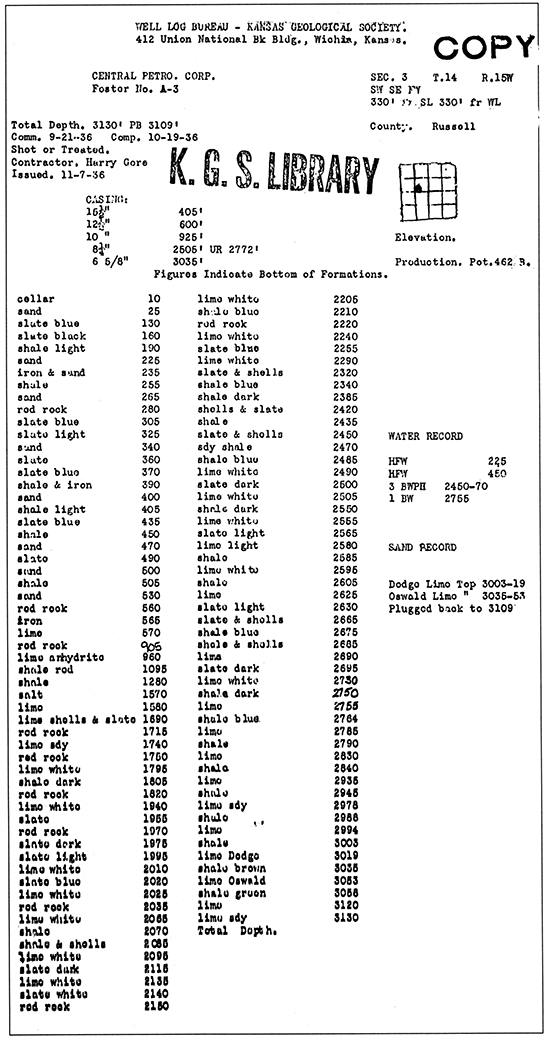

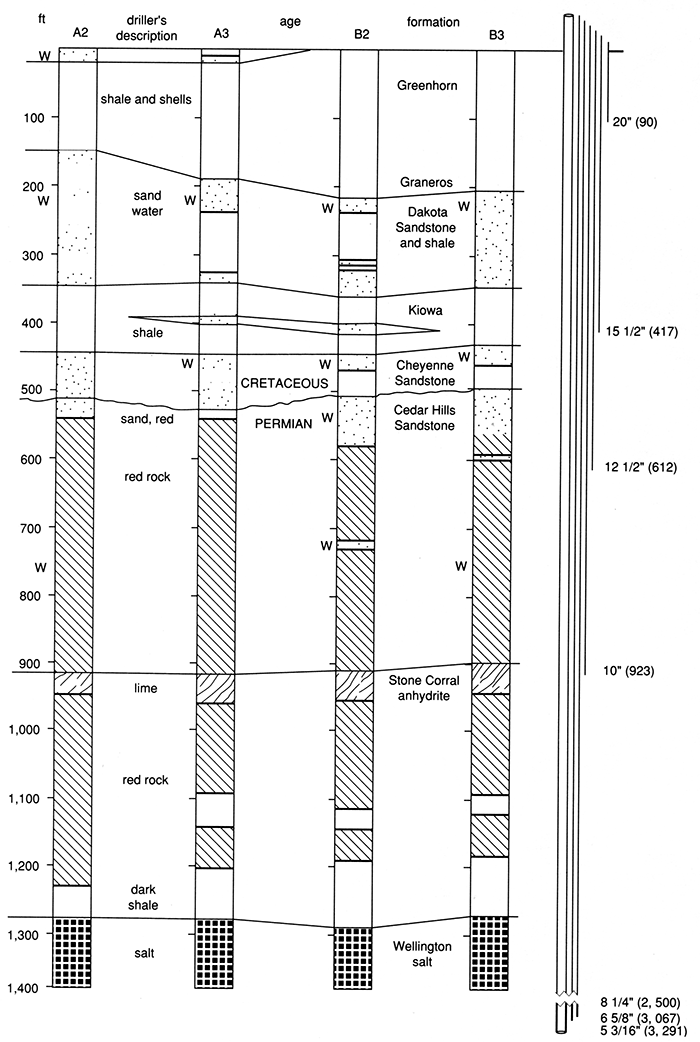

Information from cable-tool drilling was used in constructing the cross section A-B-C (figs. 5 and 6). The open circles indicate the recovery of water during drilling, thus marking the aquifers. Also the drillers' logs were correlated from well to well. What information is preserved? As the drilling progressed, the driller grabbed a handful of well cuttings after the bailer was dumped. He looked at the well cuttings, squeezed the well cuttings, felt and smelled the cuttings, and then sometimes bit into them checking grittiness with his teeth. He then either threw the handful of cuttings away or deposited them in a pile on a convenient plank lined up in depth sequence with previously caught samples. It was part of his job to record the depth and a one or two word description of the rock drilled such as "sand," "lime," or "shale and shells." The handwritten cable-tool driller's logs also recorded water as "HFW," translated "hole full of water." The holes were not completely full of water but filled to a static level at some interval below the surface of the ground as discussed for various formations by Walters (1975). This is known locally as a "Kansas hole full of water." The logs also, of course, recorded oil shows or actual oil recovered or unusual incidents or accidents. An extreme case is the Hartman and Blair #2 Roubach. A rig fire is recorded on the written driller's log as "rig fire, log burned."

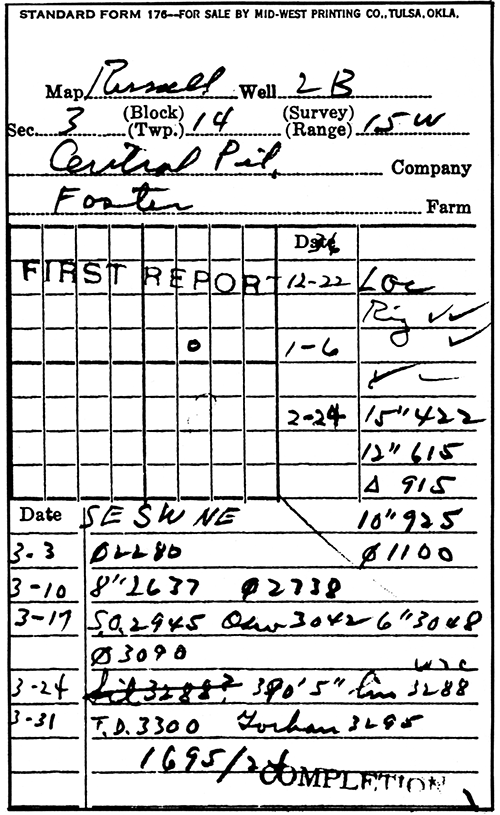

Rival oil companies, eager to learn of new oil discoveries, kept track of drilling progress. They hired scouts to go to the well, talk to the driller, and hand-copy the written drillers' log. Sometimes on "tight holes," they were barred from such information and had to rely on their own observations of oil or water dumped from the bailer, of oil in the pits, petroleum odor, or of the approximate depth of the hole by timing the bailer runs. Most often they were given information and reported it by telephone or in person at their company headquarters. With the increase in drilling, a scout could not cover all of the activity. He developed a network of friends, dividing the area among several scouts, "You check this well, I'll check the other well, and Joe will check the third well. We'll meet for lunch in Russell and trade logs." By the 1940's, this system had evolved into a formal organization known as the Kansas Log Check Association or "scout check." Each of the 15-26 major company oil scouts had an assigned district that he covered in person on Monday, Tuesday, and Wednesday of each week. He then reported to "scout check" on Thursday. The scouts gathered around a large table and each in turn read his scout report, largely condensed to well locations, drilling depths, formation tops, and oil recoveries or oil shows. Each of the other scouts seated around the table furiously wrote down the spoken information in his own shorthand. Each scout in turn gave his report. These handwritten notes were called "scout tickets" and they were usually kept in a looseleaf notebook (fig. 26a).

Figure 26a--Handwritten scout ticket, 1936, from an oil scout's notebook.

Figure 26b--Typewritten cable-tool drillers' log, 1936; courtesy Kansas Geological Society.

Figure 27--Cross section made from four plotted cable-tool drillers' logs. "W" is water encountered during drilling; logs are from the Kansas Geological Society Library. Multiple casing strings are shown diagrammatically at the right with diameter of casing in inches and the depth set in feet. After setting the deepest string, all other strings of casing were commonly pulled except the 20-inch surface pipe. It was while pulling the 6-inch casing that the derrick collapsed as shown on the cover and in fig. 29.

Samples of drill cuttings

In the late 1920's, geologists realized that examination of cable-tool well cuttings would add much information beyond that recorded in the drillers' logs. However, samples of well cuttings were regularly thrown away after the drillers inspected them. Geologists were seldom on location. With the combination of slow drilling by cable tools and the immediate recovery of gas, oil, or water by cable-tool drilling, geologists were not needed at the well site to find oil. It was difficult to get the drillers to change their ways. They resented the extra chores of collecting, saving, sacking, and labeling samples of the well cuttings. The change was gradually accomplished by providing cloth sample sacks at the rig, by having management add a clause to the drilling contracts requiring samples to be caught, sacked, and saved, and by the distribution of small gifts, usually in liquid form, to the drillers. This task was more comfortably performed during the winter months inside the boiler house where it was warm. At times it was even more comfortable to skip the sample catching except for one big bucketful. Then just before the tool dresser went off tour at midnight, he filled the required number of sacks from the one bucket and labeled them for the various depths drilled during the shift. Such samples were described as "boiler housed" by geologists. The practice became much less frequent when the drillers learned that the geologists could and did recognize the mislabeled samples.

In 1929, the Kansas Log Check Association adopted a systematic and cooperative plan to secure the well cuttings from the important wildcat or deep wells drilled in Kansas. Each of the 26 major oil companies was responsible for seeing that its well samples were distributed to other companies (Harvel E. White, personal communication, April 1986). No central place or organization existed to make such distribution. Each major oil company had its own facility for washing, drying, and dividing or "cutting" well samples and placing the separate "cuts" in labeled paper envelopes for exchange with other major companies. This work was done even in highrise office buildings with gas stoves blazing away drying the washed samples. In the late 1930's and in the pre-World War II 1940's, some geologists working for major companies were transferred from out-of-doors jobs when surface field parties and core-drill crews were shut down. They became largely office-bound except for occasional well-supervision work ("well sitting") on rotary-drilled holes. They spent whole days looking at rock cuttings through 10 to 20x binocular microscopes, plotting the results in fine print on strip logs, scale 100 feet to the inch, a scale inherited from the cable-tool drillers' logs. Their offices were not air conditioned. On summer days the heat was oppressive from the gas burners and it was difficult to keep the well log neat, dry, and unstained from perspiration. Not until 1944 was the central "sample cut" established by the Kansas Geological Society under the business name of Kansas Well Sample Bureau. Only then were the many gas stoves in major oil-company offices shut down.

In the 1930's, other geologists were needed to examine samples of well cuttings at the well site in the few holes drilled with early rotary tools. Often these geologists were production department employees, and many lived in company-provided housing in oil-field camps at such locations as Chase, Kansas, a carry-over from the 1910's and early 1920's when transportation was a problem before the common use of automobiles.

Each of the 26 major oil companies also stored boxes of samples of well cuttings, usually renting warehouse space. As major oil companies closed their Kansas exploration offices in the 1940's and 1950's, leaving only production department offices in Great Bend, Russell, and Liberal, etc., they donated their accumulated boxes of samples to the Well Sample Library managed by the Kansas Geological Survey in Lawrence. The Kansas Geological Survey opened a sample library for well cuttings in Wichita in 1938, in addition to its permanent collection of well cores at the Survey's Lawrence headquarters.

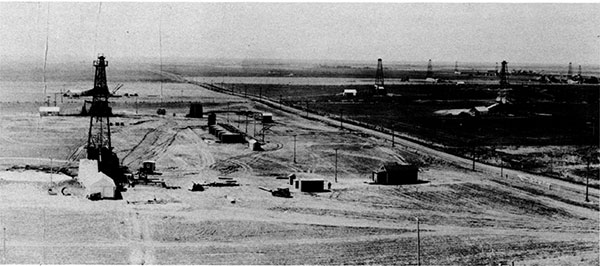

Gorham oil field, April 14, 1928

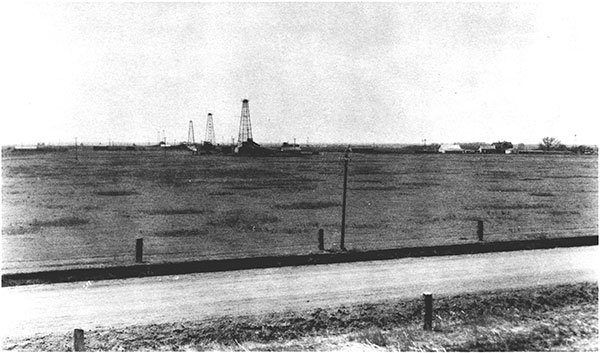

On January 28, 1928, a big oil well was completed in a new and deeper pay. The Gorham area instantly became the most exciting place in the oil fields of Kansas. The discovery well, Stearns and Streeter et al. #1 Mermis in the SW NW SW sec. 33, T. 13 S., R. 15 W., tested 1,000 BOPD from a sand at 3,317 ft (995 m). The producing formation was named the "Gorham sand" after nearby Gorham. Average actual production from the Mermis #1 in February 1928 was 580 BOPD (Folger and Hall, 1933). On April 14, 1928, photographer E. J. Banks climbed to the crown block of the derrick of Johnson Vickers #1 Gorham, a drilling well, carrying his bulky camera to photograph the oil field. The cover photograph of this report is part of his panoramic photograph reproduced through the courtesy of the Russell County Historical Society and Oil Patch Museum. The view is to the west over three derricks in a row with the town of Gorham in the background and with workers' automobiles parked in the foreground. Steam is coming from the Day Petroleum Co. #2 Joe Mermis where rigging-up operations are underway. Behind it, the Day #1 Mermis is producing oil from the "Oswald," depth 3,091 ft (927 m). The third and most distant derrick is a drilling well, the Keyes Petroleum #14 Mermis. Fig. 28 is a view to the south and southwest showing the older portion of the Gorham oil field with wells producing from the "Oswald." The section-line road runs northsouth. To the east (left) of it, the derricks of three wells are so precisely aligned that it is difficult to distinguish them. The closest is the Steams and Streeter Mermis #2, testing the Gorham sand. The second is the Stearns and Streeter #1 Anton Mermis, the discovery well, pumping 580 BOPD from the Gorham sand. The third is Keyes Petroleum #12 Mermis, drilling. Note the similarity of a drilling well, a well being tested, and a pumping oil well due to the practice of leaving the derrick erect after completion of drilling for use in production work. Note, too, that no saltwater ponds are present. Saltwater production was not a problem at this time but became one soon after. The shallow pit (left foreground, fig. 28) is a receiving pit for cuttings dumped out of the bailer.

Figure 28--Gorham oil field, April 14, 1928, a portion of a panoramic photograph; view to the southwest. In the left foreground, Stearns and Streeter's Mermis No. 2 is testing the Gorham sand. Directly aligned behind it (south), the Mermis No. 1 is pumping 580 BOPD from the Gorham sand and south of it a third. well, the No. 12 Mermis is drilling; courtesy Russell County Historical Society. See back cover.

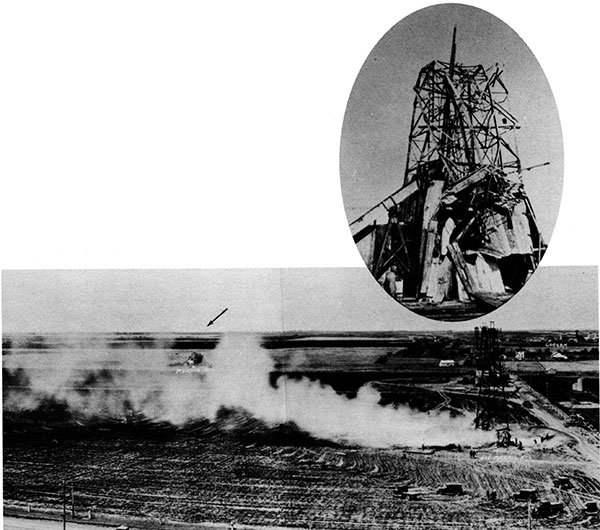

Fig. 29 is also reproduced on the front cover. An arrow designates the collapsed derrick of the Midwest Oil and Refinery Company Mermis #4, enlarged in the inset photograph. "The 6-inch casing parted while lifting it," said the Russell County Daily News, May 17, 1928.

On the date of the photograph, April 14, 1928, the Gorham oil field had seven oil wells producing from the "Oswald," depth just below 3,000 ft (900 m); one Gorham sand oil well, depth 3,317 ft (995 m); eight drilling wells, three dry holes, and one abandoned Oswald oil well. Fig. 30 is a historical map for that date. It was prepared by redrafting a contemporary oil-company production map, retaining the style and lettering of that map, and by correcting the production map to that date from contemporary newspaper files. Indicated by dashed lines are the three segments of the panoramic photograph.

Figure 29--Gorham oil field, April 14, 1928. This and fig. 28 are portions of a panoramic photograph by E. J. Banks (the middle portion with one oil well is omitted). Arrow points to the Mermis No. 4 with collapsed derrick. Inset shows close-up view of cable tools with a collapsed derrick; courtesy Russell County Historical Society and KIOGA. See front cover.

Figure 30--Historical map of the Gorham oil field, April 14, 1928. Dashed lines show area of panoramic view reproduced on front and back covers and in figs. 28 and 29. Redrafted in the style of an original 1931 map that was corrected to April 14, 1928, from newspaper accounts and scout tickets.

Oil production, 1928-1933

The wide-open flush production in 1928 can be illustrated by the wells shown in the cover photograph. The Day #2 Mermis, foreground, was completed in June 1928 for an estimated 700 BOPD but with a reported 26% water. The Day #1 Mermis, second well in the cover photo, was drilled deeper in June 1928, and completed for 600 BOPD from the Gorham sand. The two wells together produced 1,300 BO in one day, July 2, 1928. The Johnson and Vickers #1 Gorham, from the crown block of which the panoramic picture was taken, was completed in the Gorham sand for 50 BO per hour in May 1928. It produced and sold 56,173 BO in the remainder of 1928 or an average of 245 BOPD. Such high production rates resulted in the lifting of saltwater along with the oil, requiring large surface "evaporation ponds" as discussed in the environmental section of the report. Oil production was sharply curtailed after May 28, 1931, when regulations were imposed by the Kansas Corporation Commission as discussed in the oil production section.

Crude-oil prices were depressed by such overproduction in Kansas and similar overproduction from newly discovered oil fields in Oklahoma and Texas. Koester (1933) quotes the following posted prices for 40° Kansas crude oil:

| 1931 | January 1 | $1.07 |

| 1932 | April 1 | $1.00 |

| 1932 | March 5 | $0.67 |

| 1932 | Oct. 5 | $1.12 |

| 1932 | June 1 | $0.37 |

| 1932 | Dec. 16 | $0.77 |

| 1932 | July 3 | $0.22 |

| 1932 | July 24 | $0.42 |

| 1933 | Jan. 18 | $0.52 |

| 1933 | Aug. 22 | $0.70 |

| 1933 | Nov. 2 | $0.85 |

A facsimile of the July price notice is included as fig. 18.

The depressed crude-oil prices, the general Great Depression of the 1930's, the glut of crude oil in the midcontinent, and the restriction of allowed production by proration regulated by the Kansas Corporation Commission all discouraged development. Only three wells were completed in the Gorham oil field in 1931-32 (Koester, 1933). Although production for 1928 reached 587,110 BO from 23 wells in the Gorham oil field, production declined each year thereafter to about one-third as much in 1933 as shown on the oil-production graph (fig. 4) and as listed in the appendix, table 2.

Fig. 31 is a photograph of the Gorham oil field in 1928 viewed toward the south from the Union Pacific Railroad tracks. The nearest oil well is the Keys # 11 Joe Mermis. The Mermis residence and barns are in the right middle distance. In the foreground, the stone fenceposts are made of "post rock." Core drilling in 1927 along this road encountered the Fence-post limestone at a depth of 55 ft (16.5 m), The nearest oil wells are less than one-half mile (0.8 km) from the railroad on which all the crude oil was shipped to refineries. There were no pipelines in western Kansas other than the previously noted Fairport oil field pipeline running 8 mi (12.8 km) northwest to connect with the Southern Pacific Railroad at the town of Paradise.

Figure 31--Gorham oil field, 1928. View to the south from the Union Pacific Railroad track. In the foreground are stone fenceposts made of "post rock." All crude oil was shipped on the railroad as there were no pipelines; photograph courtesy Russell County Historical Society.

Acidization of Oswald oil wells, 1933-34

A new process of pumping acid down the well casing into the limestone formation to increase oil production was the most important development affecting the Gorham oil field in 1934. Oil production in that year increased to 555,655 80, more than double the production of 220,246 80 in 1933. Although the number of oil wells increased by 50% from 32 in 1933 to 47 in 1934 (including three oil wells in the newly discovered Neidenthal oil field), by far the biggest factor was the acidization of Lansing-Kansas City oil wells.

One year earlier, January 1933, oil wells in the Fairport oil field were "treated" by pumping inhibited hydrochloric acid under pressure down the casing and into the oil-producing Oswald limestone formation. The results were spectacular. For example, production from the Carrie Oswald #1 had declined to 2 BOPD. Acid increased production to 108 BOPD. This historic event is described (Anonymous, 1983) in a booklet Six decades of derricks distributed by the Russell County Historical Society. It was the first commercial application of acid to wells in midcontinent oil fields, a process that totally changed well-completion procedures in carbonate rocks such as the Lansing-Kansas City (Oswald) or Arbuckle dolomite. A second source of information is a telephone interview 50 years later with Mr. Nathan Appleman by reporter Barbara Oringderff (1984). Production of all the oil wells in the Fairport field had declined as exemplified by the Carey Oswald #1. Nathan Appleman, owner of Central Petroleum Company, acquired an option to buy many of the leases in the Fairport oil field. Oringderff asked Appleman, "What gave you the idea?" Appleman answered, '1 read in a magazine article where Dow [Chemical Company] was applying inhibited acid, acid that couldn't corrode the pipe, in brine wells in Michigan. I remembered that some of the Fairport field I looked at in Kansas had the same limestone formation as that in Michigan, and I just had a hunch that the same technique might work with oil wells. So, I took my limestone samples to Dow, in Michigan, and asked them to build me an acid wagon."

The reporter then asked if the acid wagon on display at the oil show in Russell in 1983 was his. "I don't know," he said. "I never saw it. My superintendent, Charles Gilpert, did the actual acidizing that January [1933] while I waited in a hotel room in Wichita with a cashier's check in my hand! The check was for money loaned to my father on a character loan by the First National Bank of Tulsa. Gilpert and I had it all worked up so that he could tell me through code how things were going. It took two or three days for the acidization process to work, and I stayed in my hotel room by the telephone until I got the final word to go ahead and exercise that option." Appleman's company, Central Petroleum Company, then acidized 33 more wells in the Fairport oil field with equally spectacular results. In the following year, Central Petroleum Company's leases, the Benso "A," the Benso "B," and Dortland "B" in sec. 4, T. 15 S., R. 14 W. contributed to the increased production from the Gorham oil field by development drilling and acidization.

"The biggest oil well ever struck in western Kansas," 1935

The caption is quoted from the Wichita Beacon, Wednesday, April 24, 1935, which carried the news in headlines 1-inch-high across the front page:

GUSHER OPENS NEW KANSAS POOL

with subtitles:

BIGGEST WELL IN REGION HITS RICH OIL LIME

Crude Spurts Over Derrick as Tools Bite into Pay Horizon

The following quotation is condensed from the exuberant reporting of the Beacon as this discovery was announced:

Belching an eight inch stream of high gravity oil into the derrick top Hartman and Blair's #1 Roubach, SE-SE-NW Sec. 2-14S-15W, Russell County, the biggest oilwell ever struck in western Kansas was flowing wild Wednesday forenoon.

Field men estimated the flow variously at 2,000 to 5,000 barrels daily. It was making a huge flow despite the fact that tools were wedged in the hole.

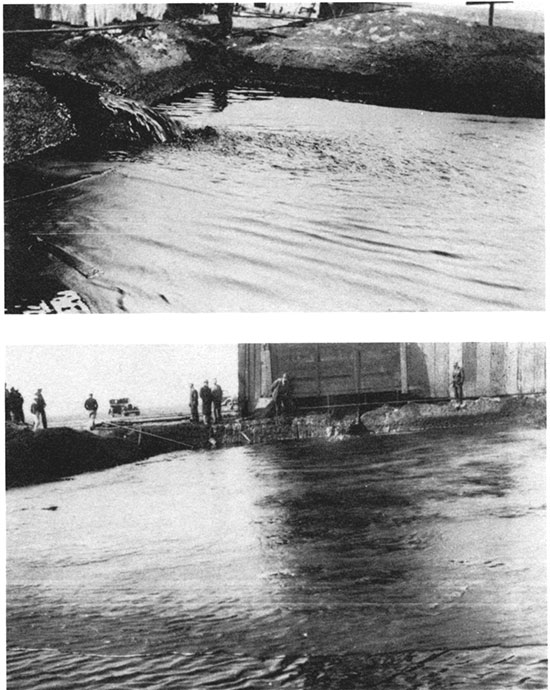

Coming in unexpectedly in a horizon (Topeka lime) that never before produced a flowing well in Kansas, the owners were caught unprepared. There was no tankage on the lease. Oil began flowing down a ravine on the Roubach land.

Teams and workmen were recruited at 10 o'clock Tuesday night to harrow up an embankment to impound the runaway oil and prevent damage to adjoining farm lands.

The Topeka Lime, the formation from which the oil is gushing, is tapped at 2,780 feet. The first oil was struck 2,790 feet and the well began flowing when a depth between 2,795 and 2,800 was reached.

FIRES ARE EXTINGUISHED

Fires in the boilers were extinguished immediately. This left the drillers without power to pull the tools. Early Wednesday the well was still running wild but Harvey H. Blair who made a flying trip to Russell between midnight and 8:00 this morning said upon his return that he hoped to have a control head in place within a few hours.

Due to the fact the oil is coming from an entirely new producing horizon, the strike is regarded as one of the most sensational ever to be made in western Kansas.

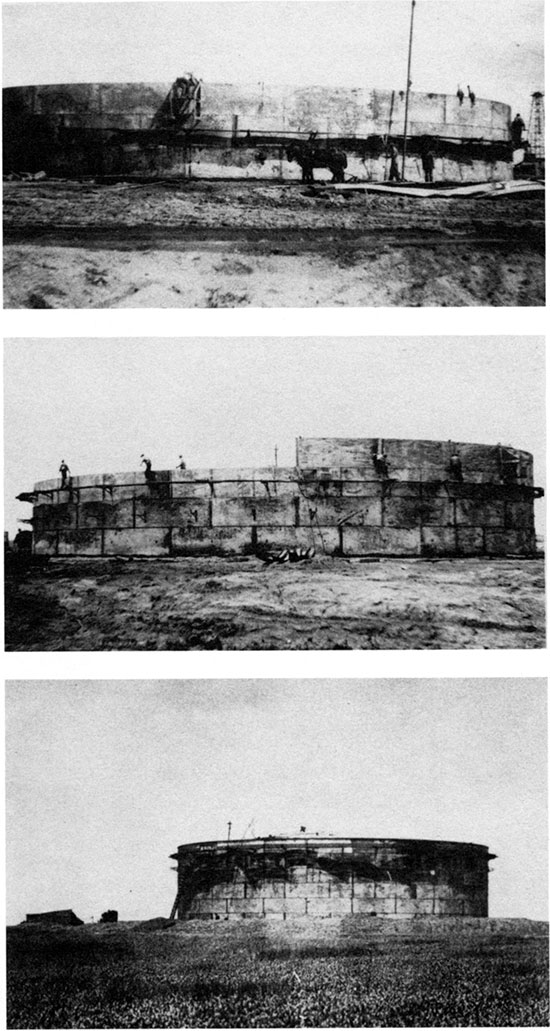

Fig. 32a is a photograph of oil flowing into the pits on April 24, 1935. The drilling tools were pushed upward, kinking the cable, and wedging the heavy bit, jars, and iron drillstem inside the pipe while the oil flowed past them out of control. Fig. 32b shows a few of the many spectators. A huge 55,000-barrel tank of the kind usually constructed for refineries and pipelines was hastily constructed on the Roubach lease as illustrated in figs. 33a, b, and c. This was the largest tank in western Kansas. It was filled in 12 days (average 4,583 BOPD). For many years the tank was a landmark visible from old US-40, 1 mi (1.6 km) north where the Russell Refinery Company built a refinery on the NE sec. 35, T. 13 S., R. 15 W. The Russell Record, October 31,1935, states: "The first oil to be used by the Russell Refinery Company was run yesterday when the plant was started. Crude for the refinery is being run through the company's own pipeline from the Roubach lease owned by Hartman-Blair." The refinery produced gasoline and kerosene, sold locally. It operated for less than three years.

Figure 32--Two views of Roubach No. 1, April 24, 1935, flowing uncontrolled into the pits at the rate of 200 BO per hour. The second view shows a few of the many spectators; both photographs courtesy KIOGA.

Figure 33--Three views of the construction of a 55,000-BBL oil-storage tank on the Roubach lease in 1935. The tank was reported as filled in 12 days with oil flowing from the Roubach No. 1, or 4,583 BOPD; photographs courtesy KIOGA.

Fig. 34a is a photograph of the Roubach lease showing the flat farmland. It was probably taken from the top of the 55,OOO-barrel tank in 1935. Fig. 34b is a close-up of the Roubach #1 pumping oil. Note the steel (not wood) derrick left on location for production use as were the heavy wood sampson post (vertical) supporting the massive wood walking beam (horizontal), which is connected by the pitman (vertical) to the belt-driven band wheel (not visible) in the shed. The Roubach #1 was indeed a giant oil well, producing over one-half million barrels of oil from the Topeka Formation. It was disappointing and perplexing when the east, the southeast, and the south offsets, only 660-933 ft (198-280 m) distant, all failed to find production in this zone although they were closely watched during drilling (Virgil B. Cole, personal communication, 1975). All were completed as oil wells in deeper "pays." The offset well, 660 ft (198 m) west, Hartman and Blair's #4 Roubach (SW SE NW), and the Roubach #5 further west (SW SW NW) flowed oil from the Topeka in 1936 and the #7 (C SL SE NW, a twin to the #1) produced Topeka oil in 1937. However, by the time #12 Roubach was drilled (C SW NW) in May 1977, the Topeka zone was depleted. Gassy oil-cut saltwater was recovered. Charles Steincamp (personal communication, September 14, 1978), who was the well-site geologist, remembered that the tools dropped 8 ft (2.4 m) into a void in the Topeka zone.

Figure 34a--Photograph of the Roubach lease, 1935, from the top of the 55,OOO-bbl storage tank. Shows the Roubach No. 1 derrick and the flat agricultural plains area.

Figure 34b--Close-up of Roubach No. 1 pumping oil. Note the steel (not wood) derrick and former cable-tool equipment left on location for production use in pumping oU; courtesy KIOGA.

It is recognized that the Topeka oil in the Roubach wells and in other wells as mapped in fig. 12 was produced from a fracture zone about 5 mi (8 km) long, parallel with and under I-70. The Topeka fracture zone is discussed on p. 28-30. For a discussion of an analogy with similar fracture zones known from lead and zinc mines in Wisconsin, see p. 30-31. Subsidence areas affecting I-70 coincide with and were initially caused by the Topeka fracture zone. Subsidence areas are extensively discussed in the section on environment.

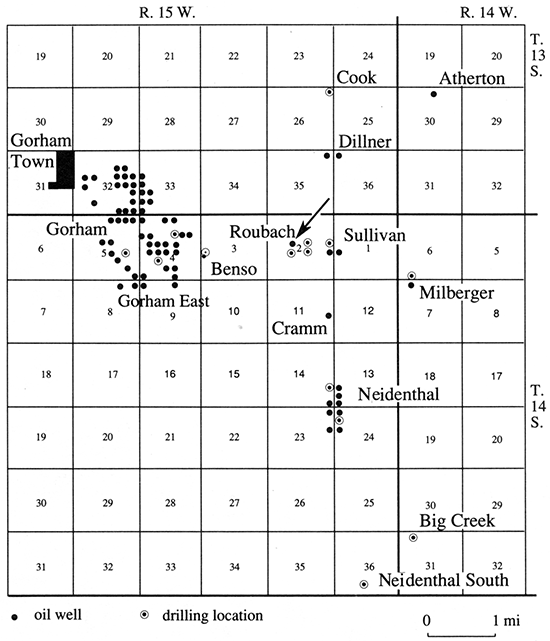

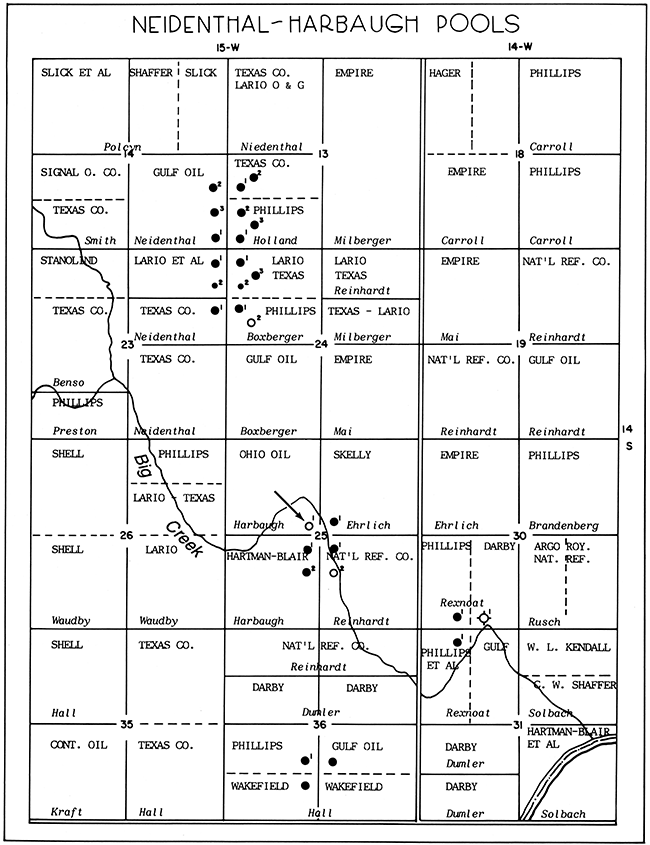

Oil-field development, 1935-1940

Before the excitement of the Roubach Topeka discovery, the Neidenthal oil field (later part of the Gorham oil field) and the Russell oil field at the edge of the city of Russell were discovered in 1934. The year 1935 saw 13 new pool discoveries in Russell County, eight of which-Roubach, Sullivan, Milberger, Cramm, Neidenthal, Neidenthal South, Atherton, and Big Creek-were later combined into the Gorham oil field. Their locations are shown on the historical map (fig. 35) dated April 29, 1935, the day that the Roubach #1 was completed for a flowing potential of 4,760 BOPD. Fourteen new oil fields were found in the banner discovery year of 1936 in Russell County, and it was second only to Rice County in Kansas oil production that year with 7,074,226 BO produced (Landis, 1937). Of the 14 new oil fields, four-Balta, Balta North, Balta Arbuckle, and Harbaugh-were later included in the Gorham oil field. By 1940, many of these new pool discoveries were recognized as part of a major extensive oil field, the 50 mi2 (130 km2) Gorham oil field with 37 discovery wells as mapped in fig. 3. The Nomenclature Committee of the Kansas Corporation Commission consolidated many of the former oil fields in 1940 into two "sectors" of the Gorham oil field. The Gorham sector was approximately the northwest diagonal half, and the Big Creek sector was the southeast diagonal half of the present Gorham oil field. Not until after 1950, were the two "sectors" officially combined into one oil field. The "geneaology" or history of the Gorham oil field had to be deciphered to complete the oil-production history graphed in fig. 4 and summarized in the appendix, table 2. This complex history accounts for the discrepancy as to the total and annual oil-production figures among various published records.

Figure 35--Historical map, April 29, 1935, the day that the Roubach No. 1 was completed for a flowing potential of 4,760 BOPD. All the newly discovered oil fields named on the map were later included as part of the Gorham oil field.

Oil production, 1934-1940

Production of oil from the Gorham oil field doubled in 1934 over the prior year. Both oil production and number of oil wells more than doubled again in 1935, then again doubled in 1936. Marketing of Russell County oil from all the newly discovered oil fields was made possible by pipeline extensions and new construction (Landis, 1937). This was the golden era of the discovery of oil fields, later recognized as separate parts of one major oil field. A climax came in 1937 with 4,543,310 BO produced from 339 oil wells. The highest oil production under proration (in terms of average BOPD per well) came in 1936 when the average was 44.90 BOPD per well. In all the years of production from the Gorham oil field (fig. 4), this was only exceeded by the wideopen unprorated oil production in the first four years, 1926-29, when the daily average ranged from 80 BOPD to 47 BOPD per well. Cable-tool drilling was still dominant in 1936 with only a few wells in the older Gorham oil field drilled by rotary tools. All new field exploratory wells (If wildcat wells") were drilled with cable tools.

Oil-field fire, 1936

The pamphlet Six decades of derricks (Anonymous, 1983) describes a tragic oil-field fire. That account is here reproduced in full:

Perhaps the most tragic accident occurred on Wednesday night, June 17, 1936, when an untameable fire broke out on the Harbaugh-Marathon well 9 miles southwest of Russell and took the lives of five workers and burned and injured five others.

Those who died were: W. T. Lusher, 61 of McPherson, drilling tool pusher; Earnest Harbaugh, 15; E. O. Wright, 33 of McPherson, a driller; Claude A. Cain, 41, and his son Donald A. Cain, 22, of Galva, drillers. Other workers burned were: Robert Helms-Great Bend, Ernest Bush-Otis, Howard Johnson-Otis, Raymond Roe-Great Bend, and Sam Richardson of Douglas.

The fire was visible for more than 20 miles and flames were said to have shot into the air 300 feet (from the Russell Record).

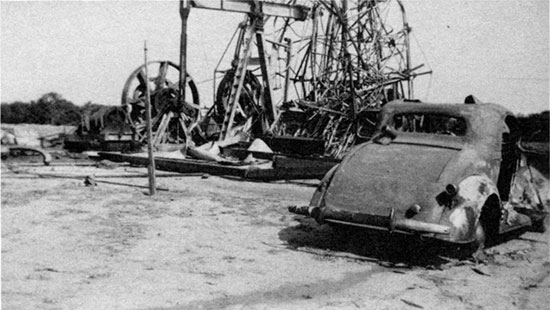

Fig. 36 is a photograph taken after the fire, courtesy of Charles Steincamp (personal communication, June 1989), who remembers accompanying his father who took the photograph. Notice the steel walking-beam supported by a metal "A" frame in place of a wood sampson post. Note also the metal pitman and the metal parts of the band wheel, which survived the fire in this late-model cable-tool rig. This is in contrast to the all-wooden derrick cable tools of 1926 (fig. 23) and the steel derrick with wood walking beam of fig. 34b, used on the Roubach No. 1 in 1935.

Figure 36--Photograph of the Marathon (Ohio) Oil Company's J. G. Harbaugh No. 1, June 18, 1936, the morning after the Wednesday night fire of June 17, which took the lives of five workers and burned and injured five others. Courtesy of Charles W. Steincamp who accompanied his father when the photograph was taken.

The quoted contemporary account credited to the Russell Record and the photograph (fig. 36) constitute the factual historical material available to the author. From a general knowledge of oil-field procedures and from dated well-information cards, the author considers that the fire was most likely caused by the accidental ignition of gas and oil from the Kansas City formation while running the 7-inch casing which displaced oil from the hole, releasing gas. Usually only two men are working on a cable-tool rig, the driller and his helper, the tool dresser. At change of tour, four men are on location. When running heavy casing, as was being done at the time of the fire, the crews double up and call out a four- or five-man casing crew. This may account for the unusually high mortality.

Oil-field fire--geological setting

A historical map (fig. 37) shows the oil fields on the date of the fire, June 17, 1936. The arrow points to the location of Ohio Oil Company's J. F. Harbaugh #1 in a meander bend of Big Creek, in the C SE SE NW sec. 25, T. 14 S., R. 15 W., where the fire occurred. The south offset, Hartman and Blair's #1 B. S. Harbaugh, the discovery well of the Harbaugh oil field completed February 17, 1936, was producing oil from the Lansing-Kansas City at 2,950 ft (885 m) TD at the time of the fire. The southeast offset, National Refining Company's 1-C North Reinhardt, was completed on May 4,1936, as an oil well in the "silicious [sic] lime" (the name formerly used for the Arbuckle dolomite) with a potential of 465 BOPD increased to 692 BOPD after acidizing. The east offset, Skelly Oil Company's #1 Ehrlich, also was a big Arbuckle oil well with a potential of 1,116 BOPD after acidizing, with an estimated 10,000 ft3 (300 m3) of gas per day. While the Skelly well was being drilled, it encountered a small show of oil, 250 ft (75 m) of oil in the hole in three hours, and an estimated 1,000 ft3 (30 m3) of gas from 2,953 ft (886 m), the same zone that was being produced in the discovery well. We can, therefore, reconstruct a situation where drilling was taking place offsetting two big Arbuckle wells, depth near 3,150 ft (945 m) and offsetting a more shallow Lansing-Kansas City well, depth near 2,950 ft (885 m): it was desired to reach the deeper, more profitable Arbuckle pay. The surviving driller's log from the Harbaugh #1 (although burned and destroyed from 3,095 to 3,140 ft [928-942 m]) shows a fill-up of 800 ft (240 m) of oil in the hole at 2,950 ft (885 m), the producing zone of the south offset. Drilling was continued with oil in the hole to 3,141 ft (942.3 m) in the Arbuckle dolomite. Apparently the 7-inch pipe being run in the hole at 3,141 ft (942.3 m) displaced the high-gravity gassy oil in the hole. This caused oil and gas to flow into the pits where it was somehow accidentally ignited causing a flash fire. The reported great intensity of the fire was probably due to an accumulation of considerable oil in the reserve pit. An accident of this severity is rare, but it also is rare to have a hole full of gassy oil deepened by drilling with cable tools. A few months later the Harbaugh No. 2 was completed for 800 BOPD at a depth of 2,958 ft (887 m) in the Lansing-Kansas City formation at a location only 50 ft (15 m) north of the Harbaugh No. 1. It was a "twin well" to the No. 1 Harbaugh, producing from a different oil reservoir.

Figure 37--Historical map, Gorham oil field, June 17, 1936, showing development on that date of the Neidenthal, Neidenthal South, Harbaugh, and Big Creek oil fields, all of which were later included in the Big Creek sector of the Gorham oil field. Arrow shows location of oil-field fire.

These 1936 oil wells were treated with acid, the stimulation process first used in 1933 to increase production. The amount of oil that the Kansas Corporation Commission allowed to be produced under proration (the "allowable") was in large part determined by the capacity ("potential") of the well as determined by a witnessed 24-hour physical pumping test. Wells were pumped as fast and hard as possible for 24 hours to obtain the highest potential for allowable purposes. Everything was bolted down and the engine was run wide-open. Sometimes special big equipment was moved in temporarily for the potential completion test. Rod breaks, engine failures, etc. occurred frequently, requiring retesting. Within a few years, it was realized that pumping as hard as possible for a high physical potential was harmful to the wells. Bottom water moved upward in a cone-shaped area, blocking off oil and greatly damaging the well's ultimate production. Amstutz and Stephenson (1944, p. 18) cautiously state "Measurements of fluids produced during and after the physical potential tests also demonstrated to some operators the fact that high pumping rates appeared to jeopardize oil recoveries through premature entrance of water into the wells." For this reason the Kansas Corporation Commission substituted drawdown potential tests. In these, the lowering of fluid level while pumping at various rates was recorded and plotted on a graph. For oil wells with a very high productivity, the plotted graph gave productivity readings approaching infinity. The Kansas Corporation Commission solved this problem by declaring that the maximum a well could be allowed on a drawdown potential test was 3,000 BOPD; hence, the term "maximum well," meaning an oil well capable of producing 3,000 BOPD or more.

The World War II years, December 7, 1941-September 14, 1945

Personnel, materials, and fuel were in short supply during the war years. Government regulations had the effect of curtailing oil-well drilling. Tubular goods were allocated in limited amounts. Gasoline and fuel oil were rationed. Price controls were placed on crude oil. Well spacing was further restricted. Drilling contractors vied with farmers for priority to purchase machinery and gasoline, and with each other for priority to purchase tubular goods. The paperwork to apply for and secure priority rights to purchase these items added to the contractor's burden and cost. The tight economy of the war years prolonged the use of full-hole (top to bottom) cable-tool drilling rigs in the Russell area long after they were obsolete elsewhere in the midcontinent. The two-man crew, the availability of parts from junked rigs, and the supply of older (deferred) skilled drillers made this possible. Oil production was maintained at a high level, 10,000 to 13,000 BOPD, from the Gorham oil field by pumping existing wells at their capacity in these years, as graphed in fig. 4. Although drilling was much curtailed by shortages of casing, tubing, rods, and personnel, most of all it was curtailed by the restriction at the time on well spacing, with only one well allowed for each 40 acres (16 hectares). The number of producing wells remained almost constant at 461, 457, and 458 for three years, then increased to 527 and 523 wells in 1944 and 1945. Most of the increased drilling was 10-acre (4-hectare) infill drilling, which added little to the reserves of oil in the ground and only temporarily stayed the decline in daily oil production. During the year 1945, daily oil production declined 30% to 8,606 BOPD. In post-war 1946, production declined further to 6,922 BOPD; many wells were plugged and abandoned leaving only 449 oil wells. Their average daily production was 15 BOPD per well as compared with a war-year's high of 29 BOPD per well in 1942 and a pre-war average of 20 BOPD per well in 1940. The price paid for 400 crude oil was frozen by government regulations near $1.20 a barrel in 1941-44, but more than doubled when restrictions were removed, reaching $2.60 a barrel in mid-1947 and remaining near $3.00 a barrel through the 1950's and 1960's as illustrated in fig. 17 and by table 5, appendix.

Stripper-production stage, 1955-1986

The Gorham oil field entered the stripper oilfield stage in 1955, defined as production of less than 10 BOPD per well average for the oil field. The field continued its stripper-stage production with gradual but constant decline. By December 31, 1986, 444 wells were averaging only 3.2 BOPD per well.

This unexciting, drab period of the Gorham oilfield history was a caretaker or custodial phase. Wells were handled carefully with a constant eye on cost and a reluctance to spend money. But the old oil field adage prevailed--"take care of your stripper wells and your stripper wells will take care of you." This adage is true because of the flattening of decline curves and the steady but small, long-continued production. In all oil fields, oil wells run out of profit before they run out of oil. In the Gorham oil field, most oil wells are abandoned while still producing 1-3 BOPD. In this connection, the graph of crude-oil posted price (fig. 17), showing the increased crude-oil sale price of the late 1970's and 1980's, explains the prolonged extension of the Gorham oil-field stripper stage.

In the late phase of oil production, where operating costs determine the life of the wells, the highest cost is often the handling and disposing of increased amounts of produced brine associated with the oil. In these stripper years, increased need for deep saltwater-disposal wells provided additional control for the map of the Precambrian basement rocks. A second history of the Gorham oil field is the history of the handling of the produced brines in all stages, not just the terminal stripper stage. A chapter is devoted to this subject under the heading, "Environment."

Drilling with rotary tools in the Gorham oil field

Operators in the Gorham oil field were reluctant to give up the use of cable tools for the more efficient and cost-effective rotary tools. Although rotary tools were common in Oklahoma and Texas in the 1930's, only a few operators in Russell County were experimenting with their use. The earliest rotary rigs used in Kansas were huge machines. They required a 120-ft (36-m) derrick assembled by rig builders, usually two 150-horsepower steam boilers, 6-inch drill pipe, and bits which bored a 9-inch hole. The "fish tail" bits used in the Gulf Coast oil fields were more easily adapted to the predominately shale drilling in Oklahoma than to the harder limestone formations in Kansas. However, by 1940, smaller "portable" rotary rigs with a built-in "jack knife" mast (eliminating the need for services of rig builders) were available. They used a 4-inch drill pipe, roller rock bits, and were powered by internal combustion engines using diesel fuel, gasoline, or even natural gas for fuel. An example of a 1936 hole drilled with rotary tools is the Skelly #1 Ehrlich, sec. 26, T. 14 S., R. 15 W. This well, discussed as an offset to the well with the tragic 1936 fire, was drilled to a depth of 2,927 ft (878 m) with rotary tools that were moved off the hole to allow deepening to 3,157 ft (947 m) TD by cable tools. Rotary drilling was discontinued near the top of the Lansing-Kansas City, encountered at 2,916 ft (875 m), in order to evaluate the known productive zones in the Lansing-Kansas City and Arbuckle by the more familiar open-hole cable-tool method. Operators were afraid of overlooking pay zones in the unfamiliar muddy rotary-drilling fluids with the scrambled well cuttings. William Brunson (personal communication, October 1988) remembers that his father, Howard Brunson, a long time operator of cable tools, leased a new rotary rig in the 1930's, drilled one well with it, got in trouble with lost circulation, and returned to cable-tool drilling.

The years of World War II further retarded the use of rotary tools in 1941-44, but from the late 1940's, the rotary-drilling method became the only method of full-hole top-to-bottom drilling. Cable tools were used only for "drilling in" well-completion work after the oil-string casing was set and cemented in place.

Rotary drilling--role of the geologist

The role of the petroleum geologist again changed with the advent of widespread faster and more cost-efficient rotary drilling. As long as cable-tool drilling prevailed, geologists were not needed at the well site to find oil which, when "struck," was obvious as it came into the empty (air-filled) hole. In rotary drilling, oil shows were not obvious in the constant flow of drilling mud carrying mixed cuttings of the rocks drilled. The drillers operating rotary rigs continued to grab and smell samples and to keep logs but they were usually unsure of what was being drilled and unable to recognize potential oil-producing formations. To evaluate oil shows and to pick the proper place to set packers for drillstem testing or to set oil-string casing, constant day and night around the clock supervision by a geologist at the well site was required. Thus in the post World War II days, in 1945 and later, the flurry of rotary drilling in the Gorham oil field and elsewhere required geologists at the well sites with their binocular microscopes and oil-detecting fluoroscopes. The principal activity of many petroleum geologists became well-site supervision, called "well sitting." Geologists doing well sitting were either employees of major oil companies, or in the 1950's when major oil companies began closing their Kansas offices, self-employed consultants. Among the first of the independent consulting geologists was the firm of Boris Lerke and Raymond Wharton. They provided well-site supervision services to independent oil operators as early as the mid-1930's when only a few rotary rigs operated in Kansas. Well-site geologists, in residence at the drilling well day and night, summer or winter, commonly took naps in their automobiles in the earlier years, but later it became customary to provide a shed or "doghouse" with a stove, then still later to provide a mobile home with a work desk, air conditioning, kitchen facilities, and real bedrooms.

Throughout all these changes the constant role of the petroleum geologist was to find oil. Historically this was done by mapping anticlines with a plane table, by core drilling, by office examination of samples, by "map making" with ideas for new oil fields or oil provinces, or by actually watching the drilling progress of a test hole at the well site.

Rotary drilling--present practices

Drilling with rotary tools is described in some detail in a current Kansas Geological Survey publication by Baars et al. (1989) Petroleum-a primer for Kansas. That publication also treats testing and logging in rotary holes. It further treats, in an introductory way, the entire subject of petroleum exploration and production specifically as applied to the state of Kansas. The publication does not, however, include any discussion of the now obsolete method of standard cable-tool drilling which was such a vital part of the Gorham oil field's early history.

Prev Page--Oil Production || Next Page--Environment

Kansas Geological Survey, Geology

Placed on web Jan. 30, 2015; originally published 1991.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/228/05_hist.html