Prev Page--Oil and gas sands || Next Page--Conclusions

The Oil and Gas Fields

Anderson County has gained the reputation of being one of the outstanding shoestring districts of eastern Kansas. The three main producing areas are of the distinctive shoestring type.

In the early part of 1927 the average daily production of the oil wells was about 3 barrels.

| Annual oil production of Anderson County, 1923-1928, inclusive. [Production figures were taken from The Oil and Gas Journal.] |

|

|---|---|

| Year | Production in barrels. (42 gallons.) |

| 1923 | 391,741 |

| 1924 | 630,406 |

| 1925 | 824,039 |

| 1926 | 1,162,282 |

| Average daily oil production of Anderson County by months for 1928. | |

|---|---|

| Month | Average daily production in barrels. (42 gallons.) |

| January | 3,202 |

| February | 3,245 |

| March | 3,180 |

| April | 3,314 |

| May | 3,353 |

| June | 3,364 |

| July | 3,211 |

| August | 3,093 |

| September | 3,011 |

| October | 3,200 |

| November | 3,001 |

| December | 3,010 |

During the development of the Colony, Welda, and Polkinghorn fields, the county led all others in the state in gas production. By 1927 the open flow volume had dwindled to a few million feet per day and many of the wells had been plugged.

Pottawatomie Valley Field

Location—The Pottawatomie Valley field is the productive territory that occupies the valley of South Pottawatomie creek from Greeley to the narrow oil field south of Garnett. It is made up of many small groups of wells that form a trend 1/2 mile to 1 1/2 miles wide and eight miles long. Most of it is in T. 20 S., R. 20 E., through which it extends in a northeast course.

Development—This territory is the oldest in the county in the order of development. The first wells were drilled in 1904 and 1905 on the Myers, Bowen, and West farms, a mile southeast of Garnett. The development was gradually extended down the valley of South Pottawatomie during the next twelve years. The small market for gas, the small size of the few oil wells, and the poor quality of the oil gave little inducement for drilling. Interest was temporarily reawakened in the fall of 1917 by several oil wells in sec. 11, T. 20 S., R. 20 E., which had an initial capacity of 75 to 200 barrels. The discovery of larger and richer fields in the county since 1921 has relieved the Pottawatomie Valley of its attraction. Most of the wells are now abandoned.

Surface structure—The surface structure cannot be determined for a large part of the belt because the wells are on an alluvium-covered valley floor. Furthermore, only a small amount of field work has been done in this old field and for that reason not much detailed information is available concerning the structure. Approximations of structural conditions have been made from surveys of the Plattsburg limestone along the edges of the valley. A broad, shallow syncline near the common township corner about 1 mile south of Greeley extends northwest-southeast. A narrow syncline, 30 feet deep, lies northeast-southwest in secs. 3). and 32, T. 19 S., R. 21 E. The structural map of the county (Fig. 2) shows how the rocks are warped adjacent to the trend.

Subsurface structure—The study of the structure below the surface, like that of many old fields, has been handicapped because many of the well logs are not available and some of those at hand are noticeably inaccurate. A deep syncline whose axis lies N. 60° W., occupies the NW sec. 11, T. 20 S., R. 20 E. The small group of gas wells in sec. 32, T. 20 S., R. 20 E., is on a west-plunging nose. Its western end has been outlined from the well logs but its eastern extent is indefinite.

Sands—The 600-foot sand, generally only 450 to 500 feet below the valley floor, was encountered in many wells but was absent in others, or represented only by sandy shale. This sand contains water, small quantities of gas, and showings of oil. The volume of gas in most cases was not large enough to make commercial wells.

The 800-foot sand, about 600 feet below the surface, produces the oil and most of the gas between Greeley and Garnett. It is very variable in thickness and quality, but maintains a continuous trend the entire length of the field. Its average thickness in producers is 35 feet. This sand does not contain water and is completely penetrated when the wells are drilled in. Its cross, section indicates that it is a channel filling. (Sec. A-A', Pl. IV.)

The 900-foot sand, only about 700 feet deep in this field, is a water-bearing sand that locally contains gas. The group of wells in the S2 sec. 21 and NW sec. 28, T. 20 S., R. 20 E., and the small field 1 1/2 miles south of Greeley obtain gas from this horizon. The abandoned wells on the Enlow farm in the SE SE sec. 32, T. 20 S., R. 20 E., produced from the 900-foot sand.

Relation of accumulation to structure—Most of the gas in the 800-foot sand was found where the sand is arched over anticlines and the oil was in the synclines or basins. As examples of this condition are the following pools: The gas wells in the W2 sec. 32, T. 20 S., R. 20 E., are near the top of a west-plunging anticline. The oil pool in secs. 2 and 11 is in a syncline.

Migration of the gas may be stopped where the sand pinches out. The gas wells in sec. 21 are flanked on the west by a dome whose crest is 40 feet higher structurally than the wells. The gas has crept up the side of the structure to the edge of the sand.

Production—The average initial volume of the gas wells in the 800-foot sand was 3/4 million cubic feet per day. The largest wells had a capacity of about 3 million feet. The rock pressure of the first wells was 240 pounds per square inch but the pressure of those drilled 10 years or more later was only 80 or 90 pounds. A few of the wells had remarkably long lives. In 1907 the Garnett Gas Company's Folz No. 3, in the SE sec. 28, T. 20 S., R. 20 E., came in with an initial volume of 1 million cubic feet and rock pressure of 240 pounds. Fifteen years later the well tested 20,000 cubic feet volume and 15 pounds rock pressure. It was still on the line in the spring of 1924. The same company's No. 1 Henning, in sec. 14, was drilled in 1905 and produced until 1920.

In general, the wells which obtained gas from the deep sand were shorter-lived than those in the 800-foot sand, but their initial volume was slightly greater. The record well of the Pottawatomie Valley district was drilled in the SW sec. 11. Its initial volume was 7 million cubic feet, but it was drilled too deep and its productivity was lessened by the early entrance of water.

For a few years the group of gas wells in the S2 sec. 21, and the NW sec. 28, furnished a large part of the gas supply of Garnett, which uses about 75 million cubic feet per year. The initial volume of these wells was 3/4 to 1 million feet each.

With the exception of those in one or two small pools, the oil wells are of negligible importance. The initial production of most of them was 5 to 10 barrels and they soon fen to half a barrel or less. The wells on the Patton farm in sec. 22 settled to 1/3 barrel each after starting at 4 or 5 barrels. The Fraker wells in sec. 14 started at 15 to 20 barrels, but lasted only a year. The richest producing area is the Poss pool in the N2 NW sec. 11, T. 20 S., R. 20 E. The wells came in at 75 to 200 barrels. On one lease 9 wells produced 57,000 barrels in 4 1/2 years, at the end of which time their average daily yield was 2 barrels per well. After 9 years they produced only 1/3 barrel each.

Garnett Shoestring

Location—The Garnett shoestring is the long, narrow strip of productive territory which begins a mile southeast of Garnett in sec. 31, T. 20 S., R. 20 E., and extends in a smooth, winding course as far as the west edge of sec. 2, T, 21 S., R. 19 E. This field is an extension of the old Pottawatomie Valley trend. The sand body is continuous, but it was not traced westward until 15 years after the wells near its eastern end had been drilled.

Development—The discovery well of the new trend was drilled by H. C. Cooper and associates on the N. L. Bowman farm in the S2 SE sec. 31, T. 20 S., R. 20 E., in September, 1921. The gravity of the oil from this new producer was 36 degrees Baume, which was 6 to 7 degrees lighter than any oil produced in the county previously. The first few wells proved that the oil occurred in a very narrow trend that was sharply defined on the edges. The operators who held leases in advance of the field drilled many holes which found no sand. Gentles and others drilled four dry holes on the Smerchek farm in sec. 1 before they located the shoestring. Three failures were the experience of Fees and others on the same farm. Sixteen dry holes in sec. 1 reflect the diligent search for the oil sand. The following incident demonstrates how some of these caused a greater loss than the price of the holes alone: The first hole on the Bybee farm was located in the southeast corner NE NE sec. 1. [Note: Attention is called to the north row of sections in township 21 south, which are about a quarter of a mile longer than the normal section.] This test proved dry and the rig was moved 1,150 feet north, where another failure resulted. When the second well came in dry, one of the royalty owners sold his holdings. The next test, 450 feet south of the second dry hole, came in as a 150-barrel well with 47 feet of sand. The two dry holes formed a "gate" through which the shoestring passed.

Production was extended as far as the middle of sec. 2 without much difficulty. Most of the drilling up to this point was completed by June, 1924. About 20 holes have been put down within a distance of 4 miles west of sec. 2. The shoestring sand was found in most of them, but, with a few exceptions, it was barren. A small group of wells in the W2 sec. 4, T. 21 S., R. 19 E., produces black oil of about 32 degrees gravity from 10 to 14 feet of sand at the south edge of the sand body.

Structure—The structure of the area through which the shoestring extends was determined from the logs of the wells by finding the altitude of the Iola limestone. In conjunction with the Iola, the Plattsburg limestone was used. The Plattsburg crops out along the edges of the valley occupied by the eastern half of the field and crosses the field at several places in the western half.

The strata in sec. 31, T. 20 S., R. 20 E., dip westward at the rate of 60 feet per mile. This westward dip is arrested at the bottom of a syncline. The rocks rise from the syncline to form a dome whose top is in sec. 36, T. 20 S., R. 19 E. The oil sand is at about the same elevation as it bends around the southern edge of this dome to the middle of the NW sec. 6. From there it swings slightly northward and diagonally descends the southwest dip of the dome mentioned above. The sand reaches its lowest elevation in the NE sec. 2, on the Zaskey farm. The dip from the east end of the field to here is approximately 80 feet. From the Zaskey farm the sand rises about 10 feet to the middle of the N2 sec. 3, and then resumes a westward dip of 50 feet to the east side of sec. 5.

Relation of accumulation to structure—The oil and gas have taken up their position according to the elevation of the sand. However, the line between them is not well defined and their separation according to structure is not as complete and distinct as would be expected ordinarily.

In the extreme eastern end of the field about half of the sand holds gas and the remainder oil. The proportion of oil to gas increases toward the west to the point where the sand is lowest. The wells in the deepest part of the syncline, in the NE sec. 2, found the sand almost completely saturated with oil. It is believed that the oil is held back in this low area by the gas that occupies the sand at a higher elevation farther west. A sharp increase in the amount of gas is noted where the shoestring starts its westward rise in the middle of sec. 2. In the Gomac Oil Company's Nichols well No. 2 it was reported at 759 to 800 feet; in H. C. Cooper's Louk well No. 2, the diagonal southwest offset, at 767 to 799 feet. The elevation of the sand is only 1 foot higher in the latter well. The Nichols well had an initial production of '60 barrels of oil and a good showing of gas; the Louk well about 25 barrels of oil and 1,4 million feet of gas. The sand appeared to be of about the same quality in each well. The producer 325 feet southeast of Nichols No. 2 made 125 barrels initially. The sand is 8 feet lower.

The top of the sand is 295 feet above sea level in H. C. Cooper's J. B. Hutchinson well No. 1, about 1,370 feet from the north line and 1,470 feet from the west line of sec. 3. This well was drilled into the shoestring sand 33 feet and made 2 million feet of gas with no oil. In Louk well No. 5, an oil well 3/4 mile east of the Hutchinson well, the elevation of the sand is 285 feet. In an oil well 14 mile west of the gas well, it is 286 feet. These two oil wells had 20 feet of gas sand capable of producing about 1/4 million feet on top of 20 feet of oil sand.

From the west side of sec. 3 to the east side of sec. 5 the sand dips 40 feet, In the east half of this distance it probably contains 29- to 32-degree oil, but in the remainder it has none except a small quantity on the south side of the NW sec. 4. Through sec. 5 it lies practically flat and has only a trace of oil.

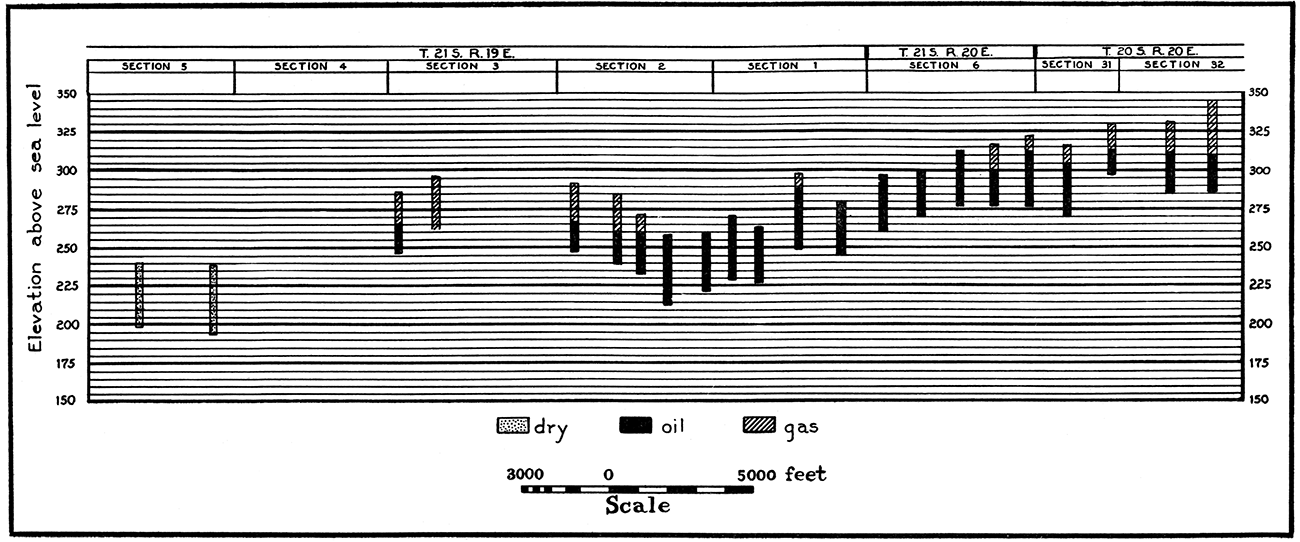

Sand—The sand is a channel-shaped deposit about 700 to 1,000 feet wide, 20 to 30 feet below the top of the Cherokee shale. Its thickness ranges to a maximum of 55 feet. The wells are completed at a depth of 700 to 850 feet. The extreme width of the sand body does not indicate the width of the productive area, because the sand wedges out at the top. It has sufficient thickness at right angles to its trend to allow for the location of two wells 300 feet apart. Its cross section does not maintain the same shape everywhere. (See sections B-B' to E-E', Pl. IV.) On the east end of the trend it is narrow, clean-cut, and steep-sided. Examples may be cited to show how sharply the bottom of the channel rises to the edge where it is "chopped off." Cooper's Bowman well No. 1, the second location west of the northeast corner of sec. 6, T. 21 S., R. 20 E., had 44 feet of sand. The dry hole which offsets it on the north, Hafel & Templeton Brothers' No. 1 Bowman, had .no sand. It is only 250 feet from the producer. Connelly and associates drilled their No. 3 Manners well 225 feet north of their No. 1 Manners. Well No. 3 had no sand; No. 1 flowed 70 barrels per day during the first week from about 35 feet of sand. On the Bybee farm the shoestring passes between two dry holes 1,150 feet apart. Each dry hole had only 5 feet, or less, of sand.Figure 6—Profile of the sand in the Garnett shoestring to show the relation of the elevation of the sand to its contents.

In the west half of sec. 2 the channel is wider and shallower. The top of the sand body begins to spread out at the eastern edge of sec. 1, and the spread increases rather uniformly until its south side is about half a mile wide. Dry holes a quarter of a mile south of the trend have found a showing of oil in this thin stratum of sand. On the north side it is represented by a thin widespread deposit covering a large area in T. 20 S., R. 19 E. In the SE SE sec. 34, and SW SW sec. 35, T. 20 S., R. 19 E., a few wells of about 15 barrels initial production obtain oil from 10 feet of this sand. In this particular area the thin deposit is not connected with the shoestring, because dry holes, one with no sand and another with but 2 feet, are between the small pool and the main trend. It is probable that commercial production is available in this locality because the sand pinches out toward the center of a synclinal basin and the oil has drained down to form a pool at the edge of the sand. The oil is of 32 degrees gravity, 3 degrees lower than the oil from the shoestring pool near by.

The sand body has been traced as far as the middle of sec. 5, T. 21 S., R. 19 E. The sand is of good quality and normal thickness in this section but holds only a "rainbow" of oil.

The material which makes up the channel filling is rather clean, fine-grained sand. The portion which contains gas is gray; that which contains oil is stained brown. Locally, a black, coarse sand about 5 feet thick forms the bottom of the deposit. It holds black oil of slightly lower gravity than the dark green oil in the upper part of the sand.

The white shale—Considerable importance is attached by some people to a white shale, 5 to 20 feet thick, immediately above the shoestring sand in many wells. It is found locally at the same stratigraphic position in the small pools of the Colony-Welda district, and in areas where there is no production. On account of its unusually light color this deposit has attracted attention, and its occurrence above the oil sand has served to give it a significance which it does not warrant. Although somewhat irregular in occurrence, it appears to be a regional rather than a local deposit, and if it did not come in the geological section just above the oil sand would probably attract little notice. Its chief value seems to lie in furnishing an indication of where the 800-foot sand may be expected and as a good formation in which to set casing.

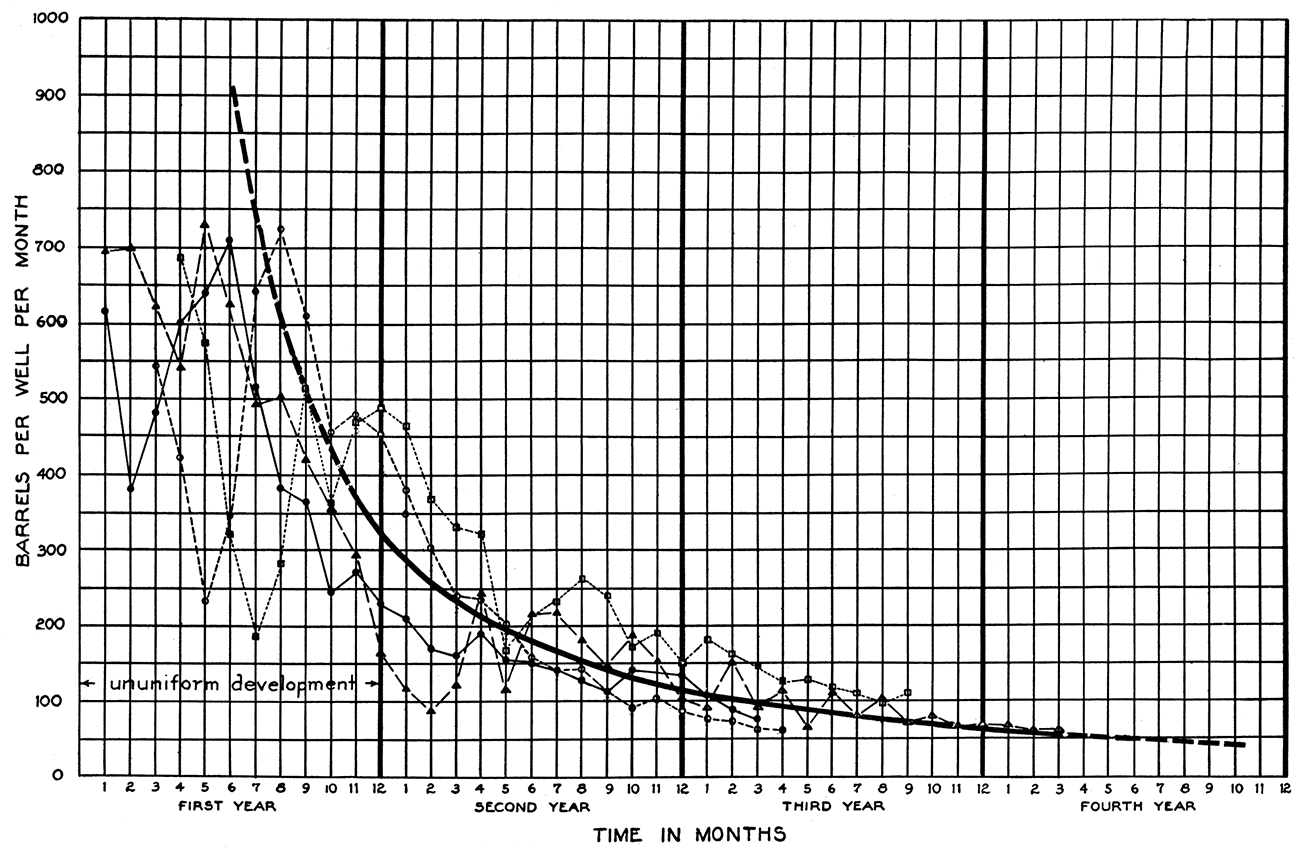

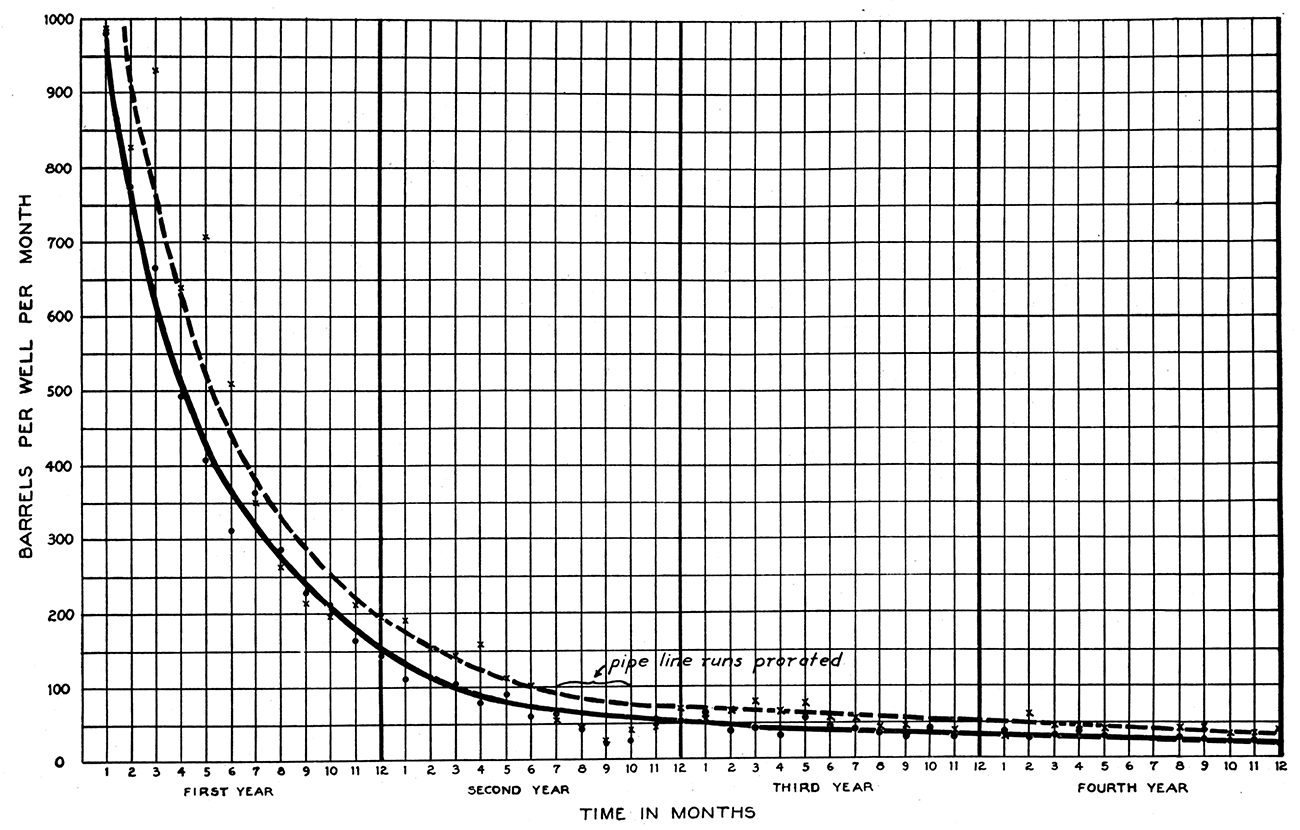

Production and decline—Considered as a whole, the Garnett shoestring field has been the richest in the county. The initial production of the wells averaged about 100 barrels and some made 250 to 300 barrels. A few flowed naturally. At the end of the first year the average well was producing 5 to 6 barrels, at the end of the second year, about 3 barrels, and at the end of the third year, 1 1/2 to 2 barrels.

Figure 7—Production decline curve of the Garnett shoestring.

One of the leases, for which complete figures are available, produced 69,000 barrels in 2 1/2 years, an average of 6,275 barrels per well or 3,285 barrels per acre of productive territory. [Note: Per acre recovery is estimated from the area within the edges of the sand.] At the end of 3 1/2 years this lease would have been furnishing about 1 1/2 barrels per well, but, as the result of the application of air pressure, the yield of each well was about 314 barrels.

Air recovery—Favorable results have been secured from the use of air pressure on this shoestring field. At the time this method was adopted, when the wells were 3 to 4 years old, the 95 wells were reported to be producing about 165 barrels per day. An increase in production was obtained from some of the properties within 3 months. It is reported that after 8 months the increase was 300 per cent in parts of the field and 50 per cent on the entire shoestring. The largest gains took place on the oldest leases.

Polkinghorn Gas Field

Location—This important gas field is 2 miles northwest of Welda. The field covers parts of secs. 21, 22, 26, 27, 28, 34, and 35, T. 21 S., R. 19 E. It bears the name of the lessor who owned most of the productive territory. This field is a continuation of the long trend which winds through T. 22 S., R. 19 E., and which has its southern terminus just southwest of Colony. The Polkinghorn field is treated as a separate unit because of its individual history and unique geologic conditions.

Development—Attention was first directed to this area in May, 1922, by an oil well producing from the 800-foot sand in the NE NE sec. 29. An attempt to obtain oil in the same sand in the E2 NW sec. 28, resulted in the discovery of gas in the 600-foot sand. Only a few wells had been completed in this shallow sand before one in the southeast corner of the NE SW sec. 21 encountered salt water instead of gas. This well was deepened and at 905 feet the Colony gas sand was found. A good market induced the rapid development of this lower sand. About 50 gas wells and 25 dry holes were drilled in the district during a period of 2 years, beginning in September, 1922,

Structure—The surface structure of the field is one of its most interesting features. [Note: Surface structure represented in Plate VI was mapped by H. E. Crum and E. L. Bradley.] A narrow anticlinal fold, which broadens toward the northwest, extends from the NW sec. 35 to the NE sec. 20. At the southeast end, where the anticline is very narrow, its southwest flank dips sharply. The other flank dips into a shallow syncline that separates the main fold from a broad structural nose which swings from the SE sec. 26 through the SW sec. 23. Another nose, the axis of which trends northeast-southwest, is in sec. 22. The fold on which the field is located is parallel to a larger and higher structure in sec. 25, 26 and 36, T. 21 S., R. 19 E., and secs. 30 and 31, T. 21 S., R. 20 E. The sand is under only the northwest tip of this larger structure.

Sands—The three main producing sands of the county are present in the Polkinghorn field. The deeper gas sand furnishes the largest part of the production. The 800-foot oil sand ranks second in importance.

The first gas well in the field was completed in the 600-foot sand, but later development outlined the productive portion of this sand to include only a small area drained by less than half a dozen wells. This sand occurs in a narrow trend on the west side of the field. It is approximately 3/4 mile in width and varies from 0 to 60 feet in thickness. Cross sections have the appearance of a typical bar deposit. (Sec. J-J', Pl. IV.) It is gray, fine-grained, and micaceous and is broken with shale in places. Traces of the same deposit are found as sandy shale in wells scattered throughout the field.

The 800-foot sand produces oil in small, disconnected areas. Most of this sand was discovered in the course of drilling to the deeper gas sand. The largest group of oil producers is in the S2 SE sec. 27 and the NE sec. 34. A few more wells are in the W2 sec. 27. This oil sand is a part of the shallow-water or beach deposits common to the Colony-Welda district. A section of the sand body in the SE sec. 27 has the shape of a bar. (Sec. K-K', Pl. IV.) In other places it was laid down as thin patches which grade into sandy shale. However, it may be replaced by shale very abruptly. Well No. 4 of D. W. Polkinghorn's, in the southeast corner of sec. 27, on the Marshall farm, had 32 feet of sand, but the well 300 feet north had none, and it was deepened to the lower gas sand.

The 900-foot sand gives the Polkinghorn field its importance. In this field it furnished wells with much larger initial volume than the average in the county, except those in the village of Colony. The sand has the same characteristics as in the Colony pool. Shale breaks, 5 to 20 feet thick, occur in the upper part. The "big gas" comes from 20 to 60 feet of sand under the broken section. The maximum thickness of the body exceeds 100 feet. Its suggested origin is mentioned in the discussion of the Colony field.

Relation of production to structure—The 600-foot sand extends across the west end of the anticline at almost a right angle to its major axis. (See Pl. VI.) On the highest part of the structure a small number of gas wells were developed; down the sides, the sand holds salt water. The following wells are mentioned to illustrate this effect of structure: D. W. Polkinghorn's well No. 1 Bell, southwest corner of the SE sec. 21, was originally completed as a gas well in the 600-foot sand. This well is 40 feet higher structurally than the dry hole in the northeast corner of the SE sec. 29, on the Frank Alexander farm, which had only water in the shallow gas sand. Lynds Brothers' well No. 4 J. M. Watkins, southeast corner of the NW NW sec. 28, had a showing of gas in the first 12 feet of this sand but was drilled into water. This well is 20 feet lower on the structure than No. 1 Bell.

Scattered deposits of the 800-foot sand occupy the top and sides of the anticline. The wells on the Marshall and Melville farms, in secs. 27 and 34, are on the steep southwest flank. Perhaps the sand is relatively richer here because the oil drained from points higher on the structure. However, it is more reasonable to believe that structure has little effect on the occurrence of oil in these small isolated patches of sand, and that the amount of oil is accounted for by the nature of the local conditions under which it was made and preserved and by the cleanness of the sand.

The deep gas sand has a very interesting and apparently close relationship to the structure of the rocks. The axis of the sand body is approximately parallel to the major axis of the fold. The southwest edge of the sand extends parallel to the anticline about 40 feet below the crest. The northeast edge is not well defined but is thought to reach as far as a line passing through the center of sec. 22 and the southeast corner of sec. 23. Thus, it passes at a right angle across the contour lines that outline the noses and synclines on that side of the field.

Where the sand is present, the gas is found on those parts of the structure which are generally considered most favorable for its accumulation. The major operator gave careful attention to the structural map of this area during development and confined his locations to the highest parts of the anticline. For this reason the narrow syncline in the E2 sec. 27 and the SW sec. 26 was not tested. It is probable that production could have been obtained in it also, because it is no lower structurally than the dome in secs. 21 and 28. Even this policy of locating the wells according to structure was not always successful because three dry holes in sec. 21 on locations as favorable as the average, made less than a half million feet of gas, due, no doubt, to the shaley sand.

It is worthy of note that wells of about the same initial volume are in belts parallel to the trend of the sand body. Probably the sand was sorted into lenticular sections of clean sand and muddy sand while being laid down. The clean sections yield the large wells and the shaley sections furnish wells of small volume, or dry holes.

The maximum thickness of the sand body is maintained where the axis of the structure plunges to the northwest. The holes in the S2 sec. 17 had a small amount of gas that was soon drowned out by salt water. These holes are at the edge of the original level of the water in the sand.

Production and decline—The largest well in the 600-foot sand had an initial volume of 2 1/2 million cubic feet and a rock pressure of 175 pounds per square inch.

The oil wells came in at 25 to 125 barrels. On one of the leases 7 wells produced about 4,000 barrels each in 30 months. At the end of this time their average daily yield was about 2 barrels.

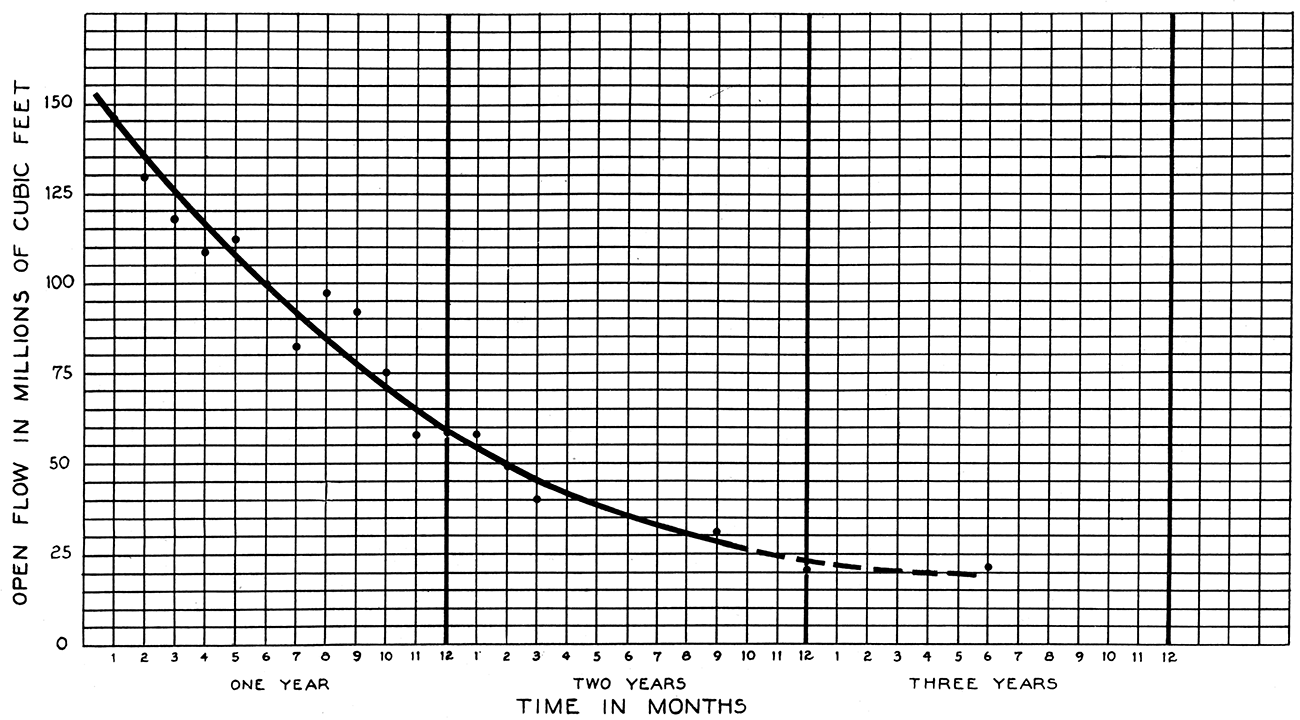

The gas wells in the deep sand varied greatly in initial production. The largest well, Graham & Long's No. 5 Melville, in the northeast corner of sec. 34, gauged 32 million feet. Two wells in sec. 27 started off at 28 and 30 million feet. Four wells made between 15 and 20 million, 5 between 10 and 15 million, and of the remainder only a few were rated at more than 5 million cubic feet per day. The maximum open flow of the field is estimated to have been 250 million cubic feet. A curve which shows the decline of the open flow of the chief properties is given in Fig. 8. The original rock pressure was 280 pounds per square inch. At the end of the first year the pressure had decreased to 175 pounds; at the end of the second year to 95 pounds; and at the end of the third year to 70 pounds. (See Pl. 8.)

Figure 8—Open flow decline curve of the chief properties in the Polkinghorn gas field.

Welda Field

Location—The Welda field extends 1/2 mile north of Welda to the Polkinghorn gas field and 3 1/2 miles south of Welda to the Colony oil district. It includes the following sections: S2 34 and 35, T. 21 S., R. 19 E., and 2, 3, 9, 10, 15 and 16, T. 22 S., R. 19 E.

Development—The productive area has a connected appearance now, but its development did not take place progressively from one end to the other. Scattered semi-wildcat wells were brought in during the period following the discovery of gas at Colony, until the present field was outlined. It forms the connecting link between the important gas and oil fields on each end. The Welda district is left for consideration after the areas on each side, with individual records, have been separated from it. When the territory was being developed the operators were anxious to secure gas production. In some instances the 800-foot sand was cased off and drilling continued to the lower sand. Later, development of the oil sand was taken up.

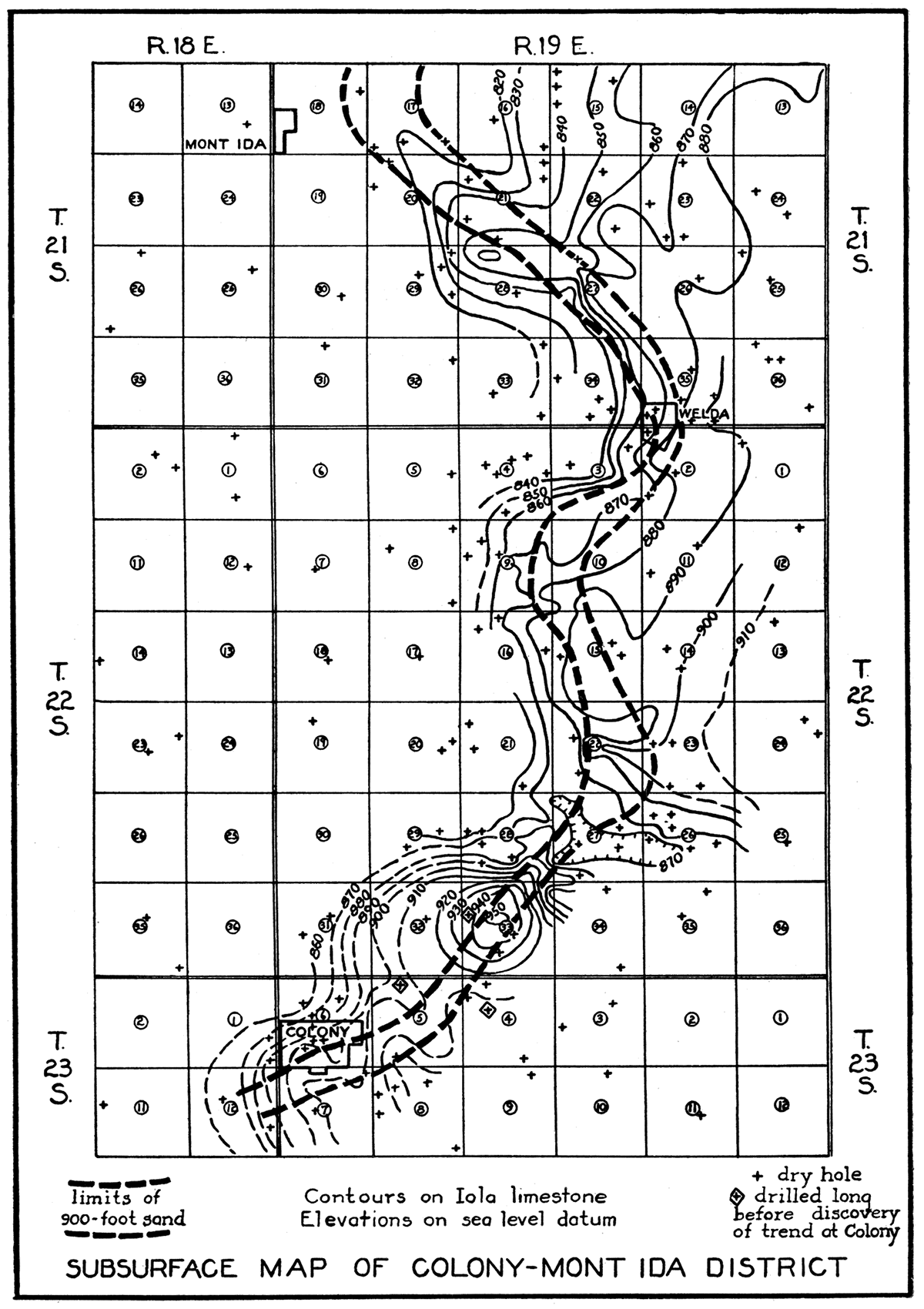

Structure—The lack of outcrops prevents a satisfactory survey of the surface rocks. The subsurface structure was investigated by use of the Iola limestone. This formation cannot be used in the west half of secs. 10 and 15, because the operator in this area did not keep complete logs of the wells. Many of the other logs are known to be inaccurate. Although a subsurface structural map cannot be relied on for the accuracy of the details, it should show the controlling dips very well.

The general dip over most of the area is toward the northwest. In the NW sec. 2, T. 22 S., R. 19 E., is a small dome with a closure of 10 feet. A syncline 30 feet deep in sec. 3 plunges westward. The lowest part of this depression is in the NW SE of the section. Irregular warping of the strata has taken place in the central part of the E2 sec. 9. The 870-foot contour line follows an irregular course in outlining three radiating noses that extend west and southwest. There is evidence of a synclinal basin in the SW sec. 9. The elevation of the Iola in three wells along the west side of the SE sec. 15 is slightly over 900 feet; in the dry hole in the SE NW sec. 14 it is 893 feet. These data indicate an east dip but the location of the axis of the fold is not definite. It is rather hazardous to draw definite conclusions affecting so large an area from the log of the one dry hole. However the topography tends to indicate that a structure is present here.

Sands—The 600-, 800-, and 900-foot sands furnish the production. They occur very near the depths indicated by their names. The shallow sand yields a small amount of gas; the 800-foot sand produces all the oil and part of the gas; and the deep sand produces gas exclusively. Some of the oil sand is present almost everywhere but is productive only in small areas where it attains sufficient thickness and cleanness. About 30 to 45 feet of it occurs in the small group of wells in the north-central part of sec. 2, T. 22 S., R. 19 E. It seems probable that this area will be connected with a like area in the middle of sec. 3, because the gas wells between them have 20 to 30 feet of oil sand at the 800-foot horizon. About 30 wells in sec. 9 have 25 to 45 feet of sand. The sand is replaced by broken sand and sandy shale at the west edge. It is thinner and broken on the east edge in sec. 10, according to the logs of the gas wells drilled to the Colony sand.

The 800-foot sand is believed to be a near-shore shallow-water deposit, the same as in the Colony oil field, which will be described later.

The 900-foot sand is a part of the same sand body found in the Colony and Polkinghorn gas fields. It maintains the same form but has more broken sand and is not as thick. (See section L-L', Pl. IV.)

Production—The oil wells had an initial production of 5 to 125 barrels. The gas wells had an open flow volume of 1 to 17 million cubic feet and rock pressure of 240 to 285 pounds per square inch.

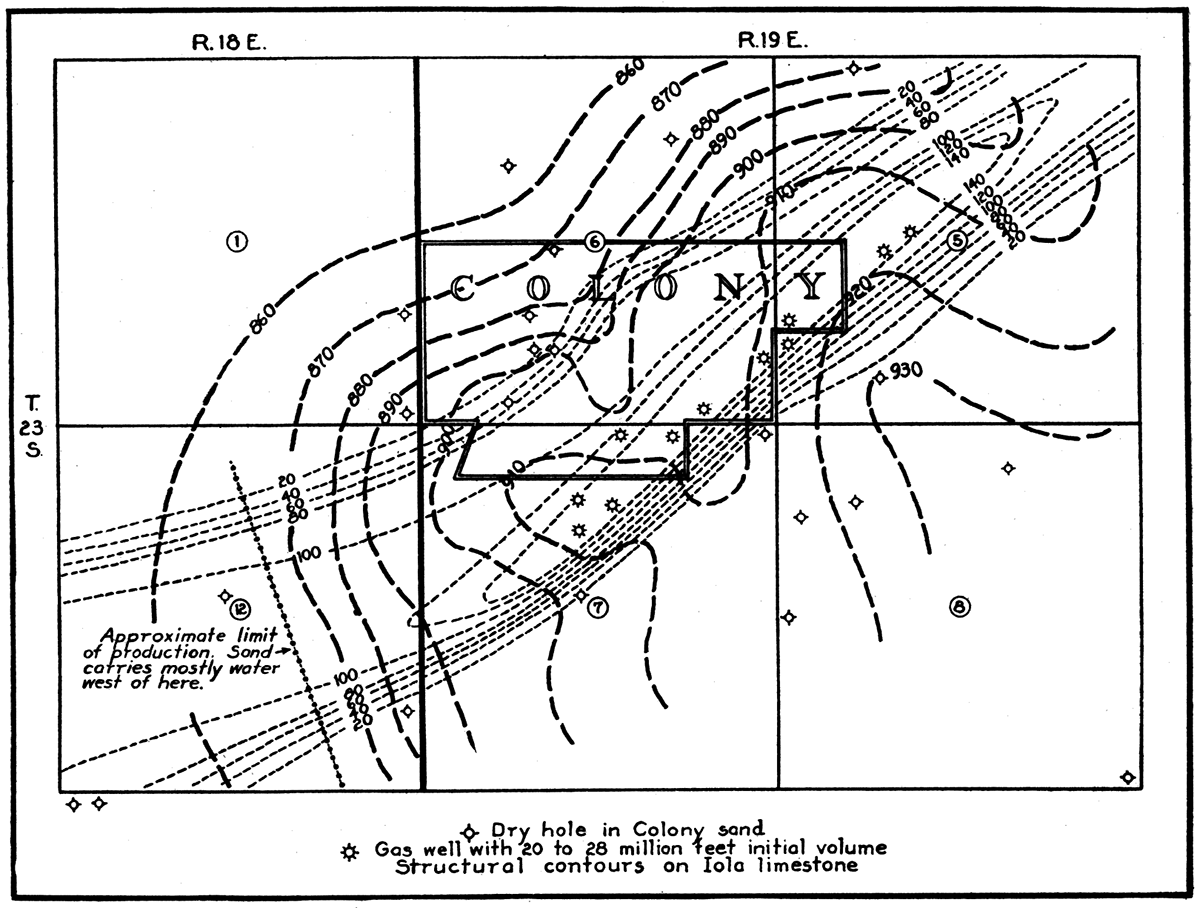

Figure 9—Subsurface structural map of the Colony-Mont Ida district.

Colony Oil Field

Location—The Colony oil field is 3 miles northeast of Colony. It is made up of disconnected areas in parts of secs. 21, 22, 27, 28, 29,32 and 33, T. 22 S., R. 19 E.

Development—Most of the wells were drilled in 1921 and 1922 during the intensive campaign that took place in the southern part of the county during those years.

Structure—The structure of the surface rocks cannot be determined accurately, because they crop out in only a few places. The outstanding subsurface feature is the change from north to northwest dip in the central part of the field. The north dip forms one side of a dome that occupies sec. 33, T. 22 S., R. 19 E. An abnormally steep dip of 50 feet in a quarter mile is in the S2 sec. 28. A long, flat, irregular nose begins in the middle of the SE sec. 28 and extends into the SE NE of the same section. The western end of a steep-sided narrow syncline, 25 feet deep, is in the northeastern part of sec. 33.

Sand—The reservoir rock is a brown, fine-grained micaceous sand at a depth of 800 feet. Most of the wells found from 16 to 18 feet of it. The thickest portion, 20 to 25 feet, is in the S2 SE sec. 28 and the NE NE sec. 33. The deposit is rather uniform and ordinarily does not have a broken upper portion as is common in the shoestring fields. The edges may gradually be replaced by sandy shale, or may pinch out abruptly. On the eastern edge of the small pool, near the southwest corner of sec. 28, the sand thins from 20 to 6 feet in 300 feet. A well on the south side of the pool has 7 feet of broken sand on top of 12 feet of "pay." The dry hole in the northeast corner NW SW sec. 28 is credited with 40 feet of sandy shale. The productive area in the SE sec. 22 is separated from the larger one to the southwest by a dry hole that had no sand.

The oil-bearing rock is considered to be a near-shore deposit. It is made up of thin, disconnected patches which were probably laid down adjacent to land very near sea level-perhaps within a shallow embayment. Its thin, even cross sections imply that is was not subjected to the disturbing effects of strong wave or current action. (See sections M-M' and N-N', Pl. IV.)

Relation of accumulation to structure—Gas is in the sand on the dome in sec. 33. Where the sand is lower, in sec. 28, it is oil-bearing. It contains no water, and oil and gas occur wherever there is sand, regardless of the minor structural features. According to the statement of one .operator, the wells located higher structurally had a slightly greater initial production.

Production and decline—The thinner but more thoroughly saturated sand in this field furnished wells of 50 to 125 barrels initial production. This compares favorably with the production of the wells in the channel sand bodies that are 35 to 50 feet thick but which are made up partly of broken sand. At the end of the first year the average yield per well in the Colony field was 5 barrels; second year, 2 1/4 barrels; third year, 1/4 barrels; fourth year, 1 barrel; fifth year, 1/2 barrel.

The oil is 33 to 34 degrees Baume gravity and it has a dark-green color.

Figure 10—Production decline curves of two leases in the Colony oil field.

Colony Gas Field

Location—The Colony gas field extends in a sharply-defined northeast-southwest course through the village of Colony and includes, also, half a mile of the gas-producing area on each side of the village. (See Pl. VII.)

Development—The development of the Colony field included a town-lot drilling campaign that was attended by the usual financial loss to most of those who participated and a further irreparable loss of a constantly diminishing natural resource. Wonder is often expressed that the village of Colony did not suffer some great disaster when this unrestricted campaign was being carried on. This wasteful drilling took place in spite of the earnest efforts of some of the experienced operators to avoid it. Plans were hurriedly formulated to "pool" the acreage and drill only one well on several city blocks. However, the opportunity presented to the unscrupulous to obtain "proven" acreage for purposes of their own prevented a sane development program from being carried out. Many drilling blocks, each made up of a few city lots, required numerous protective offsets. Feverish drilling contests were conducted by neighboring crews to reach the sand first. Fifteen to twenty portable rigs were running at one time and, on certain days, the air surrounding the village was filled with rock dust and gas blown from the open drill holes. Rigid precautions had to be taken to prevent fires. Frequently the engines of the drill rigs were operated by gas pressure because steam could not be used when no fires were permitted in the boilers. Housewives temporarily abandoned their homes to escape the danger attendant on wells being completed in their dooryards. Within 5 months, beginning in July, 1921, the drilling orgy had spent itself and left in its wake 90 gas wells within an area of 2,000 feet wide and 1 mile long. On one 40-acre tract were 31 gas wells and 2 dry holes. One well would have been sufficient to drain these 40 acres. The rock pressure of some of the wells was lowered so rapidly that they could not push gas into the gathering line after six weeks of life.

[Note: Some idea of the effectiveness with which the gas can be drained from its reservoir and the uselessness of so many wells may be gained from the development of a 240-acre lease northeast of the village. This lease, made up of the NE and the E2 NW sec. 6, T. 23 S., R. 19 E., originally had 5 wells on it. All the wells were drilled in the fall of 1921. Their average initial volume was 14 million cubic feet, and rock pressure 285 pounds. Five years later another well was put down near the center of the lease and 1,100 feet from the nearest old well, with the hope of replenishing the production. However, the attempt was disappointing because the open flow of the hole was only 65,000 cubic feet and the rock pressure 6 1/2 pounds, the latter the same as in the other wells.]

The most regrettable thing about such useless drilling is the waste of gas—gas that can never be replaced. Probably enough to supply the city of Garnett for 10 years escaped into the air when the wells were being drilled in. Other millions escaped through the avenues always associated with the development of a gas pool.

The position of three dry holes northeast of Colony (indicated on Fig. 9 by diamond-shaped enclosures) in respect to the shoestring of gas sand illustrates how the hand of fortune delayed the discovery of the Colony field. The two south wells were put down in 1908; the other in 1917. In 1921 the gas trend was traced through two sides of the triangle of old wells that are only a mile from each other. This is another example of how, unknowingly, dry holes are drilled close to oil and gas pools, and also, how dry holes in shoestring territory "condemn" only a small area around them.

Surface structure—The testing of a large anticlinal nose, on the strength of geological advice, led to the discovery of the gas sand at Colony. The structure extends about N. 45° W. through sec. 8. T. 23 S., R. 19 E., and crosses the northeast edge of Colony. The rocks dip about 50 feet from the top of the structure on the northern edge of sec. 8 to the middle of sec. 6, T. 23 S., R. 19 E. The contours which represent the lowest 20 to 25 feet of dip swing southward to include a minor flat nose, or dome, in the N2 sec. 7. The north flank of the major structure dips into a parallel syncline whose axis passes through the NE sec. 5.

The first well, on the highest part of the nose and in the NW sec. 8, found no sand at the Colony horizon. A second test, about 1/2 mile farther northwest, encountered a small flow of gas and was completed after being drilled through the gas sand into shale. Later it was discovered that the sand penetrated in this first well was only a small portion of a thick body separated by a shale break from a lower portion, 50 to 100 feet thick, that yielded the "big gas."

The majority of operators gave no attention to surface structure in the development of the field. The limits are defined by the extent of the sand body, except on the southwest end, where the sand is much lower and is water-bearing.

Subsurface structure—Contours on the base of the Fort Scott limestone follow the trend of the sand body and define a long, narrow anticline with a west flank that dips sharply at the edge of the sand. Contours on the Altamont limestone and Iola limestone indicate structure essentially like that of the surface rocks. It appears that the dips in the Fort Scott limestone are caused by differential settling over the sand. The higher horizons do not reflect this condition.

Relation of production to structure—As has been previously pointed out, the pool is only a segment of the 14-mile shoestring of gas sand that winds through the county. It ends about 1/2 mile southwest of Colony where the sand becomes low on the regional structure and contains salt water. The greater accumulation in this area may be accounted for partly by the anticlinal position of the sand in parts of secs. 5, 6 and 7. It dips off into synclines on each side—the one on the south holding water; the one on the north, smaller quantities of gas. Thus it may be observed that the Colony wells are on an anticlinal "high" that is a part of a still larger "anticline" formed by the position of the long sand body on the regional dip.

Sand—The sand, at the 900-foot horizon and generally referred to as the Colony sand, is included in a body having a maximum thickness of at least 135 feet and having thin wedge-like edges at a uniform distance of approximately 3,000 feet apart. It is fine-grained, gray, and micaceous and covers a considerable range in quality as controlled by varying amounts of shale or sandy shale. A break of pure shale, or sandy shale, occurs commonly in the upper part of the sand body and separates the "first gas," a relatively small amount in 10 to 50 feet of sand or sandy shale, from the "big gas" that comes from 50 to 100 feet of sand.

Outstanding features of the sand body are its great thickness, its rapid pinching-out on the sides, and thin fingers of sand, 5 to 25 feet thick, projecting 500 to 2,000 feet from about the middle of the sand body. In places there are at least three of these fingers of sand, separated by a few feet of shale. The top of the sand is slightly convex, or flat, and the bottom is outlined as convex where the lines defining the underside are projected beneath the depths to which the wells penetrated the sand. At Colony the east side of the sand body decreases in thickness from more than 100 to 10 feet between wells 600 feet apart. On the west side the decrease is at a lesser rate, or from 100 to 10 feet in 1,500 feet.

The characteristics of the sand body offer conflicting evidence as to its origin. Consideration of its origin here will include all the features observed throughout its extent in the county. (See secs. L-L', O-O' and P-P', Pl. IV.) Its gently winding course, in which it makes four bends, and its slightly convex underside suggest it to be a channel deposit of some kind. Its convex top, thickness, direction, lateral and vertical gradation into sandy shale, the inclusion of lenses of shale, and the variation in thickness along its trend, imply that it is a near-shore bar or beach deposit. The convex underside is not as sharp as in the channel deposits of the 800-foot sand. The average slope of the depressed section is only 1 foot in 25, or 4 per cent, whereas the slope of the underside of the 800-foot channels is often 1 foot in 6, or over 16 per cent. The depression is gentler than is suggested by the sections, plotted at an exaggerated scale. Near-shore bars are often deposited by currents flowing parallel to the shore. Such a current might scour a shallow depression in the sea floor along its course. If the current were given a load of, sand, it would fill this depression, and later, the excess sand would be piled up to form the conventionally shaped beach deposit whose features would include a gently convex top, gradation into sandy shale on the sides, and thinning to wedge-like edges. The included lenses of shale indicate times when muddy waters drowned out those bearing sand. Perhaps the fingers of sand resulted from a part of the deposit being pulled out over the ocean floor by the back-drag of the waves. It seems likely that the waves aided in piling up the sand where it is thickest. Most of the stream-channel shoestrings of this district, regardless of their position in the Cherokee shale, have general east-west courses. The direction of the Colony-Welda trend counteracts evidence that it is of the same origin.

Figure 11—Sand-thickness and subsurface structural map of the Colony gas field. The isobaths, or sand-thickness contours, are assumed from data furnished by dry holes on the edges of the sand. from wells which penetrated 100 feet or more, and from a well in sec. 5 that was drilled through the sand where it was 135 feet thick. The oblong shape of the thickest portion is based on the arrangement of the wells of large initial volume. The position of the thin edges is too uncertain to be indicated.

Production and decline—The estimated open flow of the wells at the peak of the development is 900 million cubic feet. The original rock pressure of 285 pounds per square inch declined rapidly because of the many wells that tapped the reservoir. Within one year the pressure was down to 50 pounds, even in wells outside the village and located relatively far apart. The decline of pressure of some of the wells on town lots was plummet-like in rapidity. A curve that shows the decline of one of these wells is shown in Pl. VIII in connection with the curve for 10 representative wells in the outskirts of the village.

A rather peculiar and interesting situation developed while the drilling progressed at Colony. It was noted that the largest wells, those having an initial open flow of 20 to 28 million cubic feet, were in straight, narrow alignment, 600 to 800 feet from the east edge of the sand body. This line of large wells reached from the southwest corner of the NW NE sec. 7 to the middle of the south line of the SE NW sec. 5. All were drilled 100 feet into the sand. After a few had been drilled, the size of later wells could be predicted very closely from their position in respect to this narrow trend. It seems probable that the cleanness of the thick sand was an important factor in furnishing these large producers.

The initial volume of the many wells indicates the vast quantities of gas that were stored by nature beneath Colony. A resume of the producers shows that about 11 were rated at 20 to 28 million feet, 12 from 15 to 20 million, 35 from 10 to 15 million, 26 from 5 to 10 million, and 11 below 5 million. Each of these groups might be enlarged from the 30 unclassified wells. Seventeen dry holes were drilled.

Bush City Shoestring

Location—The Bush City shoestring is the long trend which has been developed from sec. 14, T. 21 S., R. 19 E., to sec. 27, T. 20 S., R. 21 E. This narrow field, 13 miles in length but averaging only 1,4 mile in width, follows a gently curved east-west course in 8 miles of its trend on the western end and then turns northeast for 6 miles. It apparently joins the sand body of the older Goodrich shoestring at the eastern edge of the county.

Development—Approximately 775 oil wells were drilled in this 13 miles of productive territory from March, 1923, to January, 1926, and, in addition, about 100 dry holes resulted from attempts to extend the trend or define its edges. On January 1, 1927, proven locations for about 50 wells remained, so the total number in the field should eventually be about 825.

The discovery well was drilled by A. H. Keys on the Emma J. Ware farm in the southeast corner of the NE sec. 15, T. 21 S., R. 20 E. This well was located on a large anticline with the purpose of testing the Colony gas sand horizon. Two previous tests on the same structure were failures. When an oil sand was encountered unexpectedly at 800 feet in the third well, it was completed at that depth. Fate seems to have hurried the discovery of the Bush City field, because the successful well was drilled to retain a lease about to expire and on a location seemingly less favorable than many. The next well drilled after the discovery well, the southeast offset, was dry. The initial producer is only 500 feet from the edge of the sand body.

In another instance the discovery of this shoestring was delayed only by a narrow margin. Several dry holes, which had showings of oil, were drilled along the south fork of Pottawatomie creek in secs. 12 and 13, T. 21 S., R. 19 E., 3 to 5 years before the first well was brought in 4 miles west of them. The trend that was subsequently developed passed between two of these old dry holes.

The history of the Bush City field is characterized by a series of spurts of activity controlled by the price of oil and by wildcat wells brought in ahead of the proven territory.

Structure—The surface rocks along this shoestring have been surveyed carefully, because geologists still cling to the hope that some peculiarities of structure may be found which will prove useful in discovering such deposits of sand or in tracing them beyond their known limits. Surveys show that the Bush City shoestring passes over a variety of minor structural features.

| Wells which served as extensions to the Bush City field during its development. | ||||

|---|---|---|---|---|

| Operator | Well | Location | Length of extension, miles |

Date |

| Peerless Oil Co. | No. 3 Ewing" | Southwest corner NE NE sec, 14, T. 21 S., R. 20 E. | 1/2 | Aug. 1923 |

| Peerless Oil Co. | No. 1 Crozier | Southwest corner NW NW sec. 18, T, 21 S., R. 21 E. | 1 | Mar. 1924 |

| J. L. Rich et al. | No. 1 Whetstone | SW NW sec. 13, T. 21 S., R. 19 E. | 4 | May 1924 |

| Douglas Oil Co. and J. L. Rich | No. 1 S. P. Johnson | Southeast corner SW SE sec. 7, T. 21 S., R. 20 E. | 2 | June 1924 |

| Littrell and Polkinghorn | No. 4 Hydorn* | Northwest corner SW SW sec. 8, T, 21 S., R. 21 E. | 3/4 | April 1925 |

| Whitesides and Fielder | No. 1 Badders | Southwest corner NE sec. 8, T. 21 S., R. 21 E. | 1/2 | April 1925 |

| Denton et al. | No. 1 Rosell | Southwest corner NW SW sec. 4, T, 21 S., R. 21 E. | 1 | May 1925 |

| Denton et al. | No. 1 Jackson | NE SE sec, 32, T. 20 S., R. 21 E. | 1 | Oct. 1925 |

| Childs et al. | No. 1 Cleveland | Southeast corner SW sec. 28, T. 20 S., R. 21 E. | 3/4 | Jan. 1926 |

| * This is the first well drilled beyond the bend north of Bush City. | ||||

At the western end of the field, in sec. 14, T. 21 S., R. 19 E., the rocks rise to the east at about the normal rate and then flatten for a distance of 1 mile across sec. 13. From this rather flat area, or terrace, the normal northwest dip is present for 3 1/2 miles to the middle of sec. 15, T. 21 S., R. 20 E. The base of the Plattsburg limestone is 90 feet higher at that point than at the west end of the field. In the E2 sec. 15 and the W2 sec. 14 the sand body crosses a dome on the north end of an anticline that occupies the east-central part of T. 21 S., R. 20 E. From the middle of sec. 14, T. 21 S., R. 20 E., to the N2 sec. 5, T. 21 S., R. 21 E., no key beds are exposed. Subsurface studies indicate that the sand rises about 45 feet from the west side of sec. 13, T. 21 S., R. 20 E., to the crest of a dome in the NE of that section and the NW sec. 18, T. 21 S., R. 21. E. A shallow synclinal area in the NW NE sec. 18 is encountered before the sand again becomes higher in the SW sec. 8. In the next 3 miles it has minor fluctuations in elevation that amount to a maximum difference of 35 feet. The sand is highest in the NW sec. 8 and the SW sec. 5, at 425 to 430 feet above sea level, and lowest in the NW sec. 4, at 395 to 405 feet above sea level. At each end of this 3-mile section, and at points between, the sand is about the same elevation, because it follows approximately the strike of the beds. On each side of the line between secs. 27 and 28, T. 20 S., R. 21 E., the sand is relatively low, being 360 to 370 feet above sea level. From the western edge of sec. 27 it rises about 80 feet to the county line, where it is replaced by sandy shale and broken sand that have only showings of oil and gas.

Sand—The producing sand is a channel-shaped deposit, 0 to 55 feet thick and 1,000 to 2,000 feet wide, that occurs 20 to 40 feet below the top of the Cherokee shale. The depth to the sand changes from about 600 feet in the eastern part of the field to about 800 feet at the western end. This difference is accounted for mostly by the regional dip and the topography. The lowest part of the channel is not always midway between the edges, and therefore, it "pinches out" more abruptly at some points than others.

The following examples are mentioned to picture how sharply the channel bottom rises. A well with 36 feet of sand, in sec. 8, T. 21 S., R. 20 E., is offset on the south by a dry hole that had 10 feet of broken sand. A dry hole that had 6 feet of sand, in sec. 18, T. 21 S., R. 21 E., is 425 feet southeast of a well with 46 feet of sand. A failure with 2 feet of sand, in the NW sec. 8, T. 21 S., R. 21 E., is 300 feet west of an oil well that had 44 feet.

Patches of sand 2 to 30 feet thick have been discovered outside of the main trend. They contain small quantities of black oil of lower gravity. Two to four feet of shoestring sand, that had a showing of oil, was logged in three tests in the NW sec. 17, T. 21 S., R. 20 E. On the north side of the shoestring, in secs. 6 and 7, T. 21 S., R. 21 E., 12 to 30 feet of sand yields oil of 22 to 30 degrees gravity. This patch of sand is not connected with the main field through the area closest to it, but the ends of the patch may have "leads" into it. Perhaps it represents an abandoned temporary channel of the stream that was responsible for the main unit. A large number of failures 1/4 to 1/2 mile from the edge of the shoestring penetrated traces of sandy shale at the channel horizon.

The channel filling is sandstone that varies over a wide range in quality, according to the amount of shale or sandy shale associated with it. The shale occurs mostly as laminas but increases in places to form beds at least 2 feet thick. The sand is divided into alternating layers of fine and coarse material that may be noticed in the drill cuttings. Those of the fine sand are so fine as to appear muddy; those of the course sand have a texture like sugar. It is likely that the sand is far more impure than generally assumed, because, by following the general custom of washing the cuttings in a bucket, the finest sand and the mud are eliminated, and the sample left for examination is made up of the cleaner, coarser sand.

Locally, a layer of hard, black calcareous sand, 5 to 7 feet thick, and like that in the Garnett shoestring, covers the bottom of the channel. This sand is not believed to hold much oil, because no increase of oil can be noticed when it is penetrated. It is not included in the part of the sand that is shot. The main producing zone, or "pay," is above the black sand and occupies about two-thirds of the channel. It is relatively clean sand that bleeds freely in wells of average size, or larger. The remainder is chiefly brownish-gray "broken sand" that holds some gas everywhere but in varying amounts as governed by the structure. The term "broken sand" is often erroneously applied to clean sand that contains little oil. In some places the quality of the sand is uniform from top to bottom.

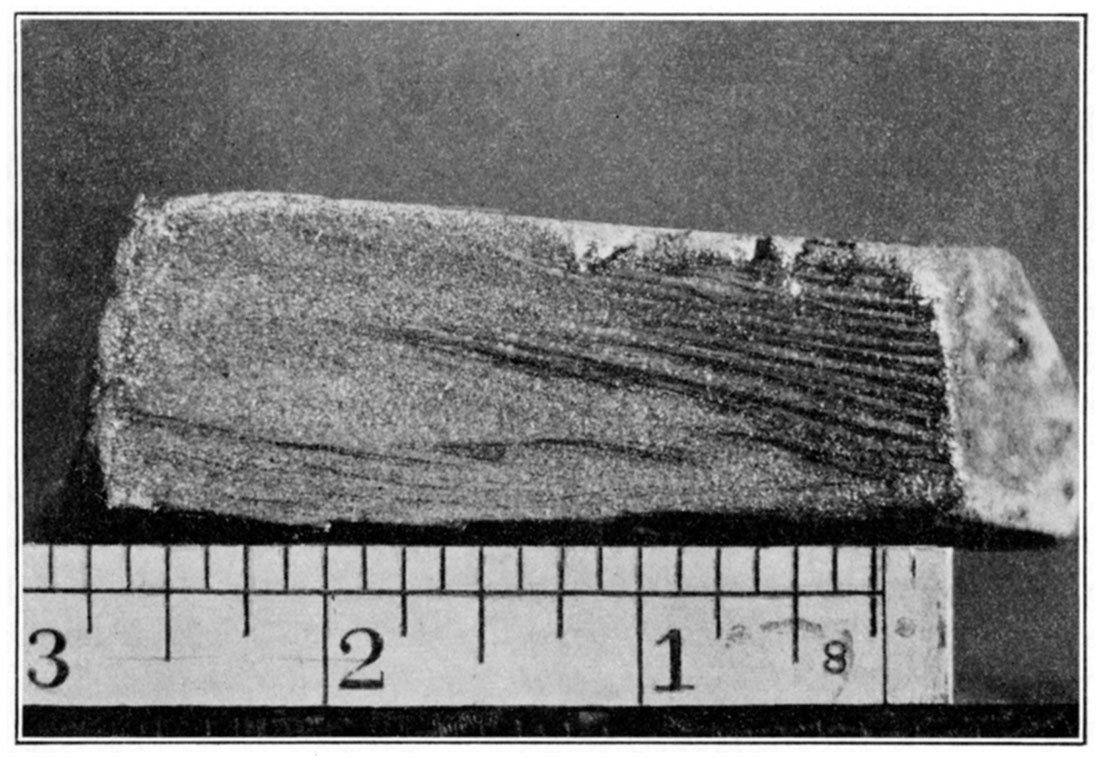

Fragments obtained from wells after they have been shot afford a good means of studying the producing rock. A poor cleavage is developed along the laminae of sand, the surfaces of which are covered with flakes of mica. Tiny layers of silt appear as dark bands, and by means of these and the edges of the laminae of mica crossbedding can be detected. After examining specimens of this fine silty sand, one concludes that it lacks much of being an ideal reservoir rock.

Relation of accumulation to structure—A noticeable condition in respect to the Bush City field is the variation in the amount of initial production of the wells in different sections. The areas of largest initial yield are structurally highest. This is shown conclusively by a comparison of the profile of the sand and a profile of the estimated initial production in various sections of the trend. (See Pl. IX.) Wells in some of the synclines made only 5 to 15 barrels, but wells on adjacent anticlines made 50 to 150 barrels the first day. Local synclinal areas that furnished moderately large producers are generally a part of a major high area. Such an area exists in the NE sec. 18, T. 21 S., R. 21 E., where wells that made 50 to 75 barrels are in a shallow syncline which is a part of a 3-mile anticlinal section that proved to be the most prolific of the entire shoestring. The individual wells within the areas of different productivity vary greatly among themselves. This is evidently caused by differences in the quality of the sand which is made up of fine and coarse, dirty and clean, lenses. The quality of the sand may offset the effect of structure, as demonstrated by the barren, broken sand in sec. 26, T. 20 S., R. 21 E., on the western edge of Linn County. This area is higher than any part of the shoestring in Anderson County and would have been expected to furnish large wells had the sand been clean.

Figure 12—Fragment of sand from the Bush City shoestring. The fine crossbedding is shown by dark streaks of silt and flakes of mica that line the irregular bedding planes which separate the cleaner bands of sand. This channel sand retains a large percentage of its oil because of its fineness and lenticular structure of impure material. (Scale in inches.)

Heavy oil—Conditions somewhat similar to those in the west end of the Garnett shoestring are also present in the west end of the Bush City field. The dark-green oil of 35 to 36 degrees gravity is replaced by heavy black oil before the sand becomes barren. However, the drop in gravity is more abrupt. A well near the west side of sec. 13, T. 21 S., R. 19 E., produces 34-degree oil; a well 300 feet farther west has 28-degree oil. The oil pumped on the last commercial leases on the trend tests 26 degrees. A stringy, tar-like oil has been found near the middle of sec. 14. Beyond there the sand carries only a stain of oil.

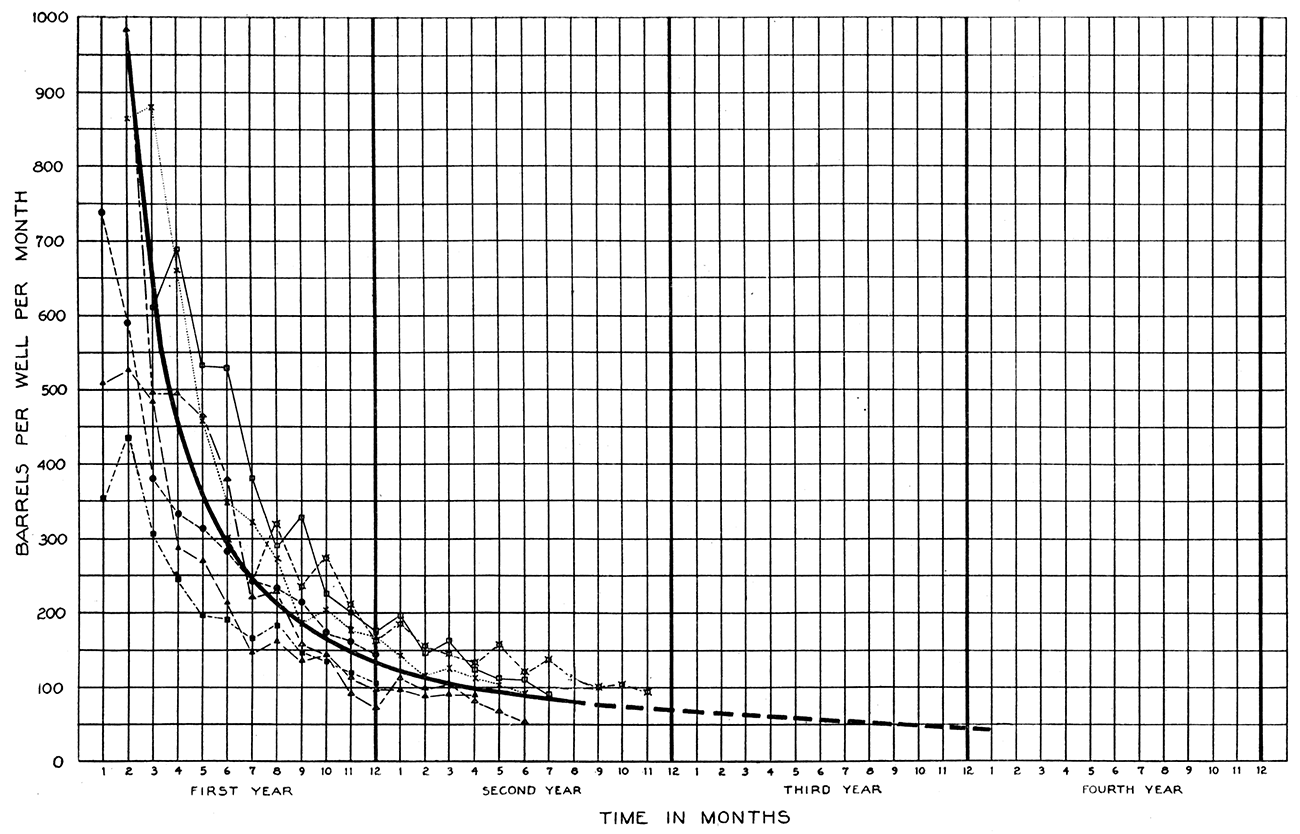

Production and decline—The extremes in initial production of the wells range from 5 to 800 barrels. It is difficult to estimate the average initial production, but it is placed at approximately 60 barrels. A few wells flowed naturally and most of those of average size flowed by heads for a day to a week after being shot. About 10 per cent started at 20 barrels or less, and 10 per cent at more than 150 barrels. The largest well of the field flowed 34 barrels per hour during the first day. This well was truly a freak, because it produced initially 500 barrels per day more than its nearest rival.

A study of the decline of leases which were drilled up rapidly and had a good flush production, furnished by 75- to 150-barrel wells, indicates that the recovery by natural methods after 15 years will be from 4,500 to 9,000 barrels per well, or 1,500 to 3,000 barrels per acre. [Note: Per acre recovery is estimated from the area included within the edges of the sand.] The average recovery per acre on the best leases can be expected to be about 2,500 barrels. The production of a well that made 100 barrels initially is 4 1/2 to 5 1/2 barrels at the end of the first year, 2 to 2 1/2 barrels at the end of the second year, and 1 to 1 3/4 barrels at the end of the third year. After the third year the production will probably decline very slowly during the next 10 to 12 years until the average daily production is 1/5 to 1/4 barrel per well.

The possibilities of increasing the recovery in the Bush City field by applying air pressure are still unknown. The few air plants that have been installed have not been in operation long enough to furnish definite information as to their worth. Judging from the favorable results secured by the use of air on the older Garnett shoestring, an additional recovery may be allowed for in the Bush City field, although poorer sand there may lessen the success of this method.

Figure 13—Production decline curve of the Bush City shoestring.

Other Fields

A few gas wells which produce from the 900-foot sand have been drilled 3 miles west and 1 mile south of Garnett. The largest wells are on the top of a small dome. Dry holes drilled off this dome encountered salt water. The initial daily capacity of the wells varied from 1/10to 2 1/2 million cubic feet and their rock pressure was 275 pounds per square inch.

A short shoestring oil pool, 3 miles southwest of Colony, trends N 30° W. The pool is about 1 mile long but only 700 feet wide. The channel-shaped sand body has a maximum thickness of 30 feet and is 10 to 15 feet below the top of the Cherokee shale. This trend has not been developed fully, because the wells had very small initial production.

A shoestring gas field in sec. 28, T. 21 S., R. 21 E., produces from the Colony sand, which is at a depth of about 700 feet here. The initial open flow averaged about 2 million cubic feet per well. The sand body is sharply defined on the edges, as shown by the dry holes, with 0 to 4 feet of sand, that are offsets to gas wells with 20 to 30 feet. A peculiar feature of this shoestring is that no water occurs in the bottom of the sand where it has been developed to date.

A narrow gas pool in the Colony sand is 7 miles east and 1lh miles north of Garnett. The sand body is on the west flank of an anticline. Seven wells, which averaged about 2 million feet open flow when drilled in, make up the pool. The 300-foot sand is productive also in this field.

The source of part of the gas used in Garnett is in a shoestring field 7 miles east of the city. The gas comes from the Colony sand. Eight wells, with initial volume of 1/2 million to 4 million feet and pressure of 250 pounds, are in a narrow line about 1 mile long, trending slightly east of north.

Prev Page--Oil and gas sands || Next Page--Conclusions

Kansas Geological Survey, Geology

Placed on web Feb. 6, 2018; originally published June 15, 1927.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/6_7/06_fields.html