Prev Page--Forward, Introduction || Next Page--Metals

Fuels

Coal

by J. M. Jewett

Summary—In 1941 production of Kansas coal amounted to approximately 3,700,000 tons. The annual production, however, has been as great as 7,500,000 tons in one year. Known reserves are sufficient to allow continuation of the present production rate for many years.

Coal is classified in three general divisions: (1) brown coal or lignite, (2) bituminous coal, and (3) anthracite or hard coal. The general properties of these three ranks of coal are so well known that they need not be reviewed here. It should be noted, however, that the purposes for which an individual coal may be utilized are dependent on its physical and chemical properties, and the classification given above is by far too simple. Coals of anyone of these major ranks may be adapted to various uses. For example, bituminous coal in Kanawha County, West Virginia, is a gas coal; bituminous coal in the Collinsville district of Pennsylvania serves as coking coal; and that in the Pocahontas field, Virginia, steam coal (Lilley, 1936, p. 224).

Coal in Kansas

With the exception of very small amount of lignite, coal produced in Kansas is classed as bituminous. It is recognized, however, that coals of different beds in the state show considerable differences in character. More technological work must be done on Kansas coals before their best uses can be determined; some such studies have been accomplished among which is the work of Young and Allen (1925).

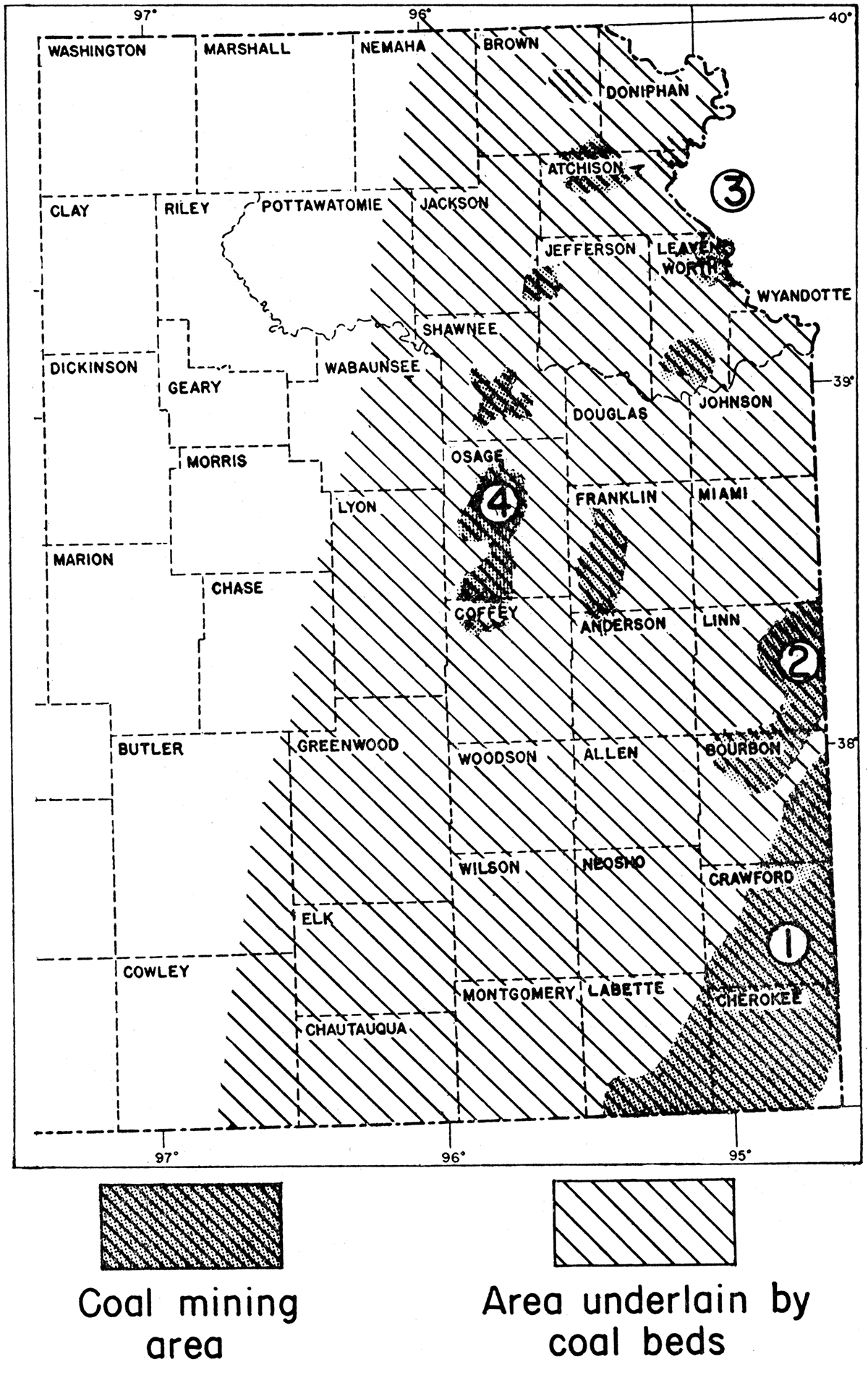

Kansas has four main coal-mining areas: (1) the Southeastern Kansas coal field, chiefly in Crawford and Cherokee counties, but including a part of Labette and a part of Bourbon County; (2) the Eastern Kansas coal field or the Mulberry coal area in Linn and Bourbon counties; (3) the Northeastern Kansas field, now nearly inactive, in Leavenworth and Atchison counties; and (4) the East-Central Kansas field, chiefly in Osage County, but including parts of Coffey, Franklin, and Shawnee counties. Figure 1 shows the location of the main coal-producing areas in Kansas and of areas of laterally extensive coal beds.

Figure 1—Map of eastern Kansas showing location of principal coal-mining areas and of region underlain by more or less continuous coal beds. (1) Southeastern Kansas coal field, (2) Eastern Kansas coal field, (3) Northeastern Kansas coal field, (4) East-Central Kansas coal field.

It is not known definitely when and where the first coal mine in Kansas was opened. Available records indicate that the first mine was opened near Leavenworth in 1854 (Crane, 1898, p. 188); it was a shallow pit or short drift constructed near the outcrop of a coal bed in the Lawrence formation. It is probable that the first mine of commercial importance was the one put down near Fort Scott in 1865 (Crane, 1818, p. 178). Soon thereafter, small strips in which coal was mined by hand labor were opened in Crawford County. Coal was mined and sold to a railroad company near Pittsburg as early as 1870, at which time a railroad recently had been completed from Kansas City to Baxter Springs. A shaft mine with a capacity of 40 tons per day was sunk near Pittsburg in 1874 (Crane, 1898, p.153) and has been reported as the first shaft coal mine in Kansas, but in 1870 a shaft was sunk at Leavenworth to a Cherokee coal bed 713 feet below the surface that had been discovered in 1865 by drilling. The prospecting for the latter mine was done by a company organized by Major Hawn, a geologist, who had a knowledge of coal outcrops in southeastern Kansas and who knew the approximate dip of the beds. Hawn predicted quite accurately at what depth the coal would be reached at Leavenworth.

Coal mining was developed rapidly in the Southeastern Kansas field in the 1870's. In those years large amounts of coal were shipped to Kansas City and to other markets. In 1878 and 1879 a railroad was constructed from Joplin, Missouri, to Pittsburg, Kansas, primarily for the purpose of hauling coal from the Southeastern Kansas field. Mining was started near Weir, Cherokee County, in 1878 and near West Mineral, Cherokee County, in 1895. By 1897, Crawford and Cherokee counties were producing 2 1/2 million tons of coal yearly (Crane, 1898, p. 153).

Development of the East-Central Kansas coal field was initiated with the beginning of coal mining in Osage County in the spring of 1869. The first mine was on Carbon Hill about 2 miles east of Carbondale. In the autumn of 1869 several mines were in operation in the vicinity of Osage City. Mines were opened at Scranton in 1874 and at Burlingame in 1878 or 1879. The East-Central Kansas field soon was producing large amounts of coal, much of which was being consumed by the Santa Fe railroad.

Coal mining was begun near Atchison in 1893, and the first mines were shallow pits and short drifts near outcrops of a 16-inch coal bed in the Lawrence formation. Later, a shaft mine was sunk near Atchison to a coal bed in the Cherokee shale. The Atchison area commonly is included as part of the Northeastern Kansas coal field.

According to Whitla (1940, p. 10), coal mining was started near Pleasanton, Linn County, between 1850 and 1860. Pleasanton is included in the Eastern Kansas field. Shafts and strip pits later were constructed in this field near Mound City, LaCygne, Boicourt, and Prescott in Linn County, and near Hammond and Mapleton in Bourbon County.

Coal mines were established near Thayer, Neosho County, approximately in 1898 (Crane, 1898, p. 133). Mining was started near Williamstown, Franklin County, in 1872. Mining on a small scale has been carried on up to the present time in these areas.

The Southeastern Kansas coal field

The greater part of the coal mined in Kansas has come from the Southeastern Kansas field, which lies chiefly in Crawford and Cherokee counties but partly in Bourbon and Labette counties (fig. 1).

There are 15 coal beds in the Cherokee shale in the area of its outcrop in Crawford, Cherokee, and Labette counties (Abernathy, 1938, pp. 195-196), where the Cherokee is approximately 450 feet thick. These coal beds range in thickness up to 3 feet, 8 inches. The thicker coals occur in the middle and upper parts of the Cherokee rock section. According to Abernathy, 5 of the 15 coal beds in this area have been mined, but more than 90 per cent of the mined coal has been taken from only two beds. The most important coal bed in this district is called the Weir-Pittsburg coal; it occupies a position near the middle of the Cherokee shale. According to Pierce and Courtier (1937, p. 85) the Weir-Pittsburg coal has been mined to the extent of over 75 per cent of that part which is greater than 2 1/2 feet in thickness. At the present time the greater part of the minable coal in the Southeastern Kansas field has been removed.

It is important to note that core drilling in the vicinity of Edna and Angola, Cherokee County, has revealed the presence of a coal bed 4 1/2 feet thick, lying from 425 to 625 feet below the surface (Pierce and Courtier, 1937, p. 68). This bed probably is stratigraphically equivalent to the Weir-Pittsburg coal. It is probable that extensive deep shaft-coal mining will be developed in this area.

Eastern Kansas coal field

This field is located in eastern Linn and northern Bourbon counties. In this area a coal bed, known as the Mulberry coal, occurs in the lower part of the Bandera shale formation. The thickness of the Mulberry coal in Kansas ranges from a few inches to 3 1/4 feet. It has been mined extensively for many years and is still important. In the Eastern Kansas field mining has been carried on near Fulton and Mapleton in Bourbon County and near Mound City, Prescott, Pleasanton, Boicourt, and La Cygne in Linn County. Both shaft and stripping methods are employed. For several years the Mulberry coal has been exploited by large-scale stripping operation in western Missouri, where it is now largely exhausted. About two years ago large-scale stripping operations were extended westward into Kansas, and, as a result, the Eastern Kansas field came into greater prominence. In 1940, Linn was the second largest coal-producing county in Kansas (see table 3).

Prior to 1940 mining activity was on a rather small scale in the Eastern Kansas field; hence there still remains a large reserve of coal. Throughout most of the Eastern Kansas field (fig. 1) the shallow depth of the Mulberry coal makes stripping operations profitable. The value of the farm land below which it lies, however, makes extensive stripping undesirable. It is hoped that in this area mining by means of shallow shafts will become increasingly important. The greatest known thickness of the Mulberry coal is in the vicinity of La Cygne in northern Linn County. Mining operations in the future may be expected to extend northward up Marias des Cygnes river valley into Miami County.

Northern Kansas coal field

The Lansing-Leavenworth-Atchison area is designated as a coal field because of the fact that deep-shaft mining of coal beds in the Cherokee shale long has been practiced there. The State Penitentiary mine at Lansing produces coal from a bed approximately two feet thick, 712 feet below the surface and 89 feet below the top of the Cherokee shale. At various times in the past, four or more mines in the vicinity of Leavenworth have been in operation. These mines reach the same coal bed that is being mined at Lansing. At Atchison a 3-foot coal bed formerly was mined at a depth of 1,126 feet. This bed also in in the Cherokee shale.

That the Northern Kansas coal field has important coal reserves is indicated by thickness data in tables 1 and 2.

Table 1—Thickness and depth of Cherokee coal beds in the Lansing-Leavenworth area. [Modified from table by Hinds and Greene (1917).]

| Coal beds | Thickness of coal bed, in inches |

Depth to coal, in feet |

|---|---|---|

| 15 | 12 | 598 |

| 14 | 6 | 617 |

| 13 | 6 | 640 |

| 12 | 14 | 663 |

| 11 | 6 | 677 |

| 10 | 24 (bed mined) | 709 |

| 9 | 16 | 728 |

| 8 | 3 | 889 |

| 7 | 13 | 918 |

| 6 | 10 | 993 |

| 5 | 26 | 999 |

| 4 | 28 | 1,031 |

| 3 | 12 | 1,087 |

| 2 | 5 | 1,097 |

| 1 | 6 | 1,127 |

| Aggregate thickness of coal beds |

197 inches | |

| Total thickness of coal in beds over 14 inches in thickness |

108 inches |

Table 2—Thickness and depth of coal beds exceeding 14 inches in thickness in Atchison deep boring. [Data from Hinds and Greene (1917).]

| Coal beds | Thickness of coal bed, in inches |

Depth to coal, in feet |

|---|---|---|

| 4 | 22 | 801 |

| 3 | 36 (formerly mined) | 1,126 |

| 2 | 28 | 1,190 |

| 1 | 15 | 1,199 |

| Aggregate thickness | 101 |

It should be noted that the Northeastern Kansas coal field borders Missouri river and that recent improvements designed to aid navigation in Missouri river have an important economic and military aspect.

A shallow coal bed in the Lawrence formation has been mined intermittently in the Northern Kansas field. At Atchison this bed is 10 to 16 inches or more in thickness. It crops out in river bluffs and along ravines tributary to Missouri river and formerly was mined in drifts or slope openings 2 to 3 miles south of Atchison (Whitla, 1940, p. 29). A lower coal bed, the Sibley coal in the Stranger formation, has been mined at various times at a locality about five miles north of Leavenworth. The Sibley coal has been mined also in the southern half of Leavenworth County. In Leavenworth County this coal bed ranges from 6 to over 22 inches in thickness.

East-Central Kansas coal field

This coal-mining area lies principally in Osage County, but the coal bed mined there extends entirely across Kansas from Doniphan County on the north to Chautauqua County on the south. Mines formerly were situated along nearly the whole extent of this district. Production is from the Nodaway coal which lies within the Aarde shale member of the Howard limestone formation. The thickness of the Nodaway coal is reported to be as great as 30 inches locally in Osage County, but averages about 15 inches. According to Whitla (1940, p. 22), its thickness north of Osage County is nowhere more than 12 inches; in Chautauqua County it is 18 inches thick. The Nodaway coal lies a few feet below the Church limestone member of the Howard formation, which acts as a very effective cover protecting the coal from weathering; good quality coal, therefore, can be obtained at very shallow depths. In stripping operations this limestone cap rock must be removed by blasting.

In the East-Central Kansas coal area the Nodaway coal is from 12 to 30 inches thick and lies a few feet below the main ledge of the Howard limestone. This coal is being mined by stripping and shaft methods. There are more than 20 shaft mines in Osage County near Scranton, Burlingame, and Osage City; they range from 25 to 118 feet in depth and are reported to contain no gas and to be unusually dry. Normally about 8 strip mines are operated in Osage and northern Coffey counties.

Areas of small coal production

The various coal deposits exploited in the four coal fields described above are more or less continuous over a wide region. These and other coal beds in Pennsylvanian rocks underlie the region in eastern Kansas shown in figure 1. Minor coal-producing areas in this region are described in the paragraphs which follow. The seemingly unimportant coal deposits in Kansas, mined on a small scale outside of the four chief coal fields, are described here because of their potential importance as a source of fuel for domestic use in a time of acute transportation problems.

It has been explained that coal beds in the Cherokee shale are mined in and near the outcrop area of the Cherokee rocks and in deep-shaft mines in the Northeastern Kansas coal field. The presence of coal in the Cherokee shale throughout most of eastern Kansas has been determined by study of drilling records. In most areas there are no individual beds which are known to be greater than slightly over one foot in thickness. With the exception of the Angola-Edna area in southwestern Labette County, new fields in Kansas producing Cherokee coal probably will not be developed in the near future. It is to be expected, however, that new developments will occur in southwestern Labette County, and renewed activity may take place in the northeastern Kansas fields.

In northeastern Bourbon County, a coal bed is mined that is about 2 feet thick and occurs in the Little Osage shale member of the Fort Scott limestone formation. The mines in this area are along tributaries of Little Osage river, north and east of Hammond.

A coal bed, called Thayer coal, occurs in the Chanute shale formation and has a maximum thickness of 26 inches near Thayer in eastern Wilson County. This coal bed has been mined near Thayer and near Blue Mound in Linn County.

Two or more thin coal beds in the Lawrence formation have been mined in Leavenworth and Douglas counties. During the depression years that followed 1929 a number of strip, drift, and shaft mines were opened, and coal was sold at local markets. At least one of these, coal beds, the Sibley coal, is present under a thin overburden in much of southern Leavenworth County and Douglas County. The Sibley coal is 18 to 20 inches thick in an area extending from a point 6 miles east of Tonganoxie, Leavenworth County, to a point 12 miles northeast of that city (Whitla, 1940, p. 20). The reported thickness in southern Douglas County is 14 inches.

The Williamsburg coal occupies a position in the Lawrence shale about 40 feet below the Oread limestone. It is 20 inches thick near Williamsburg in southeastern Franklin County. This coal has been mined rather extensively in shallow shafts, slopes, and drifts in the vicinity of Homewood and Williamsburg, Franklin County, and near Quenemo in southeastern Osage County.

As indicated in the section on the East-Central Kansas coal field, the Nodaway coal, extensively mined in Osage County, formerly was mined in a belt that extends across nearly the entire width of the state from Brown County to Chautauqua County. Much shallow coal remains in this belt.

The Elmo coal in the Cedarvale formation has been mined in Brown County near Robinson and White Cloud in Doniphan County. A still higher coal, the Nyman, in the Table Creek formation, has been mined in Wabaunsee County near Dover, and in Nemaha County. A 16-inch coal bed mined a few years ago near Admire, Lyon County, is probably the Nyman coal.

Lignite in the Dakota group

As pointed out by Whitla (1940, p. 25), there are several local lignite beds in Russell, Ellsworth, Lincoln, Mitchell, Jewell, and Cloud counties; they range in thickness from a few inches to three and one-half feet. These beds have been mined for local consumption in the counties named.

Coal production in Kansas

The foregoing paragraphs indicate that Kansas has a relatively large supply of coal in or near many of the more densely populated counties. At present, approximately 70 per cent of the coal produced in Kansas comes from the Southeastern Kansas field, but over a period of years a somewhat larger percentage of the total production, about 80 per cent, has come from that area. In 1934, 91 per cent is reported to have come from the Southeastern Kansas field. Increasing activity in Linn County has brought the Eastern Kansas field into prominence. According to the State Mine Inspector's report, Kansas' total coal production in 1940 was 3,693,455 tons. Table 3 shows the 1940 production by counties.

Table 3—Coal production in Kansas in 1940. [From report of State Mine Inspector.]

| Counties | Tons |

|---|---|

| Crawford | 1,943,581 |

| Linn | 761,425 |

| Cherokee | 589,448 |

| Bourbon | 196,221 |

| Osage | 105,916 |

| Leavenworth | 61,134 |

| Labette | 17,950 |

| Franklin | 14,180 |

| Wilson | 3,100 |

| Neosho | 450 |

| Cloud | 50 |

| Total | 3,693,455 |

The maximum yearly production of coal in Kansas was in 1918, in which year 7,561,947 tons were mined in the state. It is of interest to note that the 1918 figure was nearly reached as early as 1904, when 7,333,307 tons were produced. During the period from 1904 to 1918, with the exception of the year 1910, the state's annual production remained above 5,000,000 tons. Since 1918, there has been a decline due largely to the increased use of oil as fuel. Table 4 shows annual production figures for the period 1921 to 1940 inclusive.

Quality and uses of Kansas coal

Coal produced in Kansas is of bituminous rank, with the exception of the small production of Cretaceous lignite. The bituminous coal is somewhat friable but nearly all is non-slaking. Some pyrite is present, but much of it may be removed by washing and sizing operations. Pyrite is a byproduct of the coal industry in the Southeastern Kansas field. Chemical analyses of coals from the Southeastern Kansas field are published in Bulletin 24, of the State Geological Survey of Kansas, and in Bulletin 12, University of Kansas Experiment Station. According to Young and Allen (1925, p. 191), the British thermal unit value (B.T.U. per pound) of Southeastern Kansas coal ranges from 11,100 to 15,270; that of the East-Central Kansas coal ranges from 10,630 to 12,900; and that of coal from Leavenworth and vicinity from 10,810 to 14,240.Table 4—Annual coal production in Kansas during the period 1921-1940. [Data from U.S. Bureau of Mines.]

| Year | Tons | Year | Tons | |

|---|---|---|---|---|

| 1921 | 3,466,408 | 1931 | 1,986,870 | |

| 1922 | 2,955,170 | 1932 | 1,952,885 | |

| 1923 | 4,443,149 | 1933 | 2,217,622 | |

| 1924 | 4,247,733 | 1934 | 2,508,254 | |

| 1925 | 4,524,251 | 1935 | 2,686,164 | |

| 1926 | 4,416,480 | 1936 | 2,944,028 | |

| 1927 | 4,443,762 | 1937 | 2,892,560 | |

| 1928 | 2,809,724 | 1938 | 2,654,141 | |

| 1929 | 2,975,971 | 1939 | 2,920,000 | |

| 1930 | 2,429,929 | 1940 | 3,693,455 |

Railroads are the largest consumers of Kansas coal. Large quantities are used by power stations, packing plants and other industries. Most of the coal from the smaller fields is used in domestic and industrial heating. According to Pierce and Courtier (Kansas Geol. Survey, Bull. 24, p. 90), coke made from Southeastern Kansas coal has certain disadvantageous features. The coke is rather porous; the cell walls are thin; and it has highly fractured structure and low crushing strength.

Finely-divided coal held in suspension in fuel oil is said to constitute the most compact fuel known, an average bituminous grade containing 1,169,800 B.T.U. per cubic foot. Such "colloidal" fuels are handled and atomized for combustion like fuel oils. They have certain safety factors which ordinary fuel oil does not have.

Reserves

As indicated elsewhere in this report, Kansas coal reserves are large. The present rate of production in the Southeastern Kansas coal field can be maintained for several years. A new deep-shaft field can be opened in southwestern Labette County. The Eastern Kansas field also can continue to produce, but probably not for long at its present rate inasmuch as the recently instituted large-scale electric shovel stripping entails destruction of valuable farm land. The Eastern Kansas field, however, can continue to produce large amounts of coal from shallow shafts and small scale strippings.

There still remains much unmined coal in the Leavenworth-Atchison area, which has the advantage of river transportation facilities. This coal, as indicated in Table 1, must be reached by deep shafts.

A comparatively large amount of coal still can be produced in the East-Central Kansas field, and small-scale mining operations can be reestablished along the strike of coal beds in the East-Central Kansas field throughout most of a narrow belt extending across the state from Brown and Doniphan counties to Chautauqua County. As explained in other parts of this report, several eastern Kansas counties can produce much of the coal needed for local domestic use.

Age and origin of Kansas coals

Kansas coal is of Pennsylvanian (Upper Carboniferous) age, with the exception of the lignite in north-central Kansas which is Upper Cretaceous in age. Coal was formed from the accumulation of plant material in swamps that were probably only a few feet above sea level.

Work of the State Geological Survey of Kansas

The United States Geological Survey in cooperation with State Geological Survey of Kansas has investigated the coal resources of the Southeastern Kansas coal field. Results of these studies were published in 1937, as Bulletin 24 of the State Geological Survey. Coal beds younger than the Cherokee coals were investigated and described in 1940 in Bulletin 32. Surface and subsurface investigations of the geology of eastern Kansas have provided the files of the State Geological Survey with a large body of data pertaining to coal and other stratified rocks.

Additional work pertaining especially to the technology of Kansas coals is planned by the Kansas Geological Survey.

References

Abernathy, G. E., 1937, The Cherokee group of southeastern Kansas: Kansas Geol. Soc., Guidebook 11th. Ann. Field Conference, pp. 18-23, figs. 5-6.

Abernathy, G. E., 1938, Cyclical sedimentation of the Cherokee: Kansas Acad. Sci., Trans., vol. 41, pp. 193-197.

Campbell, M. R., 1917, The coal fields of the United States, general introduction: U.S. Geol. Survey, Prof. Paper 100, pp. 1-33. [available online]

Crane, W. R., 1898, Special report on coal: Kansas Univ. Geol. Survey, vol. 3, part 2, pp. 107-336, pls, 21-70, figs, 4-54.

Haworth, Erasmus, 1895, The coal fields of Kansas: Kansas Univ. Quat., vol. 3, no. 4, pp. 297-309.

Haworth, Erasmus, 1898, Special report on coals: Kansas Univ. Geol. Survey, vol. 3, pt. 1, pp. 1-106, pls, 1-30, figs. 1-3.

Hinds, Henry, and Greene, F. C., 1917, Leavenworth-Smithsville folio: U. S. Geol. Survey, Geologic Atlas of the United States, folio no. 206, pp. 1-13, figs. 1-10, pls. 1-10, 4 maps. [available online]

Knerr, E. Z., 1896, Coal in Atchison County, Kansas: Kansas Acad. Sci., Trans., vol. 14, pp. 216, 217.

Landes, K. K., 1937, Mineral resources of Kansas counties: Kansas Geol. Survey, Min. Resources Circ. 6, pp. 1-102, figs. (unnumbered). [available online]

Lilley, E. R., 1936, Coal: in Economic Geology of Mineral Deposits, New York, pp. 222-278, figs. 99-119.

Moore, R. C., 1929, Kansas coal fields: U.S. Bur. Mines, Tech. Paper 445, pp. 3-7.

Pierce, G. W., and Courtier, W. H., 1937, Geology and coal resources of the southeastern Kansas coal field in Crawford, Cherokee and Labette counties: Kansas Geol. Survey, Bull. 24, pp. 1-122, pls, 1-12, figs. 1-13. [available online]

Saunders, W. H., 1873, Coals in Kansas: Kansas State Board of Agr., Trans. 1872, pp. 387-389.

Thom, W. T., 1932, Status of scientific classification of American coals: Am. Inst. Min. and Met. Eng., Trans., vol. 101, pp. 201-214.

Whitla, R. E., 1940, Coal resources of Kansas: post-Cherokee deposits: Kansas Geol. Survey, Bull. 32, pp. 1-64, pls. 1-5, figs. 1-28. [available online]

Young, C. M., and Allen, H. C., 1925, Kansas coal: Kansas Univ. Bull., vol. 26, no. 5, pp. 1-202; Kansas Univ. Eng. Exper. Sta., Bull. 13; and Chem. Research Div., Bull. 4.

Oil and Gas

by R. P. Keroher

Summary—Oil and gas are produced in 62 counties in Kansas. During 1941 a total of 85,416,561 barrels of oil was produced from 21,784 wells. Proved reserves on January 1, 1942, were 752,610,000 barrels of oil. It is estimated that a maximum of 350,000 barrels of oil per day could be produced for a limited period. Kansas has over 8,000 miles of oil pipe lines with a combined capacity of over 200,000 barrels per day. The state has 27 refineries with a crude oil capacity of 175,800 barrels per day, and 15 natural gasoline plants with a daily production capacity of 321,900 gallons of natural gasoline, During 1940 Kansas produced 85,632,472,000 cubic feet of natural gas. Other Kansas products associated with or derived from petroleum include helium, produced in one plant with an annual capacity of 8,000,000 cubic feet, and carbon black, produced in two plants. Petroleum products, in addition to being used as fuels and lubricants, are employed in the manufacture of explosives, synthetic rubber, and fertilizer.

Oil

Distribution of producing areas

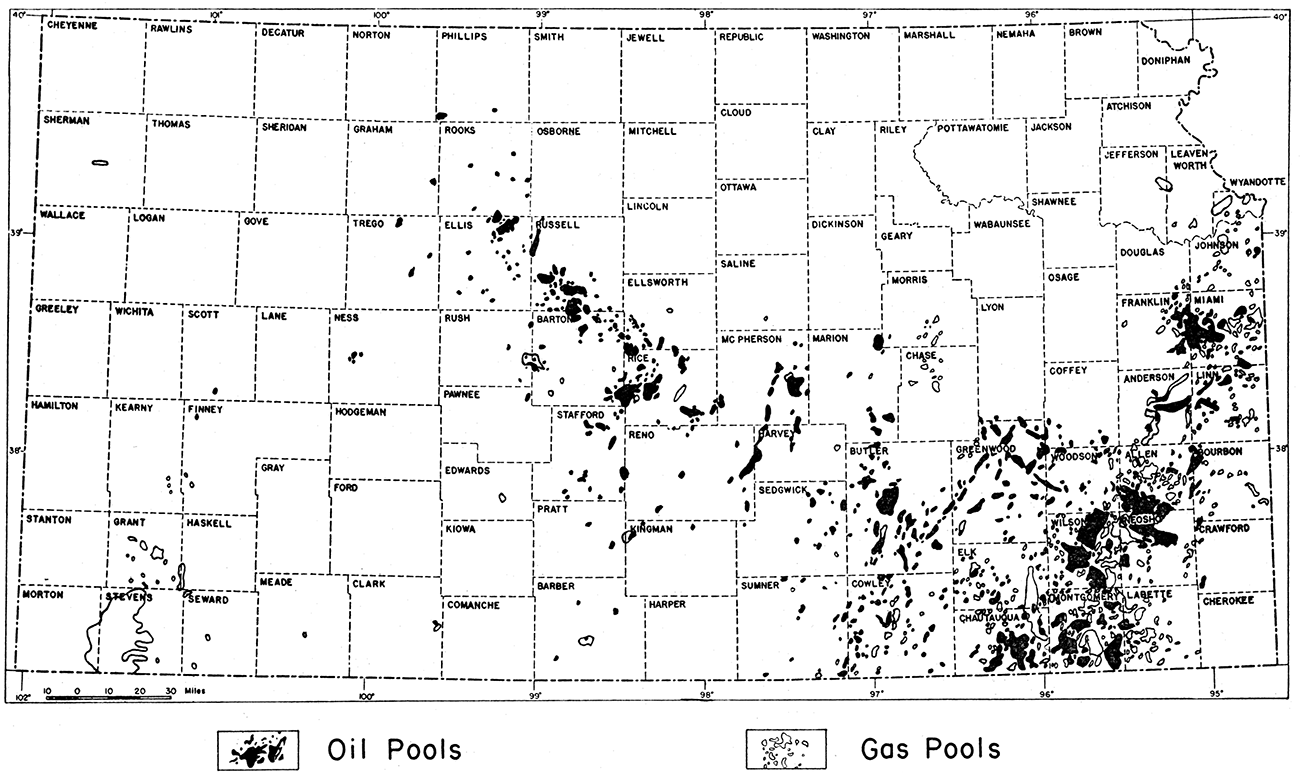

Petroleum and natural gas in commercial quantities are produced in 62 of the 105 counties in Kansas. Of these, 11 counties produce gas only; 19 oil only; and 32 produce both oil and gas. Petroleum and gas production in the state may be subdivided geographically into five districts: (1) east-central Kansas, (2) southeastern Kansas, (3) southern Nemaha Ridge area, (4) Barton Arch area, and (5) the southwestern gas area.

The east-central Kansas district includes a group of 7 counties, 3 of which are situated immediately north of and 4 south of Kansas river. The southeastern Kansas district includes 14 of the 15 counties in the southeastern corner of the state. The nine producing counties here designated as the Nemaha Ridge district lie immediately west of the southeastern district and constitute an area approximately two counties wide which extends in a northerly direction from the southern edge of the state to a point about half way across the state. The Barton Arch district includes 20 counties in the central third of the state and extends in a northwest-southeast direction across the entire state in the form of a belt two to four counties wide. The southwestern gas district includes a group of 8 counties in the southwestern corner of the state. Locations of Kansas oil fields are shown in figure 2.

Figure 2—Map of Kansas showing location of oil and gas fields.

Production statistics

According to data published by the Kansas State Corporation Commission, Kansas produced a total of 85,416,561 barrels of oil during 1941. The production per month in 1941 increased from 5,639,256 barrels in January to 9,811,469 barrels in December. The latter figure is based on the monthly allowable permitted under proration rather than on actual runs. This allowable usually varies but little from actual production.

In December, 1941, a total of 21,784 wells were producing in the state, of which 7,143 were prorated and 14,641 were unprorated. Of the total production for the year prorated wells accounted for 66,638,557 barrels of oil and unprorated wells for 18,778,004 barrels. The average daily production per well was 3.07 per cent of the average daily potential.

According to the Kansas State Corporation Commission's report for December, 1941, the allowable permitted under proration for December consisted of 8,193,458 barrels of oil. Of this amount, 3,304,252 barrels, or approximately 40 per cent of the total estimated production for the month, were allocated to wells having an allowable of less than 1.5 per cent of the daily potential; 658,791 barrels of oil, or 8 per cent of the total, were allocated to wells in which the allowables range from 1.5 to 3 per cent of the daily potential. Thus, almost half of the oil produced in the state comes from wells which are producing at a rate of less than 3 per cent of the daily potential for the entire state.

The unusually strict proration laws in Kansas reduce the rate of production in the state to a point considerably below the maximum possible rate. It is difficult to arrive at an estimate of the maximum amount of oil that could be produced in a year without complete engineering data on every producing unit. It has been estimated (Ingram, 1941, p. 93) that if proration were eliminated entirely, Kansas could produce approximately 350,000 barrels per day. This would result in a total annual production of 127,750,000 barrels, which is 50 per cent greater than the actual production for 1941.

If the 2,480 prorated wells in Kansas were permitted to produce at 3 per cent of the potential, that is, at approximately the same rate as the average of all the wells of the state, the total increase per month would be 3,304,252 barrels and the total yearly increase would amount to nearly 40,000,000 barrels, almost one-half of the total yearly production for 1941.

The state as a whole unquestionably could produce at a rate greatly in excess of 350,000 barrels per day for a limited time, but such an increase probably would result in a greatly lessened ultimate recovery.

Kansas production compared with other statesIn comparison with other states, Kansas in 1941 ranked sixth in production of oil in the United States. This position would have been improved greatly if the production of other states, in which proration is more lenient or non-existent, had been calculated on the same basis as that of Kansas.

Kansas was the only major producing state in the United States in which reserves added during the first half of 1941 were in excess of withdrawals during the same period. The United States as a whole showed a net loss of 16 per cent during this period, whereas Kansas showed a net gain of over 40 per cent (Howard, 1941, p. 39).

The comparatively shallow depth to oil in Kansas is of importance if the elements of expense, time, and material necessary to complete a well are considered. The average depth to oil in three of the six top-ranking states ranges from 400 to more than 1,200 feet greater than in Kansas.

The ratio of dry holes to producing wells in Kansas is approximately the same as in the other highest ranking states.

In addition to the above-mentioned advantageous features of Kansas as a producer of petroleum, the state is strategically located in the central portion of the continent.

Cumulative production

The total cumulative production of crude oil up to and including 1941 was 1,175,881,100 barrels. The daily average production in 1941 was 225,760 barrels of oil. The lowest daily average production for a given month was 181,911 barrels of oil per day in January, and the highest was 316,499 barrels of oil per day in December. The daily average oil production per well in 1941 was 10.34 barrels. Forty-three new fields were added in 1941, and new producing zones were discovered in ten old fields. These discoveries were made in 16 counties, 3 in the eastern part and 13 in the western portion of the state. One county, Kearny, previously had not produced oil or gas. A total of 2,112 wells was drilled in 1941,1,436 oil wells with a total initial production of 1,482,313 barrels of oil, 79 gas wells, and 597 dry holes.

Reserves

The estimated proved reserves in Kansas on January 1, 1942, were 752,670,000 barrels of oil.

Uses of petroleum

By far the most important use of petroleum is in the production of liquid fuel and lubricating oils. Ninety-nine per cent of the liquid fuel produced in the United States is obtained from petroleum; the remaining 1 per cent is derived from coal by means of processes of hydrogenation. Approximately 8 per cent of all motor fuel comes from natural gasoline, 31 per cent from straight-run refining processes, 51 per cent from thermal cracking and reforming processes, 5 per cent from catalytic cracking and reforming processes, and 4 per cent from polymerization and alkylation processes. The last two processes are used in the manufacture of gasoline of high octane rating for use as aviation fuels.

The approximate percentage of the major refined products from crude oil are gasoline 43.9 per cent, kerosene 5.5 per cent, fuel oil 38.8 per cent, and lubricants 3 per cent.

By means of polymerization processes the unsaturated hydrocarbon, butadiene, may be converted to "synthetic rubber," a rubber-like material which has many of the essential properties of natural rubber and in addition many important properties which natural rubber does not possess. Its resistance to swelling and deterioration in the presence of crude oil and gasoline is one of its most important properties.

Glycerine and toluene, petroleum derivatives, are particularly important at the present time because of their use in the manufacture of explosives.

The most important use of ammonia in peace time is in the manufacture of fertilizers. In addition, it is used in water purification, as a corrosion preventative, and in refrigeration processes. During wartime ammonia is important in the manufacture of explosives.

Other products of the petroleum refining industry are asphalt, paraffin wax, petroleum coke, plastics, solvents, synthetic resins, synthetic fibers, artificial leather, safety glass, photographic film, printing ink, cosmetics, medicinal items, antifreeze for automobile radiators, paint remover, dewaxing agent for mineral oil, rotogravure and intaglio ink, and artificial silk.

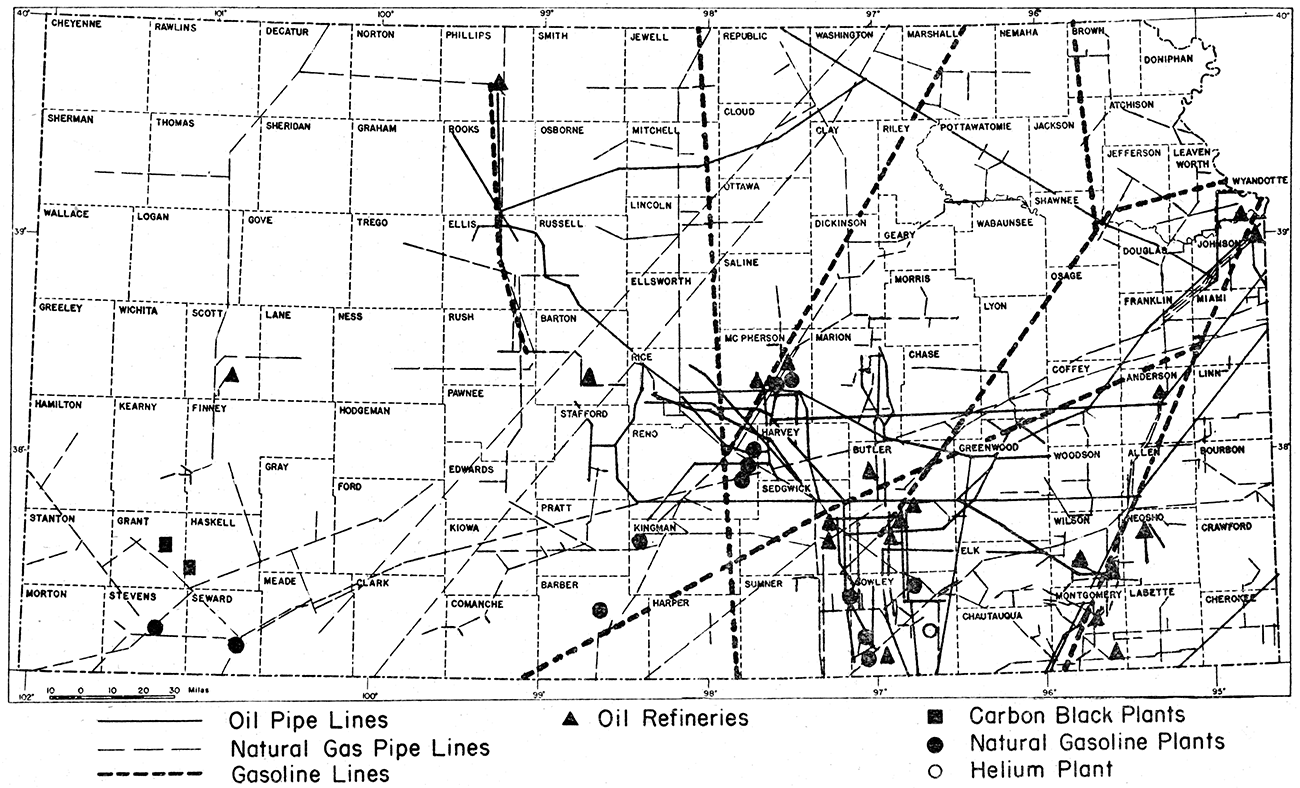

Refineries

Kansas has 27 refineries with a total crude oil capacity of 175,800 barrels per day and a cracking capacity of 92,440 barrels per day. Five of these plants are shut down at the present time. Locations of refineries in Kansas are shown in figure 3.

Figure 3—Map of Kansas showing location of pipe lines, oil refineries, carbon black plants, natural gasoline plants, and helium plant.

Pipe lines in Kansas

Seventeen pipe lines carrying crude oil, with a combined capacity of over 200,000 barrels per day are operating in the state. The daily average Kansas pipe line runs for 1940 were 180,096 barrels of oil. In 1939 Kansas had a total of 8,110 miles of pipe line of which 4,011 miles were trunk lines and 3,999 miles were gathering lines. Of the trunk-line mileage 3,296 miles carried crude oil and 715 miles carried refined products. Although the transportation facilities in the state are adequate for the present rate of production, any considerable increase in production of crude oil would necessitate a corresponding increase in pipe line or other transportation facilities. Locations of pipe lines in Kansas are shown in figure 3.

Work of the State Geological Survey of Kansas

A considerable part of the work of the State Geological Survey of Kansas is directed toward the development of oil and gas resources of the state. The types of work include research, accumulation of statistics, preparation of reports and other publications, and the holding of conferences.

The Survey's files of statistical and geological information include a constantly growing volume of records of wells drilled throughout the state. These logs are available to the public, although they must be consulted in the offices of the Survey. This type of information is extremely important to those in the industry who are interested in extending production to new areas. In many cases the decision to drill or not to drill in a given area is based upon information obtained from records of previously drilled wells. Accordingly, the Survey is making every effort to make this file as complete as possible.

The Survey, in addition to maintaining a file of the logs of wells, also maintains a large collection of samples of drill cuttings from wells drilled throughout the state. These samples are also available for study by any qualified person. For the convenience of operators in the western part of the state a branch office and sample storage warehouse is located at Wichita. Studies of these samples by geologists in the industry add to their knowledge of subsurface conditions and thus influence decisions regarding location of new areas in which to drill for oil and gas.

Oil and gas research work carried on by the Survey is somewhat similar in character to that done by oil companies. Effort is made, however, to avoid as far as possible duplication of work done by the companies. For example, geological work done by oil companies commonly is of a very detailed nature over a limited area. The Geological Survey, on the other hand, is more concerned with problems that are regional or statewide in scope and which supplement the detailed work done by private organizations.

The results of research studies by members of the Survey staff are made available to the public by means of the publications of the Survey. These publications are distributed from the office of the Geological Survey at the University of Kansas upon payment of a small mailing charge. Lists of available publications are sent free upon request.

The members of the staff, of the Geological Survey are called upon very frequently to confer with geologists and operators on their geological problems, This is of especial value in areas where consulting geologists are not available.

Natural Gasoline

Kansas has a total of 15 natural gasoline plants with a daily capacity of 321,900 gallons of natural gasoline. The average production per month for the first three months of 1941 was 6,607,000 gallons. This is approximately 4.5 per cent of the production of the entire United States.

Natural Gas

From 1886 to 1940 the cumulative production of gas in Kansas amounted to 1,643,923,126,000 cubic feet. The production for 1940 was 85,632,472,000 cubic feet. In 1941, 10 gas fields were discovered with an initial potential of 37,531,000 cubic feet. These discoveries were made in 8 counties, 4 in the eastern portion and 4 in the western portion of the state. Locations of natural gas fields in Kansas are shown in figure 2.

During 1940 a total of 96 gas wells were drilled, 72 wells in the western part of the state and 24 in the eastern part. According to available reports, the total potential added during 1940 was 1,330,859,000 cubic feet of gas per day. Of this amount, 41,900,000 cubic feet, or 3 per cent, were reported from eastern Kansas. If complete statistics were available, this figure would be increased considerably.

Helium

Helium is present in small amounts in natural gas from many fields. It commonly constitutes less than 0.3 per cent by volume of the gas. In Cowley County, in the Dexter-Otto district, the helium content of the gas ranges from 1 to 2.1 per cent.

A helium extraction plant at Dexter (fig. 3), now owned by the United States government, has been shut down for several years. Before the plant was purchased by the government, a considerable quantity of helium was sold to the government at $34.70 per 1,000 cubic feet. In 1929 the plant was described as having an annual capacity of 8,000,000 cubic feet of helium.

It is believed that the helium fields in south-central Kansas could be extended.

Carbon Black

Carbon black is made by burning natural gas under conditions in which the oxygen supply is insufficient to produce complete combustion. It is being produced in two plants in Grant and Haskell counties (fig. 3), and other plants in Kansas are being constructed. In 1939, production in Kansas and Oklahoma totaled approximately 20,000,000 pounds.

Carbon black is used mainly in the rubber industry, an average automobile tire containing about two pounds. The material is also used in paints, inks and polishes.

References

Abernathy, G. E., 1940, Oil and gas in Montgomery County, Kansas (with chapters by R. P. Keroher and Wallace Lee): Kansas Geol. Survey, Bull. 31, pp. 1-29, pls. 1, 2, figs. 1-6. [available online]

Dotterweich, F. H., 1941, Natural gasoline yields many by-products: Oil and Gas Jour., April 24, p. 39.

Emmons, W. H., 1931, Geology of petroleum, 2d ed., pp. 1-736, figs. 1-435.

Jewett, J. M., 1940, Oil and gas in Linn County, Kansas (with chapters by Wallace Lee and R. P. Keroher): Kansas Geol. Survey, Bull. 30, pp. 1-29, pls, 1-3, figs. 1-7. [available online]

Jewett, J. M., 1941, The geology of Riley and Geary counties, Kansas: Kansas Geol. Survey; Bull. 39, pp. 1-164, pls, 1-17, figs. 1, 2, tables 1-6. [available online]

Landes, K. K., and Keroher, R. P., 1939, Geology and oil and gas resources of Logan, Gove, and Trego counties, Kansas: Kansas Geol. Survey, Mineral Resources Circ. 11, pp. 1-45, pls. 1-4, figs. 1-8. [available online]

Landes, K. K., and Keroher, R. P., 1938, Geology and oil and gas resources of Rush County: Kansas Geol. Survey, Mineral Resources Circ. 4, pp. 1-31, pls, 1-2, figs. 1-4. [available online]

Lee, Wallace, 1939, Relation of thickness of Mississippian limestones in central and eastern Kansas to oil and gas deposits: Kansas Geol. Survey Bull. 26, pp. 1-42, pls. 1-3, figs. 1-4. [available online]

Leum, L. N., 1941, Chemistry in petroleum refining: Oil and Gas Jour., March 27, p. 85.

Lilley, E. R., 1928, Geology of petroleum and natural gas, 1st ed., pp. 1-524, figs. 1-173, tables 1-62.

Moore, J. I., 1938, Secondary recovery of petroleum, pt. I, Bibliography: Kansas Geol. Survey, Bull. 25, pp. 1-103.

Natural gasoline plants in the United States, 1941, Oil and Gas Jour., April 24, p.92.

Nelson, W. L., 1941, Hydrogenation of coal; insurance for the oil and automotive industries: Oil and Gas Jour., May 8, p. 55.

Oil and Gas Journal, 1942, Annual Number, January 29, pp. 1-239.

Oil and gas field development in the United States, 1941, National Oil Scouts and Landmens' Assoc., Yearbook 19-11 (Review of 1940), pp. 1-664.

Petroleum development and technology: Am. Inst. Min. Eng., Trans., 1925-1941 (yearly volumes).

Refineries operating in the United States, 1941, Oil and Gas Jour., March 27, p.189.

Stephenson, E. A., and Moore, J. I., 1941, The Otis gas and oil pool, Rush and Barton counties, Kansas: Kansas Geol. Survey, Bull. 38, pt. 12, pp. 1-44, pls. 1-17. [available online]

Ver Wiebe, W. A., 1941, Exploration for oil and gas in western Kansas during 1940: Kansas Geol. Survey, Bull. 36, pp. 1-109, pl. 1, figs, 1-40.

Prev Page--Forward, Introduction || Next Page--Metals

Kansas Geological Survey, Geology

Placed on web Nov. 2, 2017; originally published May 9, 1942.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/41_3/03_fuels.html