KU Petroleum Engineering Field Trip

A group of KU Petroleum Engineering students and faculty participated in a field trip the Wellington Field CO2 injection site on April 19th, 2016. Berexco and KGS staff gave the students a first-hand look at the active injection operations and how the CO2-EOR flood technologies are being applied at Wellington Field.

Dana Wreath and Jason Bruns show the group a typical down-hole packer that is commonly used in their Mississippian wells. For many, this was a rare opportunity to see an example of this tool up-close and hear a description of how the equipment is installed.

Adam Beren, President of Berexco, LLC. gave an informative presentation to the group about the history of Wellington Field and oil production trends in Kansas. A copy of the presentation is provided for reference.

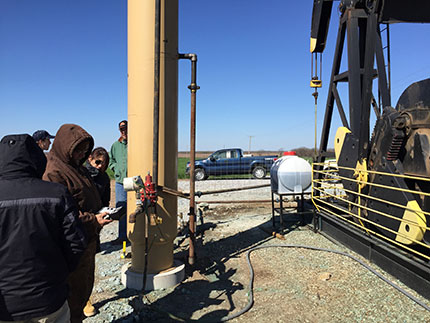

Brett Blazer, field engineer with Berexco, shows the group how oil cut and fluid level tests are conducted at each well in front of Wellington Unit #73.

Berexco field crew conduct a fluid level measurement using an echo meter while KGS, KU, and other Berexco visitors observe.

D) Brett Blazer calibrates the echo meter for the fluid measurement readings.

Measurements from the fluid level test are printed from the echo meter. Brett Blazer reviews the output for completeness.

Brett Blazer demonstrates how produced fluid is measured and estimated from Wellington Unit #73.

Roy Shepherd takes an oil cut reading from Wellington Unit #73. He explains that the foamy appearance of the oil is unusual, and is indicative of the presence of CO2 from the reservoir. These observations are continually noted from sampling performed around the field, and details are recorded into a KGS data page for the Wellington CO2 flood.

The crew views the CO2 monitoring gauge installed at Wellington Unit #61, along side the gas-phase separator that was installed to capture any produced CO2.

Dana Wreath and Jason Bruns explain how total produced fluid is estimated from Wellington Unit #61. Note the appearance of the produced fluids entering the barrel that is used to conduct the on-site tests.

A view of the new S. Erker stock tank battery that was added to capture the additional production from the CO2 wells.

Charlie Miller measures the percent CO2 composition of the vented gas at the S Erker tank battery. About 5.4% CO2 was detected, indicating the arrival of CO2 in one of the surrounding wells. This information, along with finer details recorded from each well, will help researchers identify the behavior and characteristics of the CO2 plume within the reservoir.

Jason Bruns vents excess CO2 vapor from the KGS 2-32 wellhead.

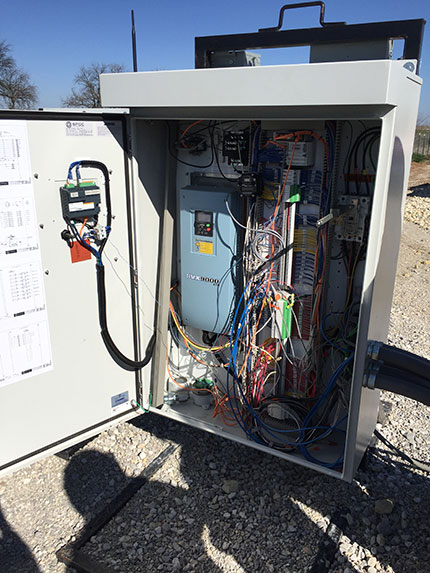

A demonstration to explain how a pressure buildup of gaseous CO2 can be vented from CO2 storage tank lines. Safety valves and emergency shutoff systems are in place throughout the entire series of lines.

Jason begins venting gaseous CO2 trapped within storage tank lines from one of the available devices.

Dana Wreath walks through the journey of CO2 as it travels from one of the six on-site storage tanks down to the Mississippian reservoir through the KGS 2-32 well head. Throughout this process, he stops to note a number of gauges and meters that have been installed to monitor temperature, pressure, and other important data that will be used to evaluate the CO2 injection.

Adam Beren gives closing remarks to the group, reminding the students that Berexco promotes its outreach program by offering internships to many current and graduating KU Petroleum Engineering students each year.