Prev Page--Pennsylvanian || Next Page--Subsurface Rocks

Part 2--Mineral Resources of Elk County

by Robert Kulstad, Norman Plummer, Walter H. Schoewe, and Edwin D. Goebel

Introduction

The known useful mineral resources in Elk County include oil, gas, limestone, shale and clay, sandstone, and gravel. Ground water, another important mineral resource, is discussed in Part 3 of this report. Natural gas has been produced in the county since 1901 and oil since 1902 (Jewett, 1954, p. 202). Both hydrocarbons still are important there. The county has very large reserves of limestone, sandstone, shale and clay, and gravel. Although several thin beds of coal occur here, there is no coal mining. Locations of limestone quarries are shown on Plate 1, which is primarily an areal geologic map. Oil and gas developments in the county are shown on Plate 2, which map shows locations of all wells drilled for oil and gas of which the State Geological Survey has record, the status of each well, the location of pipelines, and the outlines of established oil and gas fields as of 1956. For all wells known to be producing, the producing zone is indicated, and the age of the oldest rock penetrated is indicated for all dry holes. Geographic and cultural features are also shown on this map.

Economic Geology of Outcropping Rocks

Properties, sequence, and age of outcropping rocks are discussed in Part 1 of this report. Their distribution is shown on Plate 1.

Limestone

Limestone crops out extensively in Elk County. The separate beds have been quarried at several places in the county. The limestone quarry operating near Moline is one of the largest of its kind in central United States; therefore, limestone constitutes one of the county's most valuable natural resources. The locations of the Moline quarry and of the several inactive quarries are shown on Plate 1.

The potential value of a limestone deposit depends on numerous factors: the quality of the rock, the thickness of the bed, the availability of a market, and the expense necessary to quarry the rock. One of these factors could outweigh all others under special circumstances; therefore, any of the many limestone beds exposed in Elk County might have value at some time. There are some beds, however, that because of quality and thickness seem more likely to become valuable than others and therefore are discussed further.

The Plattsmouth limestone

In Elk County the Plattsmouth limestone member of the Oread formation averages approximately 15 feet thick. It has uniformly thin wavy beds and a relatively high content of calcium carbonate (Table 1). Detailed description of the Plattsmouth is found elsewhere in this report. No physical test of this limestone in Elk County is included in this report, but this limestone is quarried extensively for commercial purposes in other parts of the state. There are several small abandoned quarries in the Plattsmouth limestone in the county.

The Ervine Creek member of the Deer Creek formation and closely associated overlying limestone beds in the Topeka formation form a deposit approximately 40 feet thick in Elk County. The Ervine Creek is about 20 feet thick and is wavy bedded much like the Plattsmouth limestone. The Ervine Creek is the rock quarried at Mobine. The overlying limestone beds, assigtied to the Topeka formation, contain some shale beds but consist mostly of thick-bedded blocky limestone. Under present quarrying procedure, the Topeka beds are treated as overburden. Detailed descriptions of this total thickness of limestone can be found elsewhere in this report.

Chemical data of the Ervine Creek and associated beds, as shown in Table 1, reveal a relatively high content of calcium carbonate. Physical tests of the Ervine Creek and the overlying Topeka beds were made by the Kansas State Highway Commission in 1946 on samples obtained from the face of the quarry operating near Moline. Figure 7, which shows the results of these tests, indicates the specific gravity, Los Angeles and soundness numbers, and the place where each of the samples was taken in the quarry. The specific gravity of the rock is the ratio of its weight to the weight of an equal volume of water. It gives some indication of the porosity of the rock. The Los Angeles number indicates a degree of resistance to abrasion. A detailed description of this test is found in American Society for Testing Materials Standards for 1955; nevertheless, some description seems necessary here. The Los Angeles testing machine itself is essentially a rotating barrel containing several baffles. After the sample is crushed to the size of coarse aggregate, a specified amount is placed in the machine. The machine is then run at a specified speed for a specified number of revolutions. The size of the aggregate is measured on screens both before and after the test. The loss in weight, expressed as percentage of the original weight, is the Los Angeles number. A high number would therefore indicate a soft rock, and a bow number a hard one. The soundness number is an expression of the resistance of the rock to freezing and thawing. Various tests have been devised to measure this property of construction materials. One of these is actual freezing and thawing of the rock aggregate a specified number of times under circumstances comparable to weather conditions. The soundness is expressed as a decimal part of 1, which number would indicate a perfect specimen.

Rock from the Moline quarry is used as aggregate in road paving and airplane runways, as railroad ballast, road metal, and agricultural limestone. In bate 1955, officials of the company operating the quarry reported that the quarry employed about 40 people and that it had an average daily production of approximately 6,000 tons. The production capacity, of course, exceeds this figure. Approximately 95 percent of the production of the quarry is transported by rail. The quarry serves a small local market but chiefly supplies many parts of the state where rock suitable for construction materials is not available.

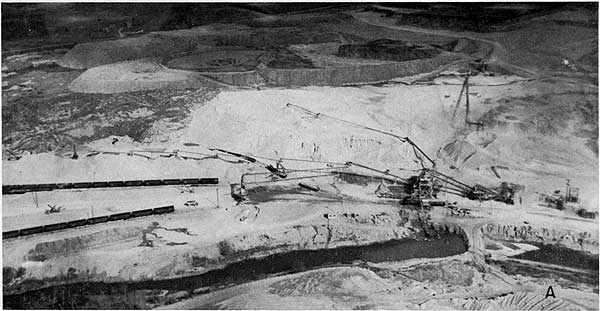

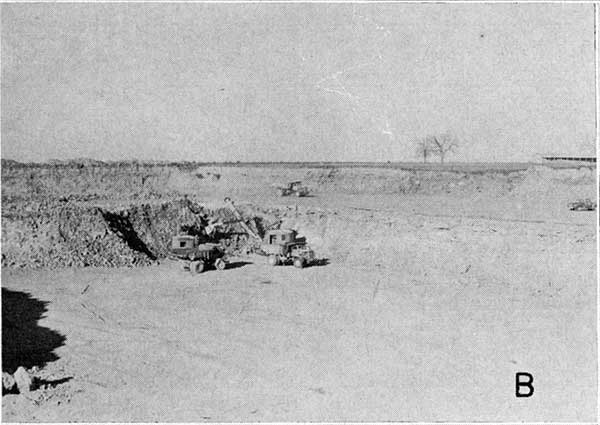

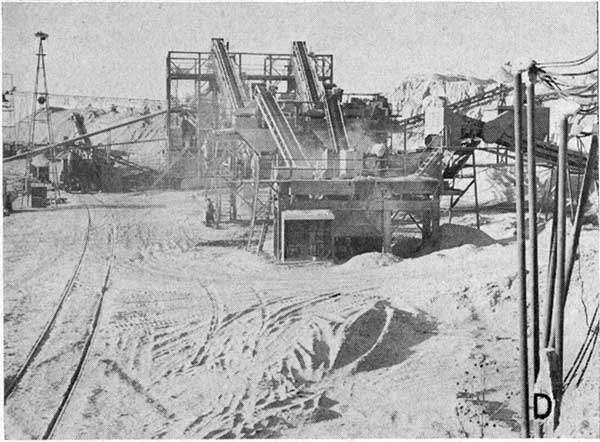

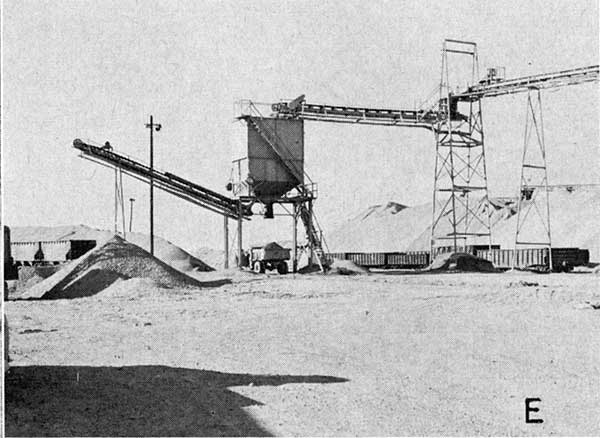

Several pictures of the Moline quarry may be seen in Plate 4. As of 1956, the average thickness of the overburden was 25 feet. Much of it is limestone; consequently, its removal is a quarrying operation in itself. After the removal of the overburden, a bed of rock (the Ervine Creek limestone) 20 to 22 feet thick is available for production (Pl. 4A). Vertical shot holes are made with wagon drills from the top of the exposed ledge of quarried rock. These are loaded and shot. Blasted rock is loaded with power shovels into trucks (Pl. 4B) that transport it to the primary crusher located near the quarry face (Pl. 4C). A series of belts transports the crushed rock from the primary crusher over a considerable distance to the rest of the plant, where it undergoes further crushing, screening, and washing (Pl. 4A, D). Finished rock products either are loaded directly for transportation or are stockpiled (Pl. 4E). The plant makes extensive use of conveyor belts for both its loading and stockpiling.

Plate 4--The Moline Quarry of Concrete Materials and Construction Co. A. Aerial view of quarrying, crushing, and loading operations. (Picture courtesy of Max F. Oelschlaeger.)

B. Loading trucks at quarry face.

C. Unloading truck at primary crusher.

D. Subsequent crushing, screening, and washing operations.

E. Loading and stockpiling of the fished product.

The Red Eagle limestone

The Red Eagle formation constitutes a third limestone of potential value. The formation consists of a lower member, the Glen Rock limestone; a middle member, the Bennett shale; and an upper member, the Howe limestone. According to O'Connor and Jewett (1952), however, in southern Greenwood County and farther south, the Red Eagle consists almost entirely of limestone. Where the Red Eagle crops out in western Elk County (Pl. 1), it averages about 20 feet thick. Chemical data pertaining to the Red Eagle, as shown in Table 1 from one sample, show a high content of calcium carbonate. A more detailed description of this limestone unit is found elsewhere in this report.

Gravel

Cherty limestones, especially the Florence, Wreford, and Foraker, of the upper part of the Elk County stratigraphic section crop out in the western part of the county. Upon weathering, these limestones yield great quantities of chert fragments that accumulate in creek beds throughout the vicinity of the outcrop area. These chert gravel deposits have provided considerable material for secondary roads in the county.

Shales from five localities were tested to determine their general ceramic properties and their bloating characteristics in the production of lightweight concrete aggregate. Sample EK-1 represented all of the clayey portion (22 feet) of the Robbins shale; sample EK-2 the entire thickness (32.5 feet) of the Heumader-Jackson Park shale; sample EK-3 the upper 17 feet of the French Creek shale; sample EK-4 the upper 31 feet of the White Cloud shale; and sample EK-5 the upper 22 feet of the Severy shale. All these shales except the Severy are predominantly clayey. The Severy is somewhat silty, as indicated by a silica content of 62.50 percent (Table 4).

The data obtained from standard ceramic tests (Table 2) indicate that all the shales tested are suitable for the production of heavy clay products such as brick, hollow tile, quarry tile, and drain tile. All the samples tested fired to some shade of red. Optimum firing temperatures range from cone 07 (about 1780 deg. F) for sample EK-1 to cone 02 (about 2015 deg. F) for sample EK-5. The optimum temperature for sample EK-2 is cone 05 (about 1890 deg. F), and for EK-3 and EK-4 cone 03 (about 1990 deg. F).

All the shales except the Severy would require some care in drying because the high clay content tends to produce warping. These same shales would also have to be fired somewhat slowly because they are "tight" and as a consequence do not oxidize easily.

The bloating tests for lightweight aggregate were made in a batch-type rotary kiln (Plummer and Hladik, 1951). The samples were fired to incipient fusion, and unit weights were determined on samples crushed through rolls set 3/16 inch apart. This crushing produced an aggregate of slightly more than 3/8 inch maximum diameter. Unit weights of the crushed samples ranged from 42.3 pounds per cubic foot for sample EK-1 to 61.3 for sample EK-2 (Table 3). This is below the limit of 75 pounds per cubic foot set by the American Society for Testing Materials for lightweight bloated shale aggregate, but unit weights in the range of 40 to 50 pounds per cubic foot are usually regarded as more desirable. This limitation would exclude samples EK-2 and EK-4 from the more desirable shales for use in the production of lightweight aggregate.

Table 3--Results of lightweight aggregate bloating tests on Elk County shales.

| Sample no. |

Time in kiln, minutes |

Firing temperature, degrees F. | Unit weight, lb. per cu. ft. |

Color of crushed aggregate |

||

|---|---|---|---|---|---|---|

| Initial softening |

Formed soft roll |

Maximum attained |

||||

| EK-1 | 9 | 2130 | 2190 | 2200 | 42.3 | Dark gray |

| EK-2 | 9 | 2190 | 2210 | 2260 | 61.3 | Gray |

| EK-3 | 8 | 2160 | 2170 | 2250 | 53.2 | Dark gray |

| EK-4 | 10 | 2180 | 2220 | 2240 | 59.8 | Dark gray |

| EK-5 | 9 | 2110 | 2180 | 2260 | 44.6 | Gray |

The five shales tested do not represent all the Elk County shales having possible ceramic value, but they do represent a quantity of good grade shale in excess of any probable demand of the future.

Coal

Coal occurs at several horizons in Elk County, but as far as is known only the Nodaway and Elmo coals, both in the Wabaunsee group of rocks (stratigraphic column, Pl. 1), have been mined. Schoewe (1946) presents data on the history, location of mines, production, and reserves of coal in the Wabaunsee group.

The Nodaway coal occurs in the Howard limestone formation above the Bachelor Creek limestone and below a limestone bed 4 to 5 inches thick, which is separated by about 1 foot of black fissile and gray shale from typical massive, well-jointed Church limestone above. The coal crops out at places along the edge of the Howard limestone escarpment, especially between Howard and Mound Branch of Elk River. The Nodaway coal is thin, and as far as known it was mined in a drift mine in the SE 1/4 sec. 21, T. 30 S., R. 10 E., where according to Whitla (1940, p. 36) the coal is 18 inches thick. About 4.5 miles north of Howard, in sec. 11 and 12, T. 29 S., R. 10 E., it is probably no more than 5 inches thick where a very small amount of coal was taken from several shallow pits.

Most of the coal mined in Elk County was the Elmo coal, which occurs just below the Rulo limestone (stratigraphic column, Pl. 1). The Elmo coal mines, four strip and one shaft, are in the valley of Mound Branch less than 5 miles southwest of Howard, in sec. 20 and 21, T. 30 S., R. 10 E. The coal ranges from 16 to 18 inches in thickness and was reported mined last in 1922.

According to published data, the cumulative coal production from Elk County totaled 3,615 tons from 1894 to 1902. It is known that coal was mined in the county for local domestic use as early as 1877; mining activity was discontinued in 1922. Total cumulative production of coal in the county is estimated at 10,000 tons, most of which was Elmo coal.

Elk County contains approximately 544 acres of band underlain by an 18-inch Nodaway coal bed. This amounts to about 1,220,000 tons of coal, of which at beast 50 percent, or 610,000 tons, is recoverable. The amount of land underlain by Elmo coal that is 18 inches thick is 986 acres (1.4 square miles) and contains 2,020,000 tons of coal, of which 75 percent, or 1,515,000 tons, is recoverable. Elk County, therefore, has a total recoverable measured coal reserve of 2,125,000 tons.

Prev Page--Pennsylvanian || Next Page--Subsurface Rocks

Kansas Geological Survey, Geology

Web version July 2002. Original publication date July 1958.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/General/Geology/Elk/03_mine.html