Prev Page--Introduction || Next Page--Douglas Group

Geography

Location of the Area

Rocks assigned to the Douglas group crop out in eastern Kansas in a belt 6 to 20 miles wide extending from eastern Atchison county to southeastern Chautauqua County (fig. 1). The northern part of the area lies adjacent to the Leavenworth-Kansas City industrial district. Topeka is only a short distance west of it. Lawrence and Ottawa are located within the Douglas outcrop area, and the Sunflower Ordnance Works, south of Kansas river near De Soto, is at the eastern margin of the area. Coal beds in the Douglas group constitute a supplementary source of coal for these cities and many smaller towns and for rural needs.

Figure 1. Map of eastern Kansas showing outcrop area of Douglas rocks. Topographic base map by R. C. Moore.

Topography and its Relation to Coal Mining

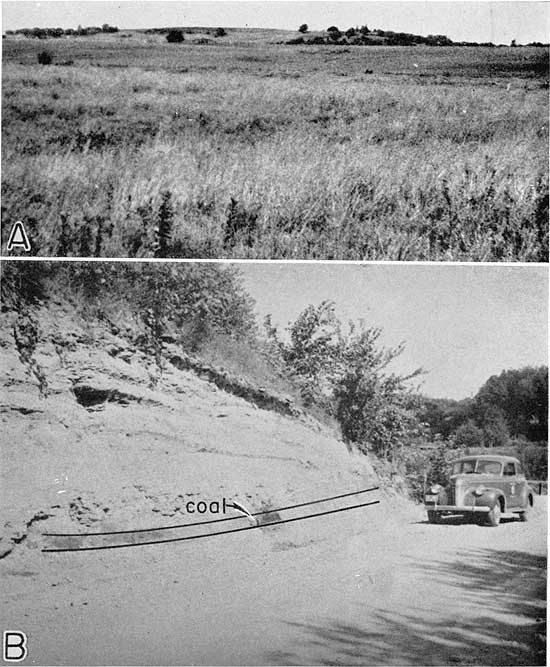

The northern part of the outcrop area of Douglas rocks lies in the Dissected Till Plains section, and the southern part lies in the Osage Plains section of the Central Lowlands. The area considered in this report lies in the Woodson and Jackson districts of the Eastern Kansas groundwater region (Moore, 1940, pp. 53, 54). Elevations above sea level in the outcrop area vary from about 800 feet along Kansas river to about 1,100 feet in southwestern Franklin County. The rocks dip westward beneath the surface, at a low angle. The western boundary of the outcrop is marked by the escarpment of the Oread limestone (pl. 1A, 2A, and 3B). This escarpment commonly rises 50 to 100 feet above the plain to the east of it, underlain by rocks of the Douglas group. In some places erosion remnants capped by the Oread limestone stand high above the plain east of the main escarpments. The local sandstone bodies common in the Lawrence shale and the Stranger formation are relatively nonresistant to erosion in the northern part of the area in which the Douglas rocks crop out. East of the Oread escarpment, these sandstone bodies form part of the broad rolling plain that slopes gently westward, and they are bounded on the east by gently or steeply rolling slopes leading down from the uplands. In the southern part of the area of outcrop, sandstone bodies belonging to the Douglas group are resistant escarpment-making and upland-forming rock units. The Haskell and Westphalia members of the Stranger formation are the only limestones in the Douglas group that markedly affect the topography. They support low rolling hills and only locally form precipitous escarpments.

Plate 1. A. A view in eastern Coffey County, Kansas. The topography shown is characteristic of the area of exposure of Douglas and lower Shawnee rocks. The escarpment in the background is held by Oread limestone. B. Exposure of the Lower Williamsburg coal and adjacent rocks, NW cor. sec. 29, T. 16 S., R. 18 E., Franklin County, Kansas.

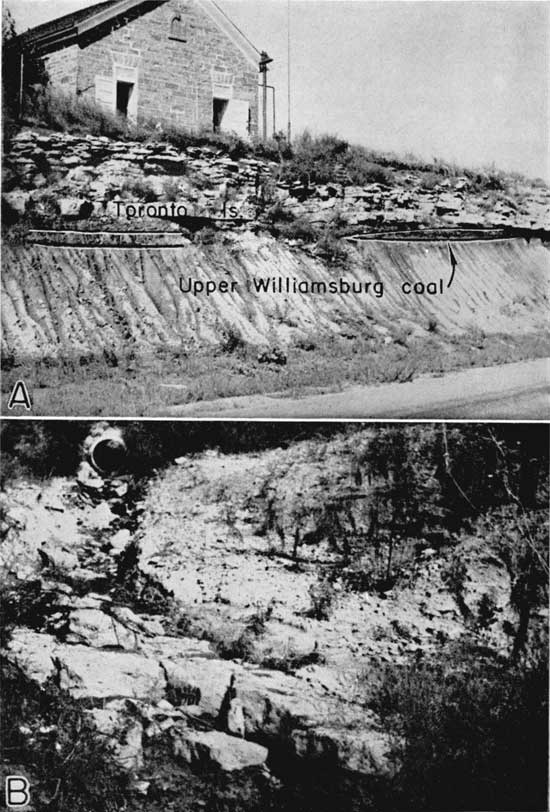

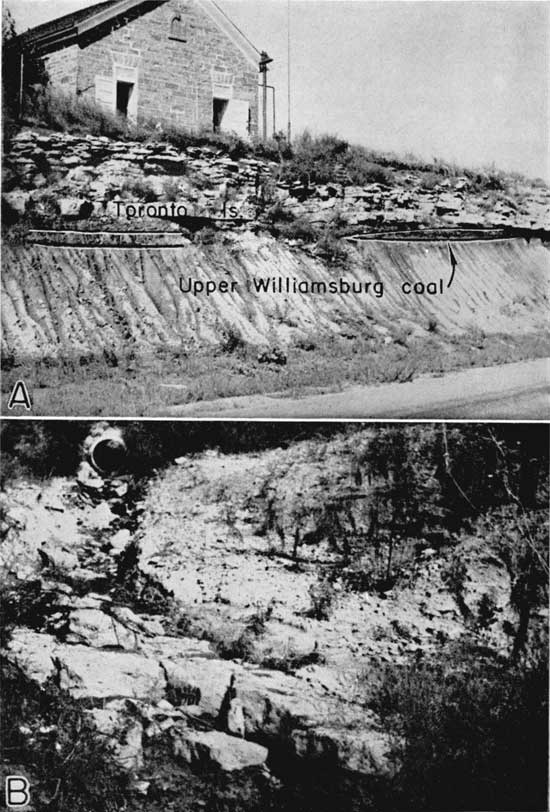

Plate 2. A. Exposure at NW Cor. sec. 35, T. 25 S., R. 13 E., Woodson county, Kansas. B. Exposure of Amazonia (?) limestone at NW cor. sec. 32, T. 25 S., R. 14 E., Woodson County, Kansas.

Plate 3. A. Tim's strip pit and limestone quary, NE sec. 35, T. 25 S., R. 13 E., Woodson County, Kansas. B. Exposure, NW cor. sec. 35, T. 35 S., R. 13 E., Woodson County, Kansas.

The low rolling topography resulting from erosion of Douglas rocks supports a rather widespread vegetation cover, and little gullying has occurred. Good exposures are rare and of small extent except along roads and places where gullying has removed the soil cover. As a result, the soft and easily weathered coal beds are not well exposed. Mining of the coal beds in the Douglas group has been limited to areas where exposures of coal indicate the presence of relatively widespread deposits. In some places gullying along escarpments produced by a resistant bed of rock has periodically exposed coal beds. Vegetation commonly tends to cover exposures of coal by accumulated plant debris and by holding the soil cover. A lack of vegetation cover may lead to exposure of the coal. Erosion by creeks or streams commonly exposes coal beds which crop out along the banks. Many of the coal mines of the Douglas group were located by the discovery of such exposures or by the finding of a coal bed during the digging of a well. Coal beds in this group are local in extent; consequently, they vary in thickness within very short distances and they may also change considerably in quality from place to place. Detailed geologic explorations of these coal deposits may be expected to reveal formerly unsuspected localities in which mining conditions are most favorable. The most important factors in determining the value of a coal bed are thickness, quality, and overburden. Because of the existing physiographic conditions along the stream channels, there are few exposures of coal along the valley of Stranger Creek in Leavenworth County, Kansas River and Wakarusa Creek in Douglas County, Marais des Cygnes River in Franklin County, and Neosho River in Coffey County.

Transportation Facilities

There are many good roads throughout the area covered by this report. Every town is located on an improved or paved highway. All towns not having rail connections lie close to one of the major truck lines, and the area is well traversed by railroads (fig. 2).

Figure 2. Map of east-central Kansas showing railroads, highways, and coal areas.

Coal used in eastern Kansas is transported primarily by rail. Only a small part of the coal tonnage used in eastern Kansas is freighted by motor truck. During the present war period, with trucking activities inhibited by rubber shortage and by gasoline rationing, the railroads will be expected to carry even more. Shipments of coal for civilian use probably will not take priority over shipments of vital war materials, so the transportation of coal to private consumers will be an increasing problem during the coming war winters.

Recent Trends in Coal Consumption in Eastern Kansas

At the close of the last century there were many small coal mines in eastern Kansas. Although many of them were operated by farmers for home use, some of the mines were operated as business ventures to serve local consumers, and coal from a few of the mines was used as fuel for locomotives and sold at distant markets. Demands for coal increased as the steam engine was developed for use in threshing small grain. These coal beds occurred over a wide area and were easily mined, so they furnished farmers with cheap fuel for traction engines and home use. The replacement of steam tractors by gasoline engines caused a steady decline in production from these coal fields. Wages paid to coal miners increased; improved railroad facilities encouraged the importation of cheaper coal from outside; and cheaper strip methods of mining, which were more readily adapted to the thicker Cherokee coal beds, were developed. The development of large-scale strip-mining and cleaning operations allows the mining concerns of southeastern Kansas to produce at less cost a clean coal with which coal from mines in the Douglas group cannot ordinarily compete. No attempts have so far been made to clean Douglas coal, and it is improbable that such small-scale production can justify the cost of treating the coal by washing or other expensive methods. Bituminous coal from Kansas, southwestern Missouri, and Oklahoma have largely taken over the market formerly supplied from deposits of the Douglas group. Many former users of lump bituminous coal have converted their furnaces to stoker units. The use of semianthracite coal from Arkansas because of its prolonged burning time and low ash content has been increasing. It must be admitted that improper cleaning and marketing of some of the coal from the Douglas group has placed it in an uncertain light as to quality; and, consequently, the demand for it has become less in some areas. It is probable that proper screening of coal from certain beds might considerably improve its quality and thereby help to reestablish a market.

It should be remembered that a coal bed which cannot profitably be mined commercially at present may become a useful fuel source later, particularly under war conditions. Mining of economically marginal coal beds is more critically influenced by small fluctuations in prices, changes in labor conditions, and changing transportation conditions than are thick extensive beds of coal. Therefore, coal beds which have not been important under peacetime conditions may become important sources of fuel, at least locally, under wartime economy. Coal which would not be burned if conditions were normal may become the best fuel available for heating homes. In this case, a previously non-available coal may become an available and much-desired coal. For these reasons the considerable reserves of coal in Douglas rocks may have great future importance.

Mining Methods

Development of Mining Methods

The first method of mining coal from Kansas rocks was a primitive form of strip-mining which may be aptly termed "crop-working." Possibly the Indians were the first to employ this method of removing coal from the outcrop by means of crude hand implements. The white man's needs were soon too great to be satisfied in this way. The amount needed and the desire to get the most coal by expending the least effort led to development of stripping operations. Manual labor was supplemented by animal labor, and horses were replaced in turn by power shovels in order that the overburden might be more easily, quickly, and economically removed from above the coal bed. This method is still employed in places where the amount of overburden is not too great to be removed economically. If the thickness and quality of the coal justify underground mining operations, tunnels may be dug along the coal bed. These workings are horizontal or slightly inclined, depending on the attitude of the beds; the coal is removed through the tunnels or entries. This method, called "drift" or "slope" mining, is the one most commonly employed in mining coal beds of the Douglas group. In many areas the coal has been extensively mined by this method for a distance of several hundred feet from the outcrop.

Such outcrop working is often referred to as "gophering." When coal is no longer available along the outcrop of a coal bed, vertical shafts may be sunk to the part of the coal bed that remains. The coal is removed from rooms along the entries, and thence hoisted to the surface through the vertical shaft.

Coal beds in rocks of the Douglas group are comparatively thin, and the coal is removed by small-scale mining operations. These factors have led to development of mining operations (fig. 3) which remove a maximum quantity of coal in the easiest manner, with little regard to efficiency of recovery or to safety of the miners. Thus, small-scale mines which are distinctive because they utilize such simple methods have been developed in eastern Kansas and southwestern Missouri. It is desirable to record brief descriptions of these methods, because they may be employed generally during the war period when such coal beds as described in this report may become important sources of coal for eastern Kansas communities.

Figure 3. Generalized block diagram showing types of coal mining operations employed in east-central Kansas.

Strip Mining

A primitive form of strip mining, or crop-working, was the first method used in mining coal from beds in east-central Kansas. Such practice of digging coal from creek banks or hillsides as it is needed is still prevalent in winter time on many farms. This method is applicable only to small-scale production. Stripping consists of removing the shale, limestone, and other rock--the overburden--from above a coal bed. The first stripping was done by hand, as crop-working was expanded. Because this method was too laborious and slow, miners soon began to use teams of oxen and horses. Trees and other vegetation were removed, and hard cap rock, if present, was broken by blasting and then removed. Black powder was used as an explosive in this work, because the powder is safer to handle than dynamite. After the cap rock was removed, the underlying softer rock was plowed and the loosened material scraped off. The coal bed was finally exposed after many alternations of plowing and scraping. Removal of overburden was accomplished with the aid of animal labor. The exposed coal was then taken up by hand.

As steam and other power-driven shovels became practical, they replaced use of animals in coal stripping. Power shovels work back and forth removing strips of overburden several hundred yards wide and trench down to the coal bed. The shovel may then be used to take up the coal. The thickness of coal beds and the nature of the enclosing rocks establishes limits of economical strip mining. In the case of the coal beds of the Douglas group these limits have been exceedingly narrow, because the coal beds are commonly rather thin. Mining of this kind has been confined to areas lying in valleys or along hillsides, and the coal beds commonly stripped lie 5 to 30 feet below the surface and below relatively thick limestone beds. For these reasons, coal beds of the Douglas group have not been extensively mined by strip mining method.

Drift and Slope Mining

In localities where the coal available at the surface has been exhausted by stripping or is of poor quality, drift or slope mining is generally employed. If the tunnel driven in along the coal bed is nearly horizontal, it is known as a drift, but if noticeably inclined, it is known as a slope. These tunnels or entries are started at points on hillsides or valley walls in places where coal "blossoms" (exposed edges of coal veins) have been found. Most mines in Douglas coal beds have been small and operated for only a short period of time. Because they are commonly worked by a few miners recovering the coal by use of picks without aid of mechanized equipment, the mines are called "pick" mines. Even this type of mining has not been extensive because the coal beds are thin.

Entries are made only as large as necessary; they are commonly about 50 inches high and 30 inches wide (fig. 4). Since most mines ordinarily operate for only a few years, there is little need for bracing or timbering the entries. An entry is dug into the hill along the coal bed, and the coal is recovered from rooms driven from either side of the main entry. The number of miners working at any time determines the number of rooms being dug off the main entry at that time. Each miner works one room. The main entry is pushed into the hill and the side entries of the first two rooms, one to the right and the other to the left, are turned off at right angles to the main entry at a point 22 feet or more beyond the edge of the area of weathered coal. These rooms generally are opposite one another, although, in some instances, all rooms may be turned off on one side. In some cases the first two side entries may be driven for a distance of 40 or 60 feet and then turned at right angles to run parallel to the main entry. The coal is then recovered from between the main and two side entries and from either outside wall of the side entries.

Figure 4. Diagrammatic cross section across main entry in "pick" mines, Quenemo mining district, east-central Kansas.

The coal is removed by chain-working along a long wall face (fig. 5). Three inches of shale, clay, or "soapstone" is removed from beneath the coal by the use of a pick or, as in several mines, by undercutting machines. The coal is blasted by a charge of black powder or dynamite placed at the junction of the coal and the overlying shale or other roof material. Black powder is used by some operators because it is safer than dynamite and because the slower dissipation of its percussion shatters the coal less than does dynamite; however, dynamite has come into widespread use in recent years. The coal which is not blown down is wedged down later by hand. The height of the rooms from which the coal is taken is only 3 or 4 inches greater than the thickness of the coal bed. The miners may occasionally work in rooms which are 16 or less inches high. The floor of the room is at the same elevation as the floor of the main entry. The coal is pushed or kicked to the entry at the center of the room by miners who lie on their sides as long as they work in the room. At the entry the coal is loaded into small cars that run on wooden rails. These cars have 6- or 8-inch wheels and stand about 14 or 16 inches high. They are pushed to the mine entrance by hand.

Figure 5. Diagram showing order of making cuts in recovering coal by chain mining method used in "pick" mines, east-central Kansas.

When the coal is removed, soft wooden posts 16 to 18 inches high are set as props under the roof (fig. 4). The props are placed within 3 feet of the face of the coal. The "gob," or waste dirt and coal, is thrown back into the propped room. In time, the roof, which is commonly of soft clay or silty shale, settles down over the props and then settles onto the gob. The roof is well supported to a distance within 10 or 15 feet of the face, and beyond this it usually rests on or near by the gob. Front sag is allowed because of the 3 feet of unsupported roof between the front row of props and the coal face. The weight of this front sag helps kick down the coal after it is undercut, thereby facilitating its recovery. Side entries are spaced at intervals of 45 feet along the main entry. Each room is therefore 45 feet wide and extends 22 feet on either side of the entries. The first rooms are started near the front of the main entry and subsequent rooms project progressively farther into the hillside (fig. 6). The rooms in some cases extend as far as 1,000 feet on either side of the main entry, although they are seldom pushed farther than 200 or 300 feet. As the last rooms worked do not extend as far as do the previous rooms, the coal face approaches nearer the main entry in the back part of the mine. Common practice in this longwall method is to remove all of the coal as the rooms are driven, but in some cases supporting pillars of coal about 30 inches wide are left between rooms. Such pillars must be cut through at intervals in order that the air tunnels are continuous. The roof, in most cases, is allowed to fall down onto the gob after the coal is removed, and only entries and air tunnels are kept open. Ventilation is accomplished by sinking a vertical shaft which has its upper end higher than the entrance to the main entry of the mine. From the base of this shaft a tunnel is dug to one of the side entries. This air outlet shaft is several hundred feet from the main entrance. The difference between density of the air owing to temperature differential in the mine and outside the mine causes circulation. If this difference is not sufficient to insure circulation of air, fans or blowers are installed.

Figure 6. Generalized diagram of plan of "pick" mines in the Quenemo district east-central Kansas.

Provisions made for drainage depend upon the problems encountered. Few, if any, mines are free of water. In some mines water causes difficult problems.

Because of its cheapness pick mining by the drift and slope method is most often used in mining coal from beds described in this report. Drift or slope mining methods can be used as long as the coal face is relatively close to the mouth of the mine. When the coal face has receded a distance greater than 500 or 600 feet, the time and labor consumed in getting coal from the coal face to the surface is so great that the mine must be abandoned. As a common practice, coal is mined during the winter and the mine abandoned in the spring. After abandonment, mines become full of water and the roofs of rooms and entries fall in. As a result, abandoned mines cannot be opened again, and the following winter new entries are made at points 100 feet or more away from the sites of the old mines. This haphazard method of mining has caused the exhaustion of much good coal mining area without recovering more than one-fourth of the available coal.

Shaft Mining

Shaft mining has been used more successfully than other methods in mining Douglas coal beds, because it allows the miner to remove coal economically from a much larger area. Under most favorable conditions a drift mine allows working of only a semicircular coal face. In contrast, shaft mining allows working of a full circle coal face (fig. 7). Early attempts to use room and pillar methods failed because such methods required that large quantities of gob be removed and that all rooms be supported until the pillars were withdrawn. In most mines the roof is composed of soft silt and clay shale which caves badly, thereby making the room and pillar method expensive and dangerous.

Figure 7. Generalized diagram of plan of shaft mines in the Williamsburg mining district, east-central Kansas.

Thickness of the coal beds and the nature of containing rocks has influenced the development of a mining method--a modification of longwall mining--which is peculiar to eastern Kansas and southwestern Missouri coal fields. A shaft is dug from above to the coal bed, at a point where coal can be mined to a distance of 1,400 or 1,500 feet from the shaft. In preparing to remove the coal, miners cut a circular coal face around the shaft and dig two main entries that extend from opposite sides of the shaft some distance into the coal bed. They cut the circular coal face in order that the mining machine can move continuously in a circular path along the coal face, thus causing a recession of the coal face from the shaft. This method of mining allows the miner to throw the gob into the empty rooms behind, where it remains, and allows the roof to slowly sag until it rests on the floor of each room. This is known as the advancing longwall method of mining.

Undercutting and blasting loosens the coal for its removal. An electric undercutting machine, developed by a manufacturer in Topeka, is used frequently. The machine operates on current brought to the machines from a near-by power line by means of insulated cables, or from a portable power plant. A sort of band saw, composed of bits set in a moving chain,, which cuts a 3-inch "kerf" under the coal, accomplishes the undercutting. The chain runs around a frame which extends approximately 32 inches from the side of the machine. The motor and the cutting frame are mounted so that the entire unit can be moved along the coal face. The machine is drawn up to the coal and the "sumping cut" made by swinging the machine so that the cutter is forced into the coal. Then, by pulling the machine along the coal face, a continuous cut under the coal is made. The machine, moving in a circle, travels completely around the room. These machines can be used in rooms as low as 16 inches in height.

A 3-inch high kerf, extending for a distance of 32 inches from the coal face, is cut under the coal bed (fig. 7). Black powder is exploded in holes drilled immediately above the coal bed. The coal, blown down by the explosion, is kicked to the haulage ways where it is loaded into cars. The coal that is not blown down by the explosion is wedged down by hand. After removal of the coal, the rooms are only 3 inches higher than the thickness of the coal bed (fig. 7). Miners, lying on their sides, work in rooms of this height. The low ceiling is necessary because the height of the rooms greatly affects the rapidity with which the roof settles. No more rock is removed than is necessary, because danger becomes greater as the height of rooms increases.

As the coal face recedes from the shaft, cross entries are driven in directions approximately perpendicular to that of the two main entries. These cross entries do not leave the main entries at opposite points but are offset at regular intervals (fig. 7). The roof settles more nearly as a single unit in cases in which the cross entries are not opposed or in line with one another. Cross entries on the same side are spaced at intervals of 40 feet. There generally are four cross-entries on each side of the main entries. Very little timbering is necessary because the entries and passage ways are kept open by constant use.

The outside row of props set next to the coal face constitute the "rib." The rib props are set after the undercutting machine has passed and the miners have removed the coal from above the last cut. After each round of the undercutting machine, the rib is moved out 32 inches. Props of the rib are removed ahead of the mining machine and replaced after it passes. The props remain standing in the room after the coal is removed. The soft clay and shale of the roof and floor are slowly deformed and the roof comes to rest on the gob in the room. The roof, in an area extending from 10 to 15 feet from the coal face, is best supported just in front of the coal face where a second sag often occurs. This slight sag throws the weight of the overburden onto the coal and helps to break it down. If mining is abandoned for several days, the roof breaks off at the coal face and settles down onto the floor of the rooms. Extended shutdowns result in cave-ins which cause expenditures of considerable labor before operations can be resumed. Longwall mining allows the miners to keep the room at the coal face cleared.

Ventilation is accomplished by passing a current of air around the coal face. A ventilator shaft is dug at a distance of about 300 feet or more from the main shaft. One of the first cross entries then is driven outward to the ventilator shaft. A short entry is made from the intake air tunnel to the adjacent cross entries. The air is then sent by this short entry to the coal face room. The air current is forced around the coal face room and out through one of the cross entries on the opposite side of the mine to the main shaft which serves as an outlet shaft. The air is forced by a fan located at the inlet shaft. Ventilation is controlled by the hanging of blankets which act as doors at the entrances of entries. These blankets are shifted at will so that any part of the mine can be ventilated (fig. 7).

This method of mining differs only slightly from longwall mining as practiced in Osage, Leavenworth, and Linn counties.

Prev Page--Introduction || Next Page--Douglas Group

Kansas Geological Survey, Geology

Placed on web Jan. 28, 2009; originally published Sept. 1943.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/46/03_geog.html