Kansas Geological Survey, Bulletin 165, pt. 3, originally published in 1963

Next page--Appendix--Test-Hole Logs and Ceramic Properties

Originally published in 1963 as Kansas Geological Survey Bulletin 165, pt. 3. This is, in general, the original text as published. The information has not been updated. An Acrobat PDF version of the bulletin (5 MB) is also available.

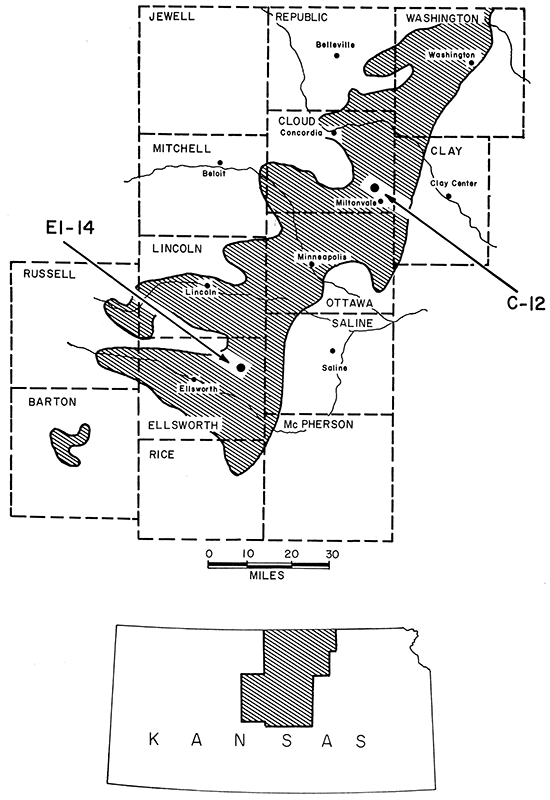

In two areas in Kansas (Ellsworth County, sec. 25, T. 15 S., R. 7 W., and Cloud County, sec. 12, T. 8 S., R. 2 W.) the Dakota Formation was systematically drilled to determine the availability of light-color-burning clay. Beds of light-burning clay lack continuity in Cloud County in the upper part of the Dakota; however, in the Ellsworth County area the lower part of the formation contains well-defined, continuous layers of light-burning clay. The lack of continuity of one and the well-defined continuity of the other is not confined to the test localities but extends over areas of several square miles. These conditions are not typical of clays in these two stratigraphic positions, but they illustrate the extreme variations in extent and continuity of beds that can be expected in the commercial exploitation of clays in either the upper or lower beds of the formation. Both test areas have clay deposits suitable for structural clay products.

In 1949 a chemical manufacturer showed interest in using Kansas clay as a parting agent for ammonium fertilizers and as a diluent for insecticides. On the basis of information gathered from pit samples taken in 1938 through 1940 and reported subsequently (Plummer and Romary, 1947), two locations, in sec. 25, T. 15 S., R. 7 W. (Ellsworth County), and in sec. 12, T. 8 S., R. 2 W. (Cloud County), were chosen as possible sources of supply (Fig. 1). Test holes were drilled during the spring and summer of 1949.

Figure 1--Index map of test-hole areas C-12 and EL-14 and outcrop of the Dakota Formation.

To be useful for the above applications a clay deposit must have the following characteristics: (1) light-gray to almost white color, (2) minimum overburden, and (3) large size. None of the clay sampled from the two locations met all of the requirements. The main deterrent was lack of whiteness in the raw clay. Clay deposits in both areas have potential as a raw material for the manufacture of red and buff structural clay products.

The purpose of this report is to describe the ceramic properties of selected clays from the two locations and the general geology of the deposits.

The areas were investigated and sampled by R. G. Hardy, then of Mineral Products Company, Kansas City, Missouri, and Norman Plummer, State Geological Survey of Kansas. [Mr. Hardy is now on the staff of the Industrial Minerals Division of the State Geological Survey.]

Clay, silt, and sandstone described in this report are in the Dakota Formation. The subdivision of the Dakota Formation and its relationship to underlying and overlying formations is shown below.

| Cretaceous System | |||

| Upper Cretaceous Series | |||

| Graneros Shale | |||

| Lower? Cretaceous Series | |||

| Dakota Formation | |||

| Janssen Clay | |||

| Terra Cotta Clay | |||

| Lower Cretaceous Series | |||

| Kiowa Shale | |||

Geologists working in Central Kansas use the unofficial term "Andrews section" to designate the lower, predominantly gray part of the Terra Cotta Clay. The Andrews section is well exposed on the Andrews Ranch 1 to 2 miles east of Kanopolis both in clay pits of the Acme Brick Company and on natural outcrops. In this report, the predominantly red-mottled upper two-thirds to three-fourths of the Terra Cotta Clay will be designated "upper Terra Cotta" and the lower, thinner, predominantly gray part the "Andrews section."

The Janssen Clay is made up of clay, siltstone, and sandstone, as well as carbonaceous material, lignite, limonite, hematite, and siderite. The rocks are predominantly gray with some irregular yellow stains; shades of red are rare.

The Terra Cotta Clay also is made up of clay, siltstone, and sandstone. In the upper two-thirds to three-fourths of the member (upper Terra Cotta), coloring from iron compounds is more evident than in the Janssen and red-mottled gray clay is a distinctive feature. The sandstone beds commonly are yellow, although gray to nearly white colors are not uncommon, and all weather to brown. The lower part of the Terra Cotta (Andrews section) is similar in appearance to the Janssen, but it probably contains less clay and more sand and silt. The Andrews section is easily distinguished from the upper Terra Cotta in the field. Commonly clay beds of the Andrews section are gray with irregular yellow stains, and the sandstone and siltstone tend to be more evenly bedded with less staining from ferric iron compounds than beds in the upper Terra Cotta. Beds near the Kiowa-Dakota contact in the lower part of the Andrews section commonly contain compounds of ferrous iron that tend to produce brownish colors in the fired clay.

Members of the Dakota Formation show many similar characteristics. Most of the clay is structureless and slakes rapidly in water. Shaly bedding is not common in the clay, though lamination may produce a shaly appearance on some weathered outcrops. Kaolinite is the dominant clay mineral in the Dakota Formation in Kansas. Illite is present, but usually does not exceed 25 percent except in the lower part of the Andrews section. Recent work (P. C. Franks, personal communication) indicates that some of these lower clays in central Kansas may contain as much as 50 percent illite. Whether or not these high-illite clays are in the Dakota Formation, or represent a mixed transition between Dakota Formation and Kiowa Shale has not been definitely established; in many locations the contact has been fixed arbitrarily. In the Kiowa Shale below the Dakota Formation and in the Graneros Shale above, illite is the dominant clay mineral. Kaolinite is rarely found in the Graneros Shale, but as much as 50 percent of it has been observed in the upper part of the Kiowa Shale. Montmorillonite may occur in both. Thin beds of nearly pure montmorillonite are found in places in the Graneros Shale.

Siderite (FeCO3) pellets, usually less than one-eighth inch in diameter, are characteristic of unweathered clay from the Dakota Formation. Upon weathering, the siderite normally alters to limonite or other iron oxides. Both pyrite (FeS2) and selenite (CaSO4 · 2H2O) are found scattered throughout the Dakota Formation. The red-mottled clay rarely, if ever, contains pyrite; selenite crystals are common on the outcrop. Both pyrite and selenite are found in the gray clay, especially in that of darker gray color.

Calcareous-cemented sandstone and siltstone, locally called "quartzite," occur as concretions in zones throughout the formation; rarely, the cementing material is barite or silica. The zones seemingly have local continuity, and exposures of the quartzite follow definite directional trends, generally northeast-southwest.

Accurate information is not available concerning the total thickness of the Dakota Formation in Ellsworth and Cloud Counties. In a relatively small area southwest of Russell in Russell County, the Dakota ranges in thickness from 213 to 300 feet (Swineford and Williams, 1945). It is estimated that the minimum thickness of the Dakota Formation in Ellsworth County is greater than 200 feet, but that it probably does not exceed 300 feet. The maximum combined thickness observed for the Dakota Formation and the Kiowa Shale in Cloud County is 400 feet (Bayne and Walters, 1959), but the thickness of the Kiowa Shale is believed to be less than 100 feet. The Dakota Formation may exceed 300 feet in thickness in the northwestern corner of Cloud County, but it is probably less than 300 feet in the C-12 area (Fig. 1).

The upper 120 feet of the Dakota Formation that was penetrated by test borings in the C-12 area (Cloud County) includes the Janssen Clay (at the top of the Dakota Formation and in contact with the overlying Graneros Shale) and slightly less than half of the upper Terra Cotta Clay. The lower 109 feet of the Dakota Formation that was explored by test drilling in the EL-14 area (Ellsworth County) includes about one-third of the upper Terra Cotta and all of the Andrews section. The lowermost beds of the Andrews section are in contact with the Kiowa Shale (underlying the Dakota Formation). Thus the beds discussed in this report constitute the full thickness of the Dakota Formation, except for approximately 50 feet of the section near the middle of the formation.

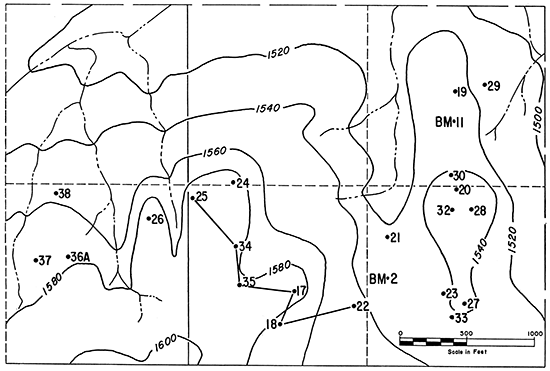

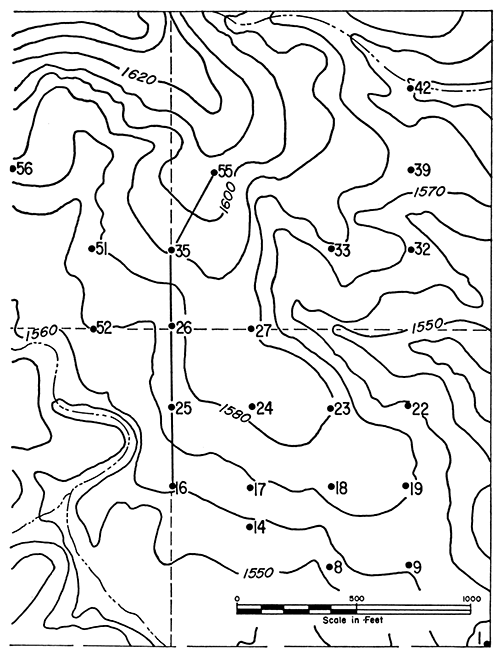

Most test holes for the Cloud County area (C-12) were drilled along contour lines (Fig. 2); the Ellsworth County (EL-14) test holes were drilled on a grid pattern (Fig. 3).

Figure 2--Test-hole pattern and topography at C-12 (Cloud County), showing location of test holes described in Appendix and line of section shown in Figure 4. C-12 area is E2 SE sec. 11 and SW sec. 12, T. 8 S., R. 2 W.

Figure 3--Test-hole pattern and topography at EL-14 (Ellsworth County), showing location of test holes described in Appendix and line of section shown in Figure 5. EL-14 area is E2 NE and E2 W2 NE sec. 25, T. 15 S., R. 6 W.

Holes were drilled using a 2-inch fish-tail rotary bit. Samples obtained by this wet rotary drilling are susceptible to contamination from overlying layers and from the recirculated clay mixed with the drilling water. Much of the buff-firing clay showed a pinkish tint when fired. This tint is attributed to contamination from overlying red-firing layers. Buff-firing clay taken from pits in the same area (Plummer and Romary, 1947) did not show this pink tint. Furthermore, for the 120 feet of clay sampled, the total thickness of buff-firing clay obtained from the pit samples exceeded the thickness obtained by rotary drilling. Undoubtedly most of the clay listed as pink-firing would have fired to some shade of buff if uncontaminated samples could have been recovered. The drilling log of each test hole is listed in the Appendix.

One representative set of graphic logs through each test-hole area, C-12 in Cloud County (Fig. 4) and EL-14 in Ellsworth County (Fig. 5), illustrates the clay stratigraphy. On the left side of each test-hole column is recorded the raw sample (unfired) color; on the right side is recorded the fired color (cone 02, or 2075°F) and the percent water absorption (five-hour boil) for each interval from which sample bricks were made. Samples were not retained for ceramic testing from all of the intervals. It was impossible to recover samples from some of the intervals, and others were worthless because of contamination by caving or by the drilling mud. Samples deeply stained with red, brown, or yellow were obviously red-firing and were not retained.

Figure 4--Graphic logs of selected test holes in C-12 area. (Locations of test holes shown on Figure 2; for test-hole numbers, see Appendix, Cloud County.) [Larger PDF version of this figure available.]

Figure 5--Graphic logs of selected test holes in EL-14 area. (Locations of test holes shown on Figure 3; for test-hole numbers, see Appendix, Ellsworth County.) [Larger PDF version of this figure available.]

The highest elevation at the top of the test holes is about 1600 feet above sea level in the C-12 area, and 1610 feet in the EL-14 area. Stratigraphically, the upper bed in the Ellsworth County area is possibly as much as 200 feet below the highest elevation in the Cloud County area because of the north-northeast component of the regional dip.

The normal sequence of beds in the Janssen is, from the top downward: gray sand or silt, dark-gray clay, and lighter gray clay. The upper Terra Cotta Clay commonly is gray with red mottling. The normal sequence of beds in the lower part of the Terra Cotta (Andrews section) is the reverse of that in the Janssen. From the top of the Andrews section downward the order is: light- to medium-gray clay, dark-gray clay, and sandstone or silt. The Kiowa Shale, where present, underlies the last-named beds.

The test-hole logs (Appendix) show much greater complexity than the above description would imply, but the relationship indicated provides a useful means for generalizing the complexity, and it explains, for example, why red-mottled clay underlies the beds of gray clay in the C-12 area, whereas the gray beds underly the red-mottled ones in the EL-14 area.

Throughout the outcrop area of the Dakota Formation in central and north-central Kansas, the thickness and continuity of the clay and sandstone beds show considerable lateral variation despite the fact that the general character is fairly constant. In general the beds of the Janssen Clay are fairly continuous, although thicknesses vary greatly. Field evidence indicates that the lithology of the upper Terra Cotta, characterized by red-mottled clay, possibly ranges locally from 90 percent clay to 90 percent sandstone and silt. Deposits of buff-firing clay have been found within the upper Terra Cotta, but little is known about either their lateral or vertical distribution. The beds of the Andrews section seem to be much less continuous and constant in thickness than those of the Janssen. Furthermore, the Andrews section may be very thin, or possibly missing in some areas. Where exposed, however, the Andrews section is characteristic enough to be recognizable.

The test-hole logs (Appendix) seem to contradict the above statements because neither the Janssen Clay in Cloud County (C-12) nor the Andrews section in Ellsworth County (EL-14) are typical of the Dakota Formation in Kansas. Although inconsistency is typical of the Dakota Formation, the Janssen at C-12 and the Andrews section at EL-14 are more aberrant than usual.

The Janssen Clay in the C-12 area of Cloud County, in contrast to the Andrews section in the EL-14 area in Ellsworth County, is made up of irregularly-shaped bodies of clay, sand, and silt of uncertain magnitude, showing great variation in thickness and lateral extent. The greatest local variability known in the Janssen Clay was observed in this area. In addition to the variability in size and shape of the deposits, irregular beds of red-mottled clay were observed in the Janssen, or at the horizon of more or less typical Janssen clays. Although Janssen beds at C-12 are certainly not typical of the Dakota Formation as a whole, the irregular shape and extent of the beds and the presence of red-mottled clay in stratigraphically anomalous positions persist in adjacent sections 2, 13, 14, and 23. Similar conditions have been observed in: (1) sec. 32, T. 7 S., R. 2 W., 3 miles northwest of C-12, (2) sec. 15, T. 5 S., R. 2 W., 13 miles northwest, and (3) sec. 14, T. 8 S., R. 4 W., about 8 miles to the west. Similar irregularities have also been noted in western Washington County, western Ottawa County, and eastern Hodgeman County. However, irregularities of this character apparently are confined to relatively small areas, and extensive beds of high-grade clay have been found adjacent to them.

Thin bands of white kaolinite have been observed in the Janssen at many localities (Plummer and Romary, 1947, p. 62), but in the C-12 area a kaolinite band was clearly present in only one test hole. It is probable that the kaolinite was present in other holes but was not detected because of the thinness of the bands and mixing caused by the drilling method.

The persistence of widespread and commonly thick beds of red-mottled clay is the most characteristic feature of the upper Terra Cotta. Gray clays, firing to colors ranging from nearly white to buff and sufficiently extensive to be of economic importance, occur within the red-mottled series of beds. The gray, light-firing-color clays constitute only a minor part of the otherwise dominantly red-mottled series, which apparently is continuous across the outcrop belt of the Dakota Formation in Kansas, except where irregular beds of sandstone and siltstone occur. In a few areas in central eastern Ottawa County, sandstone is dominant.

Upper Terra Cotta clays were found in the upper part of the higher elevation test holes at EL-14 and above the gray clay series. The same type of red-mottled clay was found in the lower part of the test holes at G-12 and below the dominantly gray clays of the Janssen. No doubt significant variations could be found within the red-mottled upper Terra Cotta clays, but any difference is difficult to detect because of the general uniformity of appearance. The red-mottled clays, although they have excellent working and firing characteristics, fire to colors ranging from dark buff to dark red. Such clays are usually of less economic importance than the white- or buff-firing clays. However, some red-mottled clay in the upper Terra Cotta fires to a dark-buff color and is refractory. One clay sampled 2 1/2 miles southeast of C-12 in the SW sec. 31, T. 8 S., R. 1 E., Cloud County, is the most refractory clay from the Dakota Formation tested in our laboratory (Plummer and others, 1960). The clay had a pyrometric cone equivalent of cone 31 1/2, which classifies the clay as a high-duty refractory fireclay according to A.S.T.M. [American Society for Testing and Materials] designation C-27-58T. It is possible that similar clay will be found throughout the Dakota Formation in Kansas when additional samples are tested.

A total thickness of 120 feet of the Dakota Formation was penetrated by test borings in the C-12 area. Earlier work in this general area (Plummer and Romary, 1947) indicated that at least 70 feet of the upper Terra Cotta, mainly red-mottled clay, is to be found below the bottom of the lowest test hole. In comparison with the C-12 area, red-mottled clay is less abundant at the EL--14 locality and does not occur in continuous, thick beds. However, previous work (Plummer and Romary, 1947) in Ellsworth County has revealed large deposits of red-mottled clay. One such deposit about 3 miles northeast of EL-14 is over 90 feet thick and extends over an area of at least 1 square mile. A composite sample of the entire thickness fired to a dark-buff color.

The most complete development of the Andrews section observed by the authors in Kansas is in the EL-14 area. The EL-14 beds can be traced for several miles, and the total thickness in this area is the maximum thickness so far observed in Kansas. The clay, silt, and sandstone beds are comparable in lithology and sequence with beds previously sampled (Plummer and Romary, 1947) in Ellsworth County in: (1) sec. 28 and 29, T. 15 S., R. 7 W. (Andrews' Ranch), 4 miles west of EL-14, (2) sec. 34, T. 16 S., R. 8 W., 11 miles southwest, (3) sec. 19, T. 15 S., R. 6 W., 1 mile northeast, and (4) sec. 14, T. 15 S., R. 6 W., 5 miles northeast of EL-14. Clay deposits of commercial size have been found in all four locations listed above and have been used in the manufacture of buff-firing bricks.

In the EL-14 area, more than one fairly continuous band of white kaolinite was detected in the Andrews section. Similar bands have been observed (Plummer and Romary, 1947) in the lower beds of the Dakota in other areas, but at the EL-14 locality a larger number and more continuous bands were found than elsewhere in the Andrews section.

General procedures for ceramic testing were as follows:

Sample preparation: Clay was ground to pass a minus 20-mesh screen.

Making of test bricks: Sufficient water was added to the clay to convert it to a formable plastic material. All samples were mixed and molded by hand. After forming, test bricks were weighed in the plastic state and shrinkage marks, 7.00 cm apart, were marked.

Drying: Bricks were air dried for 48 hours, then placed in a drying oven at 110°C for 24 hours to complete the drying. After drying, the bars were weighed to obtain dry weight, and distance between shrinkage marks was measured to obtain dry shrinkage. From these data, percent water of plasticity and percent drying shrinkage were calculated.

Firing: Firing was done in a Kanthal wound electric furnace to cone 2 (2075°F) and cone 4-5 (2129-2156°F) in an oxidizing atmosphere. After cooling, the test bricks were measured for firing shrinkage, tested for cold and hot water absorption, weighed for ignition loss calculations, and tested for hardness relative to steel. The results of the ceramic tests are listed in the Appendix in conjunction with the test hole logs.

Calculation: The following relationships were used:

1. Water of plasticity

[(plastic weight - dry weight) / dry weight] X 100 = percent water of plasticity

2. Loss on ignition

[(dry weight - fired weight) / dry weight] X 100 = percent loss on ignition

3. Drying shrinkage

[(plastic length - dry length) / dry length] X 100 = percent drying shrinkage

4. Firing shrinkage

[(dry length - fired length) / dry length] X 100 = percent firing shrinkage

5. Total shrinkage (includes drying and firing shrinkage)

[(plastic length - fired length) / dry length] X 100 = percent total shrinkage

6. Percent water absorption. Bricks were saturated by two methods: 24-hour soak in cold water and 5-hour soak in boiling water.

[(saturated weight - dry weight) / dry weight] X 100 = percent absorption

7. Saturation coefficient

[percent absorption (cold water) / percent absorption (hot water)] = saturation coefficient

Hardness relative to steel: Fired test bricks were scratched with a standard triangular file and rated: softer than steel (STS), hard as steel (HS), and harder than steel (HTS).

Fired color: The fired color varies with the oxidizing or reducing conditions in the kiln, so only the general shade of the color is given.

A comparison of areas C-12 and EL-14 shows the lithologic variability that exists within the Dakota Formation. The buff-firing clay deposits in the C-12 area are erratic in thickness and lack continuity. Contrastingly, the EL-14 area has extensive, thick zones of buff-firing clay and a large tonnage of clay could be removed from a small area. Neither area appears to have excessive quantities of pyrite present in the buff-firing clay. The clay is suitable for production of high quality structural clay products.

A conservative estimate of the amount of buff-firing clay in each of the areas is 5 million tons. Assuming a weekly consumption of 1000 tons of clay, each area could support a structural clay plant for at least 100 years. No use of the red-firing clay has been considered in this estimate.

Bayne, C. K., and Walters, K. L., 1959, Geology and ground-water resources of Cloud County, Kansas: Kansas Geol. Survey, Bull. 139, p. 1-144. [available online]

Plummer, Norman, Bauleke, M. P., and Hladik, W. B., 1960, Dakota Formation refractory clays and silts in Kansas: Kansas Geol. Survey, Bull. 142, pt. 1, p. 1-52. [available online]

Plummer, Norman, and Romary, J. E., 1947, Kansas clay, Dakota Formation: Kansas Geol. Survey, Bull. 67, p. 1-241.

Swineford, Ada, and Williams, H. L., 1945, The Cheyenne Sandstone and adjacent formations of a part of Russell County, Kansas: Kansas Geol. Survey, Bull. 60, pt. 4, p. 1-68. [available online]

Next page--Appendix--Test-Hole Logs and Ceramic Properties

Kansas Geological Survey, Light-Firing Clay in Cloud and Ellsworth Counties, Kansas

Placed on web Oct. 17, 2016; originally published in December 1963.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/165_3/index.html