Prev Page--Contents || Next Page--Geology

Introduction

Gypsum contributes significantly to our present day economy. Plaster (plaster of paris), one of its processed forms, is used in virtually every modern building to make it more comfortable, more convenient, or more beautiful. Furthermore, some gypsum is contained in most portland cement. Therefore it is a construction material of almost universal use.

In addition to the large quantity of gypsum used for construction material, small amounts are specially processed into orthopedic plaster, pottery molds, statuary, and materials used in such industrial processes as the polishing of plate glass, where a comparatively small amount of gypsum is used but plays an important part in the process.

It would be difficult to do without gypsum. Different substitutes could replace gypsum in several of its uses, but there is no universal substitute and none performs as well nor as economically. On the contrary, the uses of gypsum are increasing, because plaster is easily adapted to prefabrication and is therefore replacing material formerly built in place.

Kansas has large gypsum deposits and well-established gypsum-processing plants. Not only is the quality of the gypsum superior, but the Kansas plants manufacture somewhat specialized products. The growing importance of gypsum consequently makes these deposits and the industry increasingly important.

Previous Work

The one large comprehensive work covering Kansas gypsum deposits exclusively was written by Grimsley and Bailey (1899). It describes in detail the gypsum deposits in Kansas as they were known at that time. Haworth (1902a) wrote a historical report of the gypsum and cement industry in Kansas. Haworth (1898, 1899, 1900, 1902, 1903, and 1904) reported on the annual progress in the gypsum industry and included a description of the industry during the years 1897 to 1903. Much of the geological information that was available at the time that these reports were written is no longer at hand; this report, therefore, draws heavily upon them for some of its information. Haworth (1920) and Moore and Landes (1926) review the report of Grimsley and Bailey (1899).

Scope and Purpose of the Report

The purpose of this investigation is to assemble information that has become available since the previous reports on the Kansas gypsum deposits were published. The industry itself has changed in the intervening years; new methods of investigation have been devised and have yielded new geological information, and study of more gypsum deposits in other areas offers a chance for further comparison with Kansas gypsum deposits.

This report describes all the known gypsum resources of Kansas. The mined deposits receive more attention than the unexploited ones because of the greater amount of information available about them, but an attempt is made to at least mention every known deposit.

The history of the gypsum industry in Kansas is discussed, as well as present-day operation and products. The report includes general descriptions of manufacturing processes, but no detailed description of the Kansas operations. The mineral gypsum, its properties and uses also are discussed.

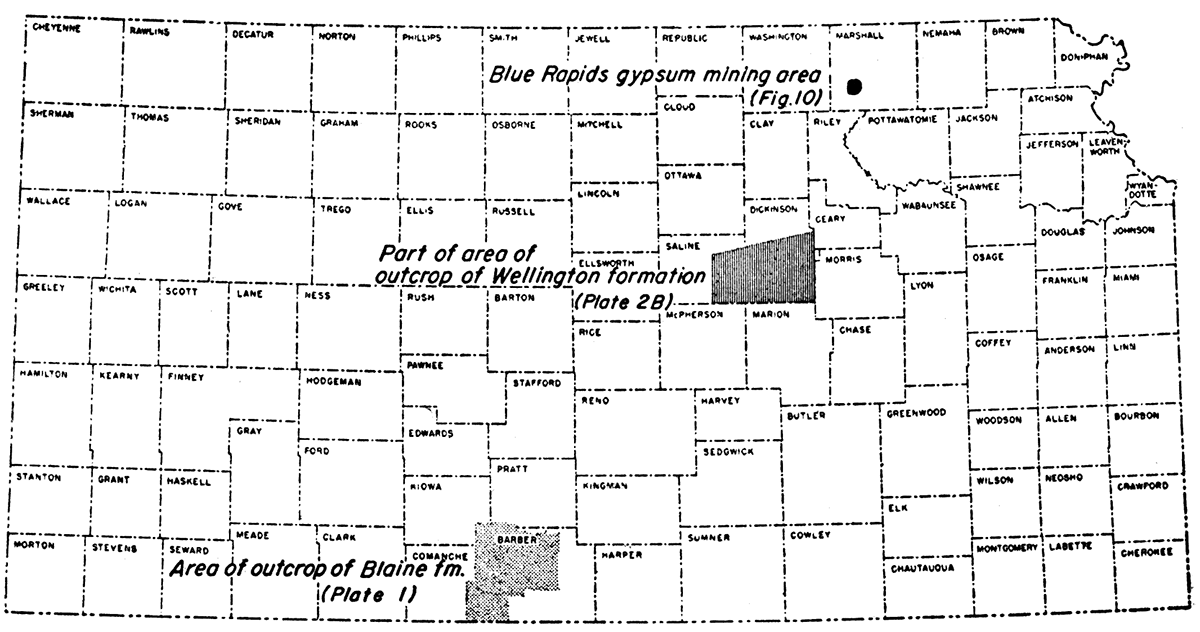

This report compiles the results of a cooperative project between the State Geological Survey of Kansas and the Department of Geology of the University of Kansas. The early work was done under the supervision of Robert M. Dreyer. The two active mining areas, one at Blue Rapids and one at Sun City, were discussed in theses written for the Department of Geology by Paul Fairchild and Duncan McGregor, respectively. McGregor completed study of the Sun City area in 1947 and prepared the section on Gypsum in the Blaine Formation in this report. Fairchild completed his work on the Blue Rapids area in 1948 and prepared the section on Gypsum in the Easly Creek Shale in this report. Kulstad's work was begun in 1952 and includes study of the Wellington gypsum and mapping of the Blaine formation. Figure 1 shows the location of the areas discussed.

Figure 1—Index map showing location of areas discussed.

Gypsum Mining in the United States

The mineral gypsum is widely distributed in the United States, but the location of mines is influenced by factors other than occurrence of raw material. The areas that consume the most gypsum are the densely populated areas, as gypsum is used chiefly as construction material. Gypsum is mined in Arizona, Arkansas, California, Colorado, Indiana, Iowa, Kansas, Michigan, Montana, Nevada, New York, Ohio, Oklahoma, South Dakota, Texas, Utah, Virginia, and Wyoming. Much gypsum also is imported into the United States, most coming from the Maritime Provinces of Canada.

Table 1 shows the gypsum production in the United States for the year 1952 as reported by North and Jensen (1954). It is presented here to show comparative production figures and prices of the various gypsum products. These figures show that almost 95% of the dollar value of gypsum products comprises prefabricated and cementitious building products. More gypsum was manufactured into wallboard than into any other single product. The average price of wallboard was relatively high, therefore it also accounted for the largest monetary figure for any single item. Base coat plaster, gypsum lath, and portland cement retarder follow wallboard in order of amount produced. Because of difference in prices of the different products, however, their values do not follow in the same order. Portland cement retarder, although the fourth largest product of gypsum in terms of quantity, has the lowest listed price, and so falls far behind other products in total value.

Table 1—Production of gypsum and gypsum products in United States in 1952

| Use | Short tons |

Value | ||||

|---|---|---|---|---|---|---|

| Total | Average | |||||

| Uncalcined: | ||||||

| Portland-cement retarder | 1,815,489 | $6,232,230 | $3.43 | |||

| Agricultural gypsum | 866,005 | 3,072,419 | 3.55 | |||

| Other uses a | 24,233 | 312,131 | 12.88 | |||

| Total uncalcined uses | 2,705,727 | $9,616,780 | $3.55 | |||

| Industrial: | ||||||

| Plate-glass and terracotta plasters | 48,587 | $626,771 | $12.90 | |||

| Pottery plasters | 43,991 | 811,609 | 18.45 | |||

| Orthopedic and dental plasters | 11,017 | 390,347 | 35.43 | |||

| Other industrial uses b | 148,621 | 3,171,052 | 21.34 | |||

| Total industrial uses | 252,216 | $4,999,779 | $19.82 | |||

| Building: | ||||||

| Cementitious: | ||||||

| Plasters: | ||||||

| Base-coat | 1,907,871 | $26,596,087 | $13.94 | |||

| Sanded | 177,679 | 3,331,533 | 18.75 | |||

| To mixing plants | 11 ,703 | 126,243 | 10.79 | |||

| Gaging and molding | 176,957 | 2,943,304 | 16.63 | |||

| Prepared finished | 16,000 | 935,670 | 58.48 | |||

| Other c | 220,997 | 6,082,843 | 27.52 | |||

| Keene's cement | 52,591 | 1,158,703 | 22.03 | |||

| Total cementitious | 2,563,798 | $41,174,383 | $16.06 | |||

| Prefabricated: | ||||||

| Lath | 1,757,771 | $54,402,346 | d $23.48 | |||

| Wallboard and laminated board | 2,964,381 | 108,974,618 | e 32.88 | |||

| Sheathing board | 123,310 | 4,281,772 | d 36.57 | |||

| Tile | 157,451 | 3,632,397 | f 78.54 | |||

| Total prefabricated | 5,002,913 | $171,291,133 | $34.24 | |||

| Total building uses | $212,465,516 | |||||

| Grand total value | $227,082,075 | |||||

|

(a) Includes uncalcined gypsum sold for use as filler and rock dust, in brewer's fixe, in color manufacture, and for unspecified uses. (b) Includes statuary, industrial casting and molding plasters, dead-burned filler, granite polishing, and miscellaneous uses. (c) Includes insulating and roof-deck, joint filler, patching and painter's plaster, and unclassified building plasters. (d) Average value per M square feet. (e) Average value per M square feet of wallboard only. (f) Average value per M square feet of partition tile only. |

||||||

Kansas Gypsum Production

The products made from Kansas gypsum are wallboard, wall plaster, Keene's cement, dental plaster, orthopedic plaster, plate glass stucco, pottery plaster, casting plaster, molding plaster, gaging plaster, and portland cement retarder. This list indicates that many of the Kansas gypsum products are special types that command a higher than average price. These products require not only a careful and special type of handling in their manufacture but also a high-grade gypsum as raw material.

Acknowledgments

The authors are indebted to many persons for information included in this report. The gaps in the historical record could be filled only by persons familiar with the local areas or directly associated with the gypsum companies. It is not possible to mention all who contributed, but their help has made the report more nearly complete.

Special thanks are due to Mr. Kenneth W. Brown, superintendent, and Mr. Fred Williams, mine foreman, of the Certainteed products Corporation operation at Blue Rapids for their help and cooperation in the studies made in that area.

Mr. Roy Rubin was especially helpful in locating old mine sites in the Hope area. He also provided many photographs having historical interest and much of the historical data concerning gypsum mining in that area.

Special thanks for their cooperation and help are likewise due to Mr. Dudley C. Chads, superintendent, Mr. M. J. Witkowski, quality control engineer, and Mr. Sam Shepler, mine superintendent, of the National Gypsum Company operations at Sun City and Medicine Lodge. Mr. S. E. Woodard of Medicine Lodge helped to obtain data for the structural map of the area near the Pioneer mine.

Prev Page--Contents || Next Page--Geology

Kansas Geological Survey, Geology

Placed on web Feb. 20, 2018; originally published March 21, 1956.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/133/02_intro.html