Resources

Asphalt

The total value of the petroleum asphalt produced in Kansas each year amounts to many thousands of dollars. The exact figures may not be disclosed because there are less than three producers. In this state asphalt is derived from crude petroleum by distillation and constitutes an important product of refining.

Exposures of asphaltic sandstone have been reported at various localities in southeastern Kansas where the Cherokee shale (Pennsylvanian) outcrops. These asphalt deposits have been formed by the seepage and partial evaporation of oil from sands in the Cherokee. In few cases is the deposit sufficient in size to be of commercial importance.

Cement

The cement production in Kansas in 1925 amounted to $10,861,506. That figure is only exceeded by those for petroleum, zinc, and coal. Since 1916 the cement industry has more than doubled. The yearly values for the past ten years are given below:

| 1916 | $4,613,609 |

| 1917 | $5,271,721 |

| 1918 | $4,219,203 |

| 1919 | $5,467,284 |

| 1920 | $8,649,157 |

| 1921 | $7,253,944 |

| 1922 | $8,138,268 |

| 1923 | $10,868,590 |

| 1924 | $9,900,647 |

| 1925 | $10,861,506 |

| $75,243,829 |

There is an almost unlimited quantity of materials in Kansas suitable for the manufacture of Portland cement. Good Portland cement requires comparatively pure limestone and shale free from large amounts of magnesia. Most of the shale deposits of the state and many of the limestone formations are excellent cement-making material.

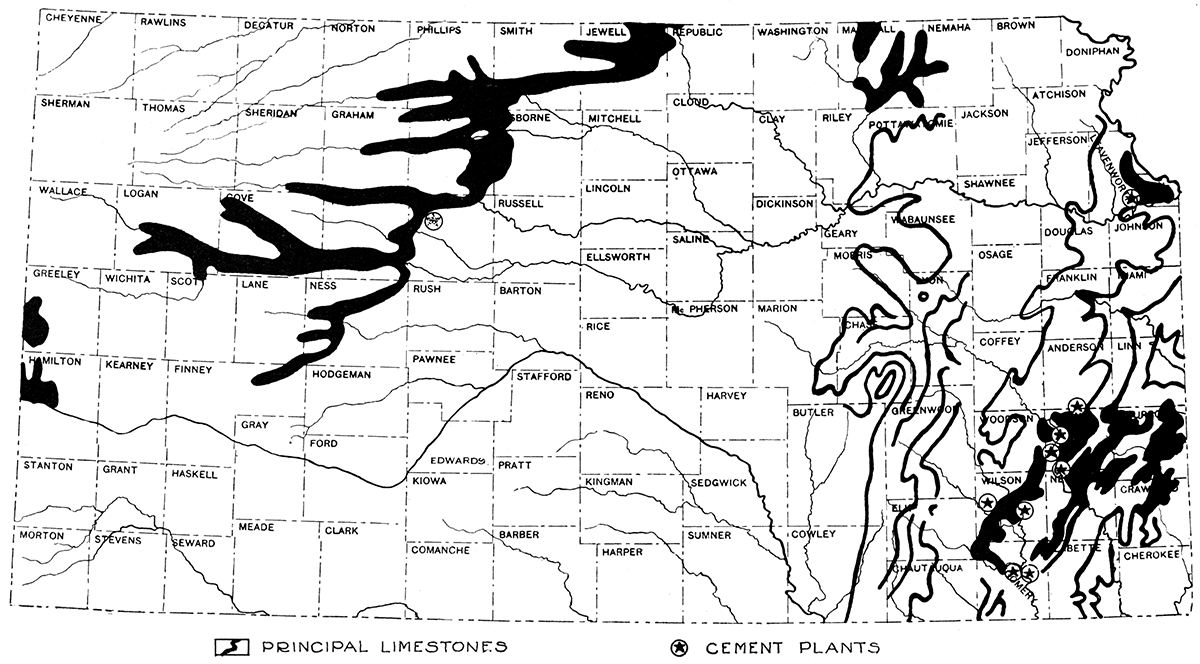

Due to their favorable location in eastern Kansas the limestones and shales belonging to the Pennsylvanian (coal measures) are most extensively used. Rocks of this age crop out in the eastern one-third of the state. Some of the Cretaceous limestones are sufficiently pure for use in cement manufacture, but to the present time but little use has been made of this series of rocks. The areal distribution of the principal limestones of Kansas is given in Figure 24. The many lines to the east represent outcrops of Pennsylvanian limestones. The heavy black bands in the west show outcrops of the Niobrara limestone belonging to the Cretaceous. Ce~ent is made by fusing mixtures of oxides of calcium, aluminum, and silicon. If the clinker is ground and water added it sets to a strong solid mass. Some impure or shaly limestones already contain the cement-making ingredients in the proper proportions. In that case the limestone is burned, and the resulting product is known as natural cement. This used to be a considerable industry in Kansas, but in 1924 only one natural cement plant was in operation in the state.

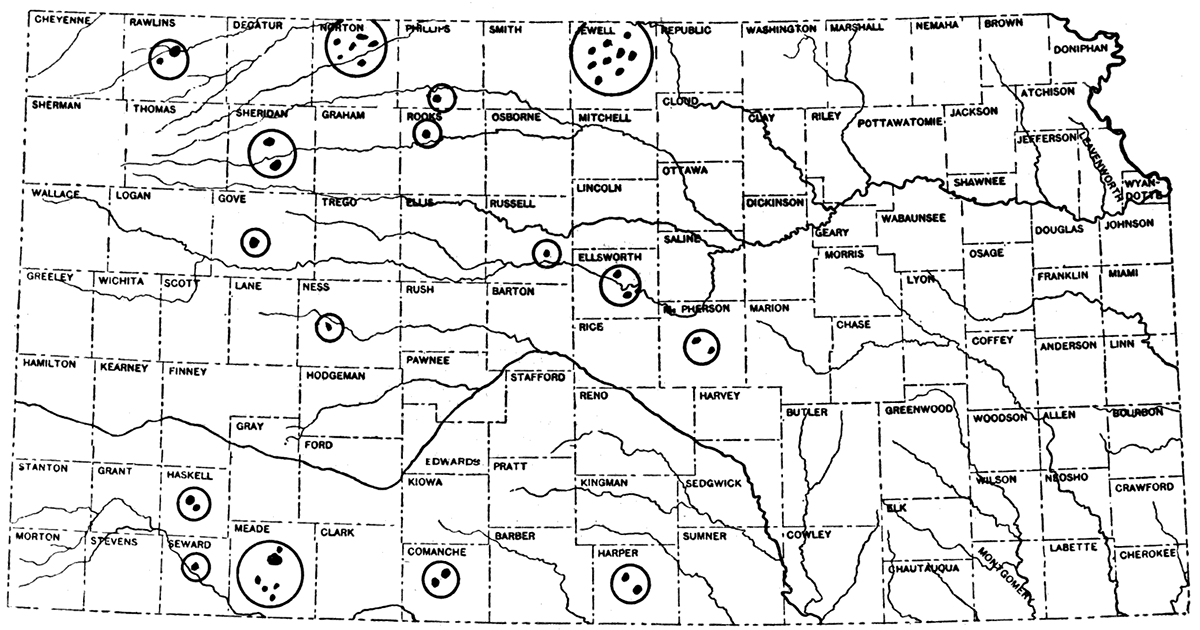

Figure 24—Map showing cement plants and the distribution of principal limestones.

Portland, or artificial, cement is made in Kansas by mixing limestone and shale and burning the mixture. Chemical analyses of the rocks are necessary in order to determine the relative amount of each ingredient to add so that the oxides will be present in the correct proportion. About 2 per cent of gypsum is added as a retarder. This affords a considerable market for the gypsum industry of the state. In 1924 there were eight cement plants operating in Kansas. These were located at Bonner Springs, Mildred, Iola, Humboldt, Fort Scott, Chanute, Fredonia, and Independence. Most of these towns are in the southeastern part of the state. The plant at Fort Scott produced natural cement. The map, showing the outcrops of principal limestones, also gives the locations of cement plants. Some of these were not operating in 1924.

Kansas produced 5,810,000 barrels of Portland cement in 1924. It is estimated that of this amount a little over 2,000,000 barrels was consumed within the state. This leaves a surplus of 3,667,000 barrels which was sold outside the state. Only two other states produced a greater surplus of cement during that year. So cement manufacture in Kansas is by no means a local industry,

Cement has an ever increasing use as an ingredient of concrete in the paving of roads. It is also indispensable in the construction of large buildings, dams, bridges, canals, etc.

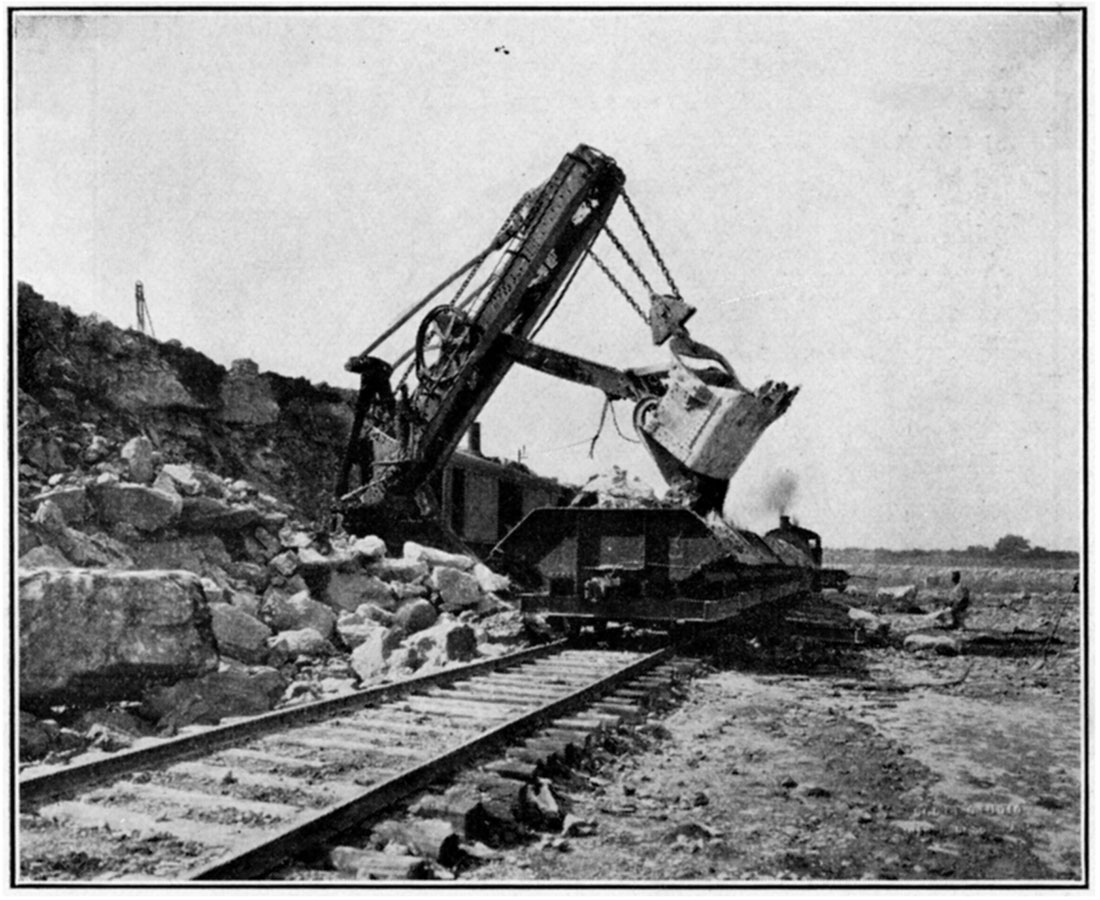

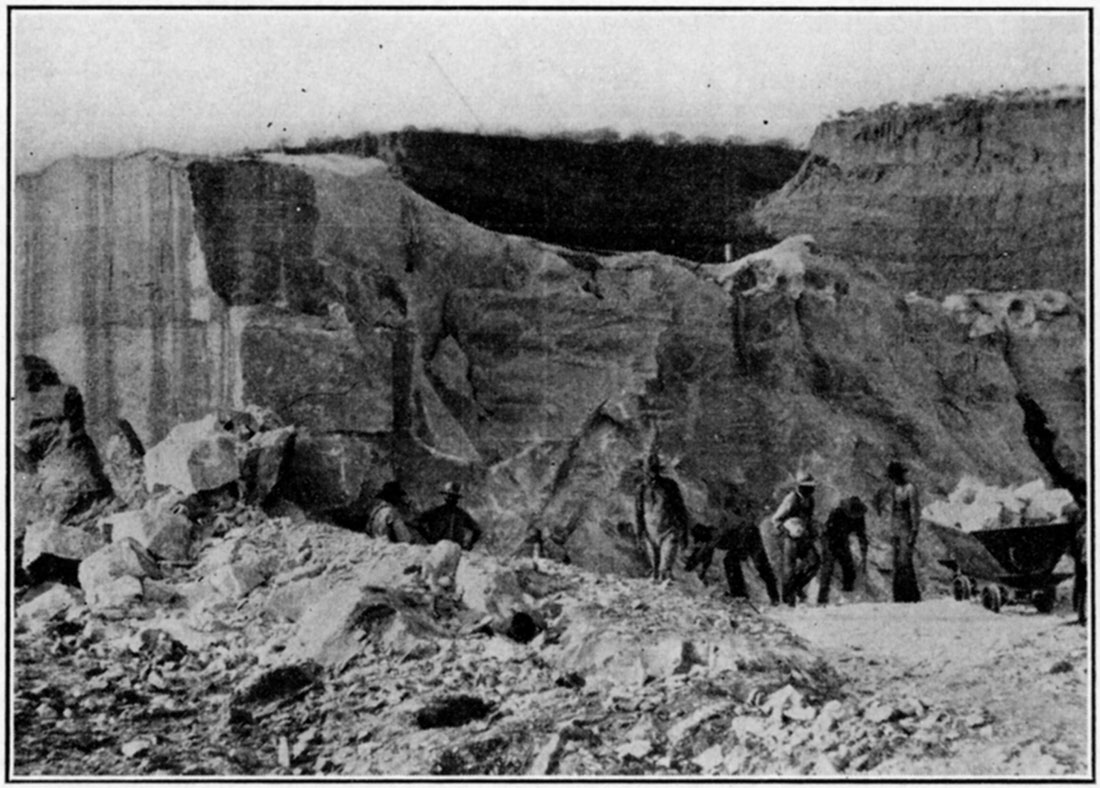

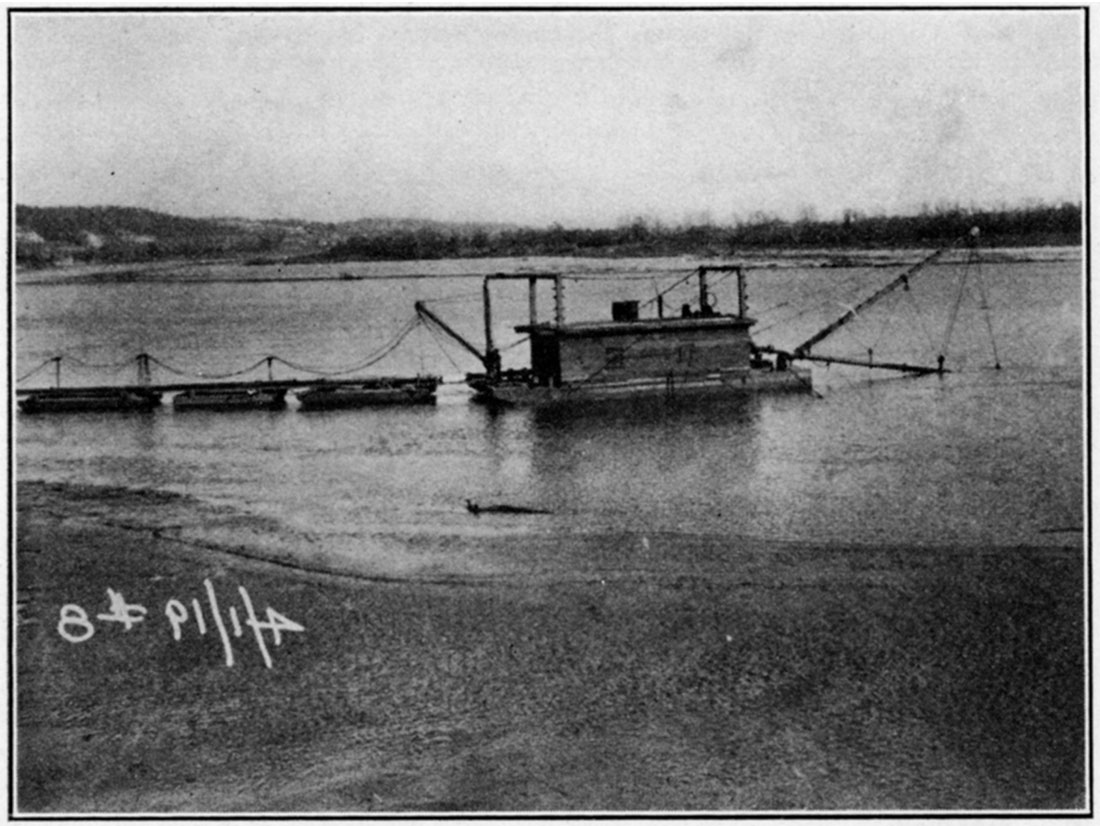

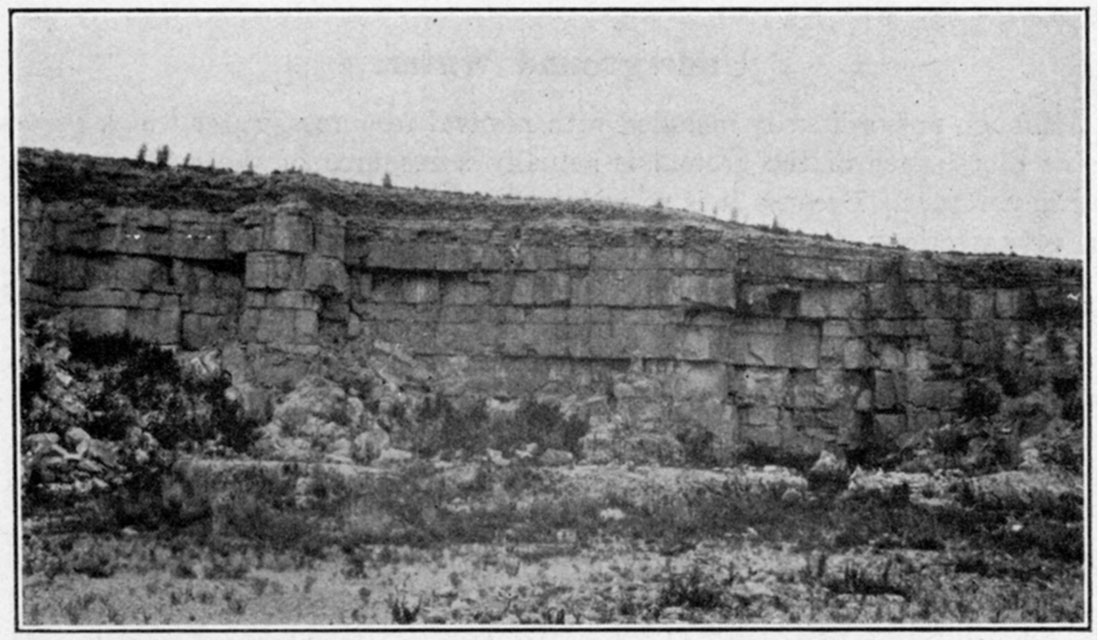

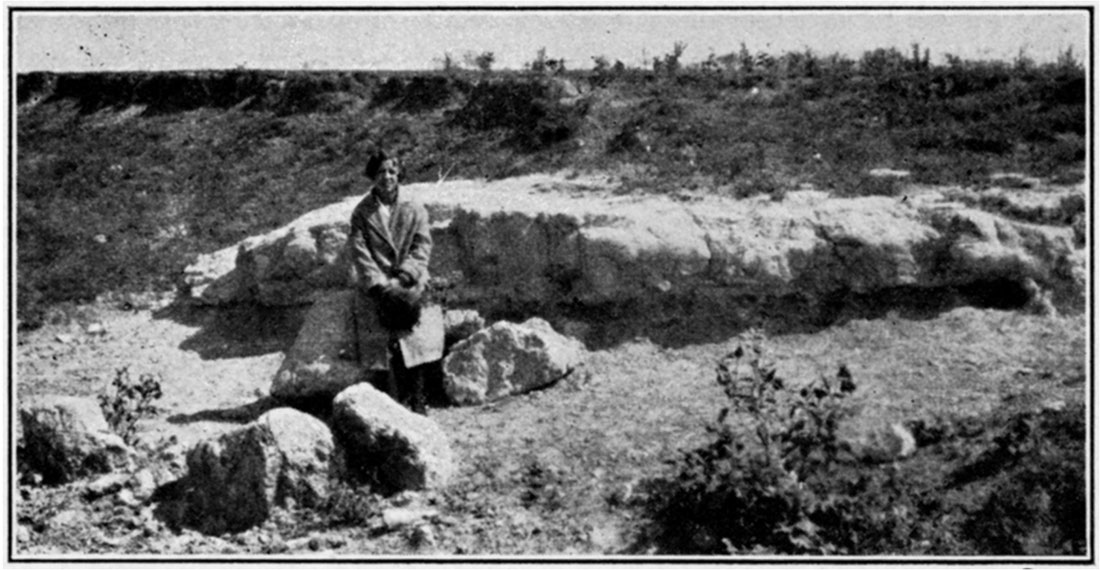

Figure 25—Quarry, Independence, Kan.

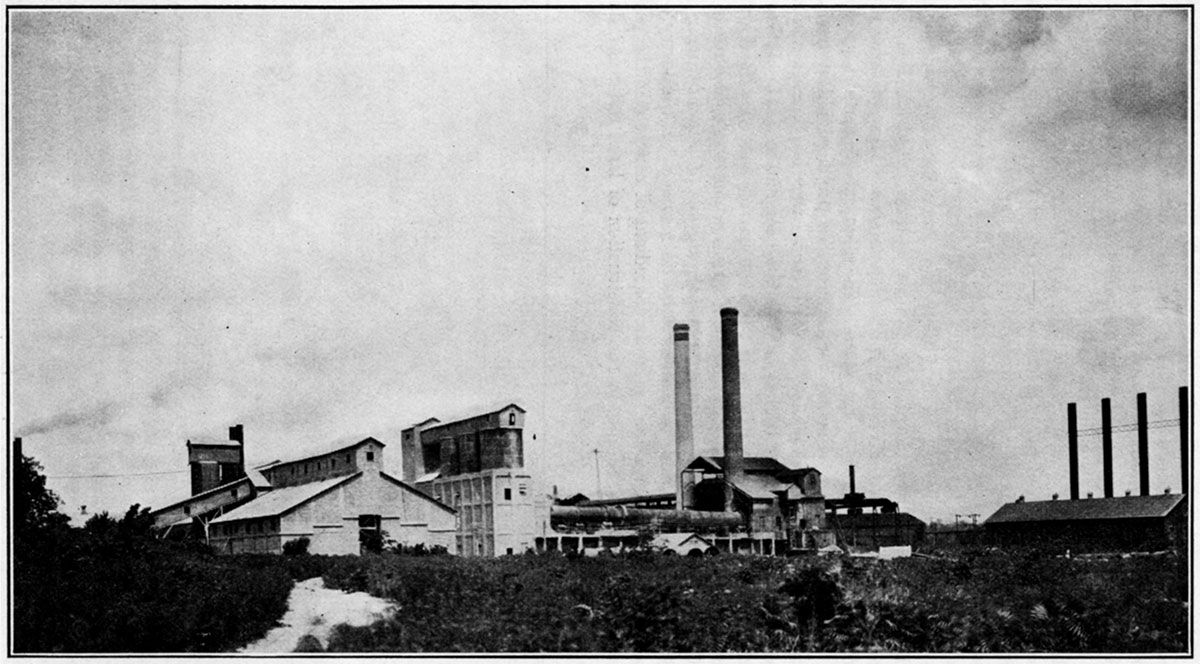

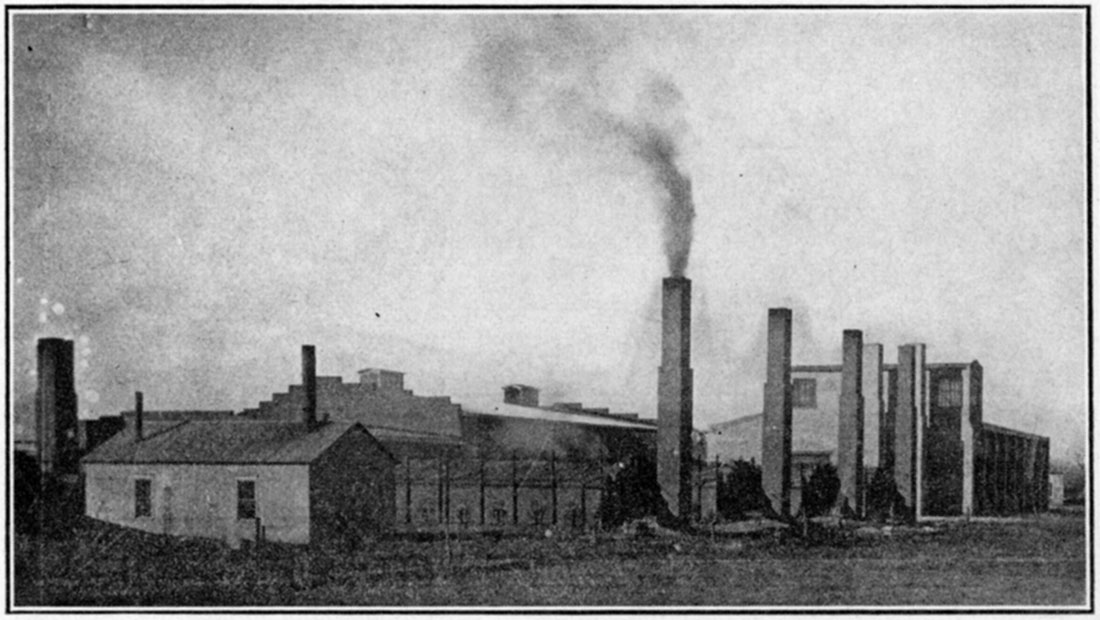

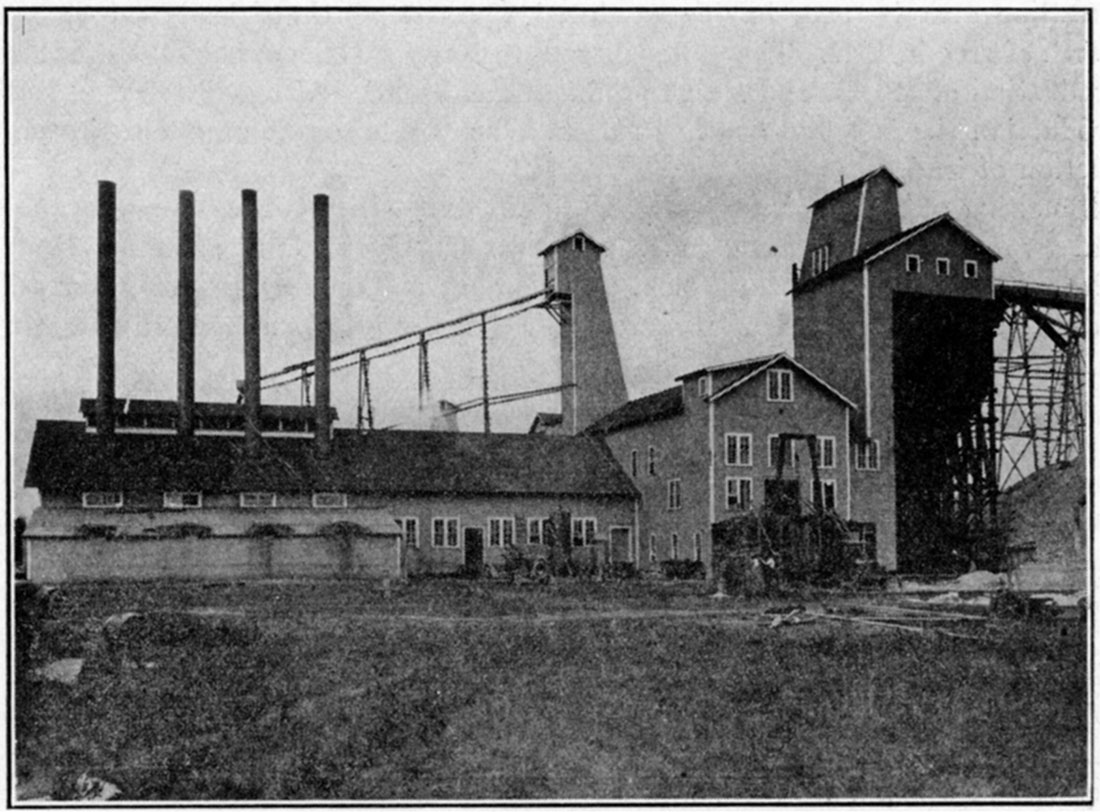

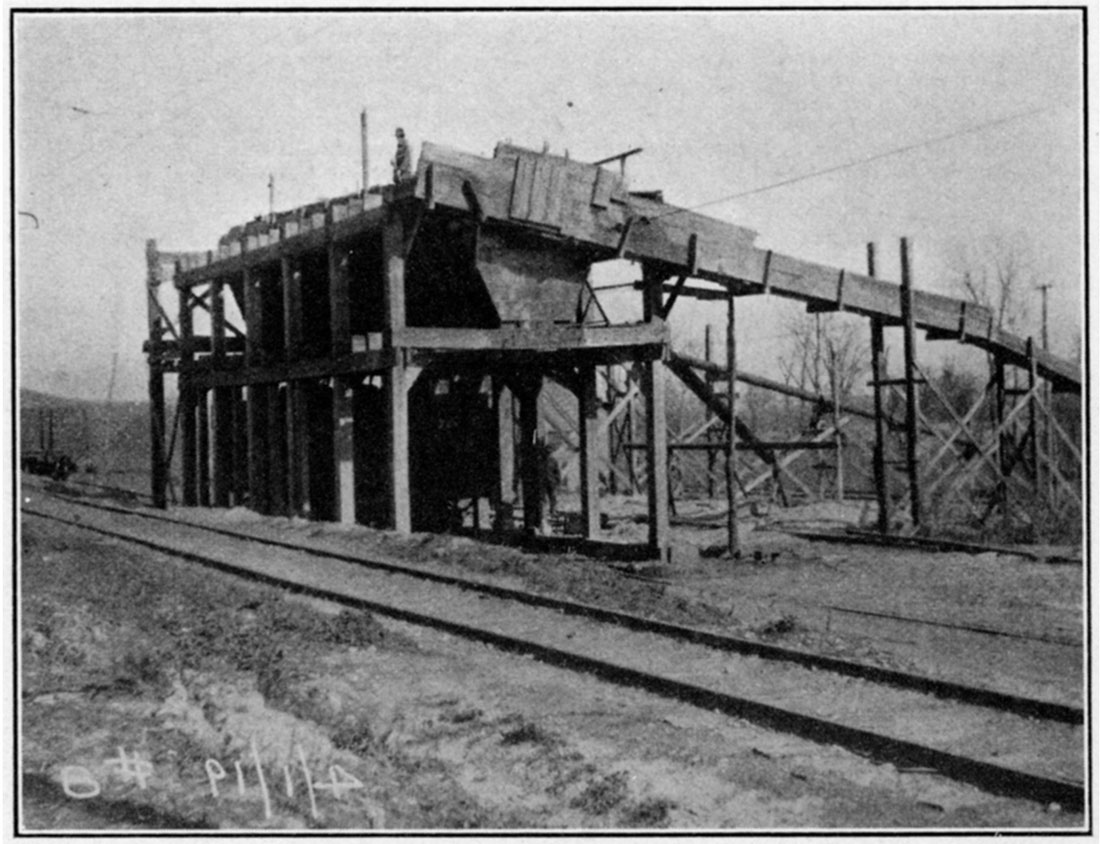

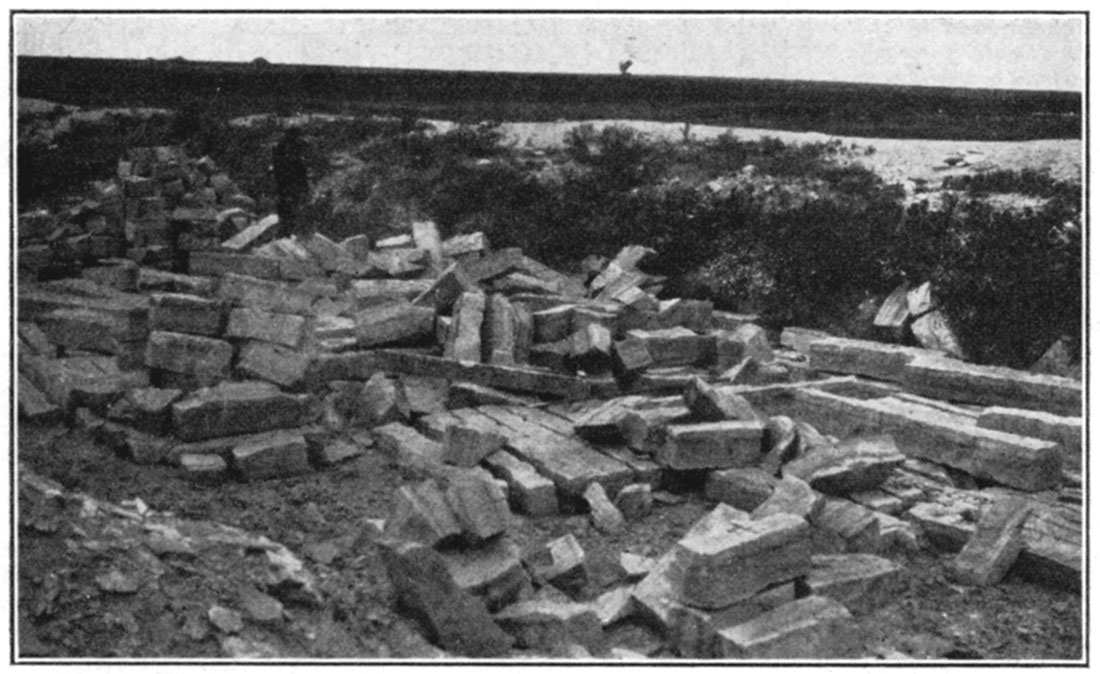

Figure 26—Cement Plant, Independence, Kan.

Clay Products

Kansas annually produces from four to five million dollars' worth of clay products. The production by years since 1916 is given in the accompanying table. The total for that period is $35,760,802.

| Annual Production Values of Clay Products in Kansas | |

|---|---|

| 1916 | $2,747,803 |

| 1917 | $2,696,722 |

| 1918 | $2,069,520 |

| 1919 | $3,426,002 |

| 1920 | $4,921,740 |

| 1921 | $3,739,594 |

| 1922 | $3,715,819 |

| 1923 | $4,425,067 |

| 1924 | $4,024,535 |

| 1925 (est.) | $4,000,000 |

| $36,760,802 | |

Pure clay is composed of the mineral kaolinite (a hydrous aluminum silicate) which is an important decomposition product of such rocks as granite. Running water may carry this material many miles from the original granite and deposit it as clay sediment on the floor of a lake or sea. Due to the weight of overlying younger material the sediment may be compacted into shale. Upon being exposed again to the atmosphere and surface waters shale has a tendency to disintegrate into a surface clay deposit. Other clays occur beneath coal beds and in glacial deposits. The latter are very rare in this state. Both clays and shales may be utilized in manufacture of the so-called clay products.

There are in Kansas large amounts of clay and shale suited for the manufacture of structural material. So far the shales have been much more extensively developed than the clays. Our knowledge in regard to the distribution and character of Kansas ceramic material is very limited. There is need for a great amount of field work and laboratory testing in order that our resources in regard to this valuable natural product may become better known. A few years ago the Kansas State Geological Survey studied the clays occurring in the Dakota formation (Cretaceous) of central Kansas. Samples were taken and tested in the well-equipped clay laboratories of the Survey. This work indicated the presence of clays suitable for the manufacture of high-grade bricks.

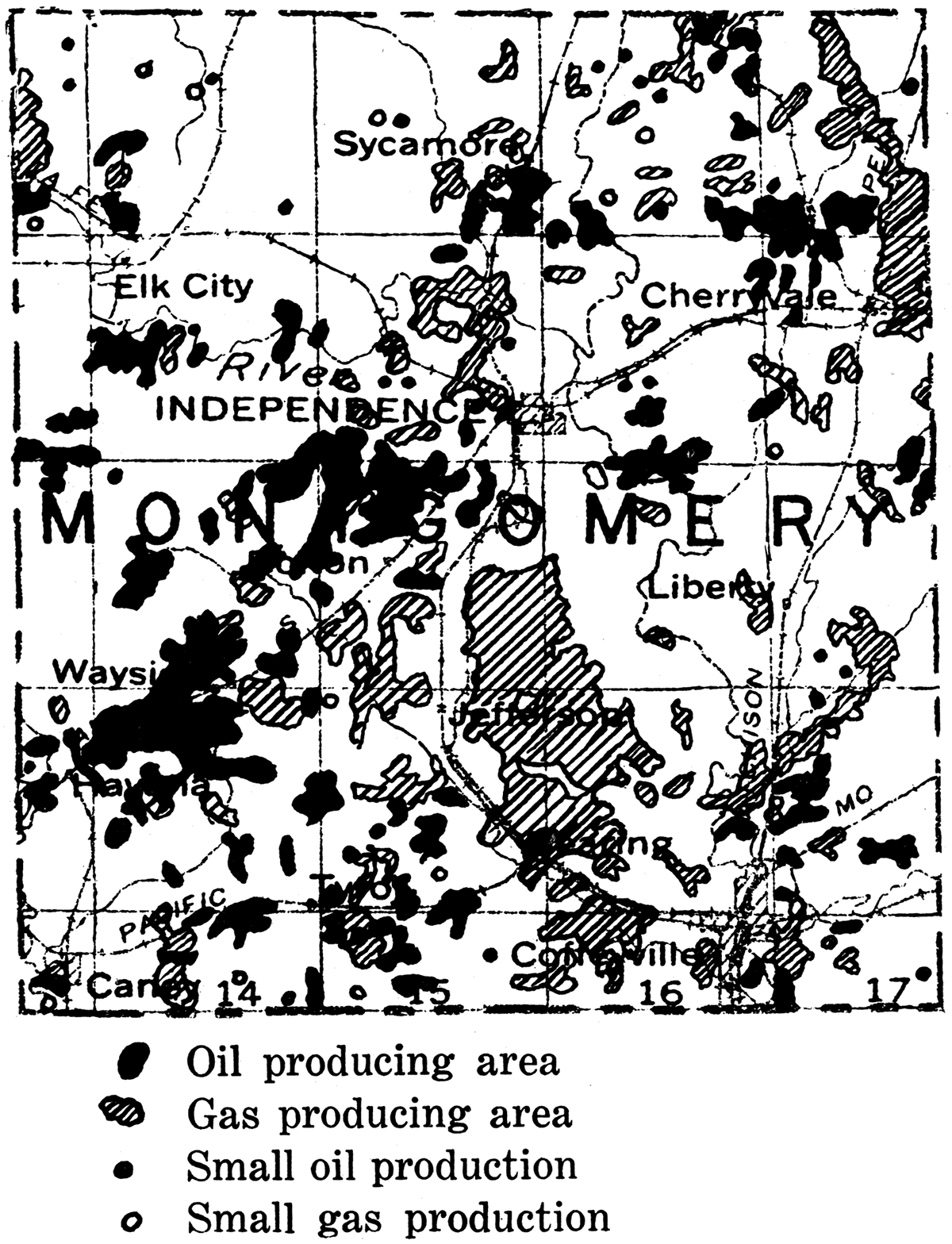

To date the main development of the clay resources has been in the eastern one-third of the state. This has been due largely to the presence in this portion of the state of an abundant supply of fuel for the firing of clay products. In four counties in the southeastern part of the state where natural gas and coal is abundant there are twenty-six operators manufacturing clay products. These counties are Montgomery, Crawford, Allen and Wilson. Another but lesser concentration of plants is noted in the northeast portion of the state where the proximity of the Kansas Cities stimulates productive activity. Most of the other counties in the eastern third of the state contain one or two brick and tile factories, but such plants are very rare in the western counties.

To date the Kansas ceramic industry has been largely confined to the manufacture of brick and tile. Clays of the degree of purity necessary for the manufacture of high-grade pottery are rare. The clays which underlie some of the coal beds in southeastern Kansas do not appear to be sufficiently refractory to be classed as fire clays. When properly fired they produce a product of light color and vitrify at a fairly low temperature.

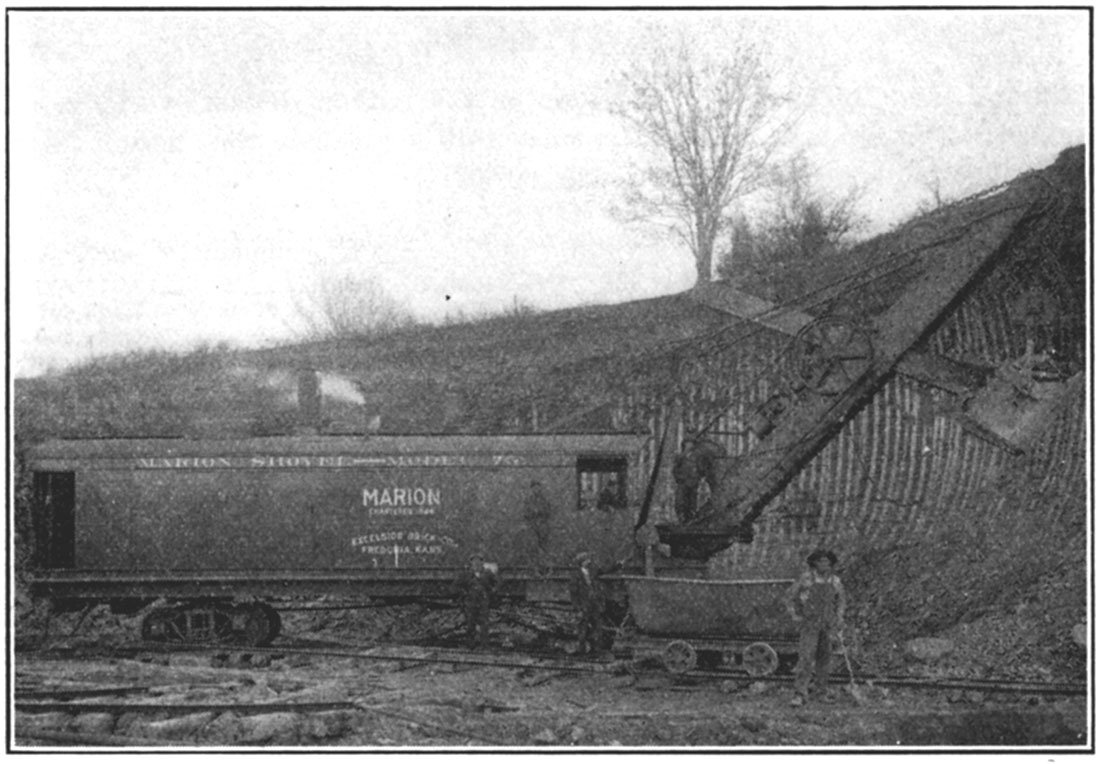

Figure 27—A clay pit near Fredonia, Kan.

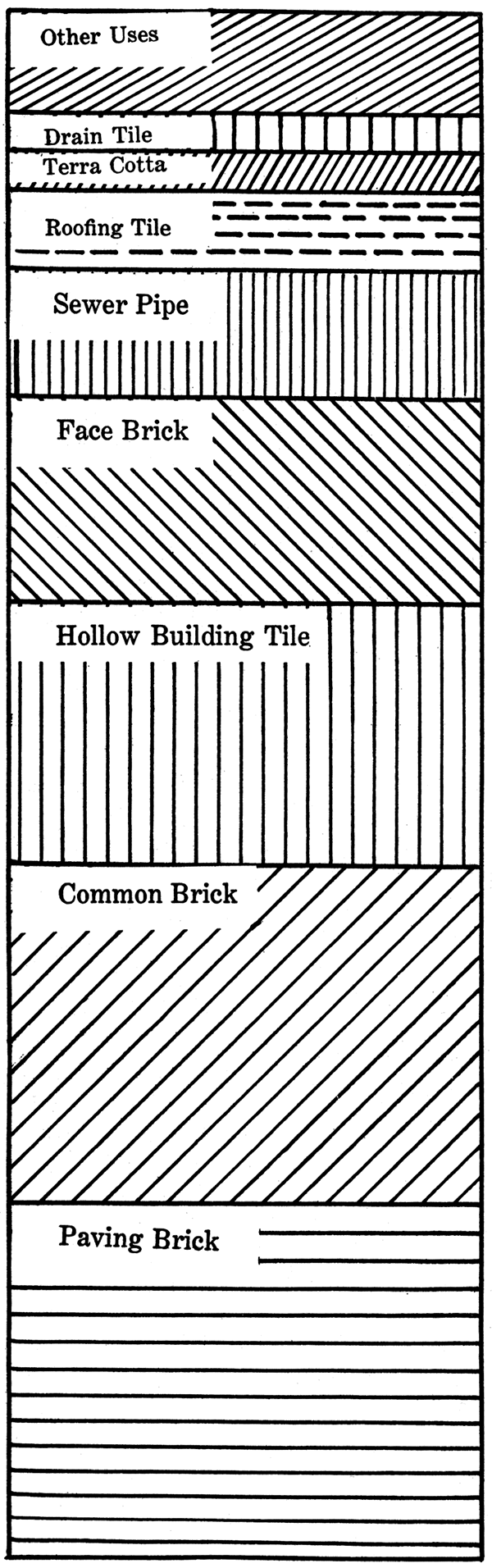

Bricks are made by molding the clay or shale into .~he desired form and then baking the material for several days in a kiln. Tile is manufactured similarly, except that a different type of kiln is used in order that the heat in burning may be more evenly distributed than is necessary in brick making. In Kansas the commonest ceramic products are paving (vitrified) brick, common brick, hollow building tile, face brick, sewer pipe, roofing tile, terra cotta, and drain tile. Products of lesser importance are furnace and flue linings, retorts, condensers, and wall coping. The more important brick and tile products of Kansas are given in a diagram in Figure 30. In this figure the size of the block represents the relative value of the product.

Figure 28—View of a Kansas brick plant, Fredonia, Kan.

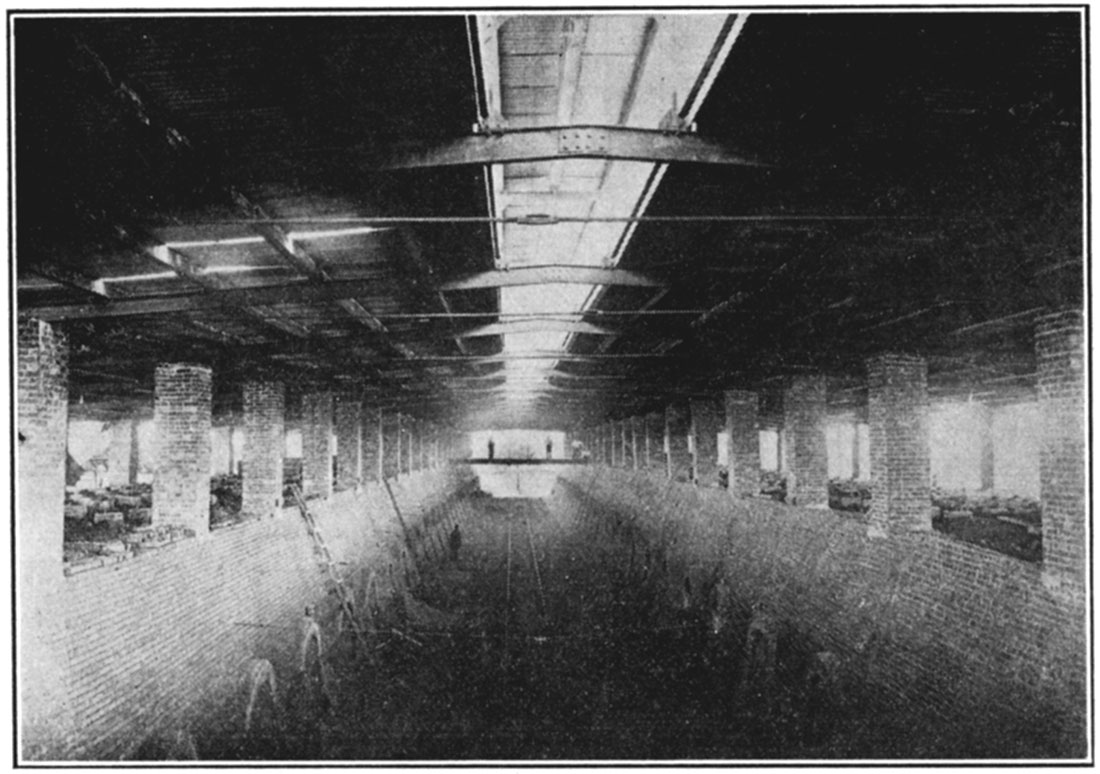

Figure 29—View in a brick kiln, Fredonia, Kan.

Figure 30—Diagram to show relative amounts of clay products produced in Kansas.

Coal

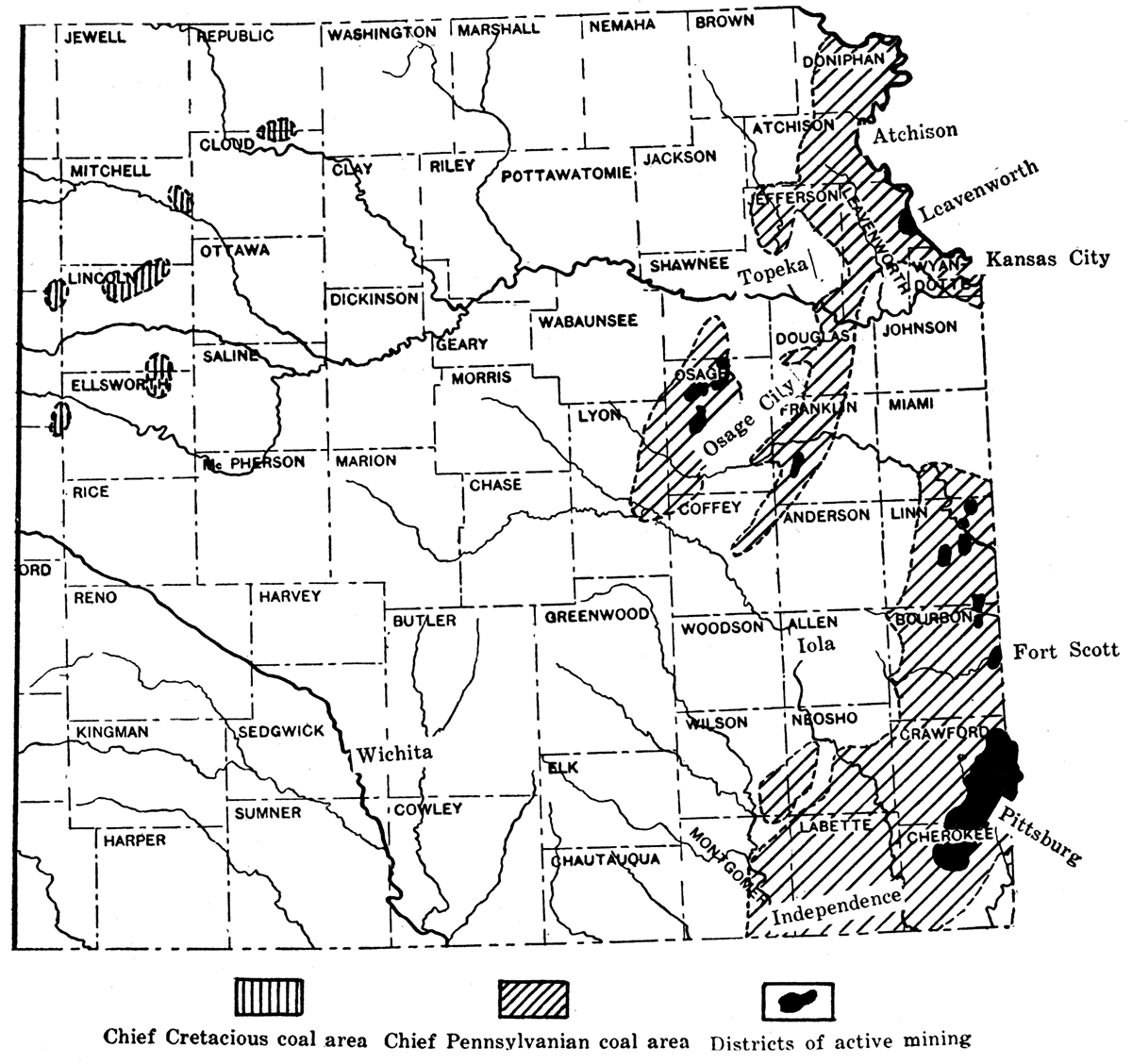

Coal is widely distributed in Kansas. It occurs at the surface or at comparatively shallow depth throughout most of the eastern one-fourth of the state, in the north-central and locally in the southwestern parts, and at considerable depth some coal is probably to be. found beneath most of Kansas. However, the commercially valuable deposits are found only in the eastern counties. Here the Pennsylvanian or as it is sometimes termed, the Coal Measures system of rocks contains many different beds of coal, some of which are traceable for many miles at their outcrop. Since in eastern Kansas the strata slope gently downward in a direction slightly north and west the lowest or oldest Pennsylvanian rocks and their included coal beds are found to the south and east and the higher or younger beds at varying distances to the northwest. The coal-bearing rocks underlie practically all of Kansas but in the central and western parts of the state they are too deeply buried to permit development of any coal which they may contain. Since also many of the coal beds which appear at the surface are too thin to be of commercial importance the actual area of minable coal comprises relatively only a small part of the outcrop of the coal-bearing strata.

Figure 31—Map of eastern Kansas, showing chief coal-producing areas and active mining districts.

The Permian system, which rests upon the Pennsylvanian rocks, and which appears at the surface in a broad band crossing the central part of Kansas, is not known to contain any coal beds. The Permian is overlain by Cretaceous rocks which in the north-central part of the state contain coal that is locally worked. Coal in these rocks extends westward under cover of younger strata, and has been encountered at places in borings but it is not very important.

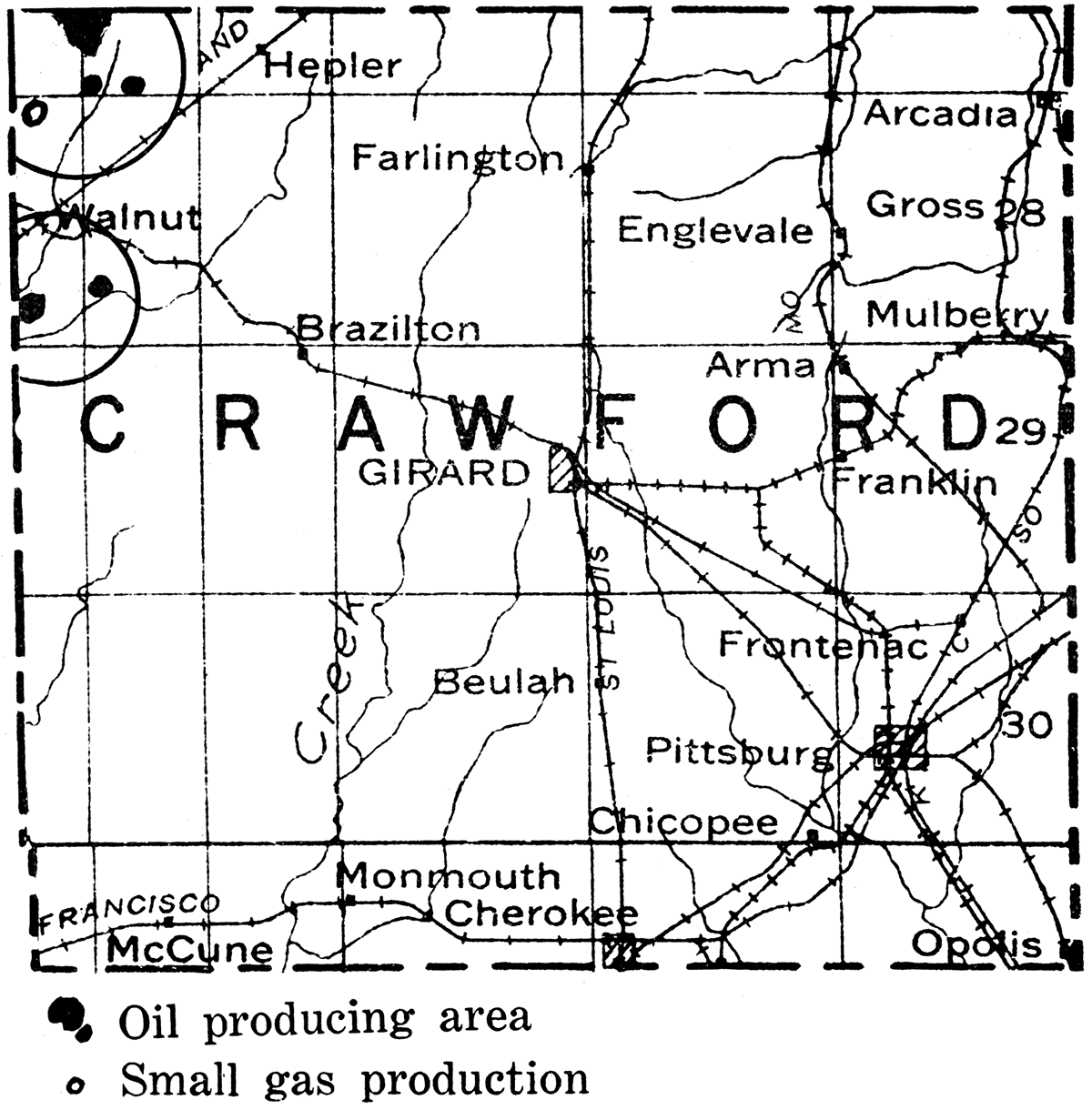

More than 90 per cent of the coal which is produced from the Kansas fields comes from the so-called Cherokee district in Cherokee and Crawford counties, in the southeastern corner of the state. The producing area, which comprises approximately 123,000 acres of workable coal, extends slightly across the line into Missouri. According to estimate there was originally something over 295,000,000 tons in this field in the coal bed which is mainly worked, but this coal is more than half worked out. There are three other commercial producing districts: (1) Linn county, in the vicinity of Pleasanton and La Cygne, (2) Osage county, near Osage City, Scranton and Carbondale, and (3) Leavenworth, in Leavenworth county. Some coal for local use is also mined in the vicinity of Fort Scott. As shown by the diagram representing total production, the amount of coal produced in these fields is relatively small.

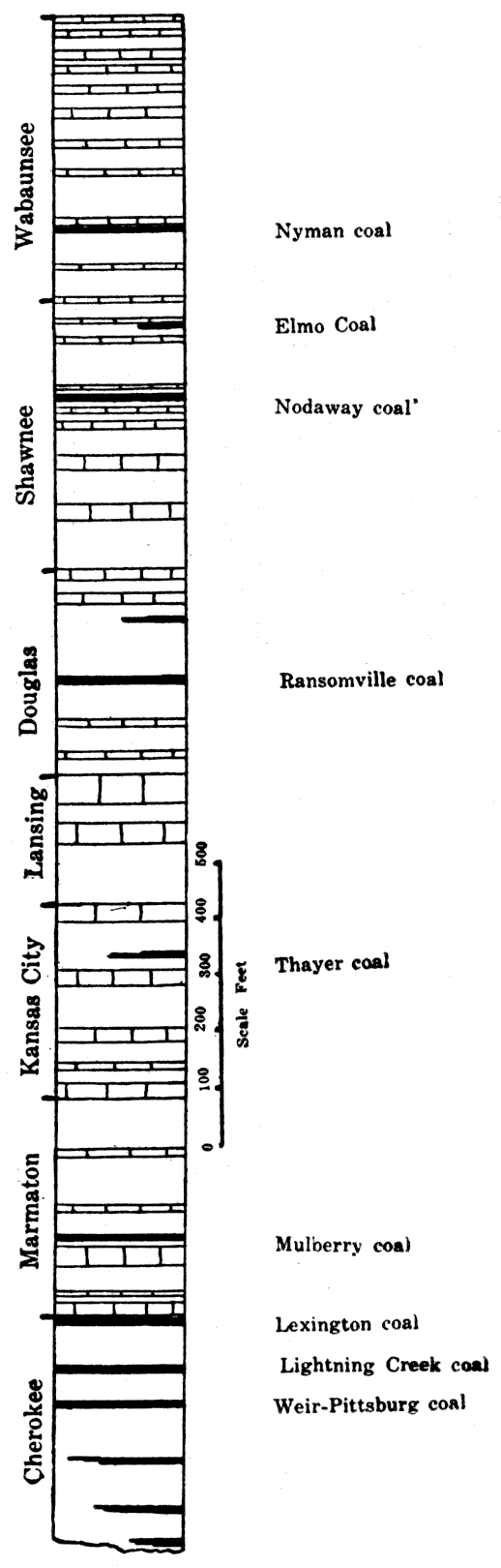

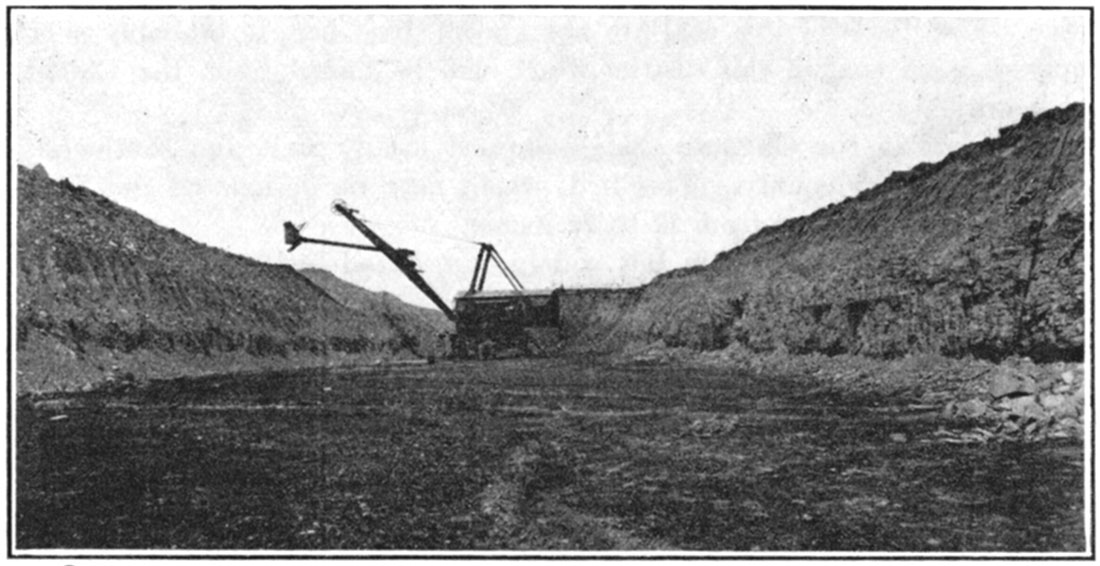

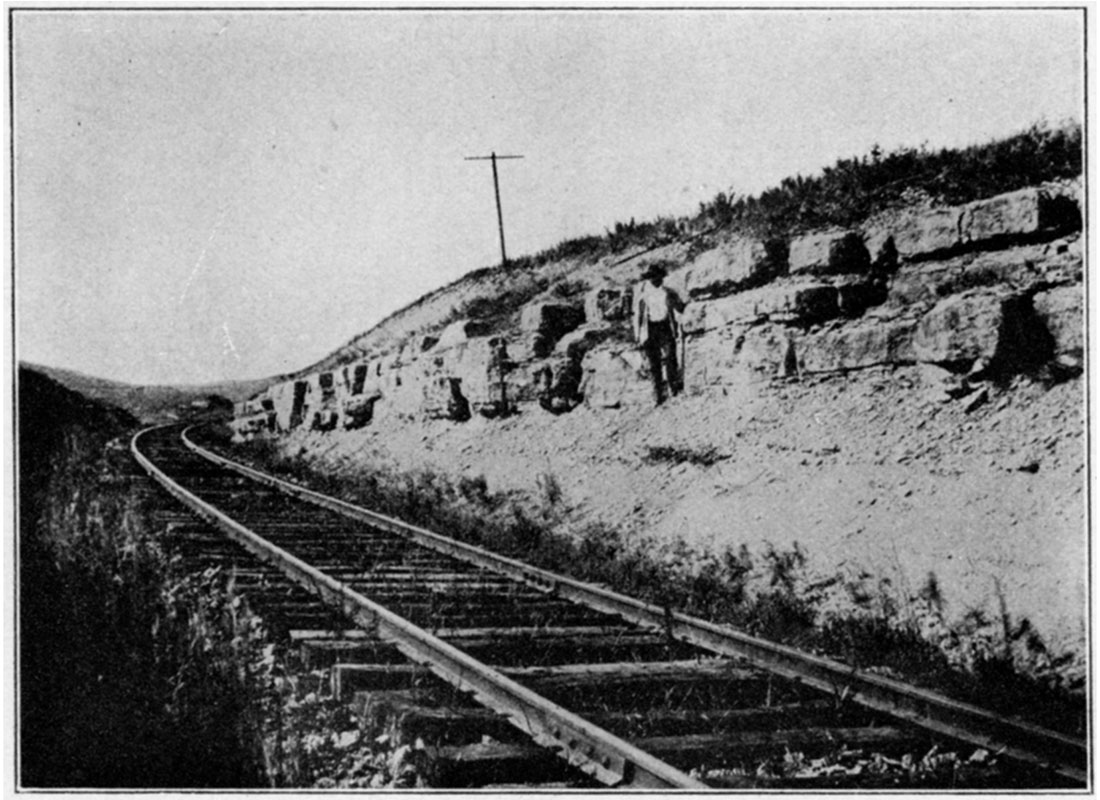

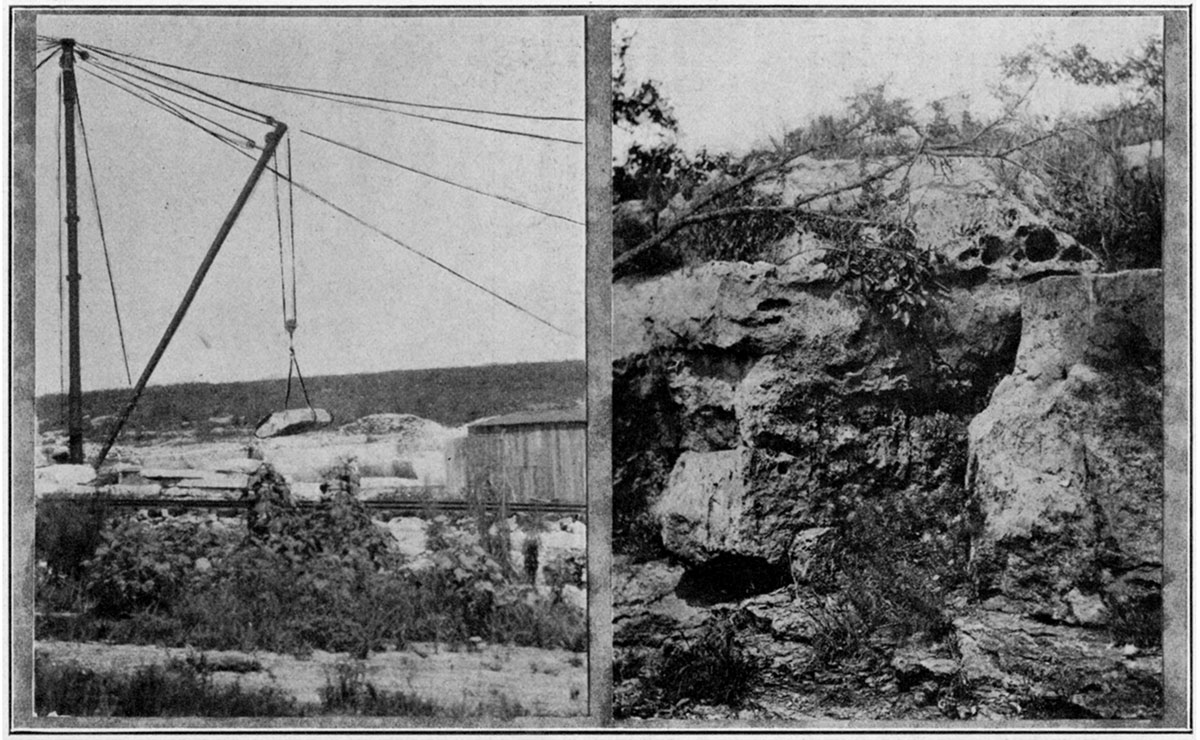

Figure 32 is a generalized section of the Pennsylvanian rocks of Kansas showing the position of the main coal beds. The Cherokee shale is the chief coal-bearing formation, containing the thick WeirPittsburg and a number of other coal beds. The lowest coal occurs locally at the base of the Cherokee, but it has never been developed. A water well at Weir shows 2 feet of coal, 64 feet above the base of the shale, but this bed has not been mined. A coal bed 12 to 18 inches thick, occurring about 150 feet above the base of the shale, lies very near the surface near Columbus, Cherokee county, and has been mined by stripping. The Weir-Pittsburg bed, which is much the most important coal deposit in the Cherokee of southeastern Kansas, is found about 250 feet above the base of the Cherokee shale'. The coal ranges in thickness from 32 to 43 inches. This coal may be present beneath Fort Scott, as a boring here records 34 inches of coal at the approximate horizon of the Weir-Pittsburg bed. Figure 31 shows the Weir-Pittsburg coal field. In the east part of the district, where the coal lies very near the surface, the bed is mined by stripping off the soil and shale that conceal the coal. For this work large steam or electric shovels are used, some of them being able to move as much as 6 cubic yards of material in the dipper which has a 58-foot handle and an 85-foot boom. Up to 40 feet of overburden is removed in some stripping operations. Farther west, where the coal becomes gradually deeper, shafts are sunk and the coal is removed by room-and-pillar method of mining.

Figure 32—Generalized section of the Pennsylvanian rocks of Kansas showing position of main coal beds.

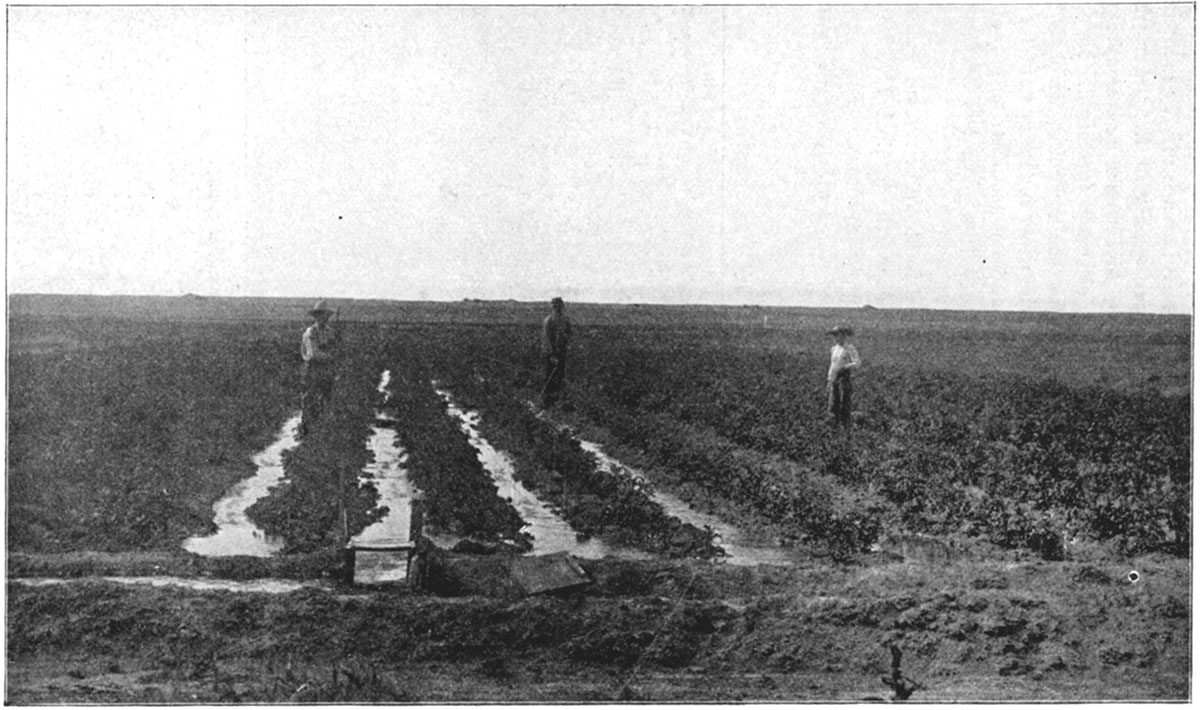

Figure 33—General view of strip pit. (Photograph by Prof. C. M. Young.)

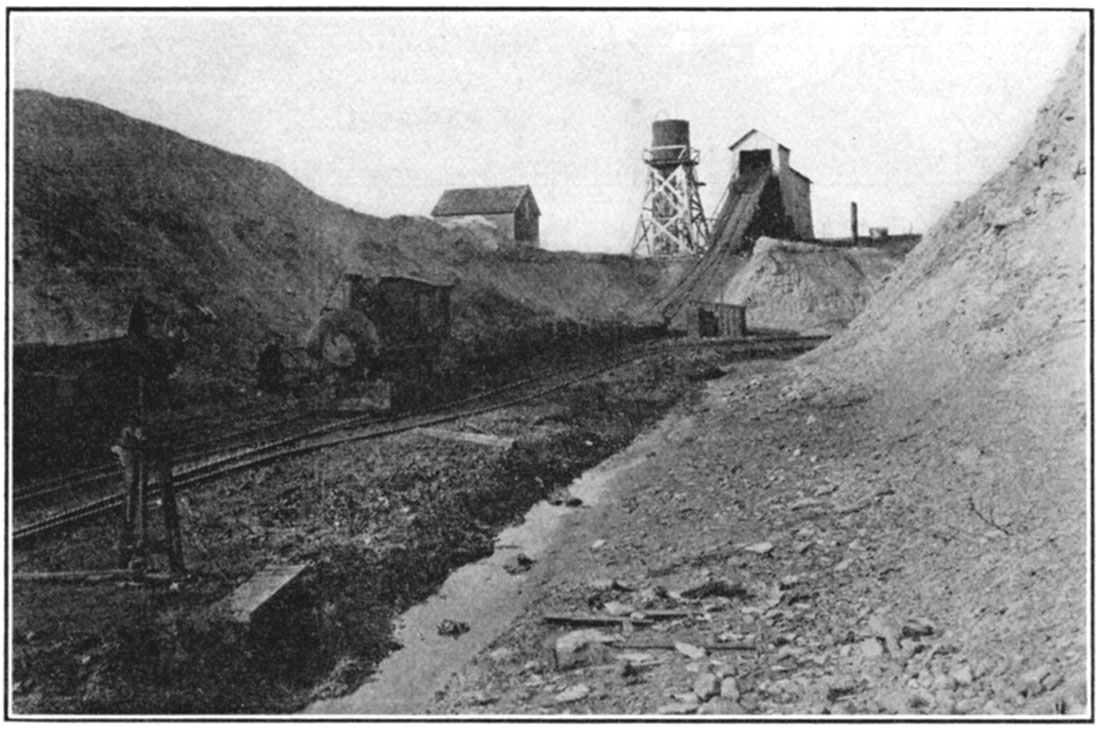

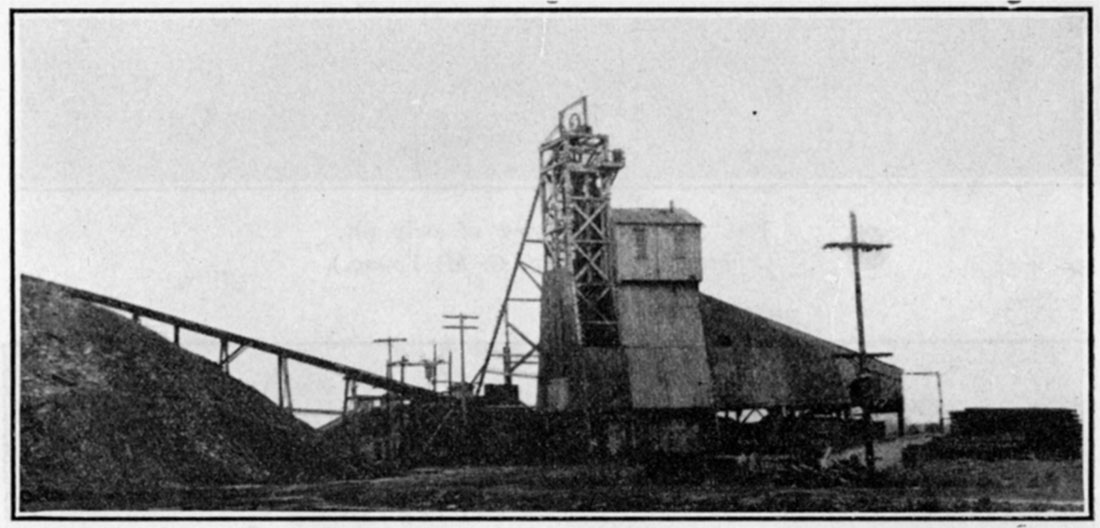

Figure 34—A scene in a Kansas coal strip pit.

At an average distance of about 60 feet above the Weir-Pittsburg coal is another bed known as the Lightning Creek coal. This bed is of about the same quality as the lower one, but is only about 2 feet thick, and at present it is not extensively mined. At the top of the Cherokee is the Lexington coal, which is mined in the vicinity of Fort Scott and in some other places. It is locally known as the Fort Scott coal. Its thickness ranges from about 15 to 20 inches. It is mined chiefly by stripping.

In the Marmaton formation there is a coal in the Bandera shale which corresponds to the Mulberry coal of Missouri. This coal ranges in thickness from 6 inches near Redfield, west of Fort Scott, to 3 feet 4 inches in the vicinity of La Cygne. It is mined by stripping near Fulton, Hammond and Prescott, and by shallow underground mining in the vicinity of Pleasanton, Boicourt and La Cygne. The limits of this coal are not known, but there is probably a large supply of good coal in this district which will be mined when the Cherokee coal is worked out.

A coal bed in the Chanute shale is mined locally west and southwest of Thayer in Neosho county. This bed, which may be designated the Thayer coal, ranges in thickness from 12 to 20 inches.

Figure 35—Tipple in Cherokee-Crawford district. (Photograph by Prof. C. M. Young.)

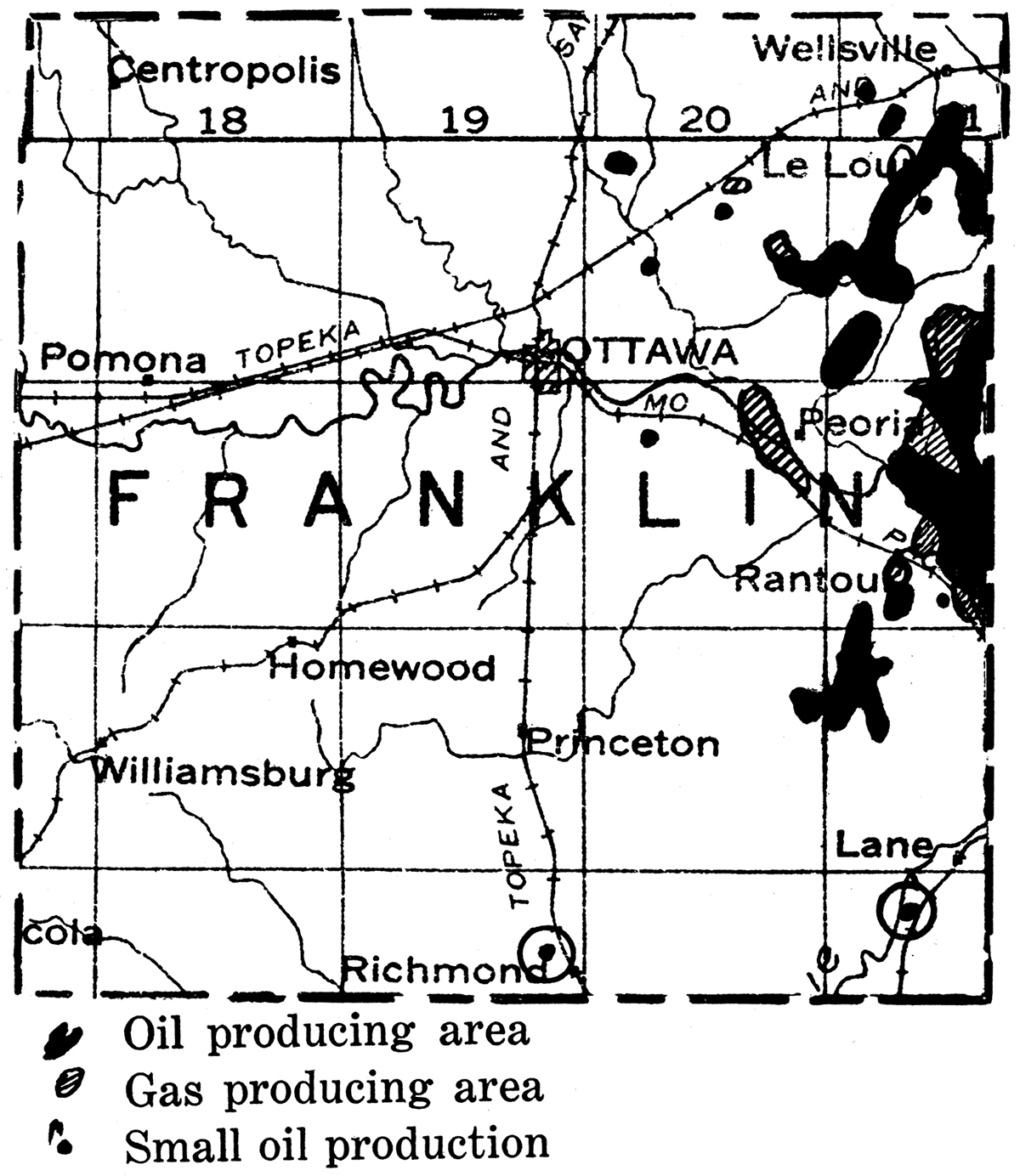

In the Lawrence shale thin but widely distributed beds of coal are found for many miles along the outcrop. The chief development is in the southwest part of Franklin county, in the vicinity of Homewood, Ransomville and Williamsburg, in a bed that may be called the Ransomville coal. It occurs about 150 feet below the top of the shale and ranges in thickness from 12 to 24 inches. A less important bed is recorded about 30 to 40 feet below the top of the shale. The Ransomville coal is mined by stripping and by underground mining, the long-wall method being employed.

The Osage county district exploits coal in the Severy shale. This coal, known stratigraphically as the Nodaway bed, is very widely traceable in Kansas, Nebraska, Missouri and Iowa, but in most places it is too thin for profitable mining. The coal at this horizon in Kansas is only mined actively in Osage county, and it is known commercially as the Osage coal. Its thickness where mined ranges from 11 to 30 inches, but the average is about 15 inches. It is interesting to note that this coal is approximately 2,000 feet higher in the series of rock strata than the Cherokee bed. The coal is mined by the longwall method. An estimate of the original workable coal in this field is recorded by C. M. Young as 89,000,000 tons.

Thin beds of coal are known higher in the Pennsylvanian section of Kansas. The Elmo coal, occurring a few feet below the Burlingame limestone, has been mined in the northeastern corner of Kansas and is exploited in a small way by the only coal mine in Nebraska, just north of the Kansas line, in Richardson county. It extends at least as far southwest as Greenwood county, but is not workable there. The Nyman coal, found just below the Table Creek limestone of Nebraska, that is, in the lower part of the Admire shale of present stratigraphic classification in Kansas, is mostly too thin to work, but was mined in Nemaha county, Kansas, in the early days before rail transportation made other fuel readily available.

Coal in the Cretaceous is found at various points in Cloud, Ellsworth, Lincoln, Mitchell, Republic and Russell counties, and is generally mined by stripping along the outcrop. The thickness of the coal ranges up to 22 inches. It is a fair grade of lignite. This coal has never been extensively exploited but is used chiefly for local supply.

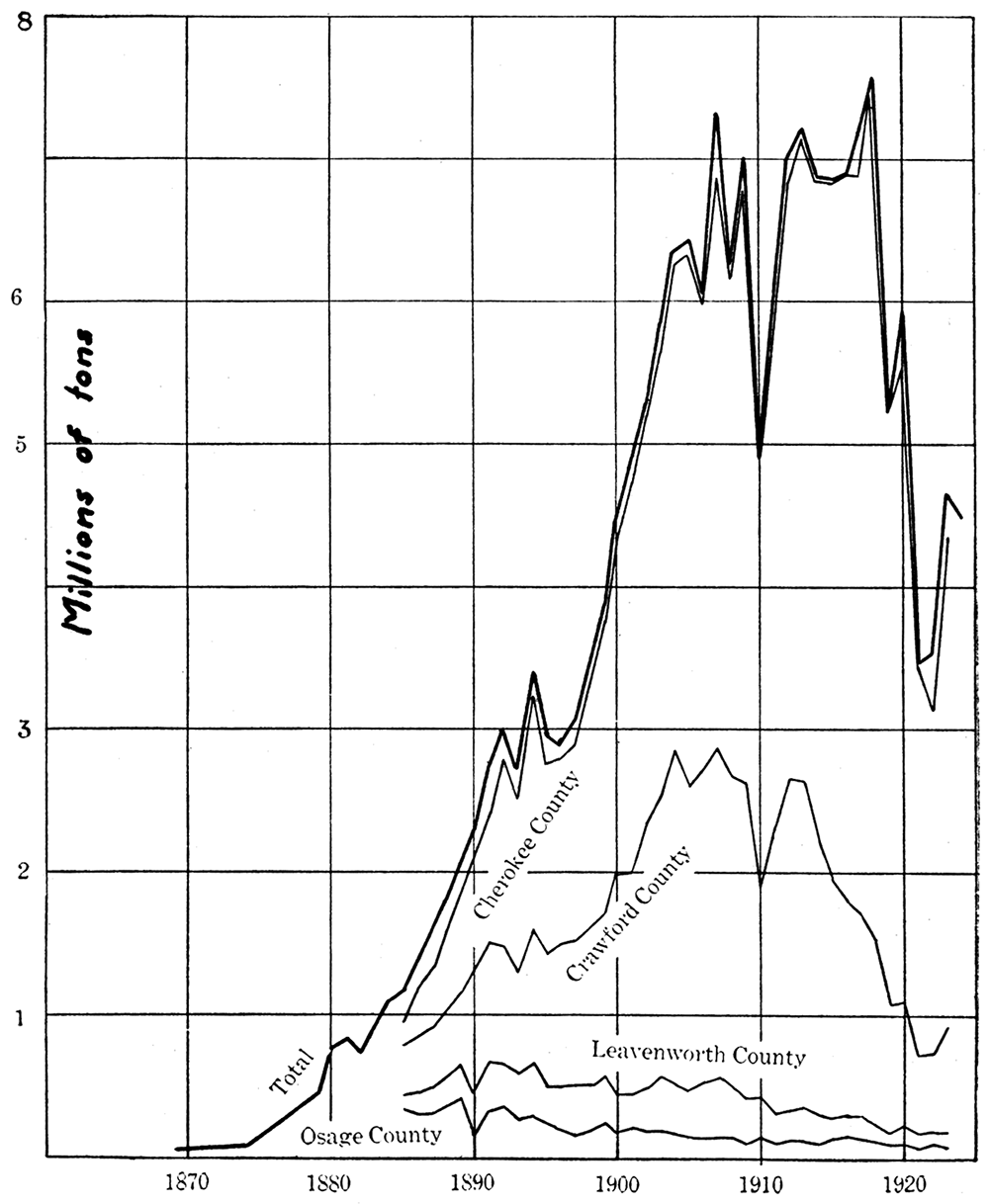

According to the best available records Kansas produced 196,865,404 tons of. coal with a total value of $352,733,000, up to the beginning of 1926. Figure 36 shows the total production of Kansas coal for years since 1869 and the yield of the main producing counties for years since 1889. During the period up to 1908, there was a fairly steady and rapid increase in the production of coal in the state. Following years show considerable fluctuation, partly resulting from strikes and from the apparent saturation of the market. Since peak production in 1918 there has been a marked decline, ascribed to competition with oil and gas, with Illinois coal which was introduced by reason of favorable freight rates from the east and because of various labor difficulties in the mining district.

Figure 36—Curve showing the cumulative production of coal in Osage, Leavenworth, Cherokee, and Crawford counties in long tons, and the total production since 1870.

Kansas coal is a good grade bituminous coal. In heating value it compares favorably with bituminous coal from other districts in the United States, but is somewhat softer than some of the Illinois coals. If stored for too long a time it tends to slack, and its ash and relatively high volatile matter make it naturally less valuable than semibituminous or anthracite coals for many purposes. Good coke can be made from Kansas coal, but the sulphur content makes this coke unfit for some uses, especially in metallurgical work. Studies by Professor H. C. Allen, of the Kansas University Division of State Chemical Research, indicate interesting possibilities in manufacture of a semi coke from Kansas coal. The coal is heated to a lower temperature than in ordinary coking, and as by-products many valuable materials are obtained. The coke derived from this treatment, made in the form of briquettes, is an excellent domestic fuel, Analyses of average Kansas coals, as given by Allen, are recorded below. The most detailed recently published description of Kansas coal will be found in a report by Professor C. M. Young, University of Kansas, Engineering Bulletin 13, "Occurrence and Production of Kansas Coal," and H. C. Allen, Chemical Research Division, Bulletin 4, "The Chemistry of Kansas Coal."

| Average Analyses and Heating Values of Kansas Coals | |||||||

|---|---|---|---|---|---|---|---|

| No. | Form | Proximate analysis | |||||

| Moisture | Volatile | Fixed carbon |

Ash | Sulphur | British thermal units |

||

| 1 | A | 9.12 | 35.66 | 40.26 | 14.96 | 4.59 | 10,810 |

| B | 39.25 | 44.35 | 16.40 | 5.06 | 11,910 | ||

| C | 46.95 | 53.05 | 14,240 | ||||

| 2 | A | 7.29 | 36.62 | 45.78 | 10.31 | 4.42 | 10,630 |

| B | 39.48 | 49.36 | 11.16 | 4.77 | 11,470 | ||

| C | 44.46 | 55.54 | 12,900 | ||||

| 3 | A | 4.65 | 32.25 | 49.89 | 13.21 | 4.18 | 11,100 |

| B | 33.83 | 52.32 | 13.85 | 4.38 | 11,650 | ||

| C | 39.24 | 60.76 | 13,510 | ||||

| 4 | A | 3.26 | 33.55 | 54.24 | 8.95 | 4.26 | 13,402 |

| B | 34.68 | 56.06 | 9.26 | 4.40 | 13,860 | ||

| C | 38.22 | 61.78 | 15,270 | ||||

| No. | Number of analyses | Source of coal |

| 1 | 537 | Leavenworth and vicinity |

|---|---|---|

| 2 | 18 | Osage City and vicinity |

| 3 | 337 | Southeastern Kansas |

| 4 | 8 | Samples from seams in southeastern Kansas mines |

| Total Production and Value of Coal Produced in Kansas, 1869-1925, Inclusive |

|||||||

|---|---|---|---|---|---|---|---|

| Year | Tons | Value | |||||

| 1869 | 32,938 | ||||||

| 1880 | 550,000 | ||||||

| 1881 (Long tons) | 750,000 | $4,200,000* | |||||

| 1882 (Long tons) | 750,000 | ||||||

| 1883 | 900,000 | ||||||

| 1884 | 1,100,000 | ||||||

| 1886 | 1,082,230 | 1,410,000 | |||||

| 1886 | 1,000,000 | 1,680,000 | |||||

| 1887 | 1,596,879 | 2,236,000 | |||||

| 1888 | 1,850,000 | 2,775,000 | |||||

| 1889 | 2,221,043 | 3,297,000 | |||||

| 1890 | 2,269,922 | 2,948,000 | |||||

| 1891 | 2,716,705 | 3,567,000 | |||||

| 1892 | 3,007,276 | 3,956,000 | |||||

| 1893 | 2,662,546 | 3,376,000 | |||||

| 1894 | 3,388,251 | 4,179,000 | |||||

| 1896 | 2,926,870 | 3,482,000 | |||||

| 1896 | 2,886,801 | 3,295,000 | |||||

| 1897 | 3,054,012 | 3,602,000 | |||||

| 1898 | 3,406,555 | 3,703,000 | |||||

| 1899 | 3,852,267 | 4,478,000 | |||||

| 1900 | 4,467,870 | 5,466,000 | |||||

| 1901 | 5,900,528 | 5,993,000 | |||||

| 1902 | 5,266,065 | 6,868,000 | |||||

| 1903 | 5,839,976 | 8,872,000 | |||||

| 1904 | 6,333,307 | 9,641,000 | |||||

| 1906 | 6,423,979 | 9,861,000 | |||||

| 1906 | 6,024,776 | 8,980,000 | |||||

| 1907 | 7,322,449 | 11,160,000 | |||||

| 1908 | 6,245,508 | 9,292,000 | |||||

| 1909 | 6,986,478 | 10,083,000 | |||||

| 1910 | 4,921,461 | 7,916,000 | |||||

| 1911 | 6,178,728 | 9,474,000 | |||||

| 1912 | 6,986,182 | 11,824,000 | |||||

| 1913 | 7,202,210 | 12,036,000 | |||||

| 1914 | 6,860,988 | 11,288,000 | |||||

| 1915 | 6,824,474 | 11,860,000 | |||||

| 1916 | 6,881,466 | 12,253,000 | |||||

| 1917 | 7,184,975 | 16,618,000 | |||||

| 1918 | 7,661,947 | 22,028,000 | |||||

| 1919 | 5,224,724 | 15,917,000 | |||||

| 1920 | 5,926,408 | 22,928,000 | |||||

| 1921 | 3,466,641 | 18,467,000 | |||||

| 1922 | 2,955,170 | 10,816,000 | |||||

| 1923 | 4,035,404 | 12,981,000 | |||||

| 1924 | 4,150,000 | 13,000,000* | |||||

| 1925 | 4,092,000* | 11,600,000* | |||||

| *Estimated. | |||||||

Gypsum

Slightly over one million dollars worth of gypsum was mined in Kansas in 1925. This places gypsum twelfth among the mineral industries of Kansas. It likewise places Kansas ninth among the states of the union in value of gypsum production. Gypsum production by years since 1916 is given below.

| Annual Production Values of Gypsum in Kansas | |

|---|---|

| 1916 | $322,785 |

| 1917 | $424,611 |

| 1918 | $848,749 |

| 1919 | $620,673 |

| 1920 | $968,298 |

| 1921 | $655,164 |

| 1922 | $690,740 |

| 1923 | $842,740 |

| 1924 | $894,262 |

| 1925 | $1,009,510 |

| $6,672,681 | |

Chemically gypsum consists of calcium sulphate with combined water. It is formed by precipitation on the floor of the sea or of saline lakes in the same manner as salt. In fact strata of the latter substance often underlie or overlie gypsum beds. Anhydrite, which is calcium sulphate without chemically combined water, is another common associate of gypsum. In some regions gypsum beds when followed beneath the surface for some distance change into anhydrite. In this case the gypsum is secondary, having been formed through the hydration of anhydrite by near-surface waters. Anhydrite has no commercial value.

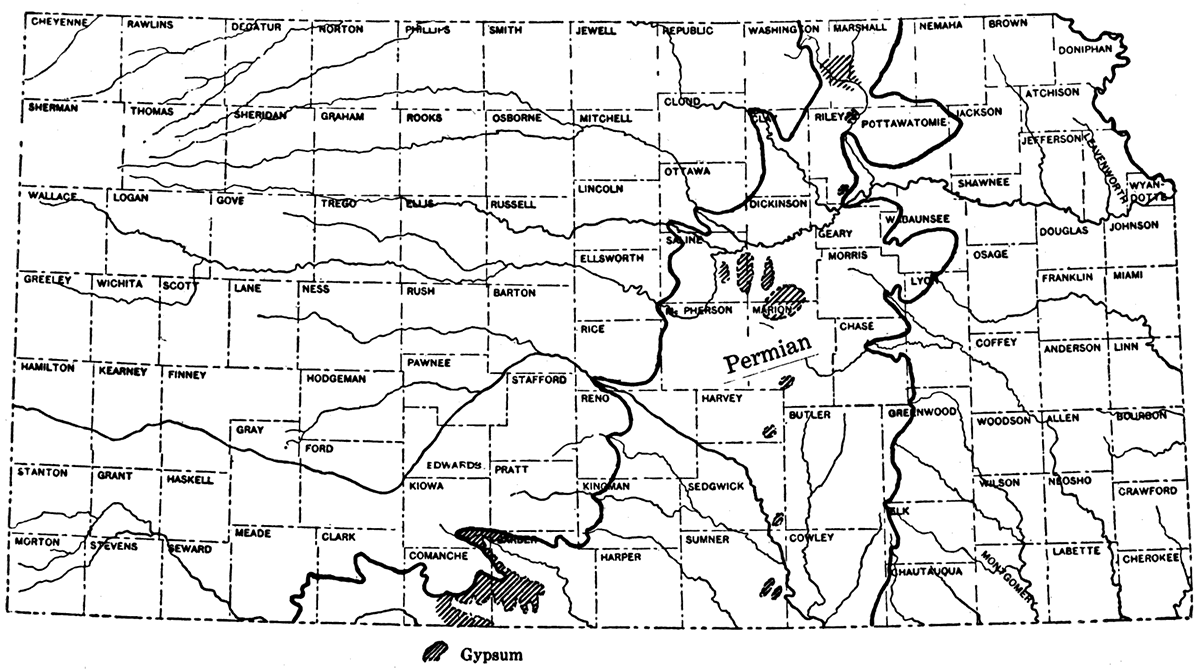

Workable deposits of gypsum are found in Kansas in rocks of Permian age. Strata of this age appear at the surface in a broad band extending from the center of the southern boundary of the state to the Nebraska line in a direction slightly east of north. The gypsum mining districts are located along this band. There are three main centers of production. The northern two contain gypsum beds interstratified with limestones and shales. In the southern part of the state thick layers of gypsum are interbedded with red shales and sandstones known as the "red beds." In this area the gypsum is higher stratigraphically and therefore younger than in the districts to the north.

Figure 37—Map of Kansas showing the distribution of gypsum deposits. (From Bull. 697, U. S. Geol. Survey.)

The Blue Rapids district is in the northern part of the state in Marshall county. Southwest of the town of Blue Rapids the United States Gypsum Company is mining by underground workings a bed of gypsum averaging 7 feet in thickness. At Blue Rapids both this company and the Beaver Products Company operate plants.

The central, or Gypsum City district, lies in Dickinson and Saline counties. There are two well marked horizons of gypsum in this area, with some indication of a third and lower horizon in the southern part. The upper or thinner of the well marked horizons has been quarried at Hope, where the gypsum bed is about 5 feet thick. The lower horizon, containing 14 feet of gypsum in places, was penetrated by an 8O-foot shaft a quarter of a mile west of the Hope quarry. This bed has also been mined near Solomon, twenty miles northwest of Hope. The central district had no regularly operated plant in 1924.

The southern, or Medicine Lodge district, is located in Barber and Comanche counties. It is the largest of the Kansas districts and, with its continuation in Oklahoma and Texas, forms the largest area of gypsum in the United States.

The principal gypsum bed of this district, known as the Medicine Lodge, is massive, with the lower portion very compact. It forms the cap rock for the gypsum hills which lie to the west of Medicine Lodge. Underlying red sandstones and shales crop out along the flanks of the hills. The gypsum layer varies in thickness from 3 to 20 feet, depending upon the amount of erosion. Elsewhere in the region a bed of gypsum 15 feet in thickness appears above a red shale of equal thickness which overlies the Medicine Lodge bed.

Figure 38—A Kansas gypsum quarry.

The Best Brothers Keene's Cement Company operates a quarry at Sun City, in northwestern Barber county. They mine a single bed of gypsum 16 feet thick which is covered by a small overburden. From Sun City the quarried material is transported by rail to Medicine Lodge, where the company has a mill.

About one-fifth of the annual production of gypsum in the United States is marketed without calcining. This "raw" gypsum is mainly used by the cement industry as a retarder. In the manufacture of Portland cement 2 per cent of gypsum must be added to prevent too quick setting. The next largest use for crude gypsum is as a land plaster, or fertilizer. It is not in itself a plant food, but it often reacts with other substances to produce plant foods.

Raw ground gypsum is used in manufacturing blackboard crayons, as a base for paints and insecticides such as Paris green, and as a filler for cotton and paper. In arid regions rock gypsum may be used as a road metal and building stone.

The remaining four-fifths of the gypsum produced in the United States is calcined. This process consists of driving off by heat about three-fourths of the chemically combined water. The resulting material, plaster of Paris, has the property of setting or hardening when mixed with water. If all of the water is driven off anhydrite will be formed, which reunites with water too slowly to be of commercial use. Gypsum plaster sets so rapidly that for most uses a retarder is employed. A common retarder is one containing hair, caustic soda, and lime.

Figure 39—A gypsum mill at Medicine Lodge, Kan.

The greatest use of calcined gypsum is as wall plaster. For this purpose other ingredients are added such as hair, wood fibre, and sand. Gypsum plaster is a very poor conductor of heat. A more recent use of gypsum is in the manufacture of plaster board, tile, and blocks. These products are of value for their fireproof character and their ability to deaden sound. Other major uses are in the manufacture of stucco and Keene's cement. The plate glass industry is a large purchaser of calcined gypsum for use in bedding plate glass for polishing.

Several score minor uses for gypsum could be mentioned. Among these are in the manufacture of statuary, relief maps, and models; as pottery, terra cotta, and foundry molds; for making artificial marble, surgical casts, and specimen mounts; and as a mild abrasive, such as tooth pastes and powders. Calcined gypsum is also used as a binder in match heads, and as a chief ingredient in pipe covering.

Lead and Zinc

Lead and zinc occur in the southeastern corner of Kansas in Cherokee county. Although the producing district is very limited in areal extent, Kansas produced in 1925, 22,775 tons of lead and 118,778 tons of zinc. The value of this production was $22,017,106, which places lead and zinc second only to petroleum in the mineral resources of the state. Considering the country as a whole Kansas is the second largest producer of metallic zinc and the seventh state in lead production. Since 1906 Cherokee county has produced one hundred and two million dollars worth of zinc and twenty-one and one-third million dollars worth of lead. A statistical table showing this production by years is given herewith.

The metalliferous deposits of southeastern Kansas are a part of a much larger lead-zinc district which extends over the state boundaries into Missouri and Oklahoma. At one time during 1917 one thousand rigs were at work in Oklahoma and Kansas searching for new ore. They were so successful in their hunt that the center of mining activity was shifted from the vicinity of Joplin, Mo., to a point near the border between Kansas and Oklahoma. Here it has remained for the ores in this area are richer than those in the neighborhood of Joplin and may be profitably worked during periods of deflation when the mines in the older district are forced to shut down.

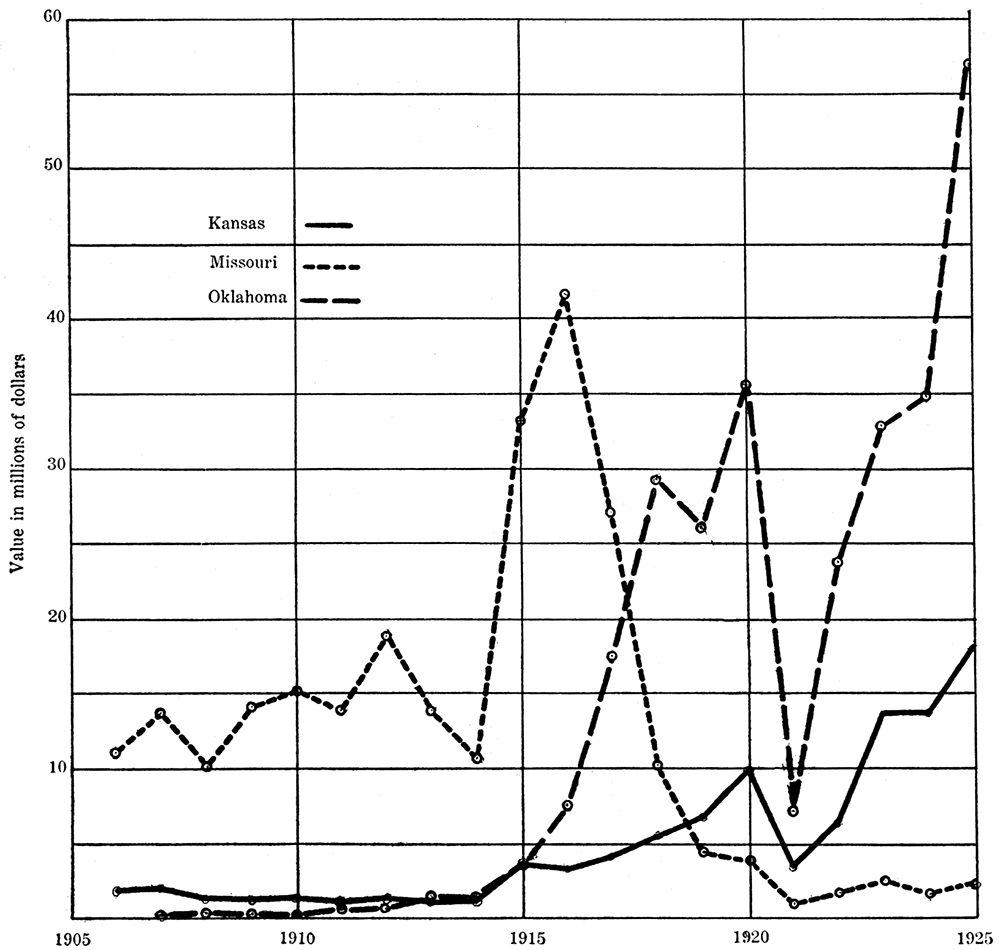

The tri-state district produces 61 per cent of the country's zinc. At one time Missouri led the other two states, but now Oklahoma leads, and Kansas is second. The production curve for each of the three states in the district is given in Figure 40. This graph illustrates forcibly the meteoric rise of the two western states as zinc producers, coincident with Missouri's decline. It is believed by many that Oklahoma is at or near the peak of production. On the other hand, Kansas in all probability has not yet reached that point, as indicated by the trend of its production curve. This state will undoubtedly become an even greater producer of zinc than it is to-day.

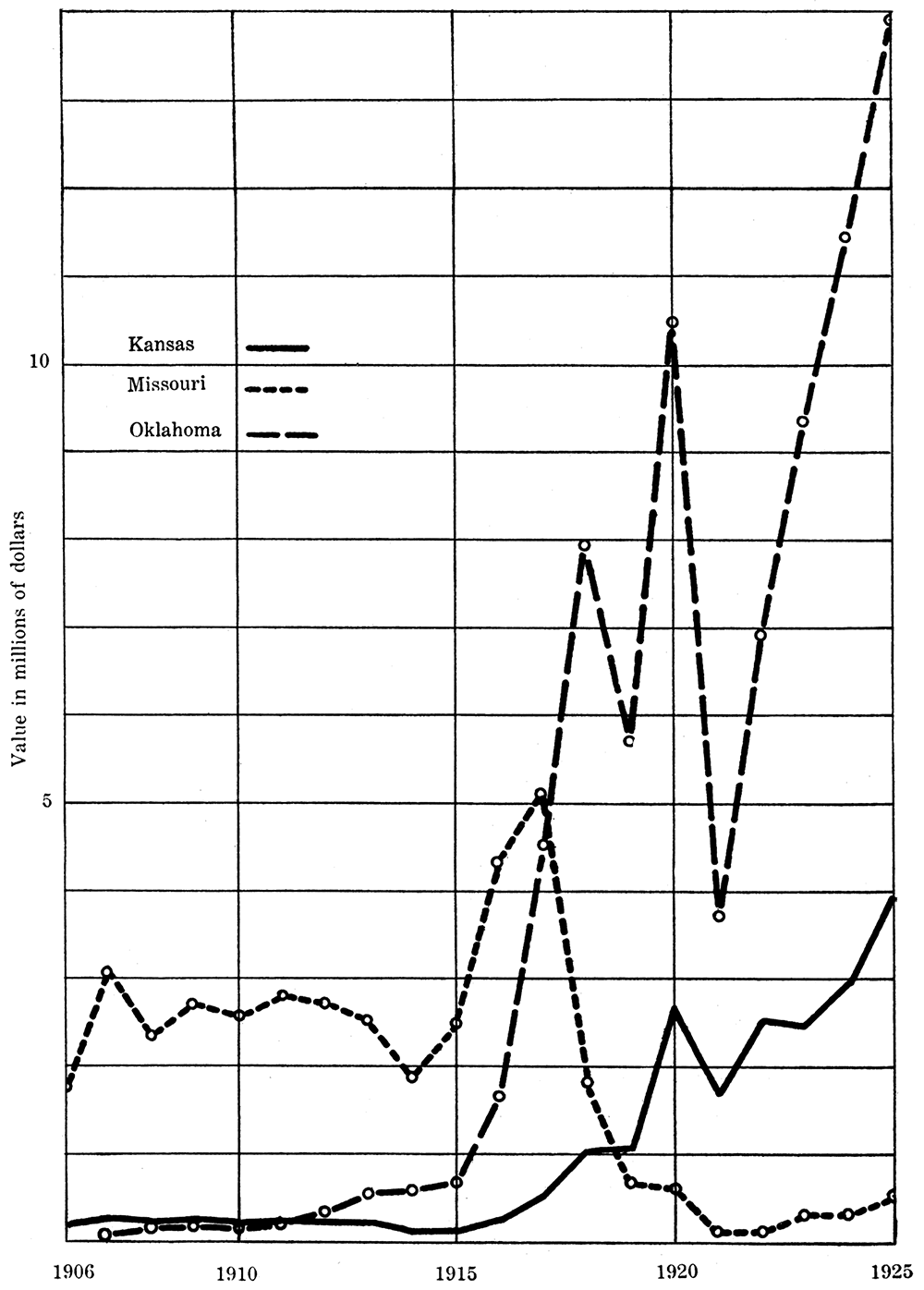

Curves showing production of lead in the tri-state area are shown in Figure 41. They likewise illustrate the ascendency of Oklahoma and Kansas over Missouri in recent years. Furthermore the production of the tri-state district as a whole has grown enormously since 1915. The annual increase for the last three years exceeds the annual production for any single year before 1915. Oklahoma and Kansas consequently should have a great future in the production of lead.

The lead and zinc ores mined in.the tri-state district occur in what is known as the Boone formation of Mississippian age. This formation crops out in the southeastern corner of Cherokee county and extends across the state boundaries into Missouri and Oklahoma. It has a gentle dip of a few feet per mile to the northwest. This inclination carries the ore-bearing strata under the surface of the land in that direction. Above the Boone formation lie sandstones, shales, and coal beds of Pennsylvanian age, which crop out in successive bands to the west and northwest. The newer mines in Kansas are located on shale which must be penetrated before the ore is encountered.

The Boone formation consists largely of limestone and chert beds. The minerals containing the lead and zinc have been deposited by subsurface waters along certain horizons in the chert and in cavities existing in the limestone. Most of the mining is confined to the first three hundred feet beneath the surface, although drill records show the existence of ore to greater depths.

| Annual Production Values of Lead and Zinc in Kansas | ||

|---|---|---|

| Year | Lead | Zinc |

| 1906 | $198,170 | $1,996,615 |

| 1907 | 270,830 | $2,097,096 |

| 1908 | 211,512 | $1,327,186 |

| 1909 | 237,704 | $1,236,060 |

| 1910 | 212,256 | $1,428,732 |

| 1911 | 257,310 | $1,171,008 |

| 1912 | 213,390 | $1,467,354 |

| 1913 | 213,576 | $1,129,856 |

| 1914 | 109,902 | $1,160,968 |

| 1915 | 113,928 | $3,562,620 |

| 1916 | 227,424 | $3,336,064 |

| 1917 | 520,300 | $4,130,796 |

| 1918 | 1,029,784 | $6,495,854 |

| 1919 | 1,195,998 | $6,954,856 |

| 1920 | 2,686,080 | $9,893,826 |

| 1921 | 1,681,110 | $3,699,400 |

| 1922 | 2,559,810 | $6,409,650 |

| 1923 | 2,463,720 | $13,731,784 |

| 1924 | 2,969,600 | $13,700,960 |

| 1925 | 3,967,850 | $18,064,266 |

| $21,340,254 | $101,974,839 | |

Figure 40—Curves showing the relative values by states of zinc produced in the Tri-state district.

Figure 41—Curves showing the relative value by states of lead produced in the Tri-state district.

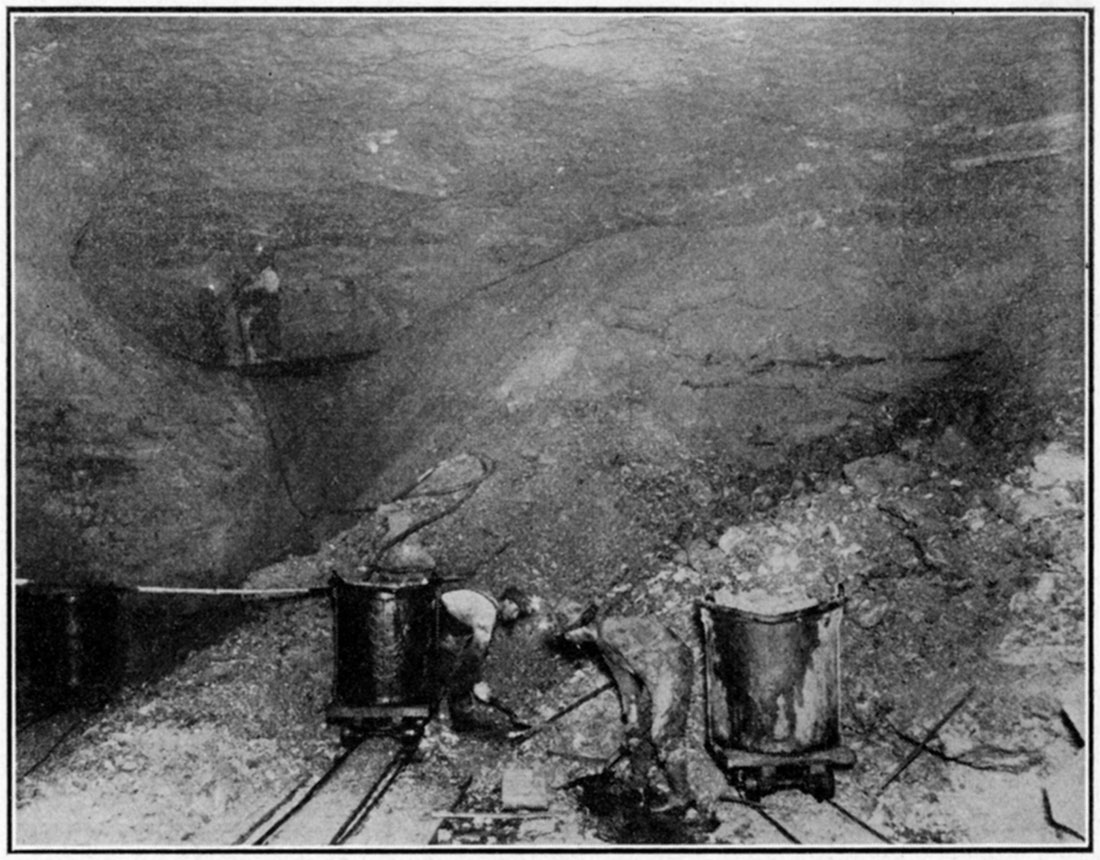

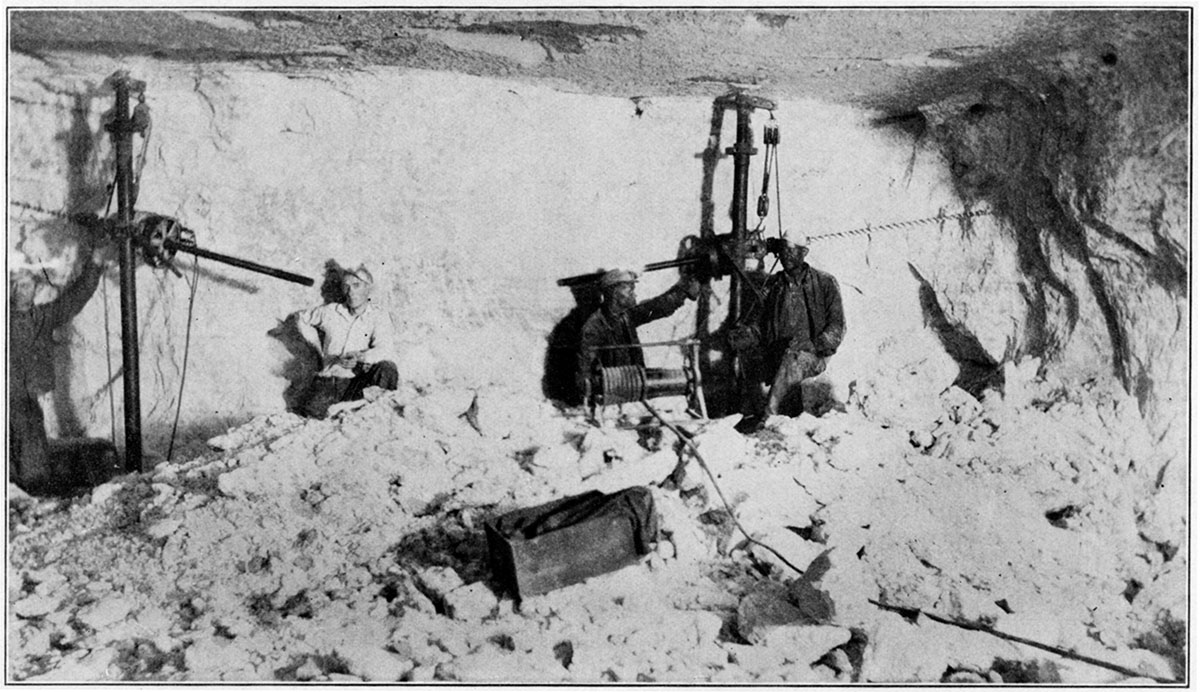

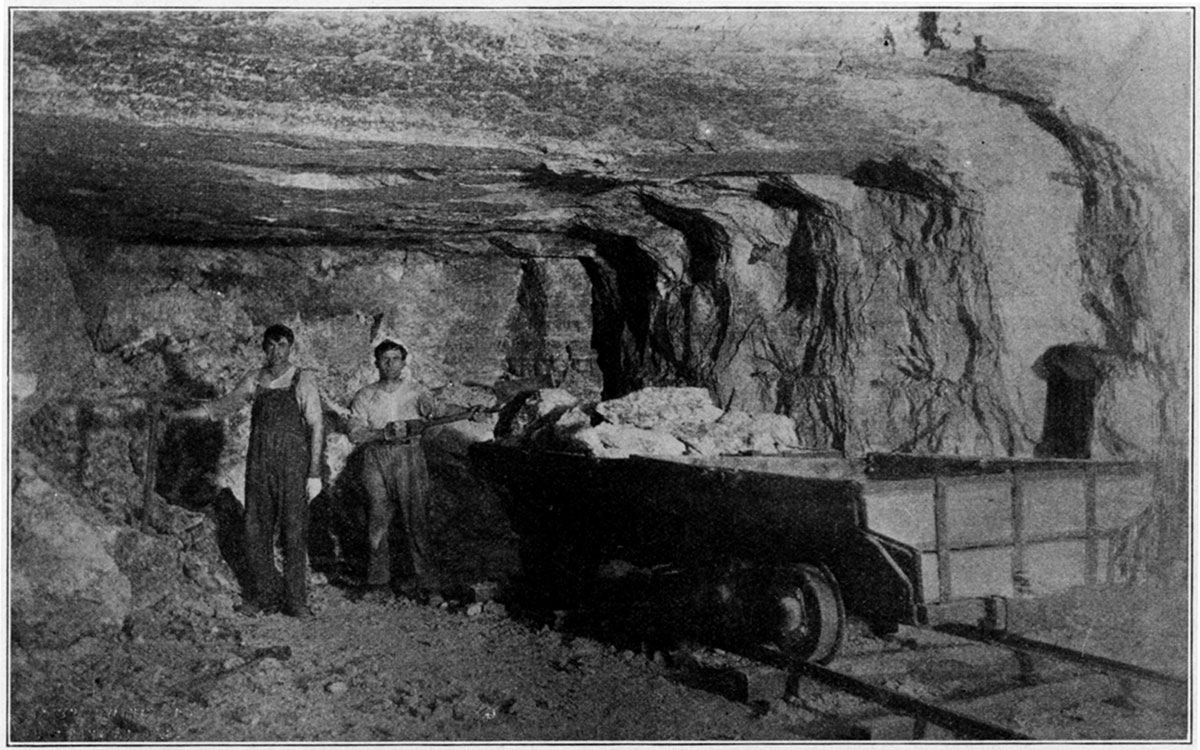

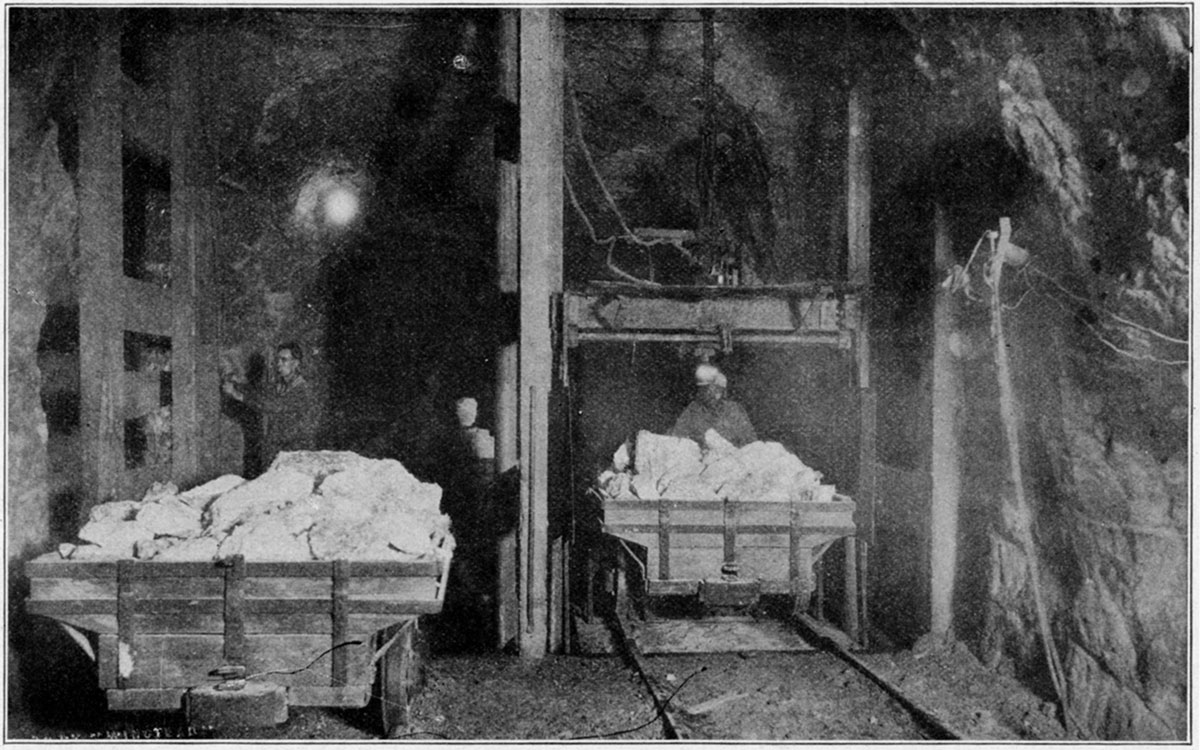

Figure 42—Underground view in Tri-state mining district.

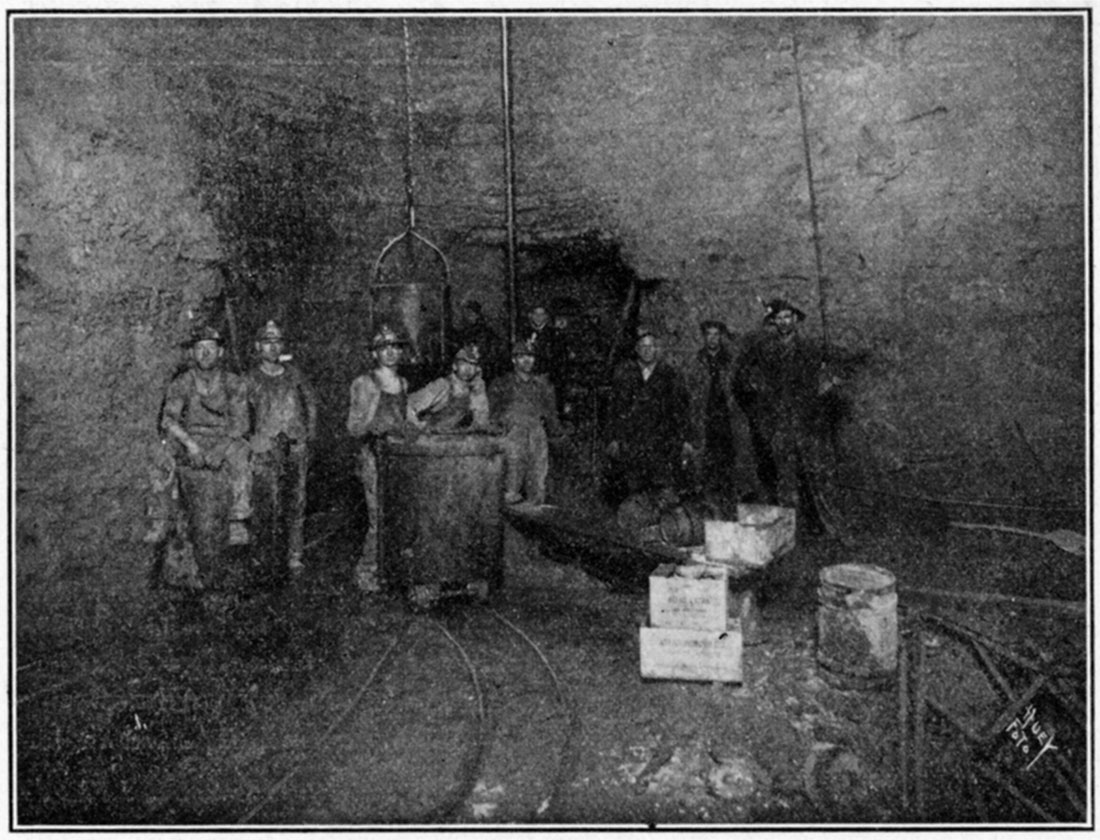

Figure 43—Underground mining scene, southeastern Kansas.

Assuming stable market conditions, there are three possible causes for the shutdown of a mine. In the first place the operators may run out of ore. Secondly, the ore may become of such poor grade as to be unprofitable. Lastly, the ore may descend to such depths that increased operating costs will exceed the receipts from the marketing of the ore. In the first instance the property will have to be abandoned. But in the second and third instances one of a. variety of causes may allow the mine to continue in operation. Slowing up of production may create a world shortage and a consequent increase in market value. Improved methods in mining and milling often allow the working of leaner or deeper ores at a profit which was not possible with older methods.

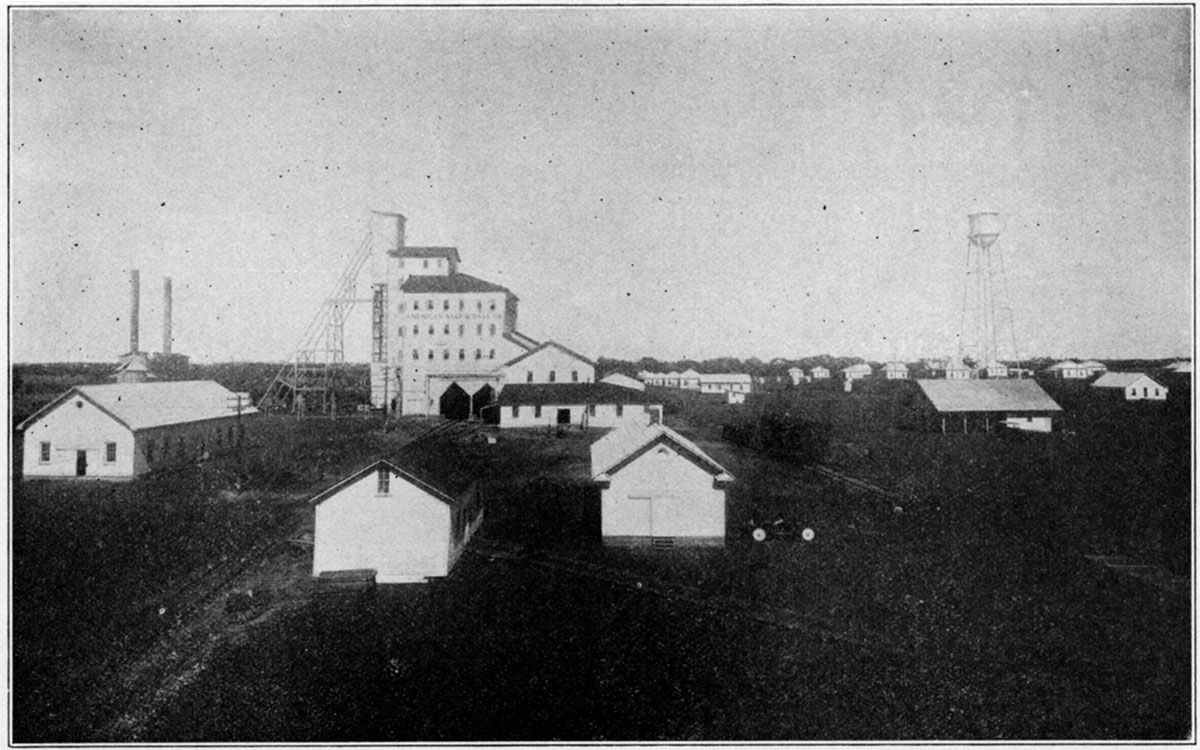

Figure 44—Lead-zinc mill at Westville, Kan.

In the Kansas portion of the tri-state district there is little possibility that the miners will soon run out of ore. But when the near-surface deposits have been worked out deeper mining win be necessary, which will, of course, involve greater hoisting and pumping expense. Kansas operators will have a choice of two courses to follow. They can go deeper in their present mines or they can follow the ore horizons in the Boone formation to the northwestward under the overlying shales, as is already being done by some operators. If they follow the latter course they may encounter areas of flatter and even reversed dips which will delay for a time the downward trend of the ore body. On the other hand the Boone formation may cease to be ore bearing at greater depth. There is need for an intensive underground study of the Kansas lead-zinc district. The question as to the distance below the surface that ore may be expected is an all-important one. Detailed research by the Kansas State Geological Survey would certainly thrown some light on this subject and thereby save the operators from useless expenditure of funds.

Southeastern Kansas may be divided into four principal mining camps. Of these the Blue Mound-Baxter Springs district just north of the Oklahoma line is by far the most important. Of the sixty mines operating in Kansas in 1924, forty-four were in this neighborhood. These mines produced almost twelve million dollars worth of zinc and over two and one-half million dollars worth of lead in that year. This is 93 per cent of the state's lead-zinc production.

The Kansas portion of the Waco district comes second with a zinc production of $1,700,000 and a lead production of $27,360. The Badger-Peacock-Crestline area is next, having produced $211,000 worth of lead and $24,000 worth of zinc in 1924. The oldest district in Kansas, Galena, is last with a lead production of $56,480 and a zinc production of $2,080. Although lower in total production the last two districts exceed Waco by a large amount in the production of lead.

Smelting of the ore is necessary to produce metallic lead and zinc. Kansas had two smelters operating in 1924, one at Cherryvale, the other at Caney. The presence in the state of smelters affords a market for our coal, clay and natural-gas industries. Unfortunately much of the locally mined ore goes outside of the state for smelting.

The chief uses of zinc are in galvanizing and brass making. A considerable quantity of the metal every year is rolled into sheet zinc. It also has a variety of other uses, such as in the manufacture of French oxide, die castings, and in the desilverization of lead. The most important uses of lead are in the manufacture of storage batteries, white lead, and in covering cables. It is also used in the manufacture of litharge, water pipe, and shot.

As in most other industries the mining and milling of lead and zinc is not without its by-products. Silver very often accompanies lead in highly profitable amounts, but that is not the case in the tri-state district. However, the sulphur separated from the metals during the process of smelting is manufactured into sulphuric acid, which is one of our most important commercial chemicals. The chert accompanying the ores is crushed during milling into a product known as chats. Twenty-nine thousand dollars worth of this material was marketing during 1924. It is used for road metal, ballast, and in concrete work.

Mineral Paints*

[*Much of the material for this chapter has been secured from an article on "The Manufacture of Zinc Oxide," by H. W. Curry, in the 1919 Chameleon, published by Sherwin-Williams Company.]

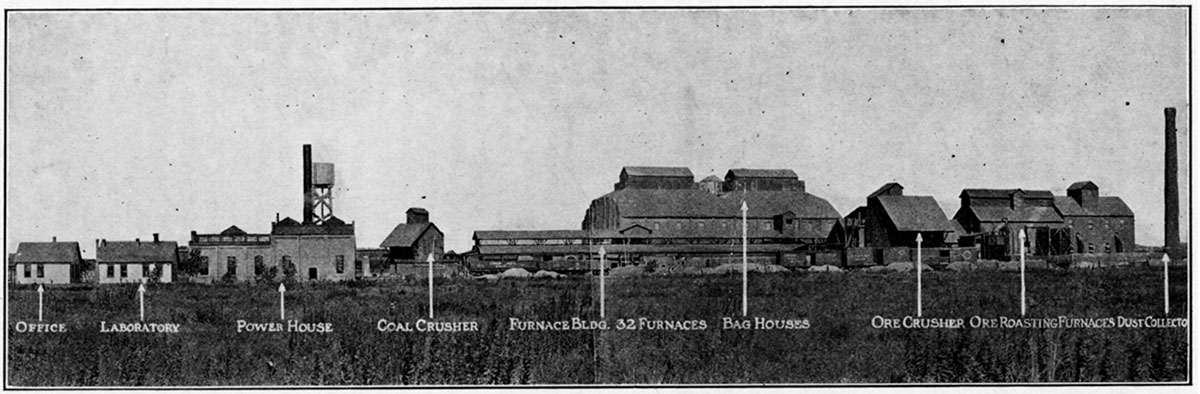

Kansas has one plant in which zinc and lead pigments are made directly from the ores. This is located at Coffeyville, in southern Montgomery county. The plant is owned by the Ozark Smelting and Mining Company, which is a subsidiary of The Sherwin-Williams Company. The value of the 1925 production of mineral paints in Kansas is included in the miscellaneous column of [Table 2].

The main product of the Coffeyville plant is leaded zinc oxide. Ores containing about thirty per cent of combined lead and zinc, and free from impurities which might later discolor the pigment, are roasted to drive off the sulphur. Just enough sulphur is left behind to combine with the lead to form lead sulphate. Then the roasted product is mixed with coal and siliceous material and charged into the pigment furnaces. At Coffeyville there are three blocks of these containing sixteen furnaces each. Here the lead and zinc are reduced, separated from their impurities, and immediately reoxidized to zinc oxide and lead sulphate. The fume containing the latter compounds is led through combustion chambers and pipes where the impurities still present are either burned off or precipitated, and then into a bag house where the leaded zinc pigment is caught by the bags. It is removed at certain intervals, refined and marketed.

Figure 45—Mineral paint plant.

The usual tri-state ore is so easily concentrated that it is too valuable to be made into pigment. The mineral paint industry affords a market for ores of lesser concentration.

Zinc oxide is used in the manufacture of high grade rubber goods, as its presence increases the durability and resiliency of the material. It is also used in the manufacture of linoleum, and when mixed with zinc chloride it is used by dentists in filling teeth. As a pigment zinc oxide is inferior to white lead in covering power, but it has the advantage of being nonpoisonous and of not becoming discolored by hydrogen sulphide. A very practical pigment is one containing sixty-five per cent zinc oxide and thirty-five per cent lead sulphate. The leaded zinc oxide manufactured at Coffeyville is all ready for use, as it contains these two ingredients intimately mixed through their simultaneous deposition in the bag house. If the zinc oxide and lead sulphate are produced independently they must be mechanically mixed, involving an extra Step, before being ready for use.

Mineral Waters

Although one of the smaller industries of Kansas the value of mineral waters produced in 1923 amounted to $72,935. This does not include water that is given away, or water furnished to guests at hotels or patients of sanitariums for drinking or bathing purposes. Mineral water may be classified by uses into two groups, medicinal and table. Medicinal waters valued at $47,503 were sold in 1923. The production of table waters amounted to $30,432.

On a basis of chemical composition mineral waters may be classified into the following groups [this is the classification followed by E. H. S. Bailey, in "Special Report on Mineral Waters." (Geological Survey of Kansas, Vol. VII, 1902.)]:

- 1. Chloride group.

- 2. Sulfate group.

- 3. Chlor-sulfate group.

- 4. Carbonate group.

- 5. Chlor-sulfo-carbonate group.

- 6. Sulfide group (those waters that give off hydrogen sulfide and are commonly called sulfur waters).

- 7. Iron and manganese group.

- 8. Special group (containing some special substance such as lithium, boron, etc.).

- 9. Soft water group (containing only small quantities of mineral substances).

In the report by Bailey 108 natural mineral waters of Kansas are described; of this number 21 belong to the sulfate group, 18 to the chloride group, 16 to the iron group, 13 to the carbonate group, and the remainder scattered among the other groups. These springs are all located in the eastern two-thirds of the state where the Paleozoic and Mesozoic rocks crop out at the surface. They are more abundant in the Paleozoic rocks than in those of younger age.

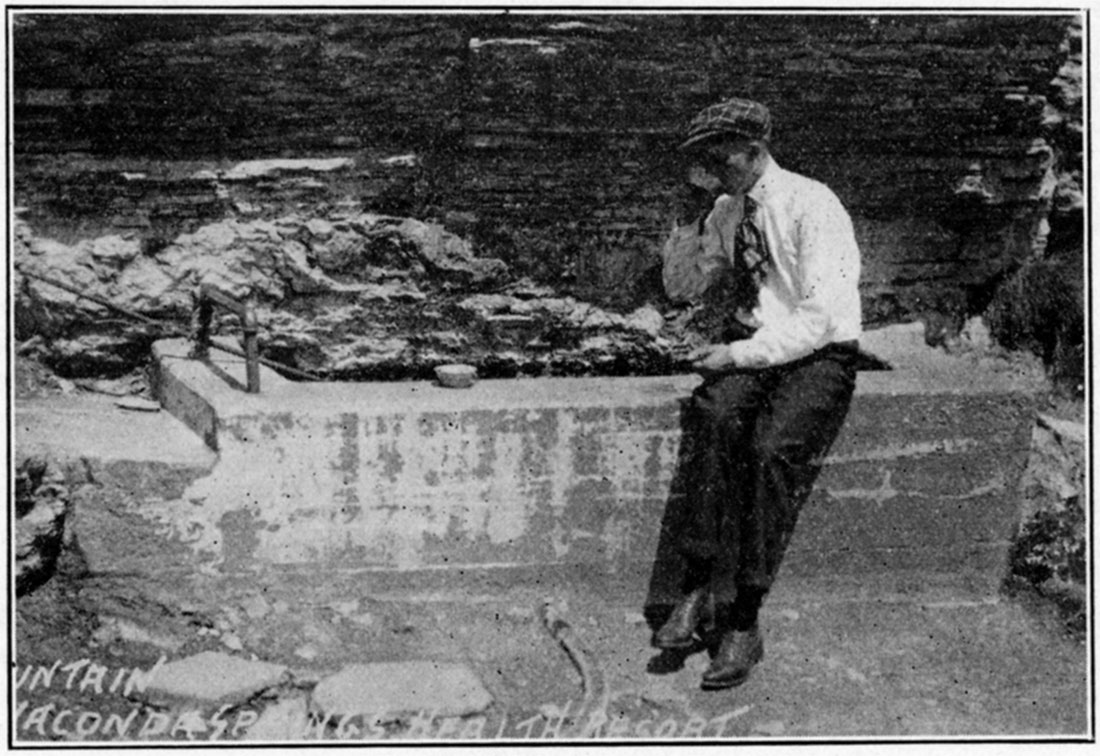

Figure 46—Mineral spring fountain at Waconda.

Figure 47—Mineral spring at Waconda.

There were twelve mineral springs in Kansas from which waters were sold in 1923. These are listed below:

| Spring or well | Nearest post office | County |

|---|---|---|

| Abilene wells | Abilene | Dickinson |

| Blasing's Springs | Manhattan | Riley |

| Conway Springs | Conway Springs | Butler |

| Crystal Springs | Coffeyville | Montgomery |

| Geuda Springs | Geuda Springs | Cowley |

| Mineral Rock Springs | Kansas City | Wyandotte |

| Mission Springs | Mission | Harvey |

| Rockheart Mineral Springs | Parsons | Labette |

| Sunnydale Springs | Valley Center | Sedgwick |

| Sycamore Springs | Morrill | Brown |

| Viola Springs | Viola | Sedgwick |

| Waconda Springs | Waconda Springs | Mitchell |

At Blasing's Springs and Waconda Springs there are bathing establishments and hotels in connection.

Natural Gas

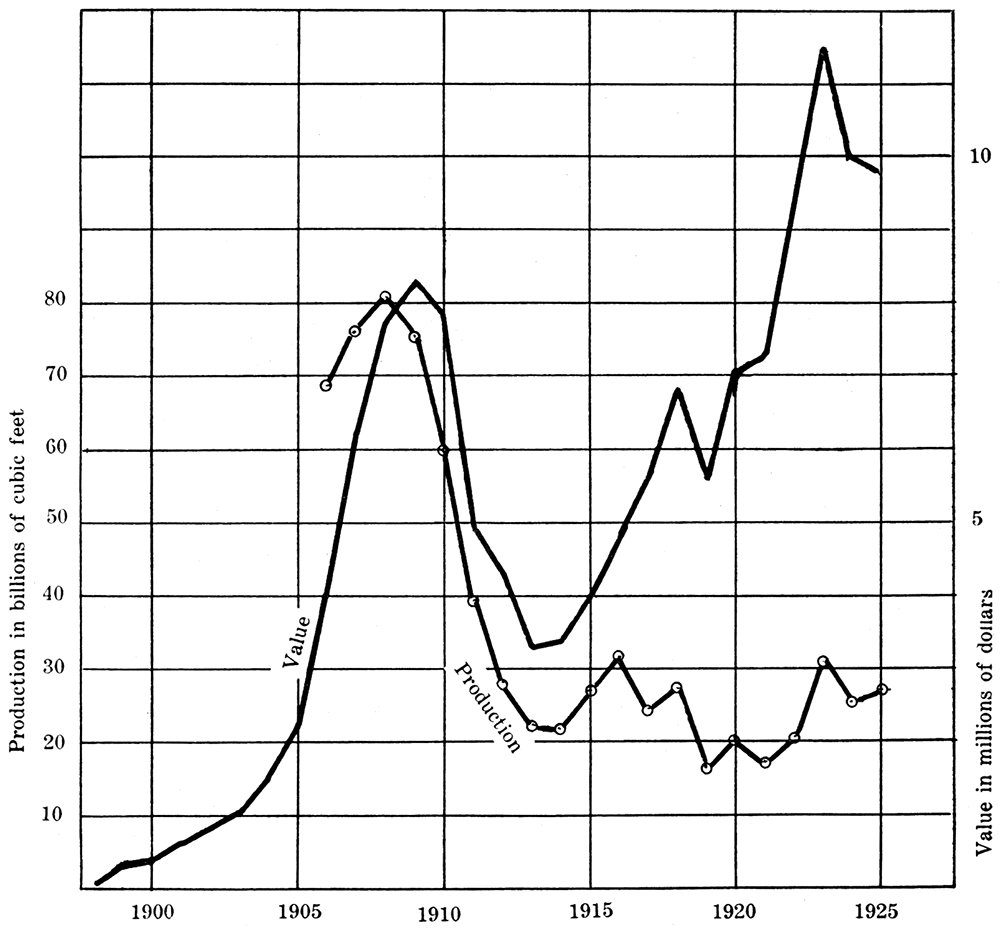

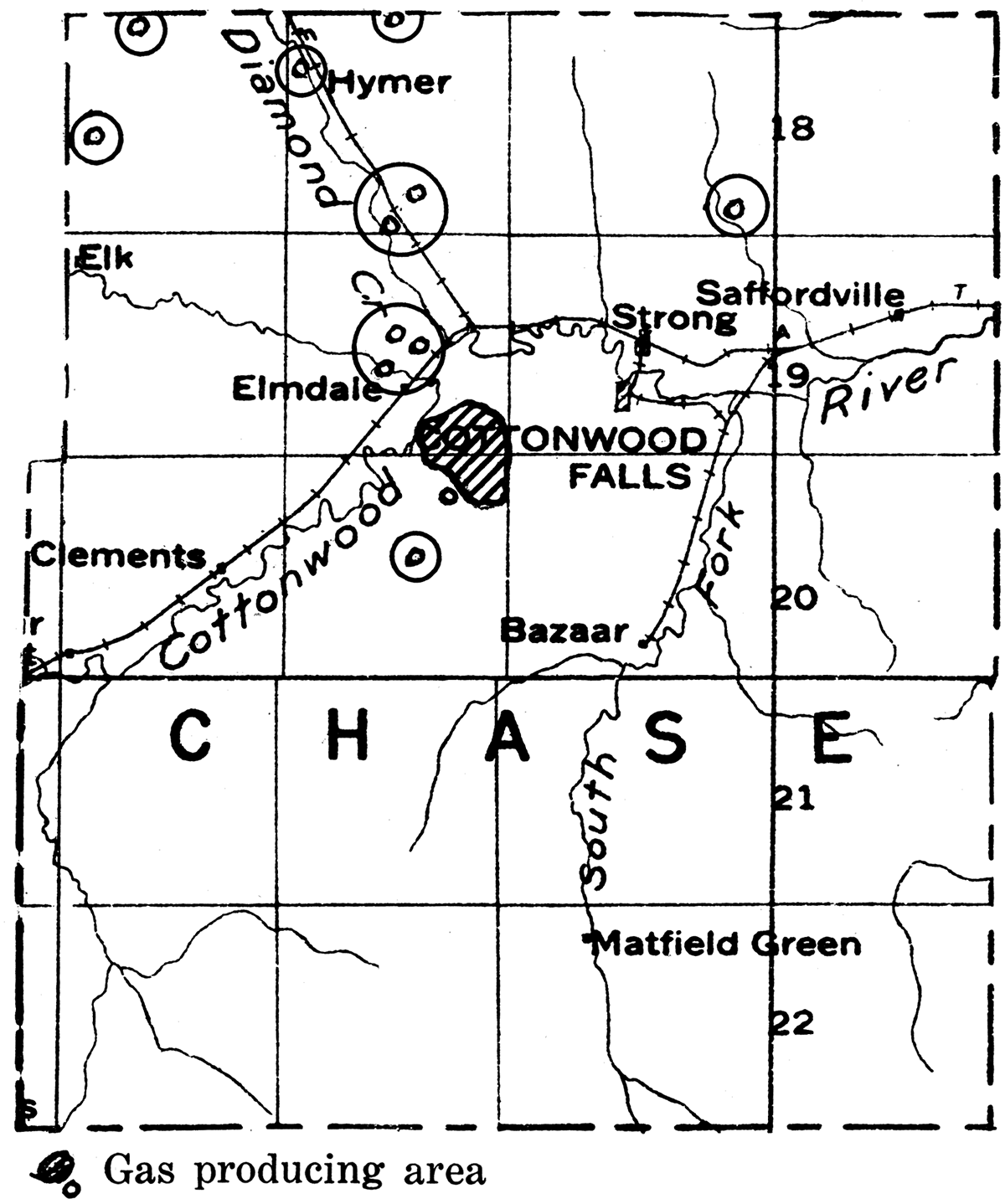

More or less gas has been found with the oil of the Kansas oil fields, but in some districts large gas production is obtained without finding oil. In the mad scramble for petroleum in past years much of the gas has been wasted. From 1908 to 1910 Kansas ranked third as a gas producing state and fourth as to the value of the gas produced. In 1911 it fell to fifth place in both regards, and since that time, while production has been large, it has not reached the peak of 80 billion cubic feet which was produced in 1908.

The number of gas wells in the state is relatively small when compared to the total number of oil wells. Many of the latter have also yielded considerable quantities of gas. Sometimes the gas has been utilized in field development. The fact that the rich Longton gas field was developed in an area that had already been tested for oil seems to indicate that future developments may still find good gas supplies in the old long prospected shallow fields of eastern Kansas. The following table shows the production of natural gas in Kansas by years and the value of the production. Brief description of some of the gas pools is given under county headings in the chapter on "Petroleum."

| Natural Gas in Kansas 1898-1925 | ||

|---|---|---|

| Year | Production in billions cu. ft. |

Value |

| 1898 | $175,000 | |

| 1899 | $888,000 | |

| 1900 | $857,000 | |

| 1901 | $659,000 | |

| 1902 | $824,000 | |

| 1908 | $1,124,000 | |

| 1904 | $1,518,000 | |

| 1905 | $2,262,000 | |

| 1906 | 69,328 | $4,011,000 |

| 1907 | 76,707 | $15,199,000 |

| 1908 | 80,740 | $7,692,000 |

| 1909 | 75,074 | $8,299,000 |

| 1910 | 59,880 | . $7,555,000 |

| 1911 | 88,799 | $4,855,000 |

| 1912 | 28,068 | $4,265,000 |

| 1913 | 22,884 | $3,288,000 |

| 1914 | 22,628 | $3,340,000 |

| 1916 | 27,046 | $4,037,046 |

| 1916 | 31,710 | $4,865,000 |

| 1917 | 24,488 | $5,701,000 |

| 1918 | 27,825 | $6,641,000 |

| 1919 | 16,150 | $5,492,000 |

| 1920 | 21,158 | $7,164,000 |

| 1921 | 15,717 | $7,382,000 |

| 1922 | 20,289 | $9,123,000 |

| 1923 | 80,918 | $11,249,000 |

| 1924 | 26,680 | $10,087,000 |

| 1926 | 26,917 | $9,991,000 |

Figure 48—Curve showing value and production of natural gas in Kansas since 1898.

Natural-gas Gasoline

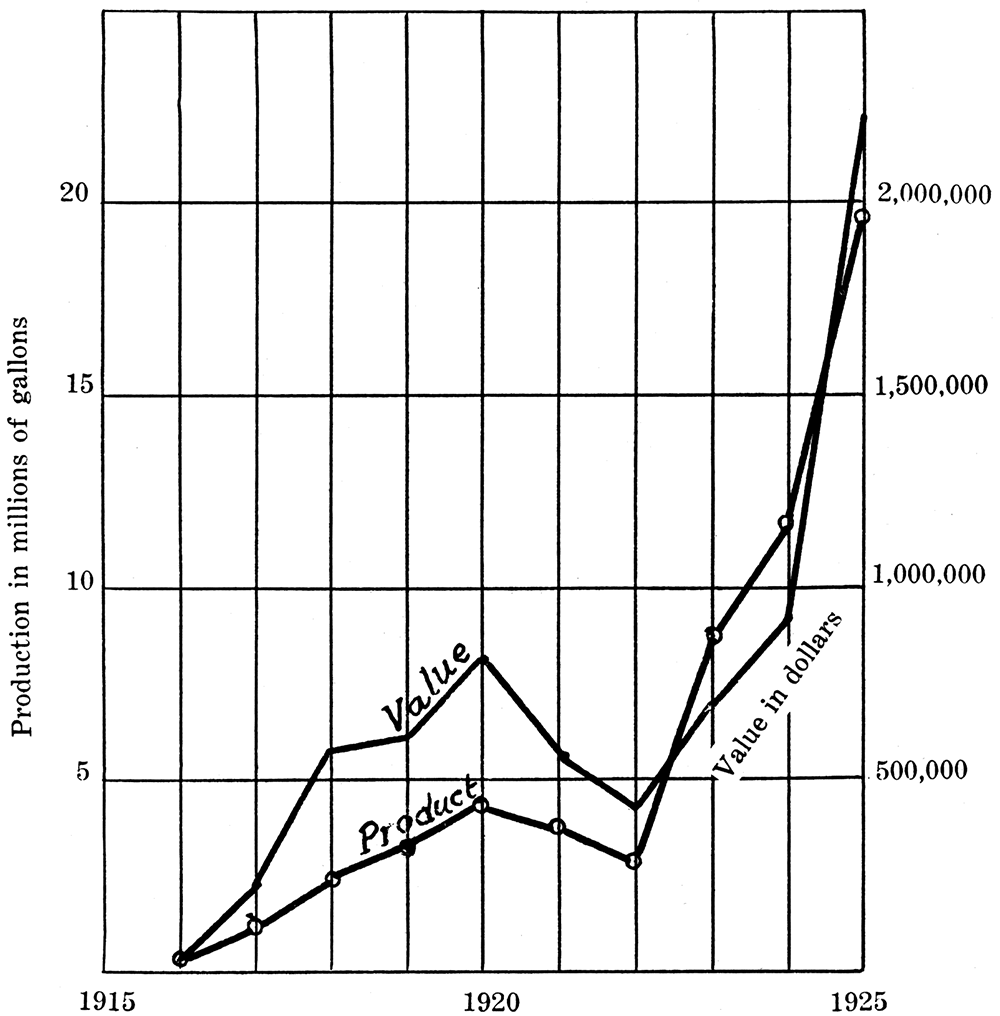

The production of natural-gas gasoline by treatment of natural gas has been steadily increasing in Kansas and throughout the country during the past few years. Formerly this gasoline which is abstractable from the natural gas was run through the gas mains and used by consumers, In 1924 there were fourteen natural-gas gasoline plants in the state, five making gasoline by compression methods and nine by a combination of compression and absorption processes. A total of 19,592,000 gallons of this gasoline was produced in 1925, valued at $2,223,000. The recovery of this gasoline is obviously profitable, and it has been estimated in some fields, such as the Rainbow Bend, that the extraction of the gasoline from natural gas may yield approximately 25 per cent of the total oil recovered.

Some of the natural-gas gasoline is run into the pipe lines, but most of it is blended for use as a motor fuel with the gasoline from refineries. In 1925 approximately 25 per cent of the motor fuel produced in the United States was made by cracking processes in refineries, about 64 per cent from straight-run processes of manufacture from petroleum, and 10 per cent from raw natural-gas gasoline, and about 1 per cent from benzol derived in the coke industry. At present about 90 per cent of the natural gas produced is treated to recover gasoline, and within a very short time the amount of gasoline that is derived from this source will probably be limited by the quantity of natural gas produced. Growth of the natural-gas gasoline industry in the state of Kansas for the past years is indicated in the following table:

| Amount and Value of Natural-gas Gasoline Produced in Kansas, by Years, 1916 to 1925, Inclusive |

||

|---|---|---|

| Year | Number of Gallons | Value |

| 1916 | 215,000 | $35,030 |

| 1917 | 1,175,000 | $241,219 |

| 1918 | 2,390,000 | $593,730 |

| 1919 | 3,284,000 | $620,876 |

| 1920 | 4,331,000 | $828,887 |

| 1921 | 3,587,000 | $565,408 |

| 1922 | 2,855,573 | $435,056 |

| 1923 | 8,775,000 | $690,000 |

| 1924 | 11,658,000 | $913,000 |

| 1925 | 19,592,000 | $2,223,000 |

Figure 49—Curve showing production and value of natural-gas gasoline in Kansas since 1916.

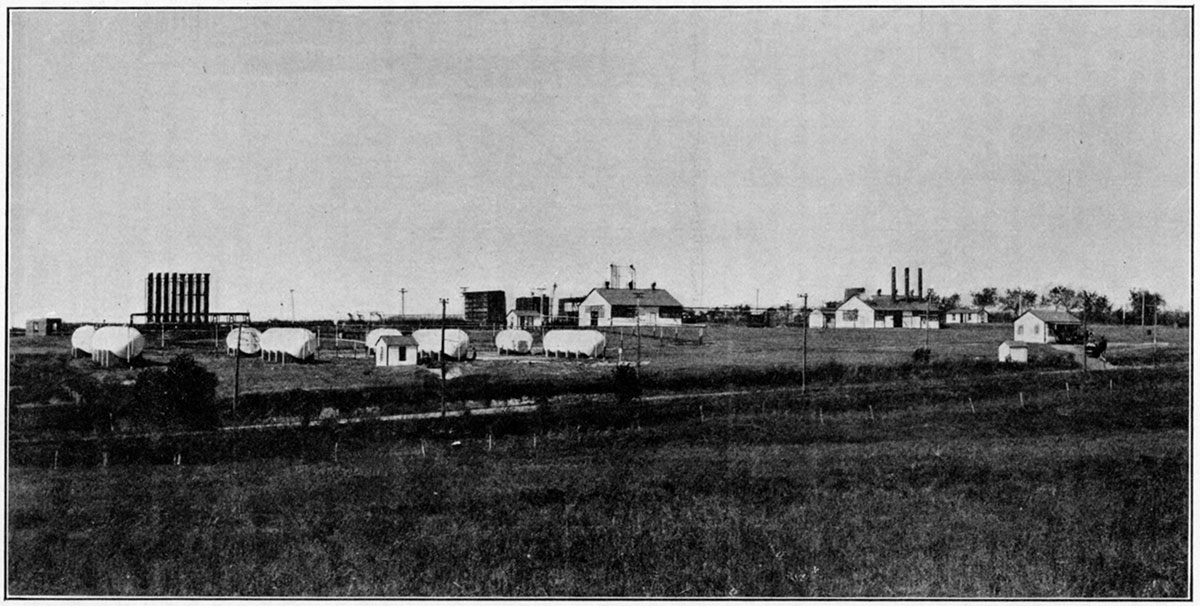

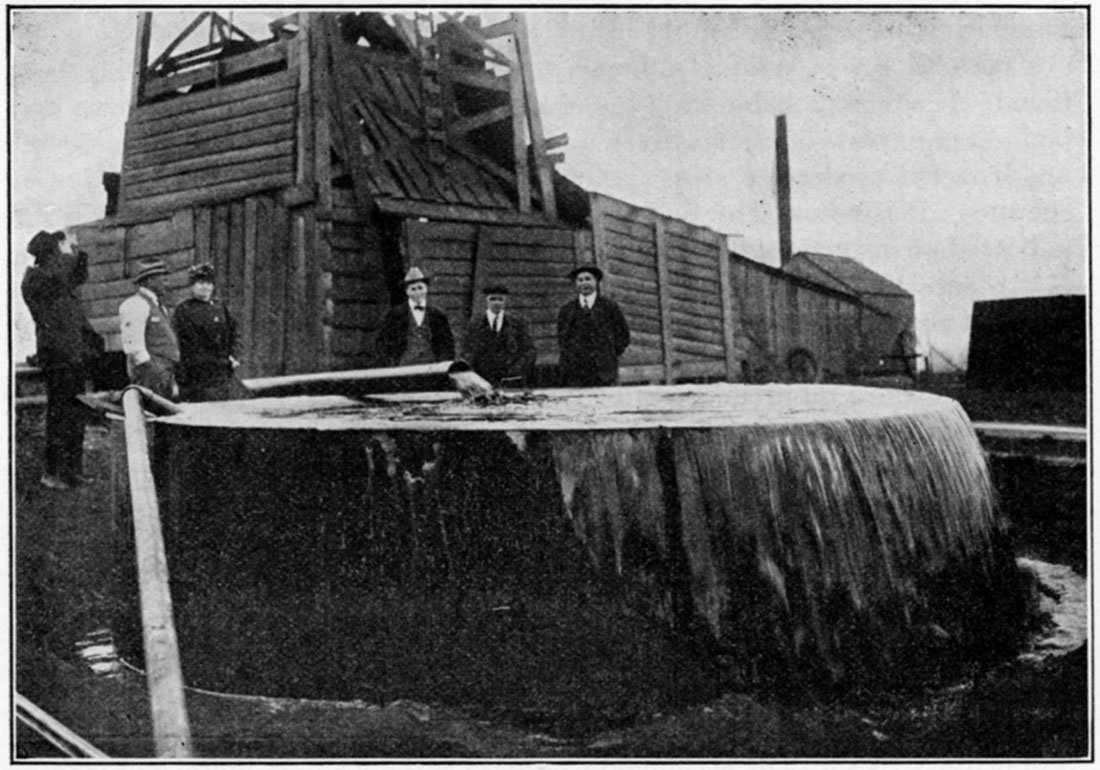

Figure 50—The Empire natural-gas gasoline refinery at Arkansas City.

Petroleum

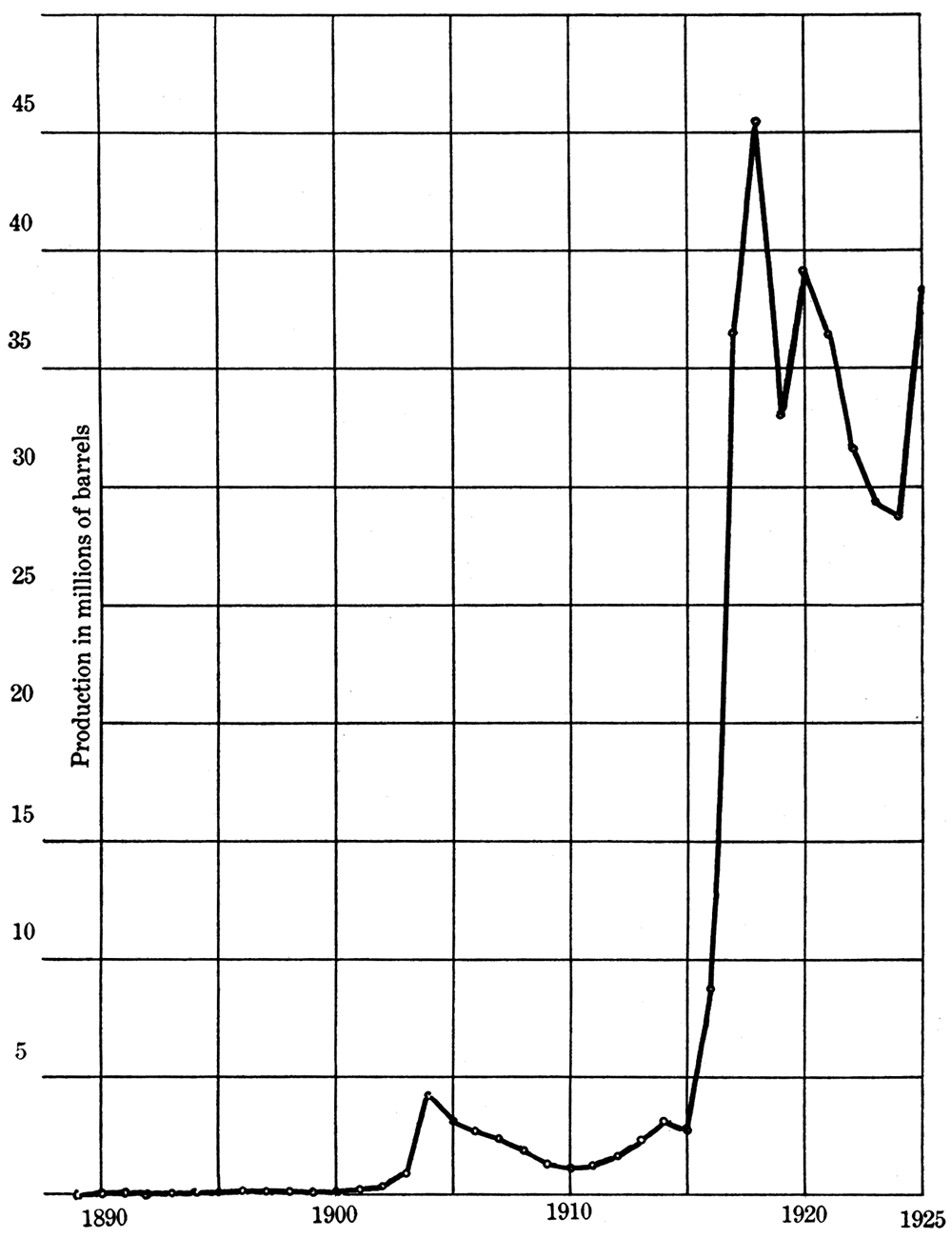

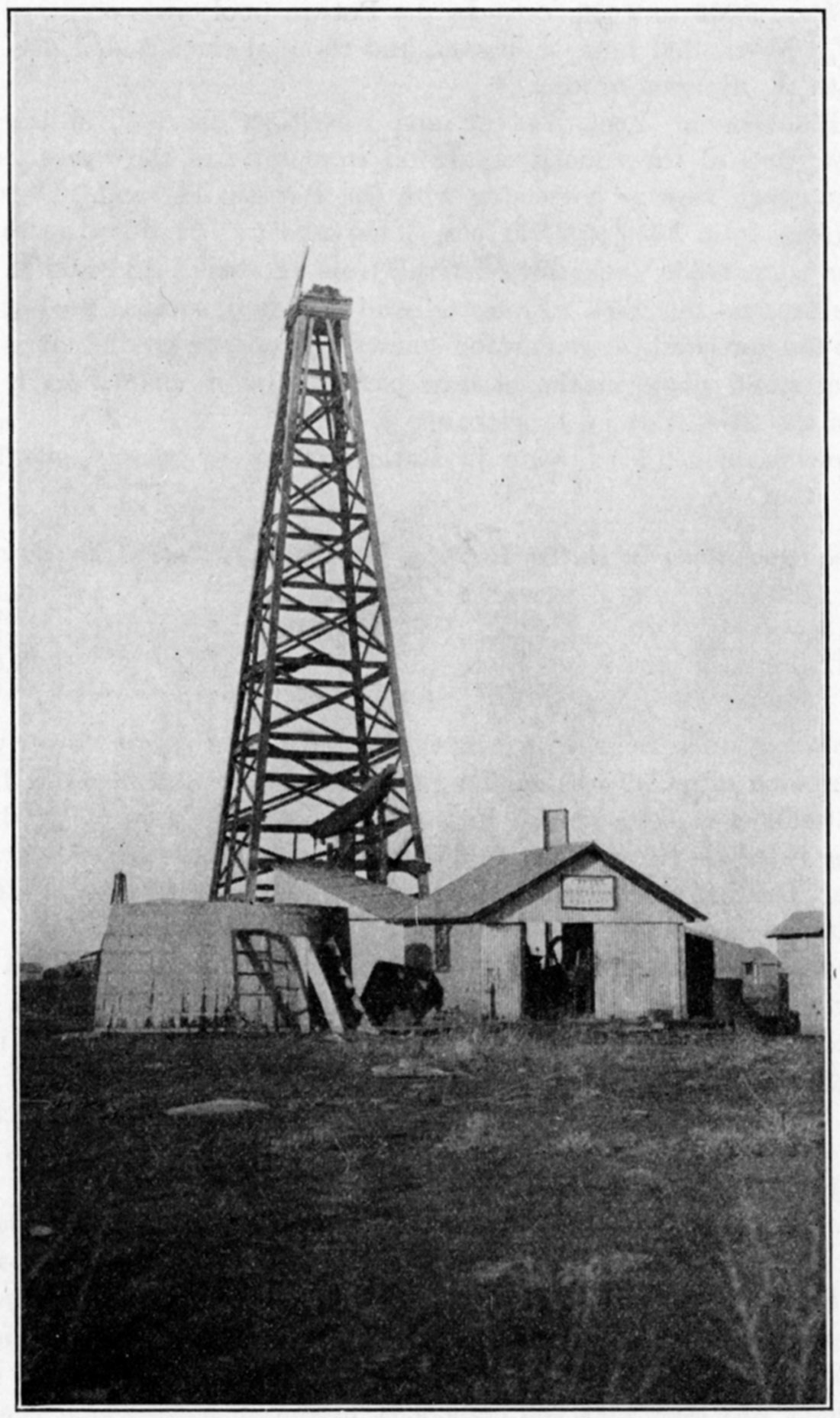

As a producer of petroleum Kansas has held for many years a prominent place. Prospecting for this fuel, so important in modern commerce and civilization, began in Kansas almost as soon as the prairie soil had been furrowed by the plow, only shortly after the famous Colonel Drake discovery of oil in Pennsylvania in 1859. Despite this early beginning of exploration, production of commercial importance was developed very slowly, and it is only within the last ten years that Kansas has assumed a real place among the oil-producing states. At the present time (1925), though production is not so great as in the banner year, 1918, the annual oil yield of the state is about equal to the total combined Kansas oil production up to 1916. For the years since 1916 the lowest annual production of oil in Kansas was 28,836,000 barrels, in 1924. The production of 1925, 38,284,000 barrels, was surpassed only by the yield for the years 1918 and 1920. On December 31, 1925, there were 19,358 oil wells in Kansas, with a daily average production of 5.69 barrels. According to records, Kansas had produced up to the end of the first six months in 1926 the huge total of 377,873,000 barrels of oil, which exceeds the production for all time of any foreign oil field except Russia and Mexico. In the United States Kansas is surpassed as an oil producing state only by California, Oklahoma, Texas, Pennsylvania and Ohio. For the year 1925 Kansas ranked fifth among the states in quantity of oil produced, the order being: California, Oklahoma, Texas, Arkansas, Kansas.

In a report of a committee of the American Petroleum Institute, organized to make a thorough study of the oil resources of this country for report to the Oil Conservation Board appointed by President Coolidge, the entire 82,158 square miles of Kansas are classed as producing or potentially producing oil territory. All of the state is indeed, underlain by rock strata which in certain places and under certain conditions do yield oil, but from the fact that at least 40 wells have been drilled entirely through the sedimentary rocks into the underlying barren crystalline rocks, and many hundreds of wells have been drilled without success through all of the rocks likely to contain oil, the promise of commercial oil deposits in many places is not very great. In regions that have been intensively drilled, the limits of commercial production seem to be fairly well defined. Up to the end of 1924, 1,027 dry holes had been drilled in Butler and Marion counties, and 600 dry holes had been drilled in Greenwood county. On the other hand, commercial-oil fields have been found in parts of the shallow producing district in eastern Kansas after hundreds of dry holes had been drilled, and the very rich pools in Greenwood county were located after the county had been widely tested and practically condemned by oil men as prospective producing territory. The great oil pool in Russell county was located by a wildcat test more than 100 miles from a commercially productive field. It is therefore obvious that the petroleum resources of Kansas are only partly developed, and very much remains to be done in further exploration. For this exploration an authentic record of the results of past drilling, the recording and interpretation of geological information obtained and much detailed study by qualified specialists is required in order to develop the future oil supply which may be derived from this state.

Figure 51—Curve showing production, in barrels, of petroleum in Kansas since 1889.

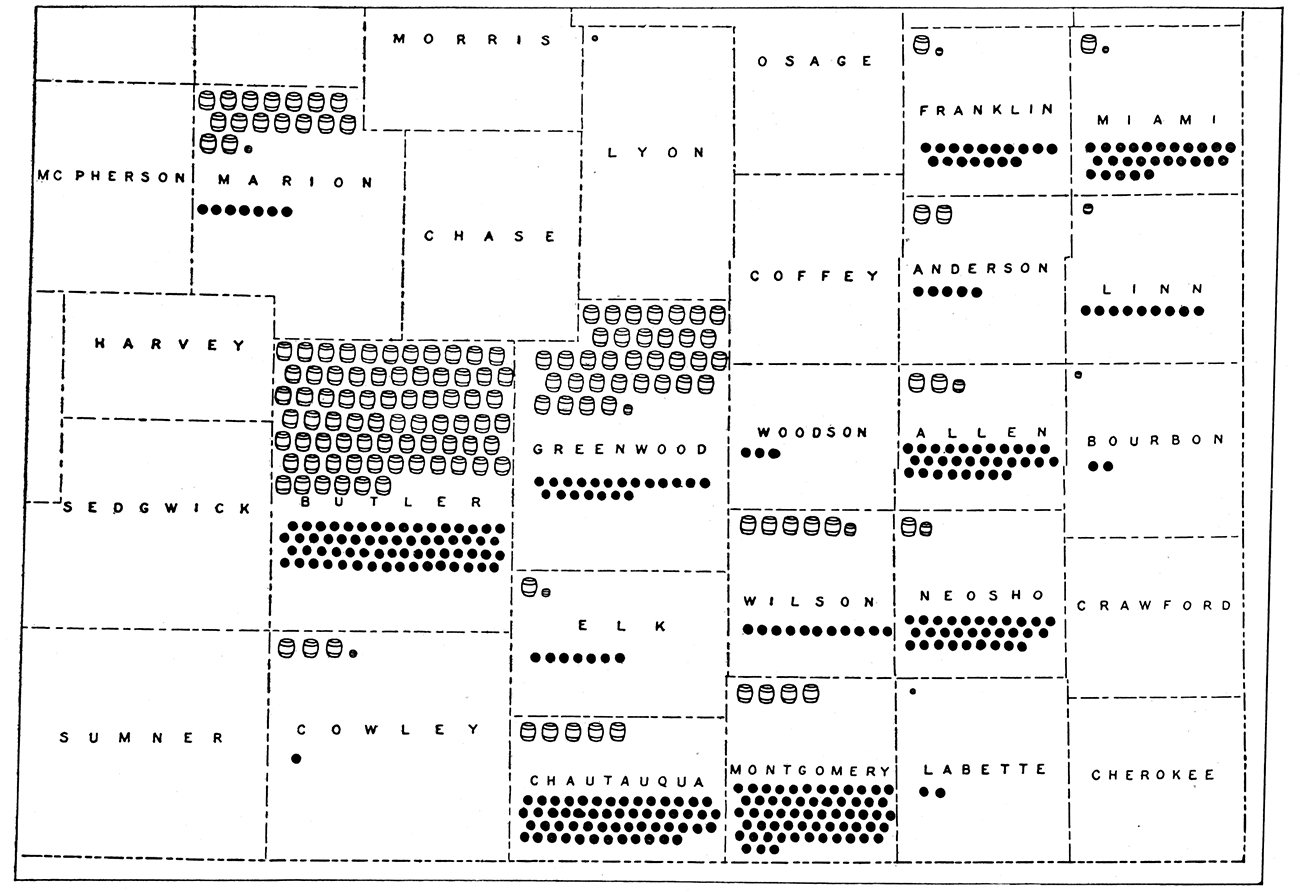

Figure 52—Showing relation of oil production to producing wells. Large barrel indicates annual production of 200,000 barrels. Heavy dot indicates 50 producing wells.

The oil fields of Kansas may be conveniently grouped from a geographic standpoint into four districts.

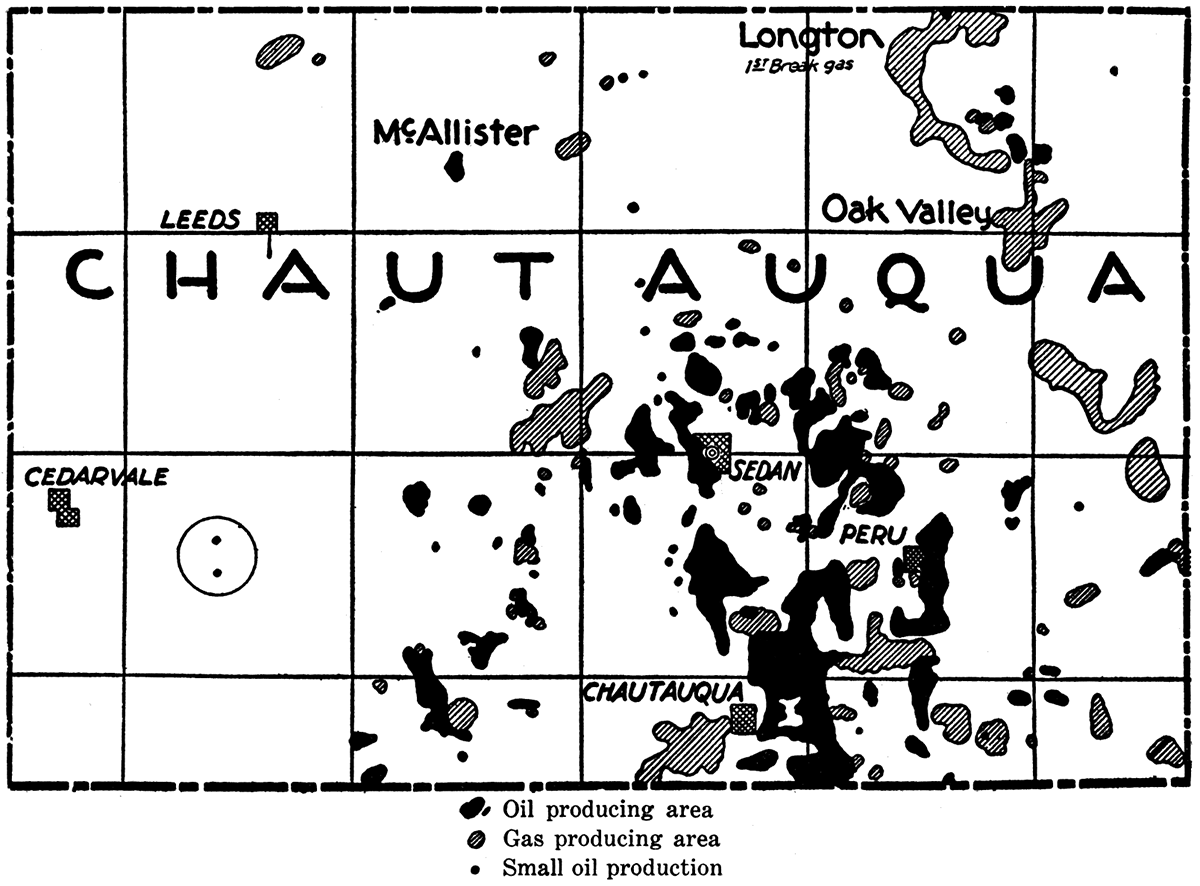

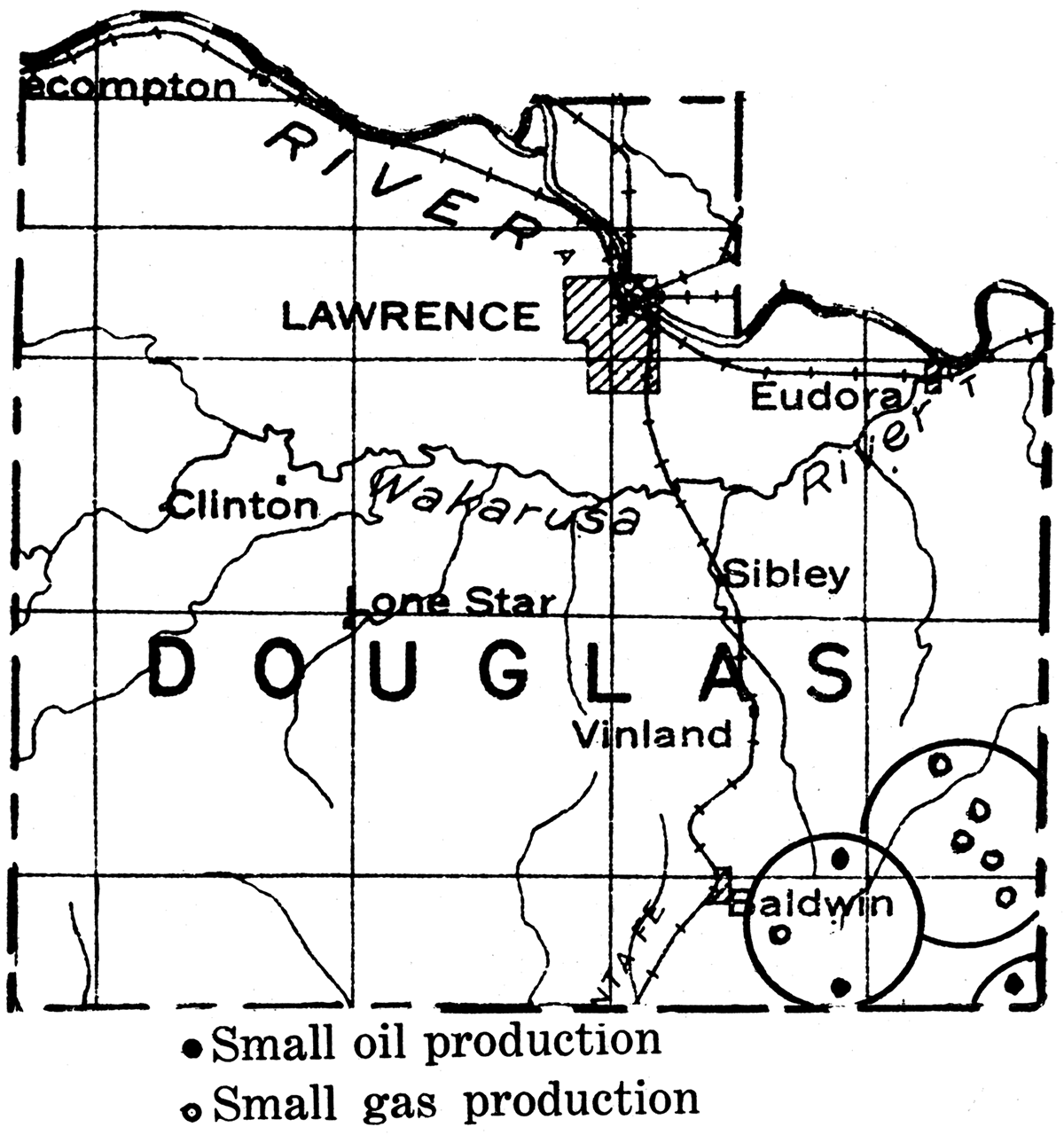

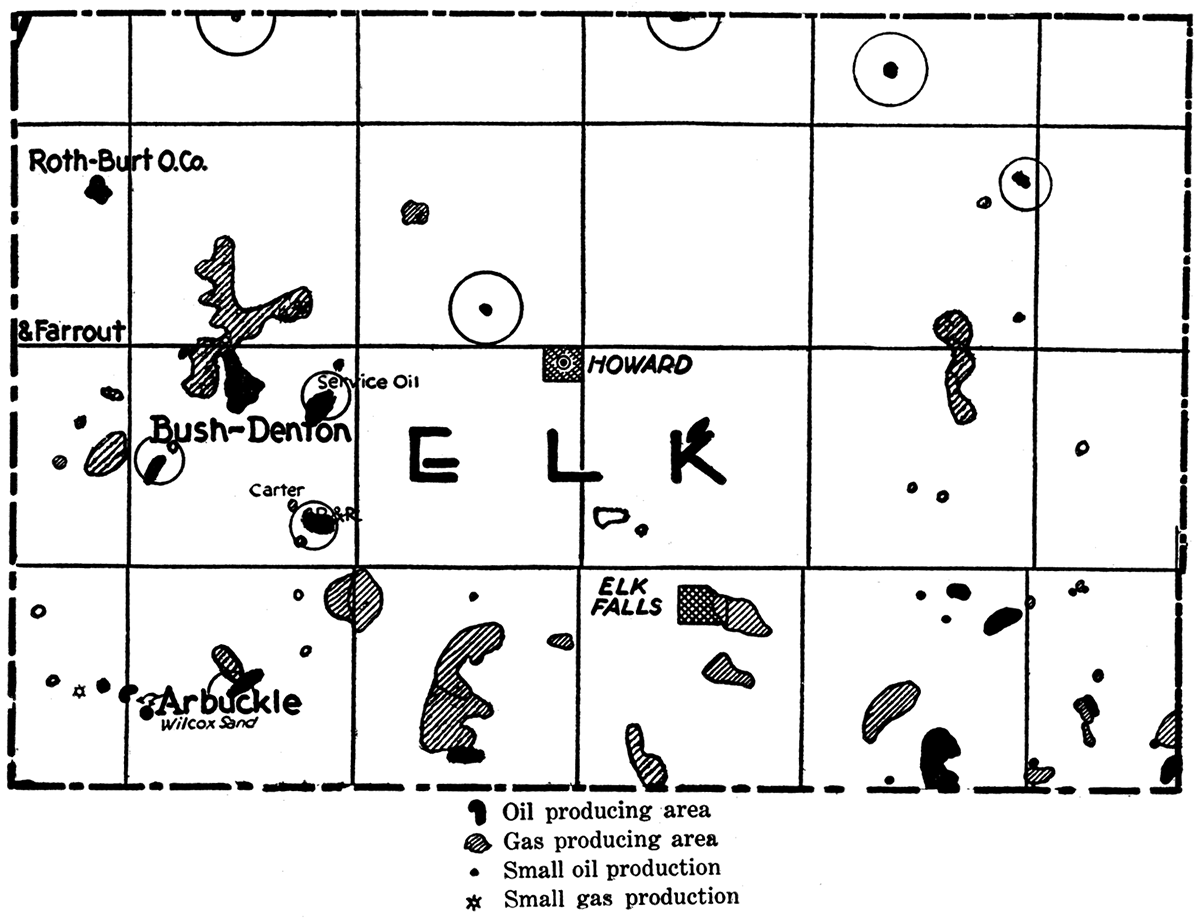

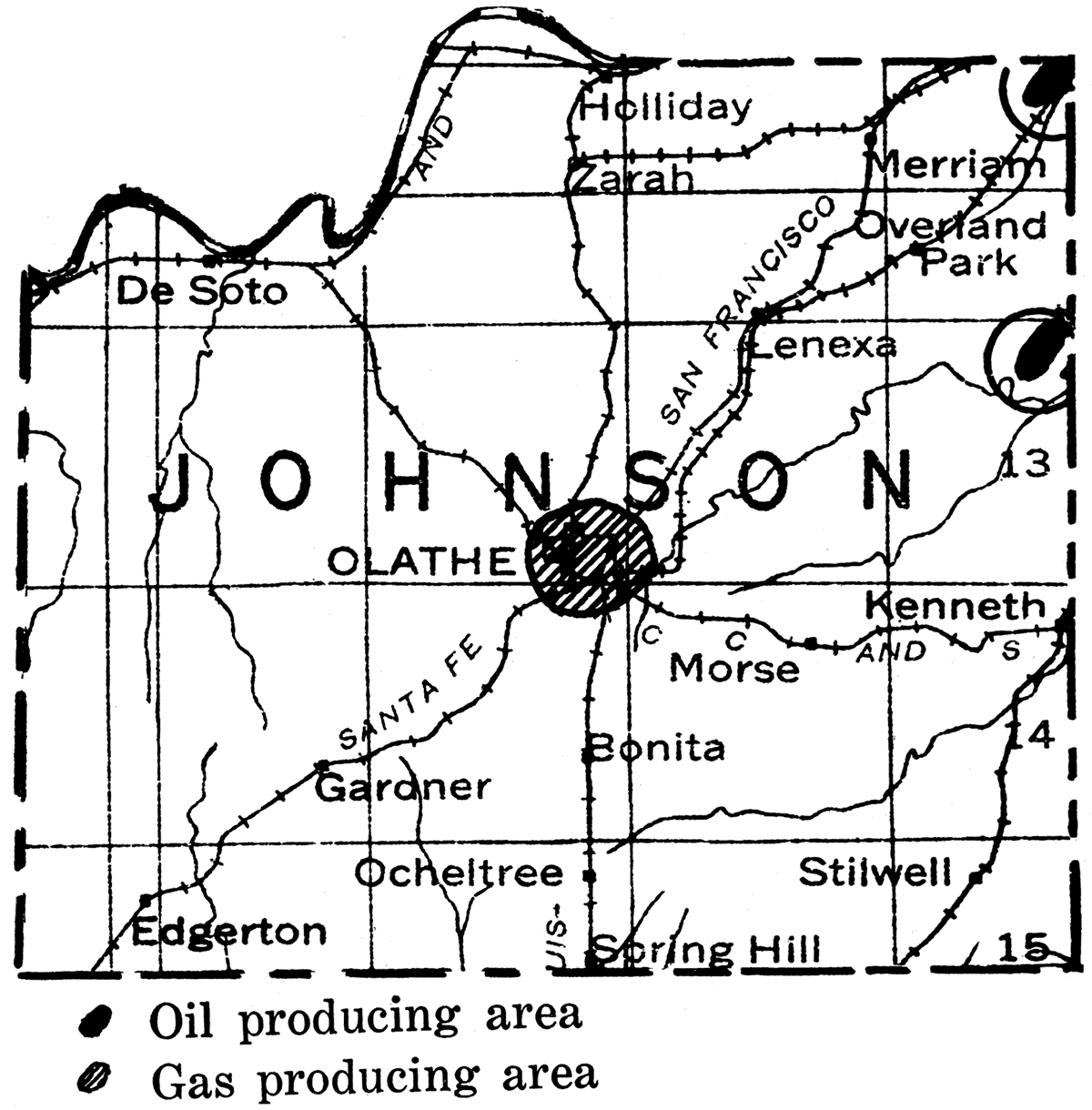

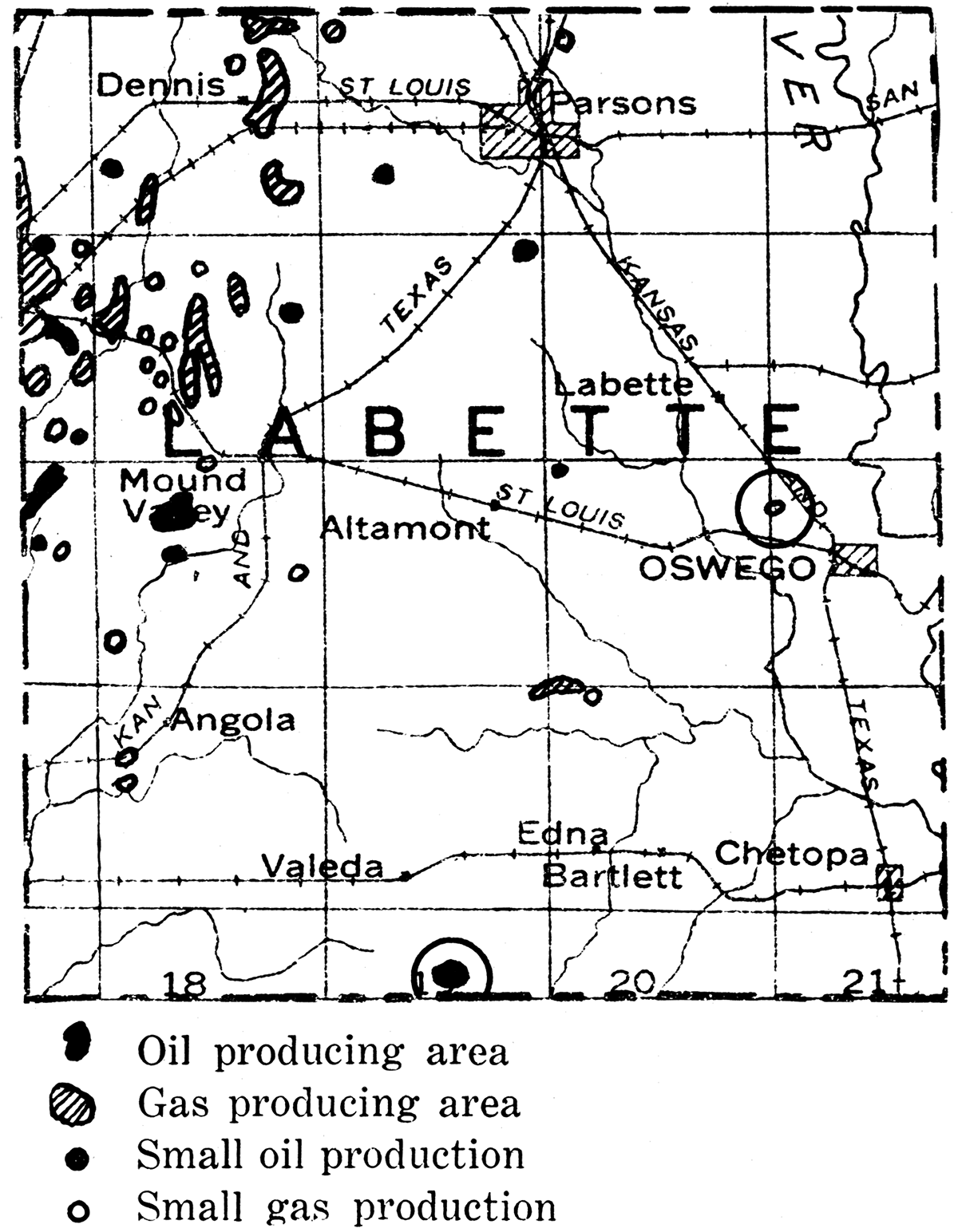

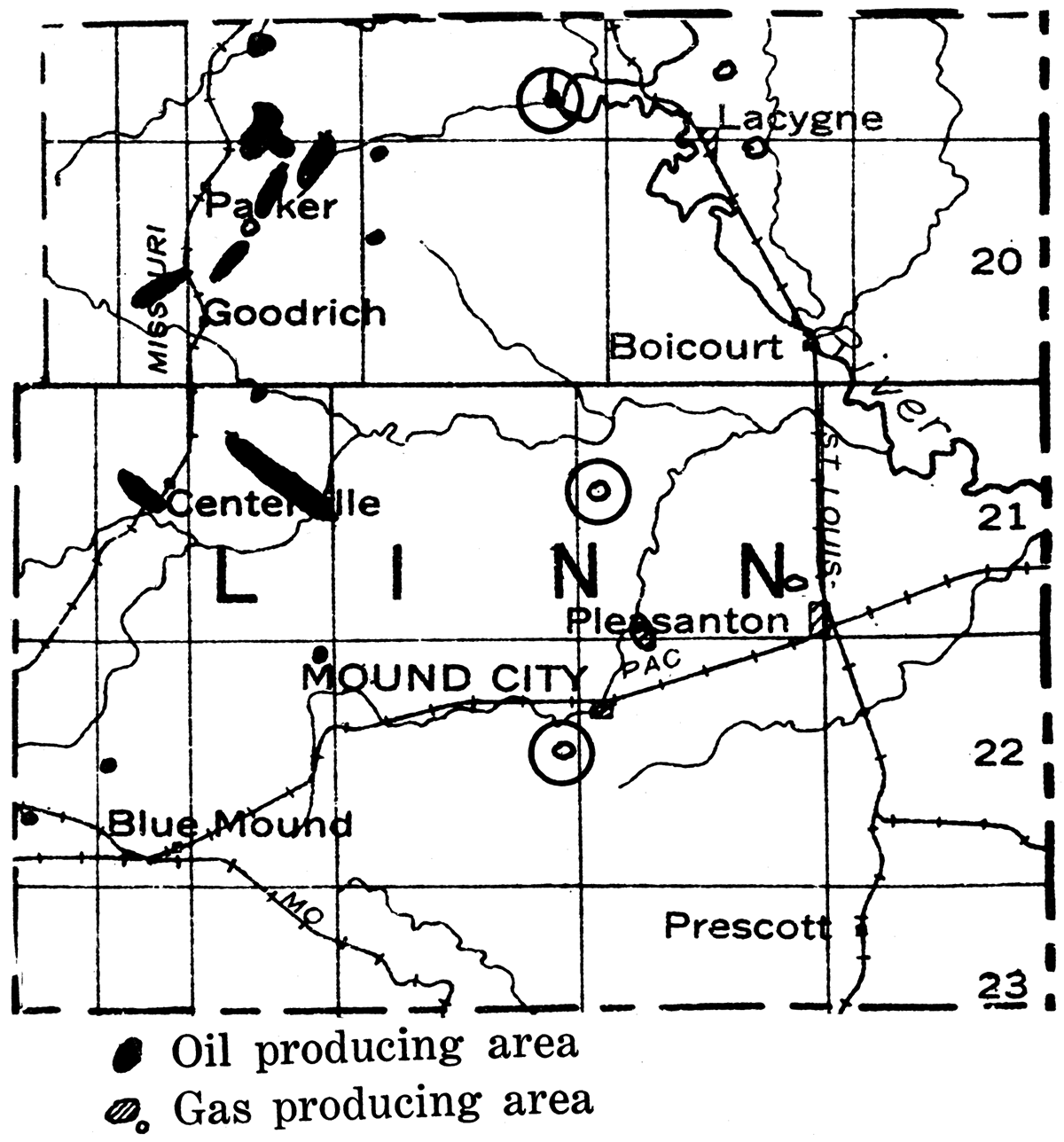

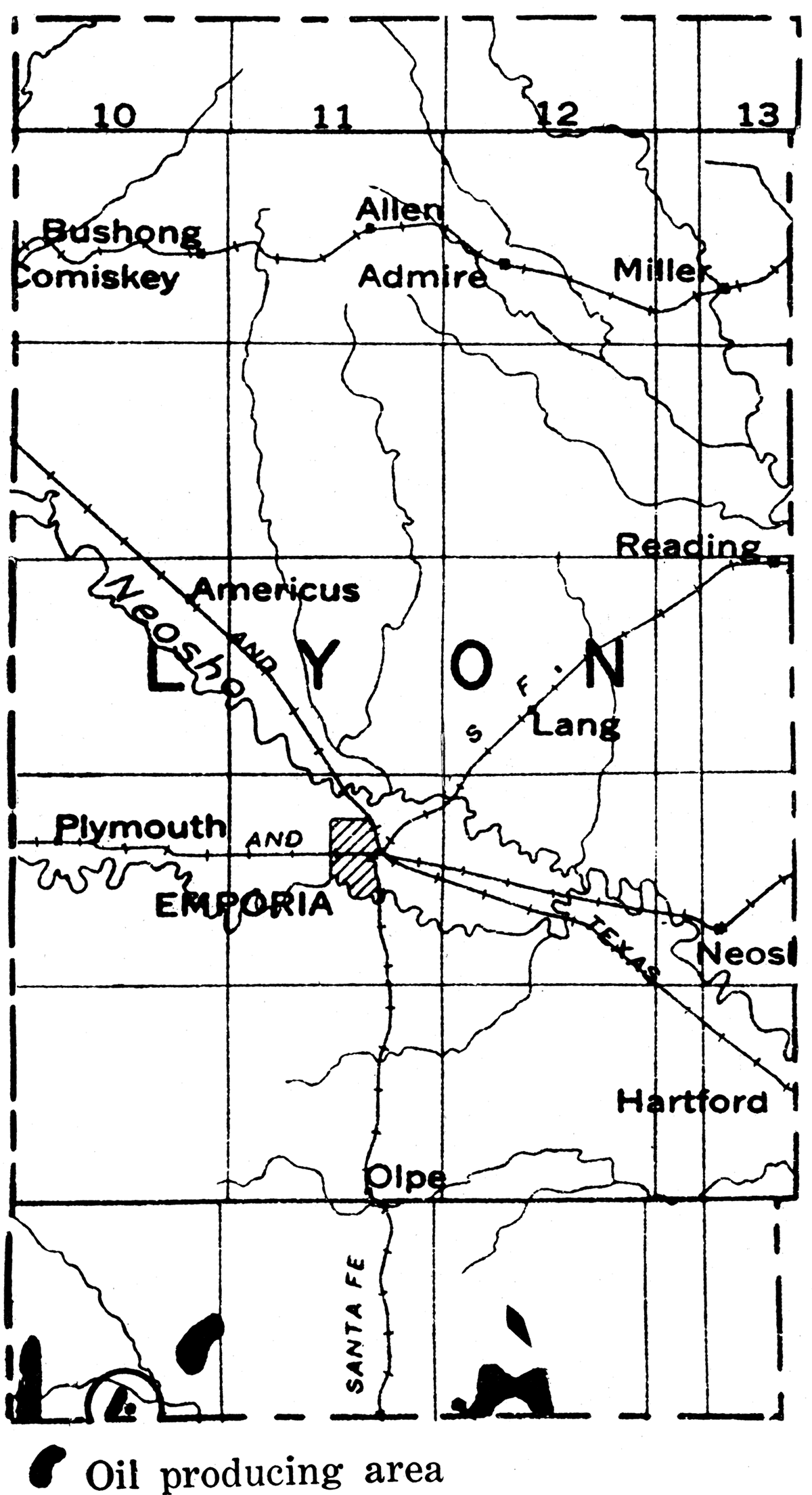

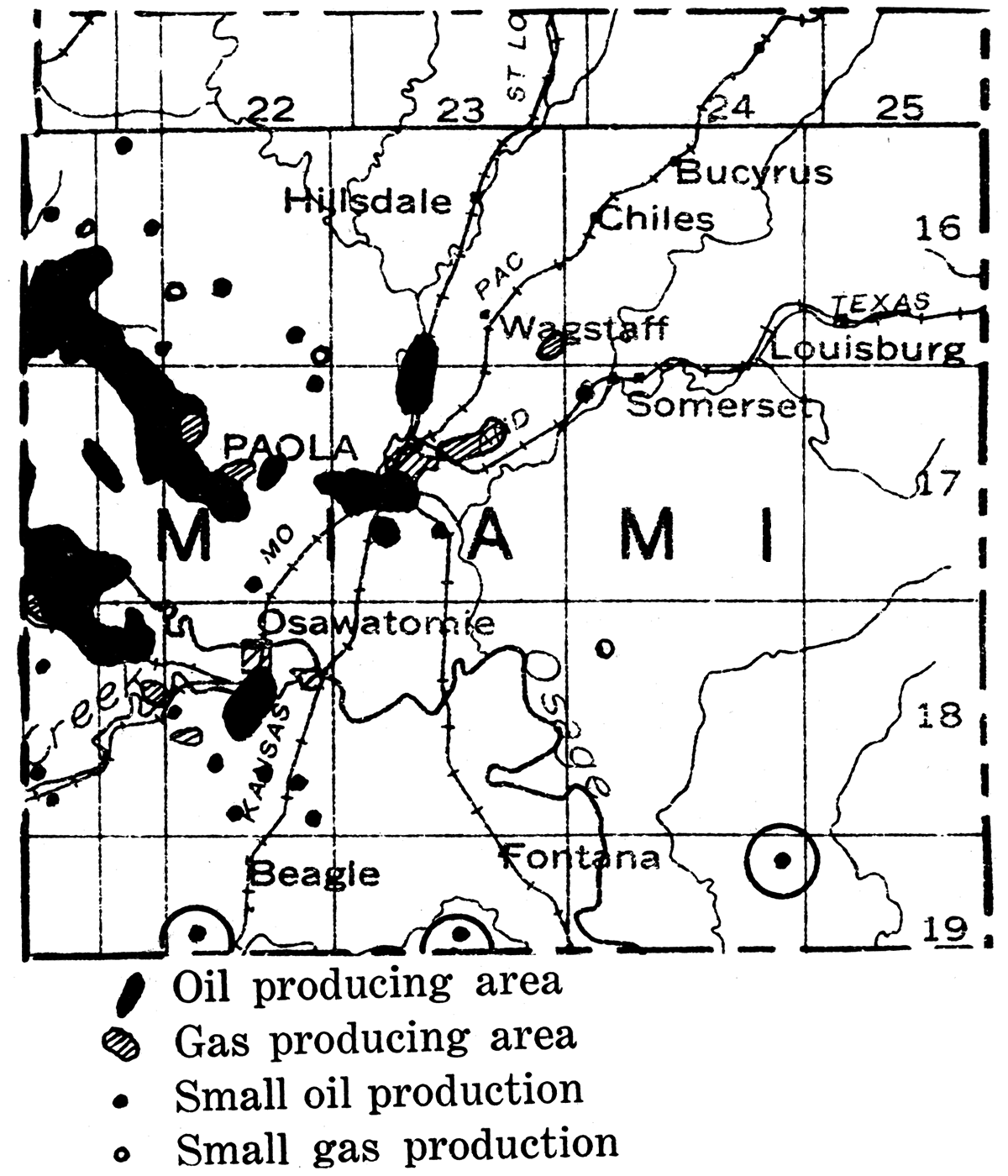

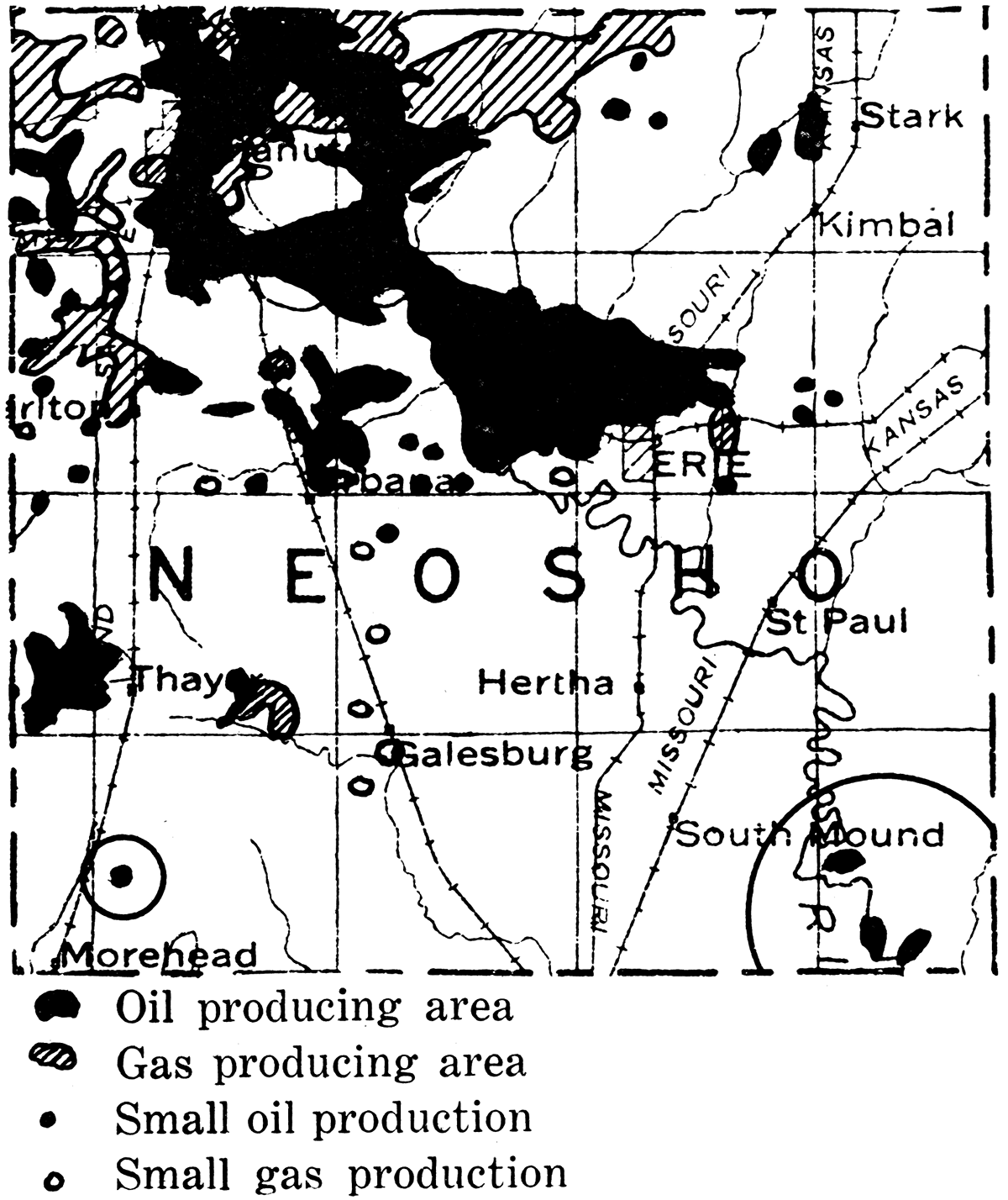

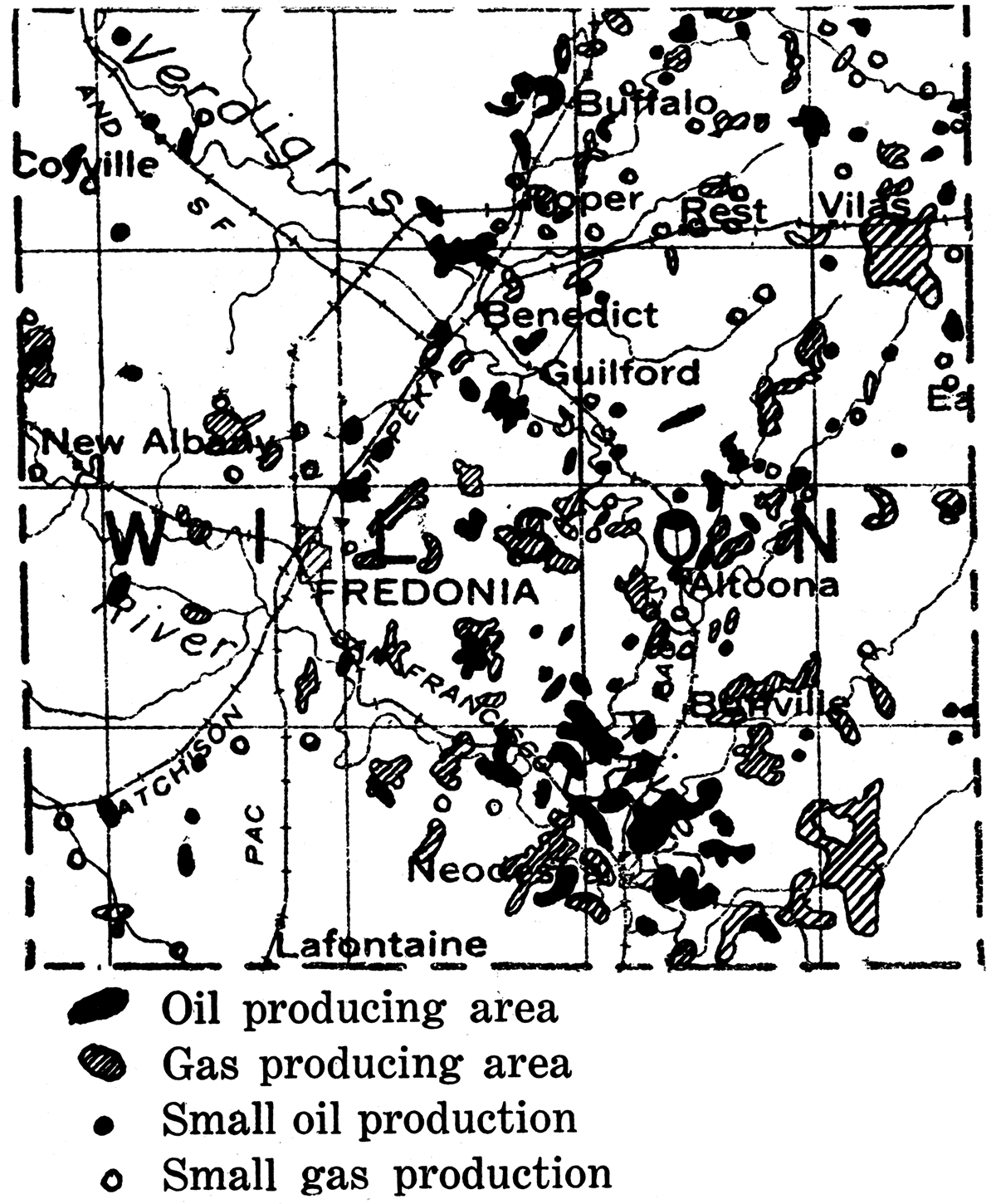

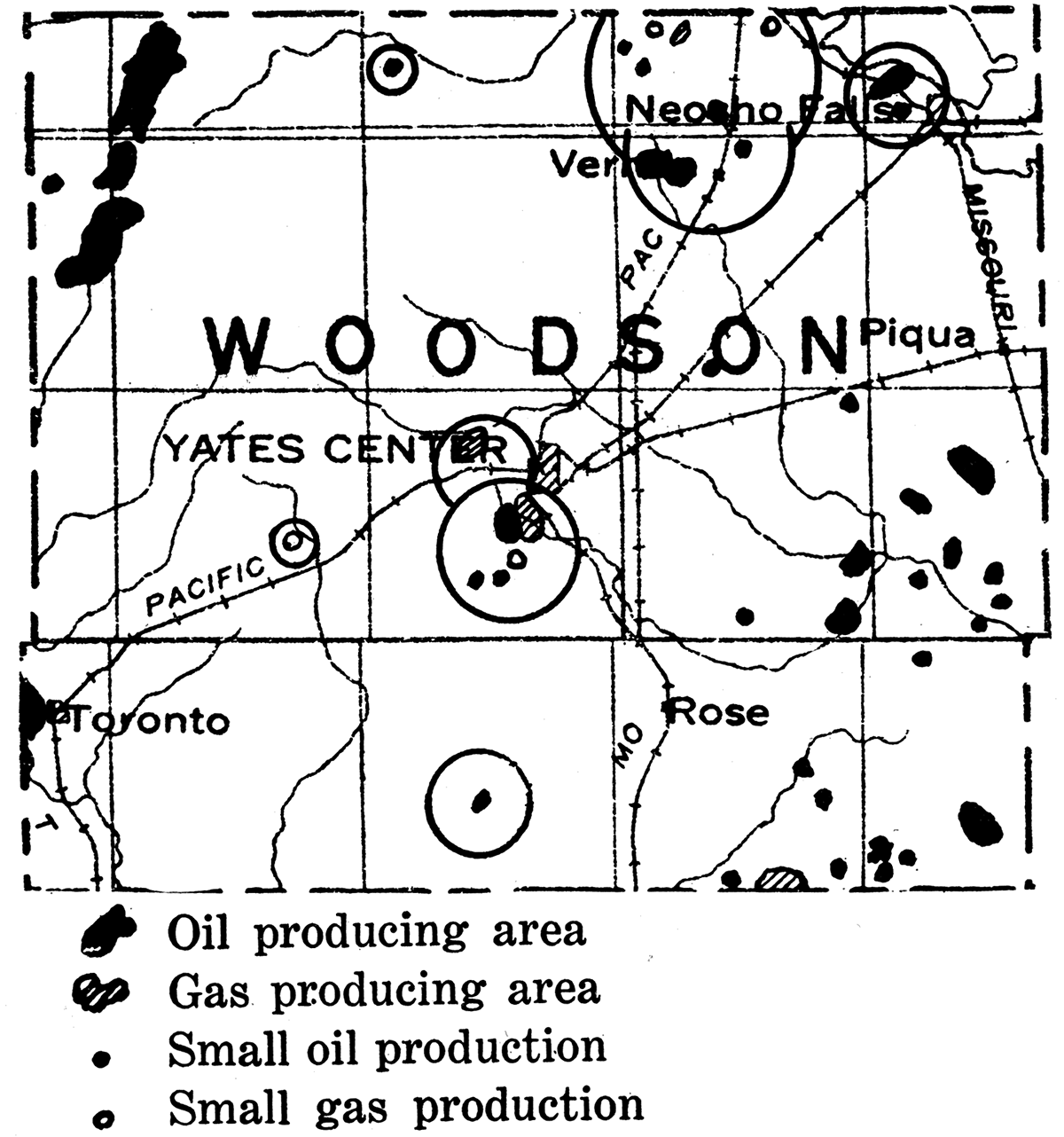

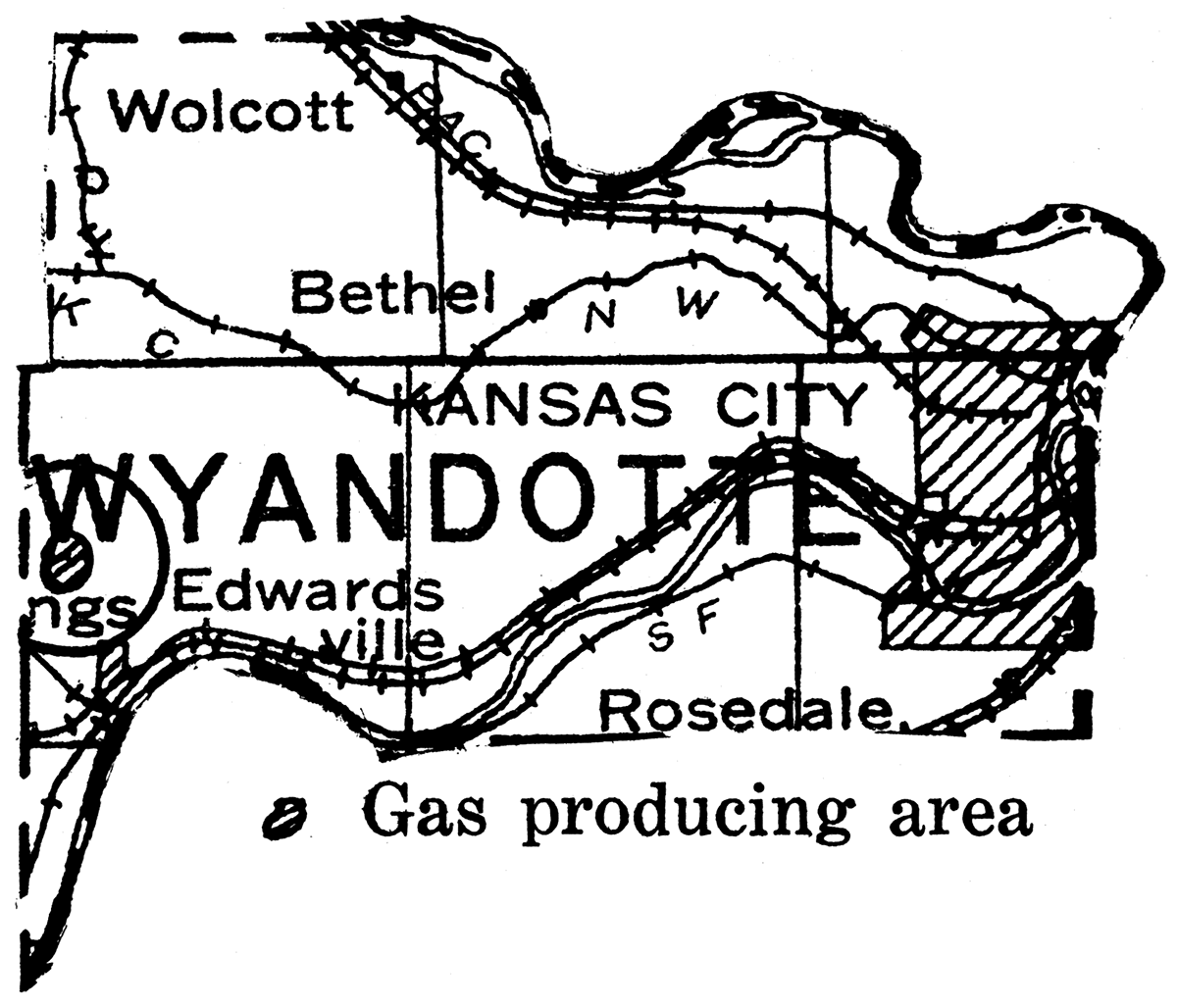

(1) The first, which may be termed the eastern Kansas shallow district, includes the fields southeast of a line drawn through Lawrence, Ottawa, Yates Center and Sedan. The principal oil-producing counties are Douglas, Miami, Franklin, Anderson, Allen, Linn, Bourbon, Wilson, Neosho, Chautauqua, Montgomery and Labette. In this area the lower and middle strata of the Pennsylvanian system are exposed at the surface and the oil-containing sands which are found in these rocks are reached at depths of 100 or 200 feet up to 1,500 feet. The average depth of wells in the district is 700 feet. The rocks slope gently downward in a direction slightly north and west, so that a given sand or formation is encountered at increasing depths below the surface in going from east to west. Most of the oil in the shallow district is obtained from more or less lenticular sand bodies in the lower part of the Pennsylvanian; a smaller part is obtained from the underlying Mississippian and older rocks, chiefly in Chautauqua and Montgomery counties. In general the accumulation of the oil in pools appears to depend less on structured conditions than the porosity and thickness of the sands. Some of the sands, especially in Anderson county and northern Allen county, are known to be very elongate, narrow "shoestrings," which have the form of a channel-filling in the associated shale. They represent stream valleys that were carved in the early Pennsylvanian rocks and filled with sand before the deposition of the overlying strata. In other cases there are lenticular sands that appear to be ancient sandbars which existed along the shore line of the sea which occupied eastern Kansas in early Pennsylvanian time. The rock strata are only slightly affected by minor folding, and in some places oil occurs in synclines as well as on anticlines.

Although a very large number of wells have been drilled in the eastern Kansas shallow fields the individual production is commonly small, often amounting to only one or two barrels per day. Initial production of as much as 500 barrels a day has been reported, but a 50-barrel well is ordinarily accounted a good one. On the average these wells produce for many years by pumping. The quality of the oil is in general lower than that of the deeper fields, ranging from about 19 to 37 degrees Baumé and averaging about 31 degrees. The total production of the district is small as compared with the deeper fields which lie to the west. However, the small expense of drilling a well largely offsets the hazard in exploration for new fields, and since it has been found that productive territory often lies in a region that has apparently been pretty fairly drilled there is prospect of continued activity in the shallow fields, especially under favorable market conditions.

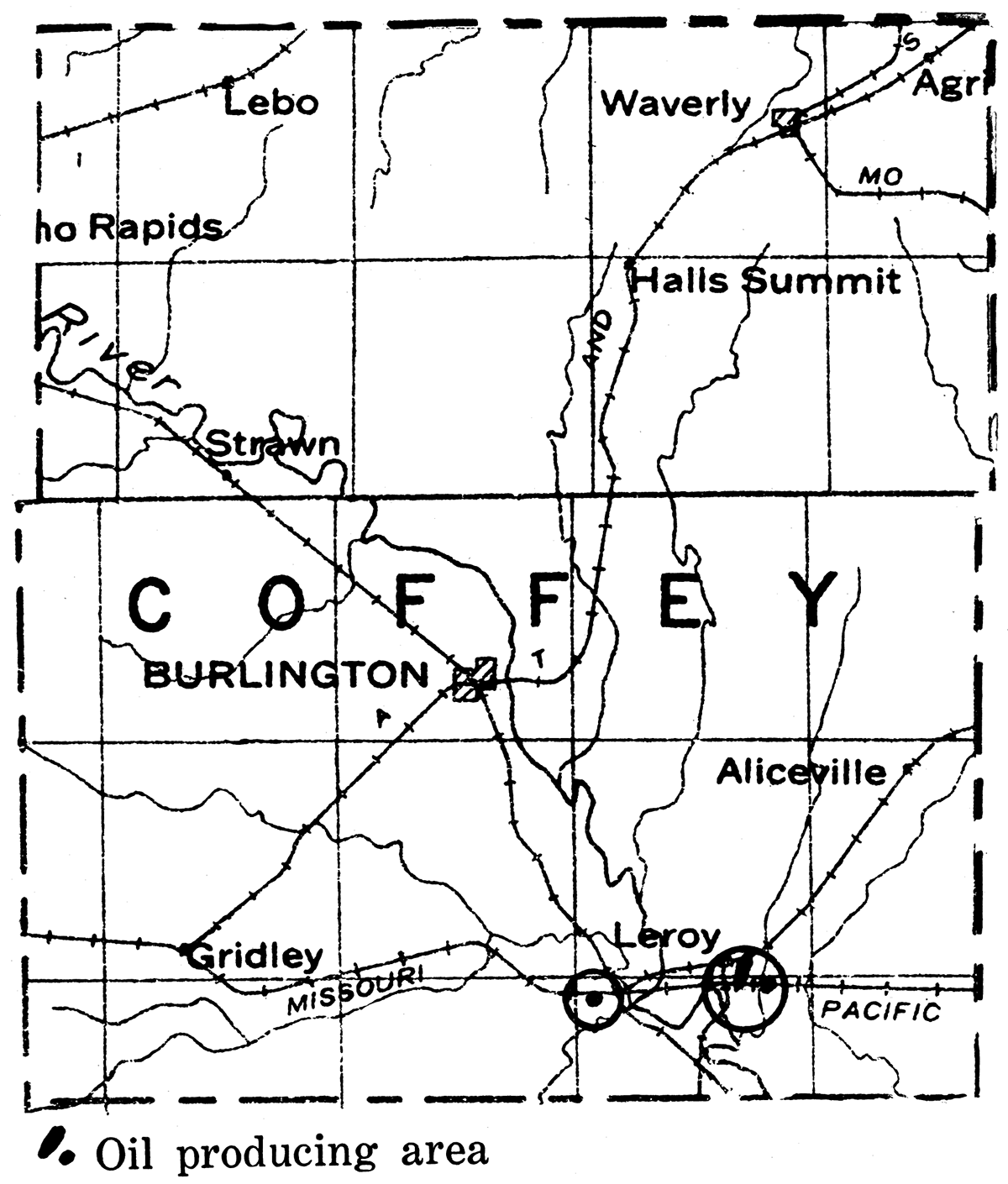

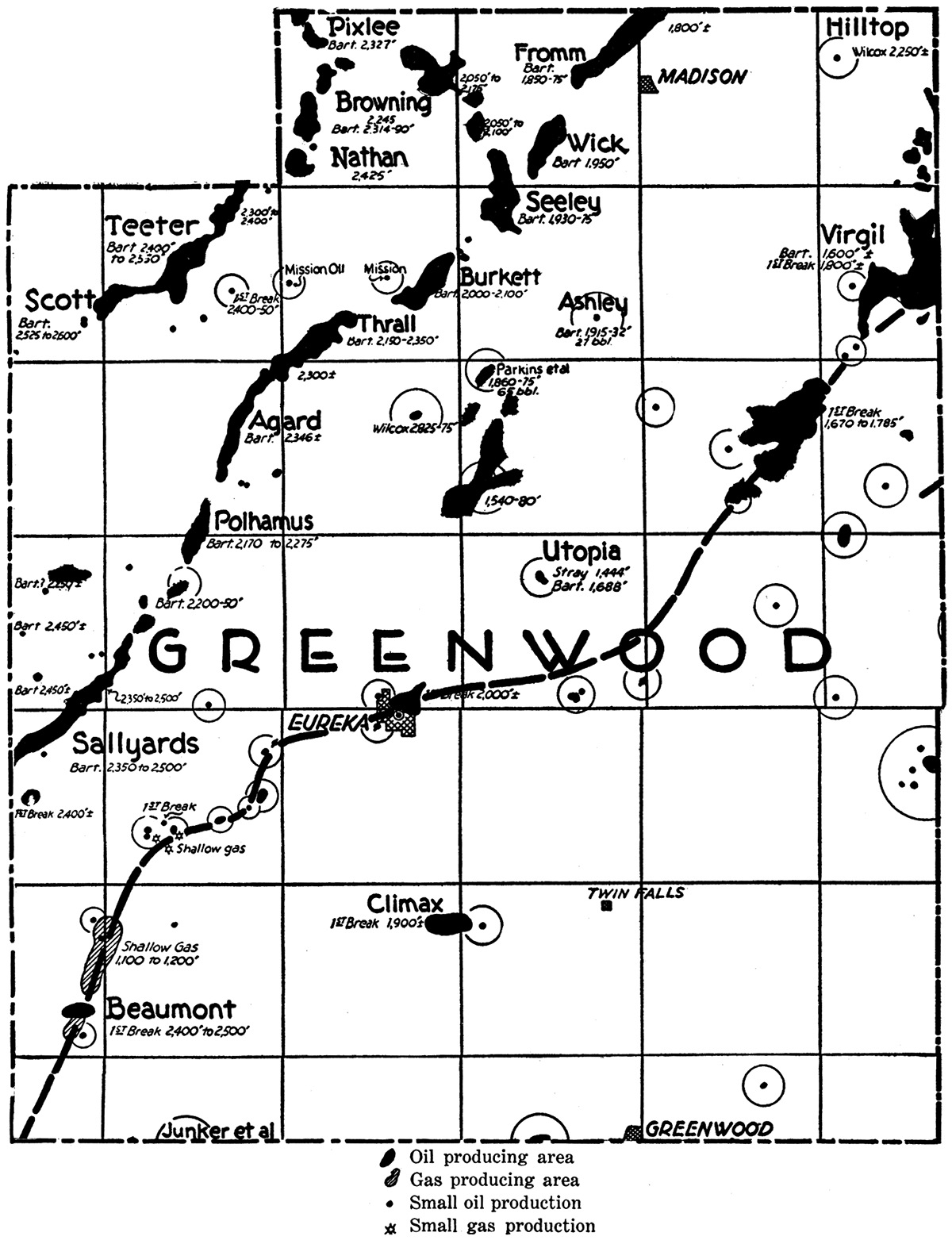

Figure 53—A Kansas gusher.

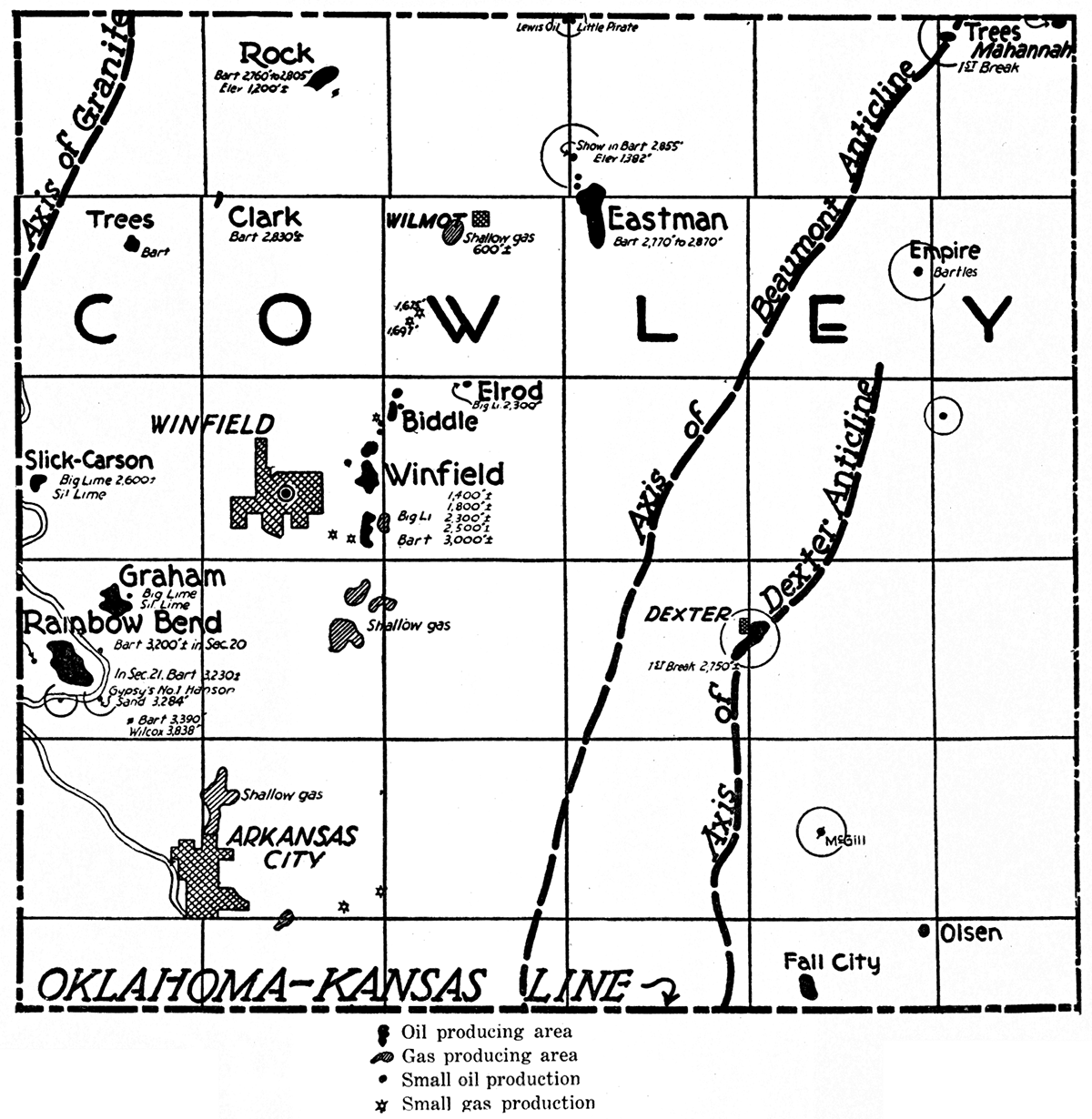

(2) The second district, which may be designated the eastern Kansas deep district, comprises a belt including western Chautauqua and Elk, eastern Cowley, Greenwood, eastern Butler, and southern Lyon counties. In this region the average depth to the producing horizon is around 2,000 to 2,500 feet. The oil comes chiefly from sands in the lower part of the Pennsylvanian, but in certain districts is obtained also from the underlying Mississippian limestone. Greenwood county is the main producer, and it is of interest that the prolific "golden lane," trending northwest across the county from Sallyards, was discovered after widespread and apparently exhaustive drilling. The sands in this area are lenticular in cross section and extend in a nearly straight line for more than 40 miles. Like some of the sands farther east these appear in part to represent bar deposits along the shore of the sea of early Pennsylvanian times. The average production of the wells is very much greater than in the shallow district and the quality of the oil is better, ranging from 36 to 41, and averaging around 39 degrees Baumé, Extensive drilling in northern Greenwood and southern Lyon counties in the effort to extend the area of production has not been wholly successful, although several outlying pools have lately been found. It seems probable from the character of the sands that extensions may be located in parts of eastern Lyon and Coffey counties, and there are probably undiscovered productive areas in Greenwood, Chase, east Butler, and Cowley counties. It is noteworthy that the location of the main producing area is not indicated at the surface by a distinct anticlinal flexure of the beds. Knowledge of the actual conditions underground obtained by careful subsurface study of the well records, cuttings from the wells and other data is very important in planning exploratory work.

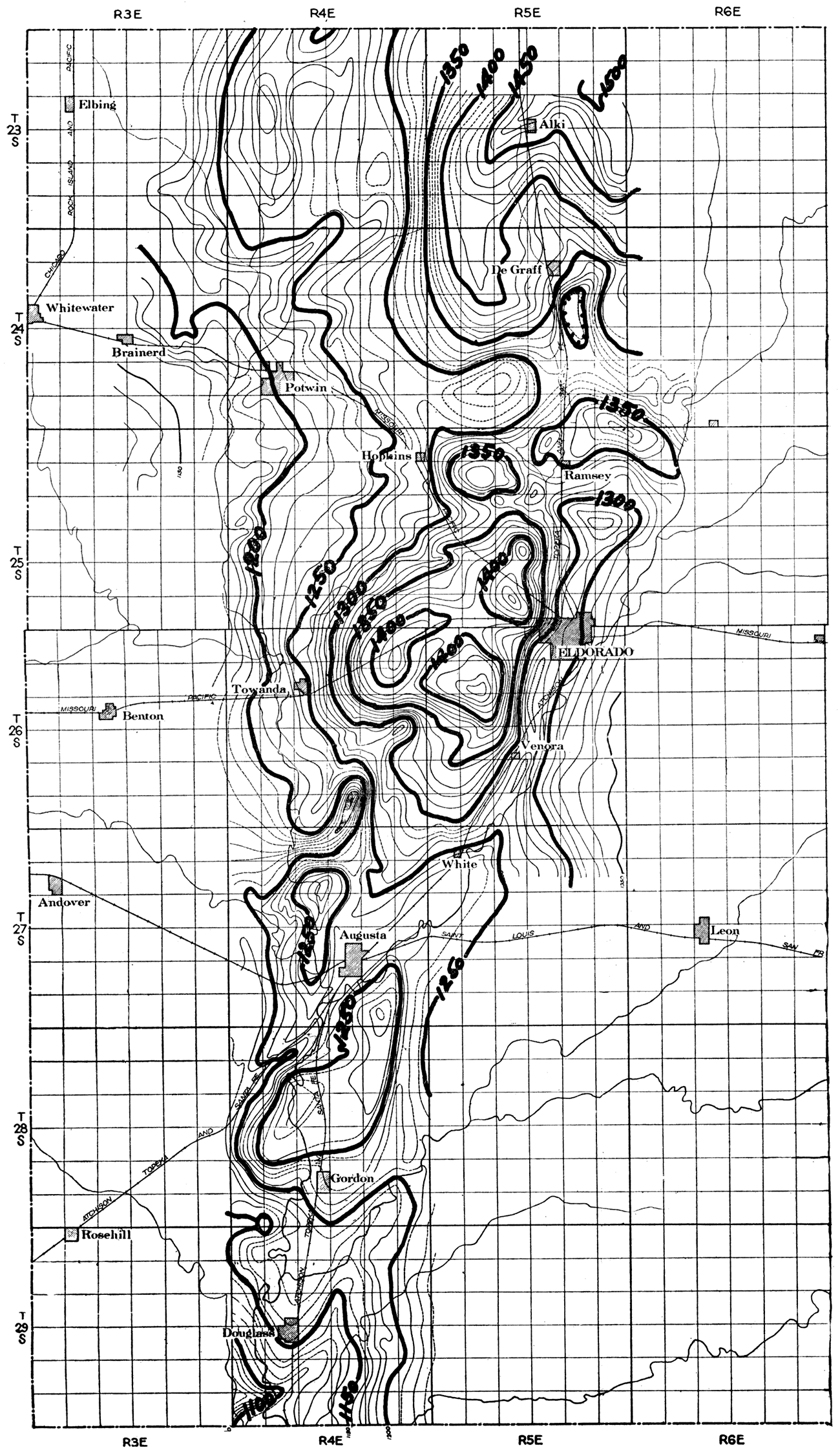

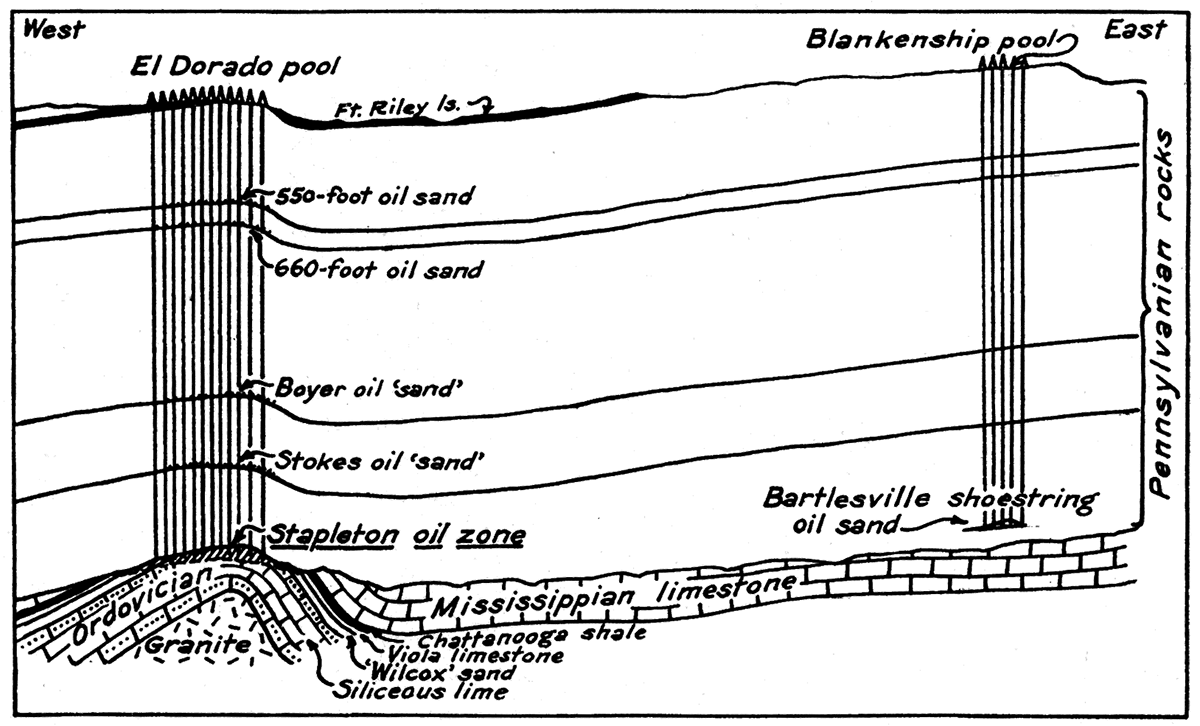

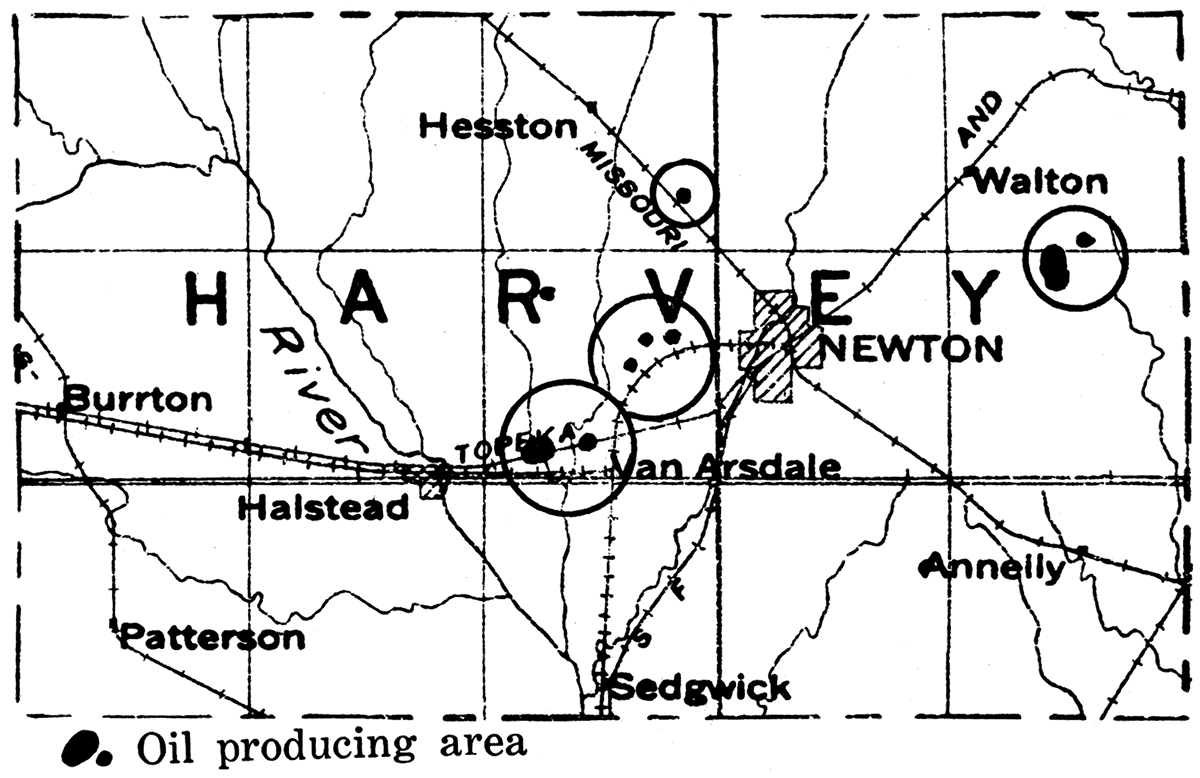

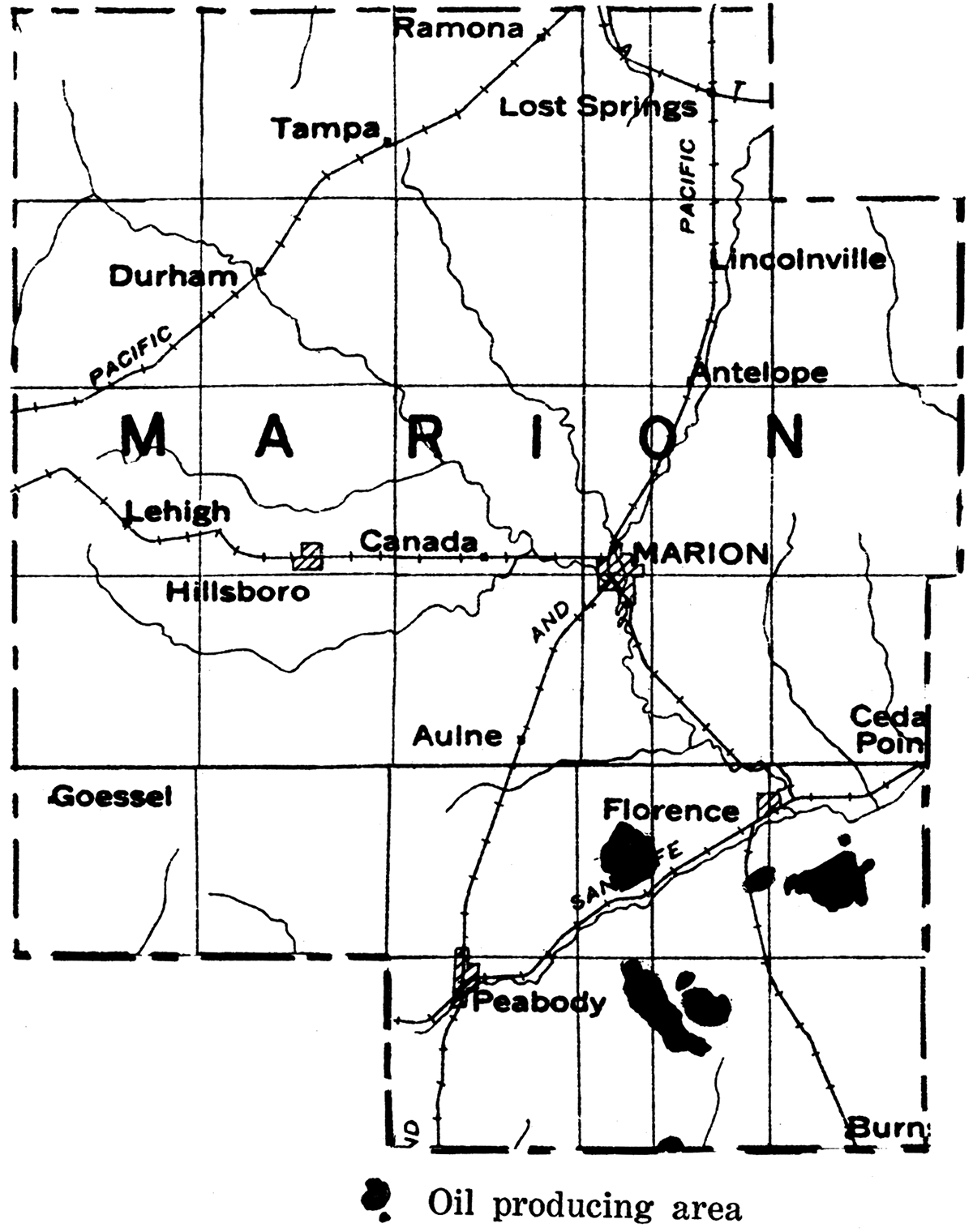

(3) The third oil-producing area may be designated the Granite Ridge district. This includes the fields along the trend of the buried granite ridge which extends across Kansas in a nearly straight line from Nemaha county on the north to western Cowley county on the south. No oil has been discovered above or on the flanks of this buried ridge in the north part of the state, but on the west side in Marion county, and above the ridge in the vicinity of El Dorado and Augusta and in western Cowley county, important fields have been developed. A strongly defined anticlinal structure in the stratified rocks of Permian age which occur at the surface in this region marks the trend of the underlying granite. The oil at El Dorado is found in part of the uplifted sedimentary rocks. The accumulation covers several square miles, and because of the porous character of the sand and limestone in which the oil occurs, production has been very prolific. Some wells which flowed without pumping have yielded as much as 20,000 barrels per day. While some oil and gas are obtained in sands in the Pennsylvanian, most of the production has come from more or less weathered parts of Ordovician rocks, chiefly the "siliceous lime" and Wilcox. Farther south oil has been produced mainly from sands that lie on the flanks of the major anticline above the granite. The oil has an average gravity of 32 to 34 degrees Baumé.

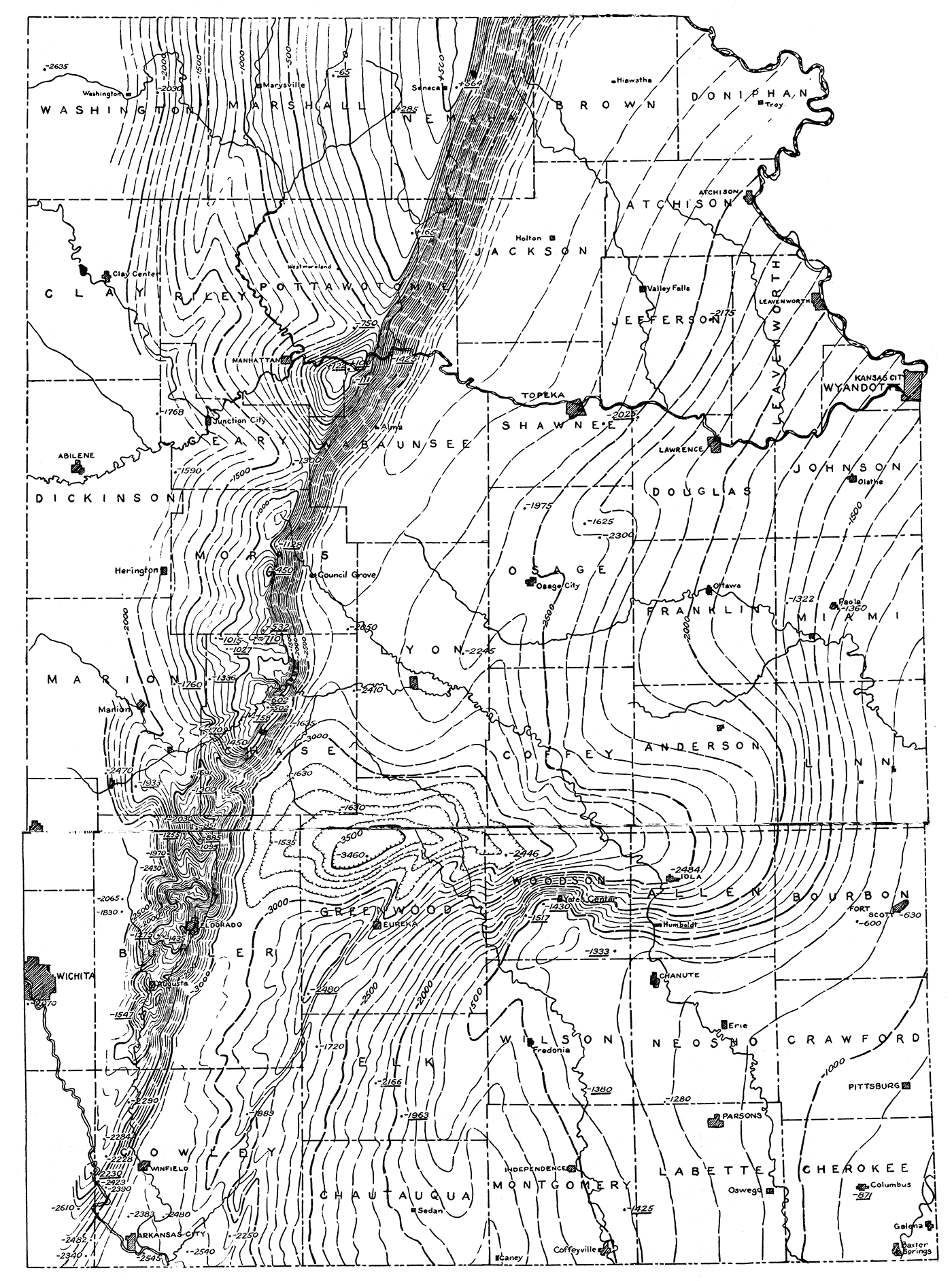

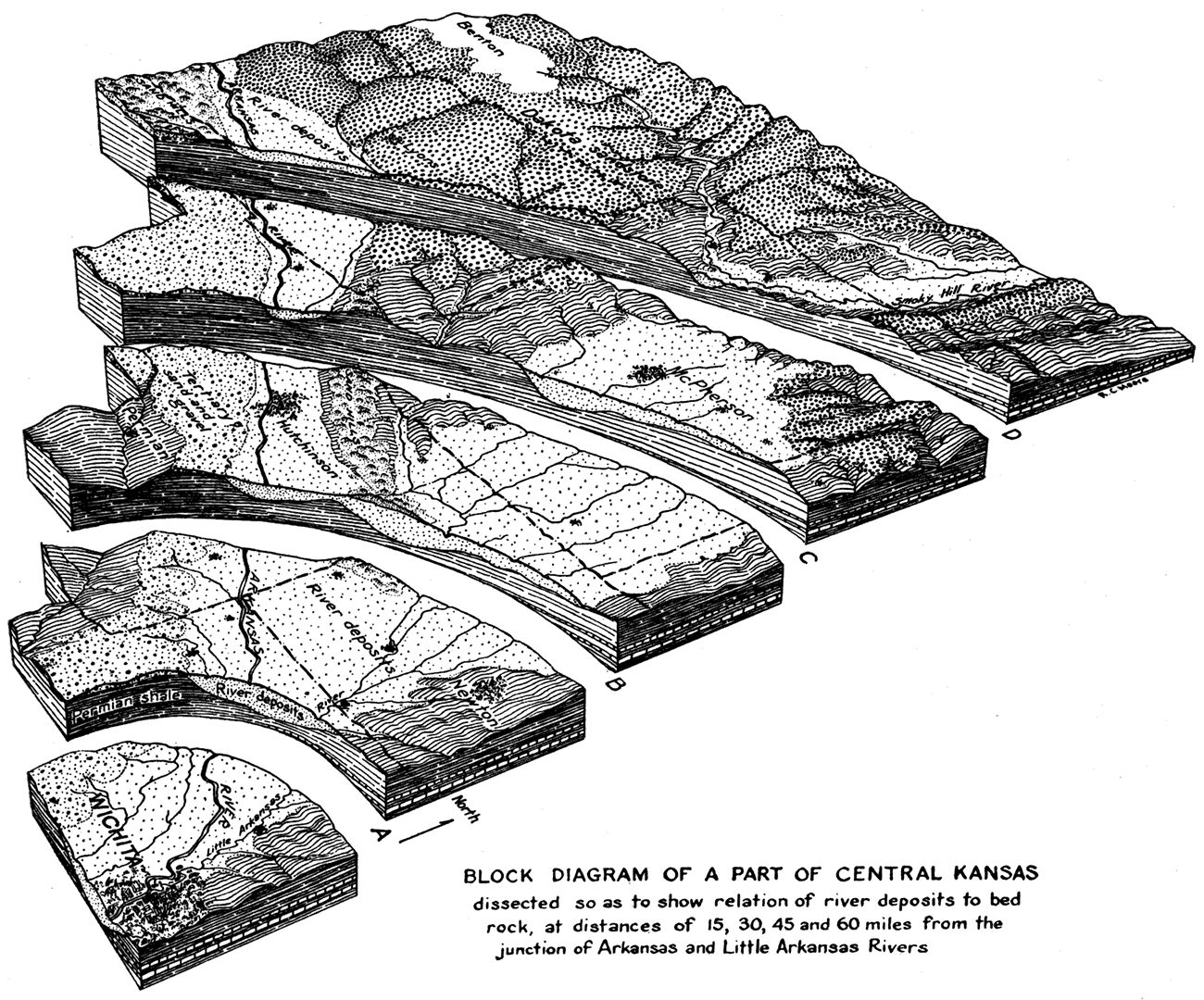

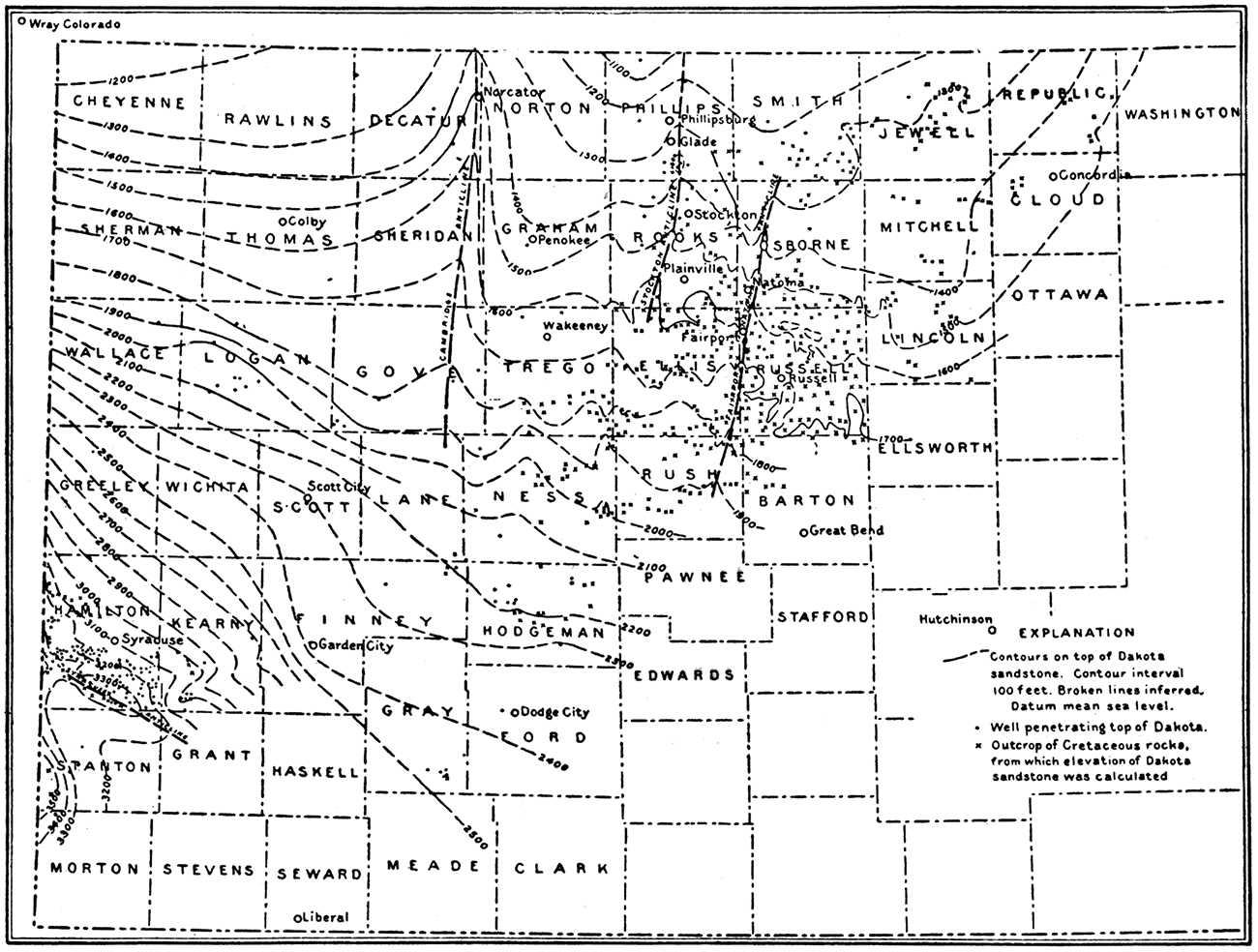

Figure 54—The "Granite Ridge" of Kansas. Drilling for oil in Kansas has afforded interesting information concerning the ancient rock floor on which the oil-bearing and other sedimentary rocks of the region were deposited. A prominently elevated portion of the floor, consisting mainly of granite, underlies the oil fields of Butler and Marion counties and extends entirely across the state. It rises to within 500 feet of the surface in the north, but is gradually depressed southward. (Contoured by Raymond C. Moore.)

Contour interval, 100 feet.

Elevation of granite, underlined figures.

Elevation of bottom of deep well, no granite, not underlined.

[Also available as an Acrobat PDF version, 3.1 MB.]

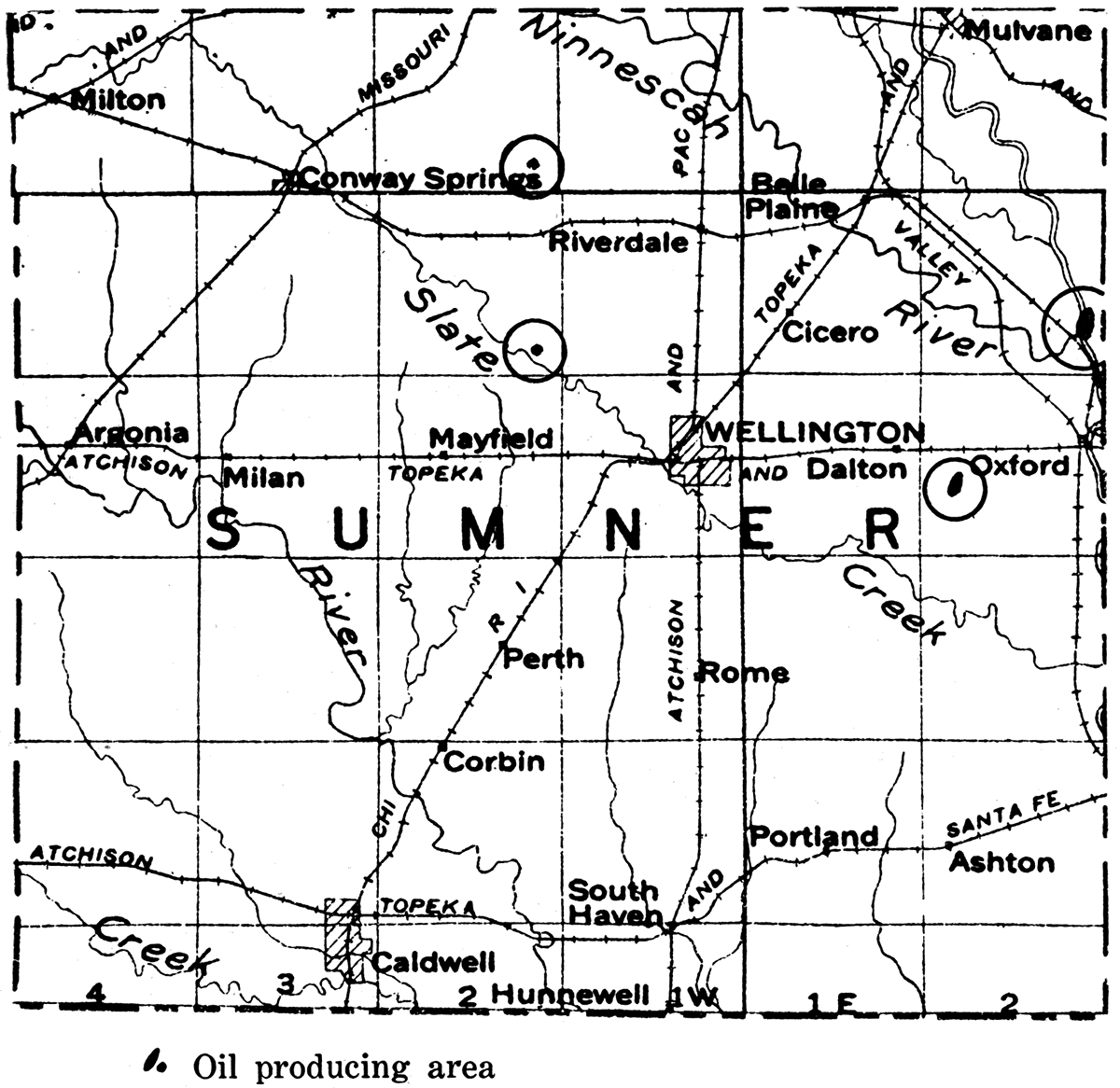

While it is possible that no new field will be discovered which will yield as much oil as El Dorado, it is known that there are important possibilities of future production in certain parts of this district. Exploration in western Cowley and eastern Sumner counties is very difficult because there are no surface hard rocks which show the detailed structure of the rock strata. This obstacle is being overcome by some of the larger companies by shallow test drilling which reveals the position of a marker bed and permits determination by the geologist of the structure of the rocks. In Marion county, and possibly farther north, bodies of sand deposited on the flanks of the uplift have been found or may be found productive of oil. In this region also there is possibility of production from porous zones in pre-Pennsylvanian rocks. Since for the most part there are no good surface evidences of oil accumulation, exploration is hazardous.

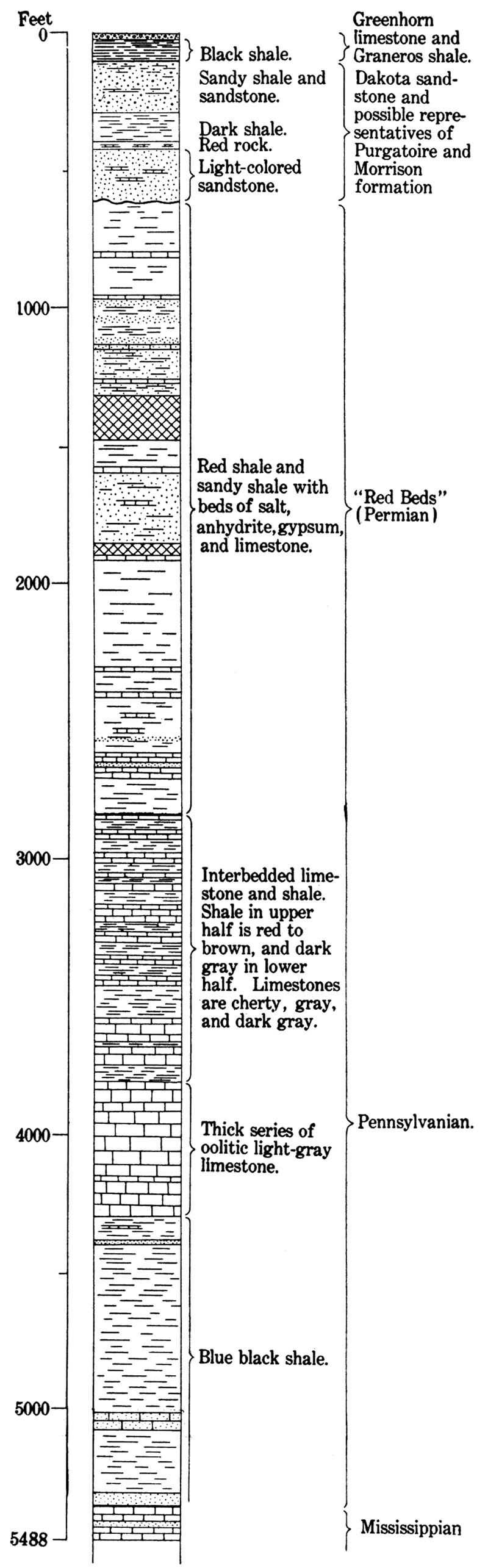

Figure 55—Generalized stratigraphic section of buried rocks of Hamilton County, Kansas, as shown in log of well drilled in sec. 5, T. 26 S., R. 41 W.

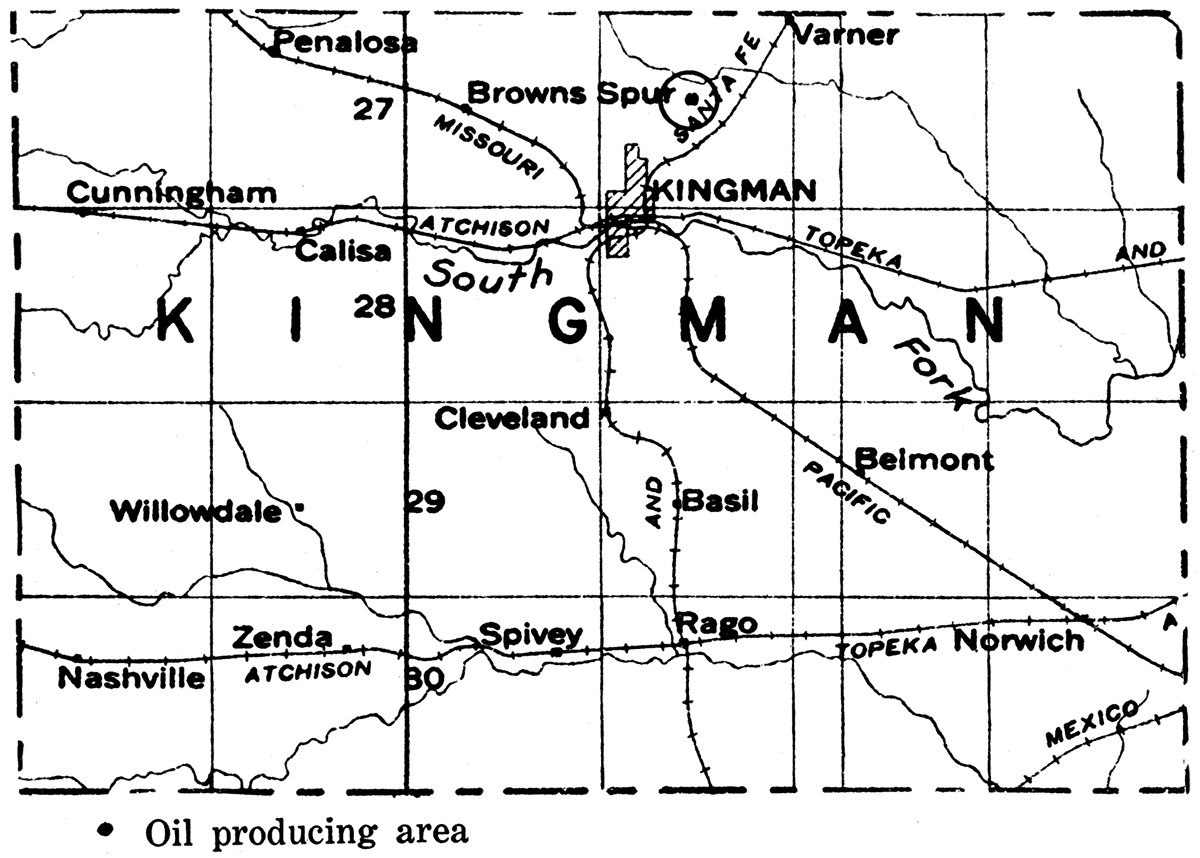

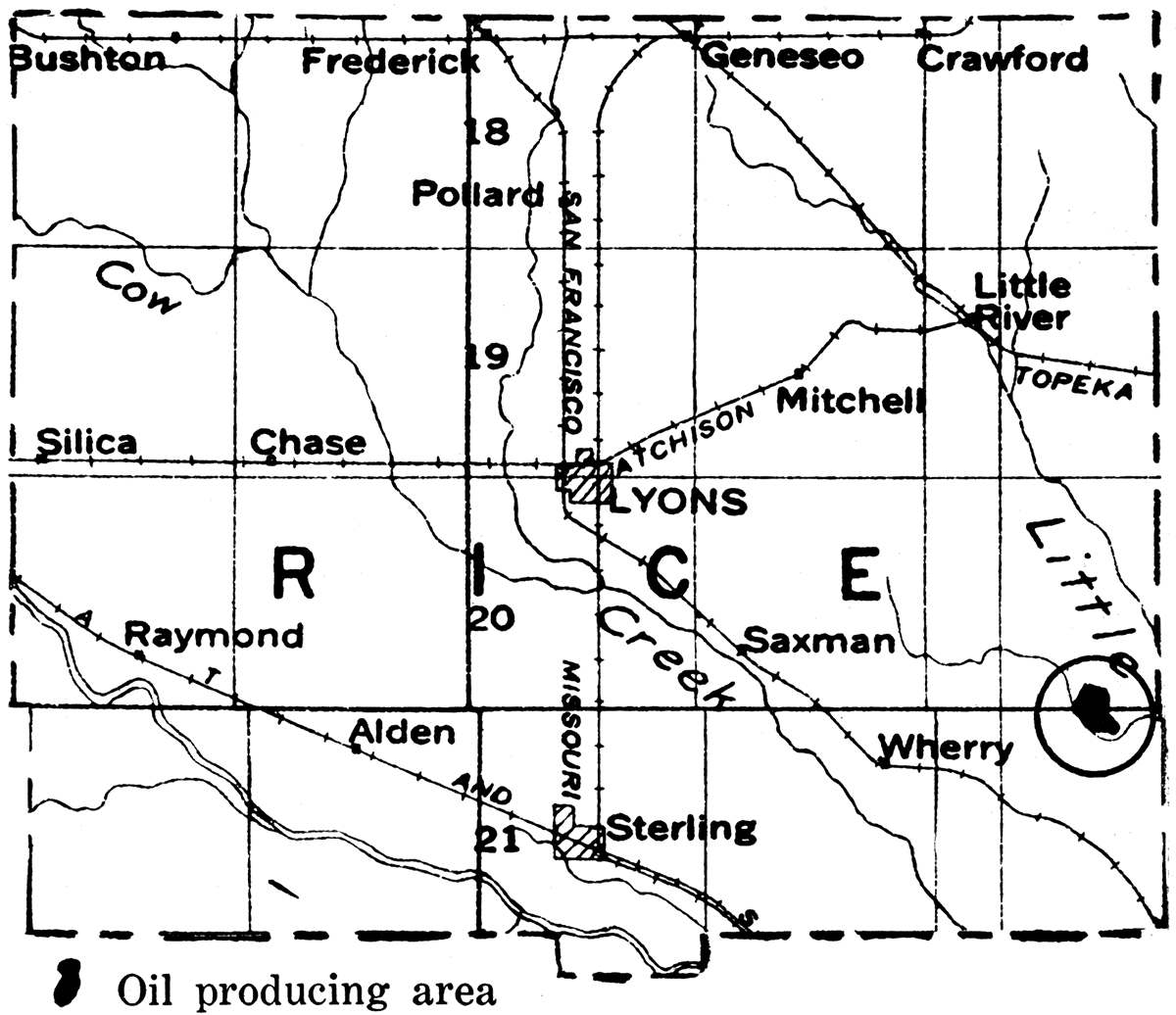

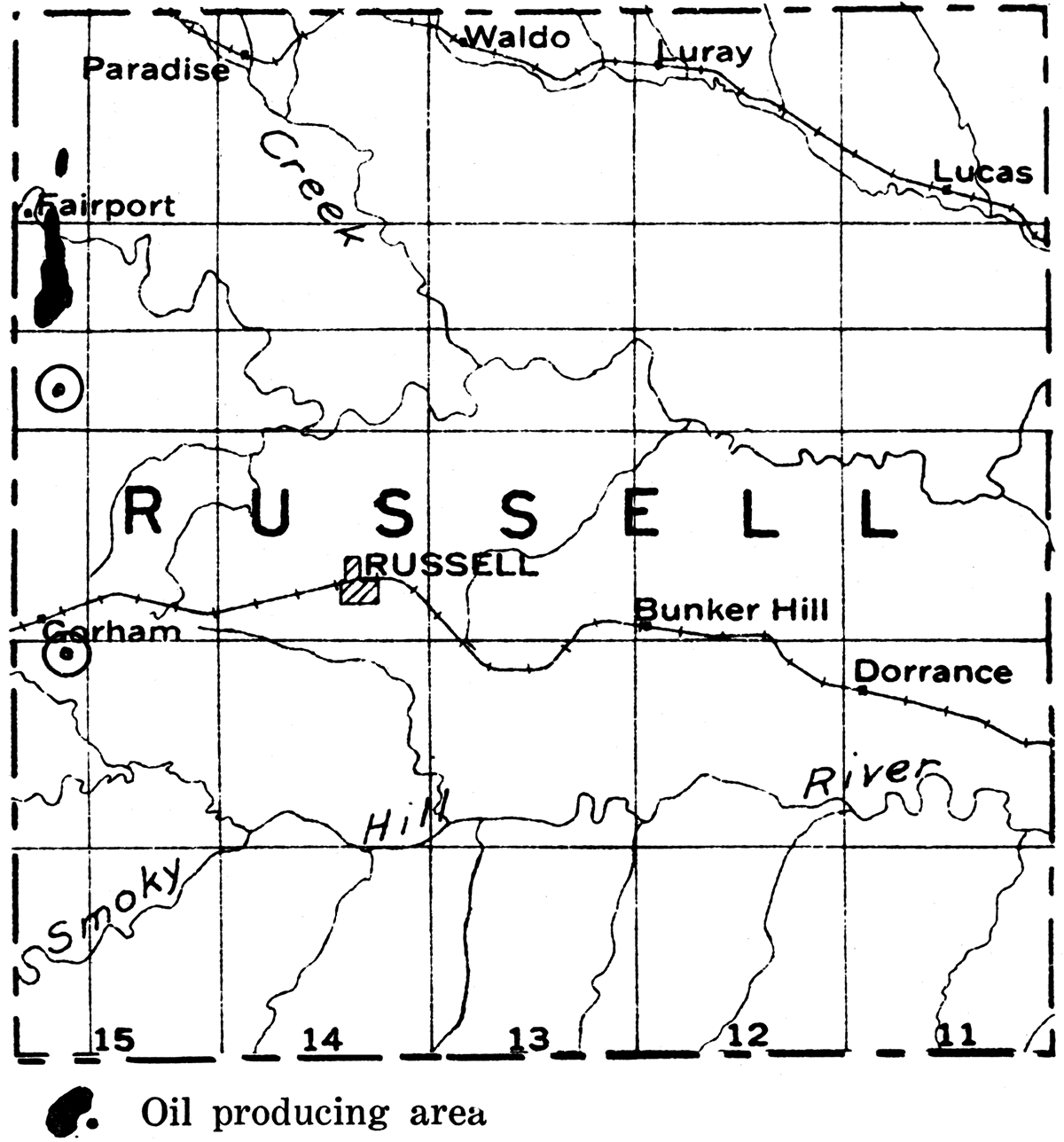

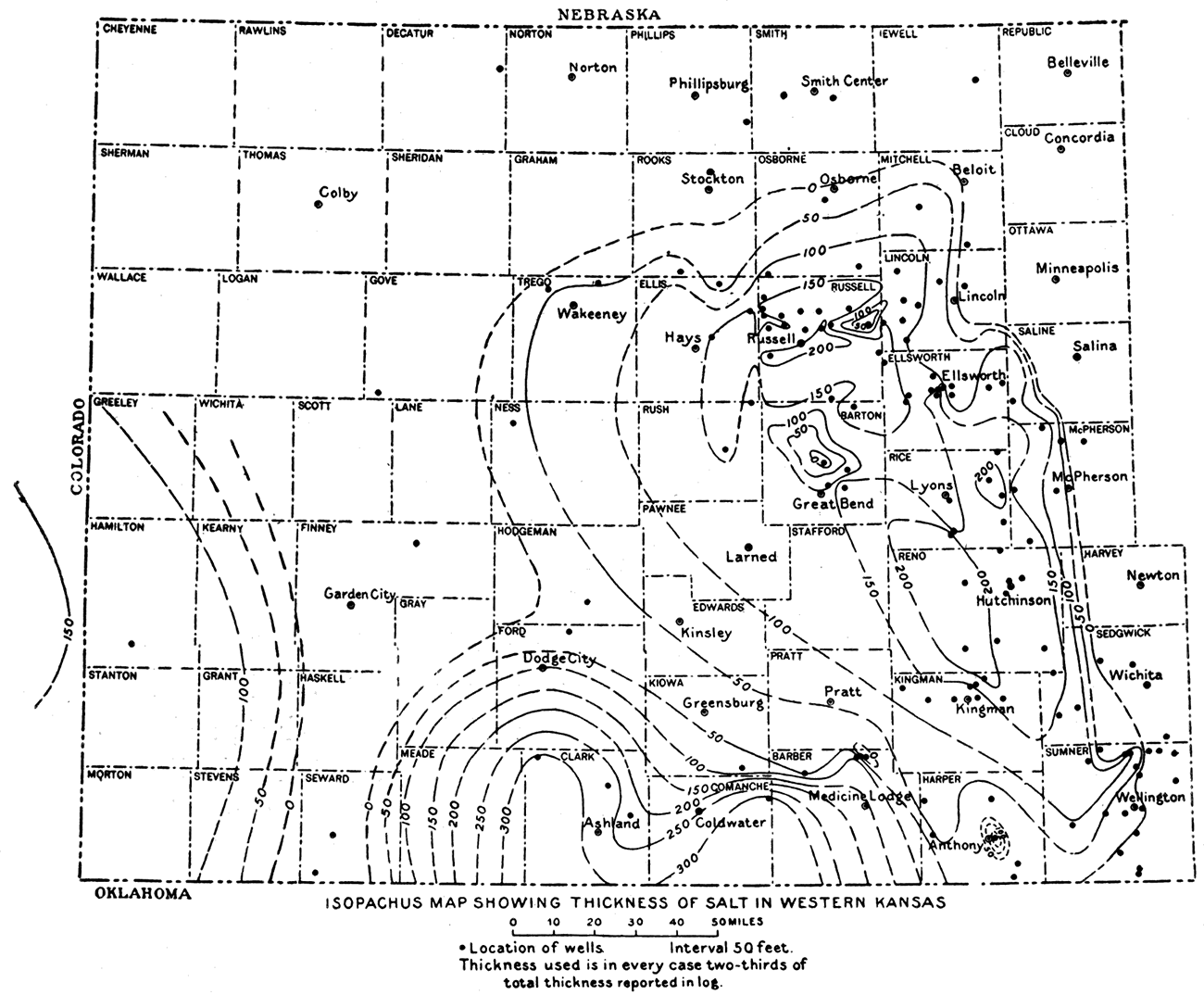

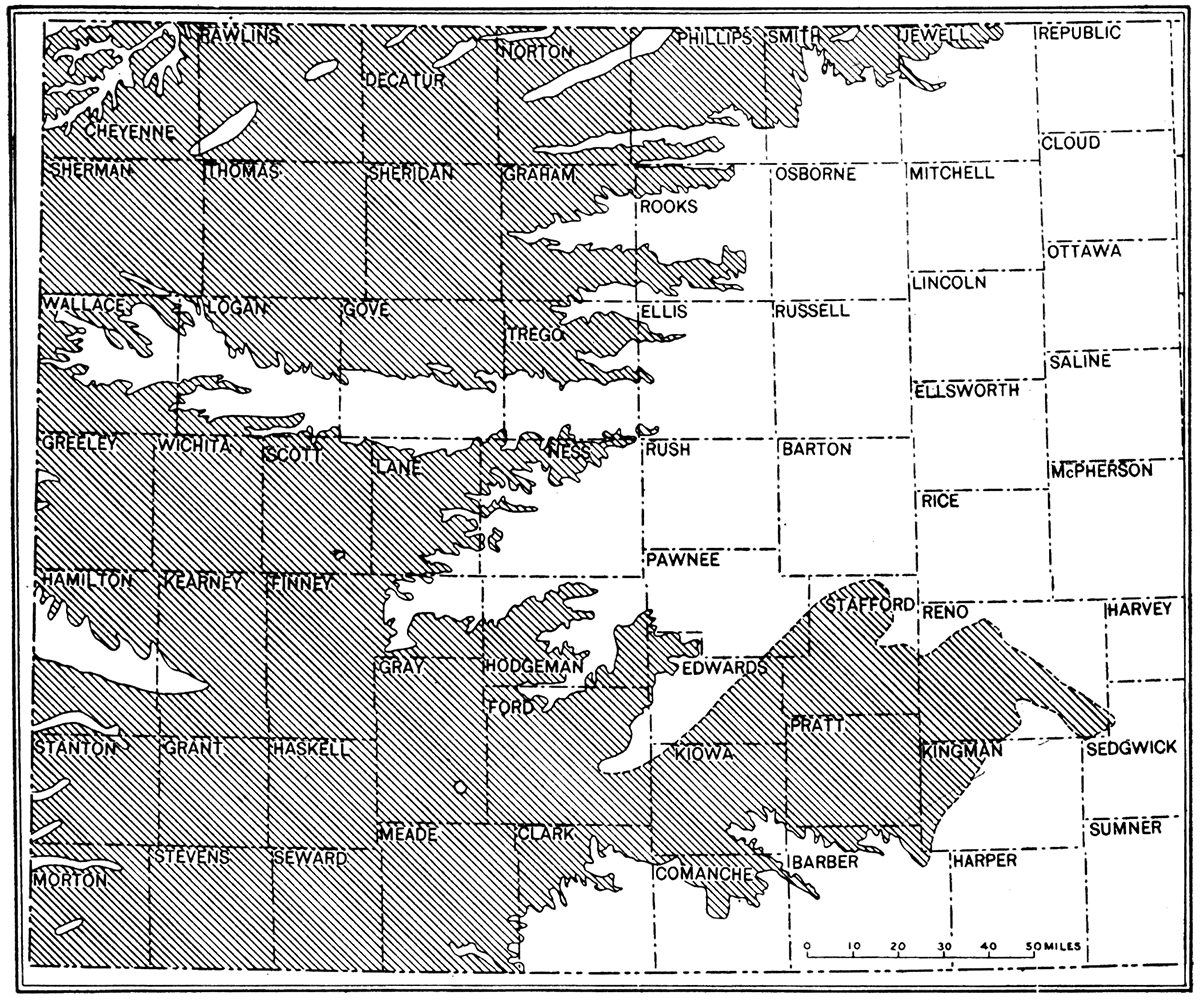

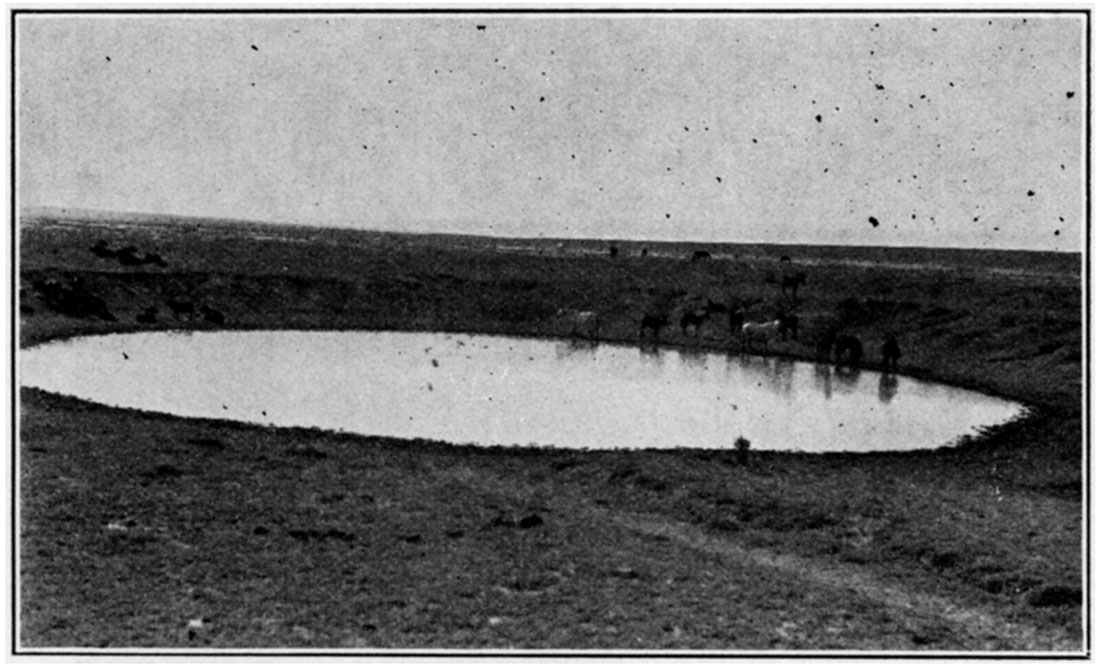

(4) In the fourth district may be included all of the western part of Kansas beyond the Granite Ridge. district. A convenient eastern boundary is the sixth prime meridian which crosses the state from north to south through Wichita. Up to the present time oil in commercial quantities has been found in only a few parts of this great territory and the ultimate importance of the region from the standpoint of oil production is very uncertain. [Note: On January 1, 1927, after this report was in the hands of the printer, Hartman & Skaer and Skelly Oil Company brought in a 150-barrel well in sec. 24, T. 24 S., R. 8 W., near the town of Abbyville, Reno county. Production was obtained from a depth of 3,545 feet.] The largest oil yield and the most interesting development in Western Kansas is in Russell county, approximately 135 miles northwest of the El Dorado field. The oil here occurs along a well-defined north-south trending anticline which was located in the course of geologic exploration and tested by a well drilled late in 1923. The discovery well produced first at the rate of about 10 barrels a day, but on drilling slightly deeper another pay zone was encountered at 2,998 feet from which 300 barrels a day was obtained by pumping. Other wells subsequently drilled showed larger production, some with a capacity reported up to 1,600 barrels per day. The main pay zone lies near the bottom of the Pennsylvanian rocks in this region, and is encountered at a depth of around 3,000 feet. Deeper pay zones have been encountered in some wells. Development in the last three years has considerably extended production. The Russell field has already (to August 1926) produced more than 2,500,000 barrels of oil, and the county ranks fourth in the state in volume of production. The oil which has a gravity of about 41 degrees Baumé is unusually light for Kansas oil and its content of gasoline, amounting to 43 per cent, is correspondingly large.

An interesting oil field has been developed about 12 miles north of Hutchinson in the southeast part of Rice county. The oil here occurs in a porous residual chert that belongs in the Cherokee shale of early Pennsylvanian age. Data are not available on the local and regional structures in this area. Most of the legion lacks traceable key beds and is in part covered by extensive deposits of dune sand, the discovery well being located without geologic guidance. In Kingman county oil has been found at a depth of around 4,000 feet in beds which may correspond to the siliceous lime. The commercial possibilities of this region are as yet undetermined, but increasing amounts of water in the one producing well and the failure of offsets and other tests are very disappointing. Reports of oil and gas in adjacent territory, especially to the south, seem to suggest that production of commercial importance may be found here.

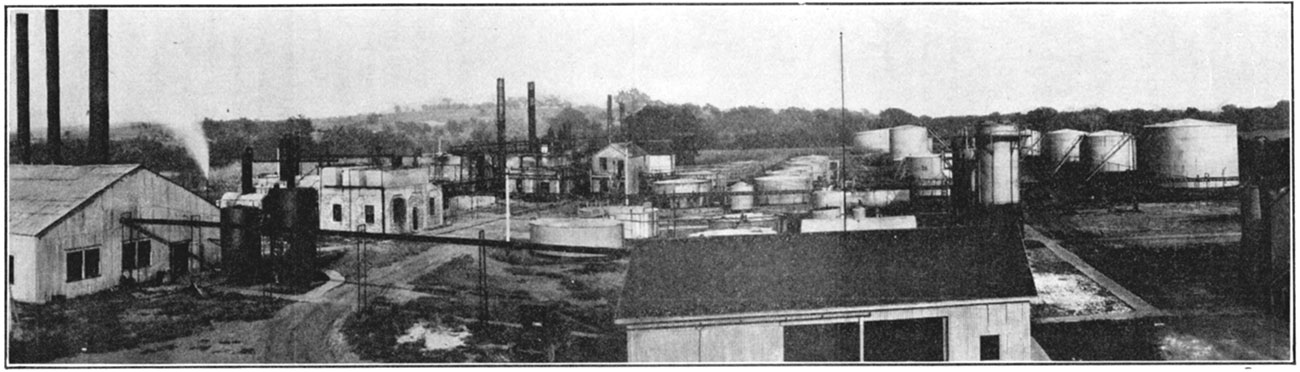

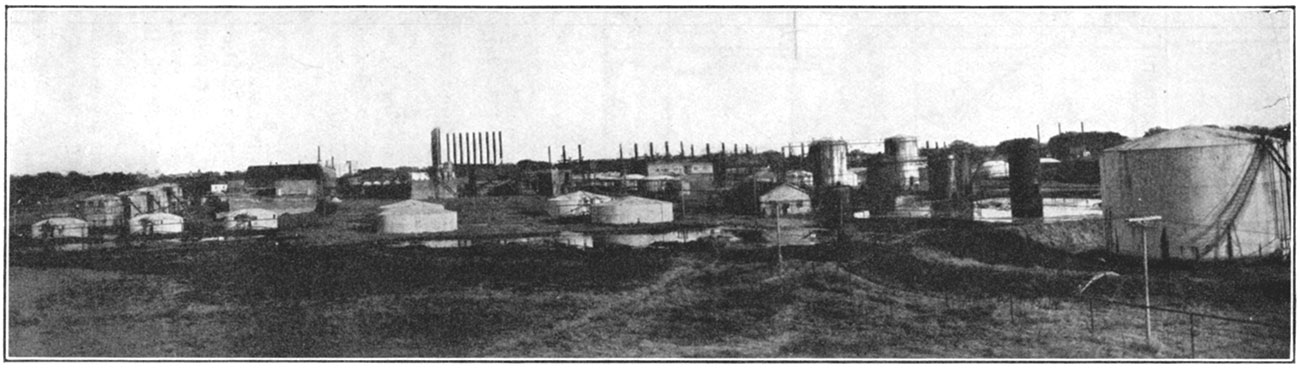

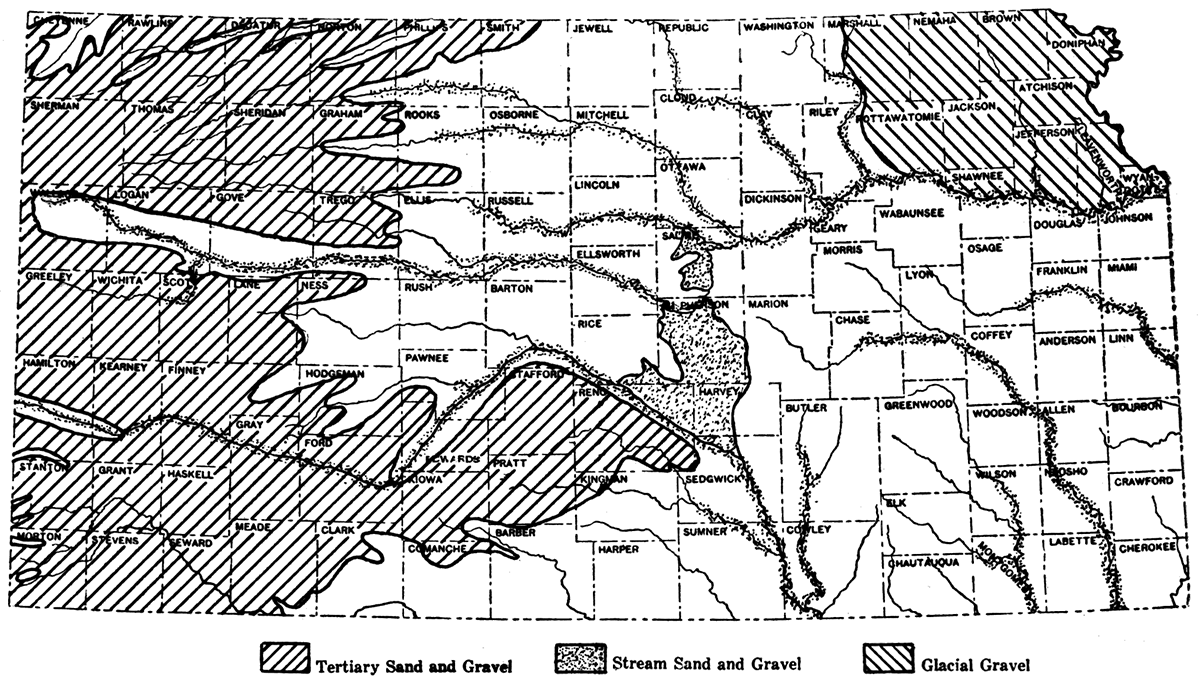

Figure 56—Kanotex oil refinery. Arkansas City.

Several tests have been drilled in various parts of western Kansas, one in Hamilton county to a depth of 5,488 feet, and another in Clark county to 5,679 feet. With the exception of showings of oil and gas these explorations have not as yet proved successful. The deep Clark county well in sec. 20, T. 32 S., R. 21 W., reported a showing of oil at 5,318 feet and 25,000,000 cubic feet of gas at 5,304 feet. A well west of Liberal in Seward county reported 10,000,000 cubic feet of gas at a depth of about 2,700 feet. [Note: In June, 1927, a wildcat well southwest of Hugoton, Stevens county, in sec. 31, T. 33 S., R. 37 W., struck a gas flow estimated between 7 and 10 million cubic feet in a porous layer tapped at 2,660 feet. The gas caught fire and burned the rig.] The finding of oil in Russell county, the successful developments of gas at Wray, Colo., just west of the northwest corner of Kansas, the knowledge of a fairly prominent anticline trending south from the line between Decatur and Norton counties, and the scattered showings of oil and gas which have been mentioned encourage prospecting in the western part of Kansas. [Note: On July 6, 1927, the Vickers Petroleum Company brought in a 200-barrel wildcat at a depth of 3,257 feet in the southwest 1/4 of southeast 1/4 of sec. 11, T. 9 S., R. 16 W., in southeastern Rooks county. This is 22 miles northwest of the Fairport pool of Russell county.] However, the fact that through many hundreds of square miles in this section of the state there are surface deposits of sand and gravel which conceal the underlying stratified rocks and make surface observations of structure impossible, and the fact that many of the surface beds that are exposed lack good key beds for structural geologic study, make exploration for oil in this region unusually difficult. Further, the very deep borings which have been put down in Clark and Hamilton counties show that the Pennsylvanian lies at great depth, and unless oil is found in higher beds the expense of this deep drilling will be an important factor in the attempt to develop new fields.

| Kansas Petroleum Production in Barrels, by Years, 1889 to 1925, inclusive |

|

|---|---|

| 1889 | 500 |

| 1890 | 1,200 |

| 1891 | 1,400 |

| 1892 | 5,000 |

| 1893 | 18,000 |

| 1894 | 40,000 |

| 1895 | 44,000 |

| 1896 | 114,000 |

| 1897 | 81,000 |

| 1898 | 72,000 |

| 1899 | 70,000 |

| 1900 | 76,000 |

| 1901 | 179,000 |

| 1902 | 332,000 |

| 1903 | 932,000 |

| 1904 | 4,251,000 |

| 1905 | 3,100,000* |

| 1900 | 2,700,000* |

| 1907 | 2,410,000 |

| 1908 | 1,801,000 |

| 1909 | 1,264,000 |

| 1910 | 1,128,000 |

| 1911 | 1,279,000 |

| 1912 | 1,693,000 |

| 1913 | 2,375,000 |

| 1914 | 3,104,000 |

| 1915 | 2,823,000 |

| 1916 | 8,738,000 |

| 1917 | 36,636,000 |

| 1918 | 45,451,000 |

| 1919 | 33,048,000 |

| 1920 | 39,005,000 |

| 1921 | 36,456,000 |

| 1922 | 31,766,000 |

| 1923 | 29,407,000 |

| 1924 | 28,836,000 |

| 1925 | 38,357,000 |

| Total | 358,270,000 |

| *Estimated | |

| Kansas Wells Drilled in 1924 and 1925 | ||

|---|---|---|

| 1924 | 1925 | |

| Wells completed | 1,125 | 2,003 |

| Dry holes | 396 | 636 |

| Gas wells | 79 | 86 |

| Oil wells | 650 | 1,281 |

| Initial daily production, barrels | 92,268 | 207,880 |

| Average initial daily production, barrels | 141.9 | 162.3 |

Allen County

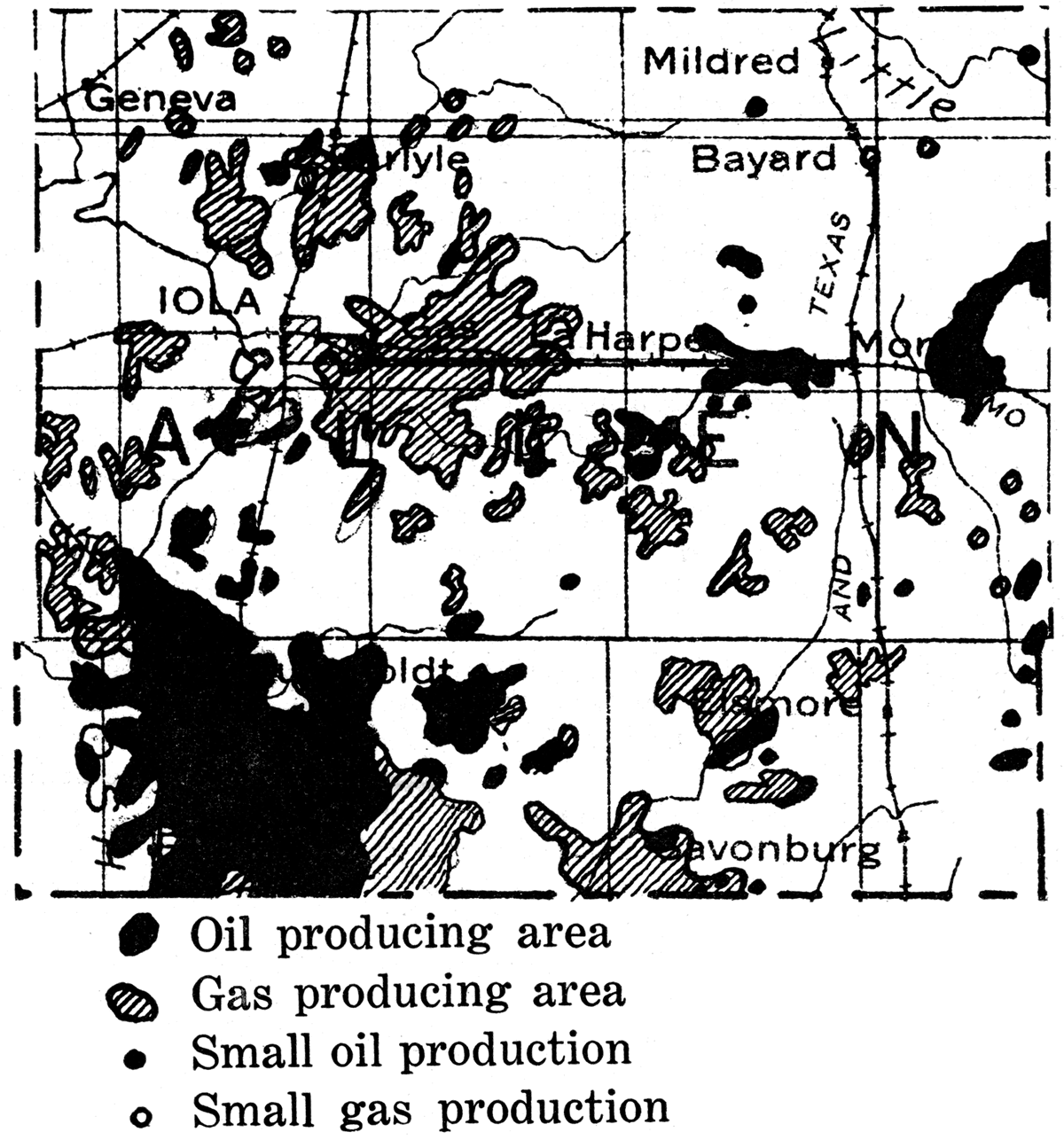

The production of oil and gas has long been a well-established industry in Allen county, the gas pool at Iola being one of the very early developments in Kansas. Some production of oil and gas has been found in almost all parts of the county, but the main producing areas may be grouped into three pools: the Iola, the Moran and the Humboldt.

The Iola pool is primarily a gas producer, but there are some oil wells, mainly in the area three or four miles west and southwest of Iola. The field extends from the south side of T. 25 S., R. 17 E., northeastward about 15 miles to the vicinity of Carlyle. The productive area has an average width of about five miles, but near Iola and La Harpe it is fully ten miles wide. Some of the wells had a reported capacity of 15,000,000 cubic feet per day, but most of the wells are smaller. Much of the gas has been put to industrial uses, and it is responsible for the location at Iola of large zinc smelters. The producing sands occur in the Cherokee formation. They are lenticular in shape, and in places grade into shale in very short distances. The average depth of wells is 600 to 850 feet.

Figure 57—Allen county.

The Humboldt pool lies in the southwest part of the county, including practically all of T. 26 S., R. 18 E., and extending east and northwest into parts of adjoining townships. As a matter of fact production is almost continuous with the Iola gas pool to the north and the Chanute oil pool to the south. Most of the wells yield oil, but there are some gas wells scattered throughout the district, especially in the southwest part of the field. The oil is mostly a low grade heavy-crude, with a gravity ranging from 18 to as much as 38 degrees Baumé, The wells have a small initial production, few producing more than 100 barrels a day, and most of them being much smaller. However, production declines. very slowly and this fact, coupled with the shallow drilling, has permitted profitable development.

Near Moran there are oil fields east and west of the town and gas in a small area to the south. Conditions are essentially similar to those in the Humboldt and Iola pools, but drilling is slightly shallower. There are smaller areas of gas production east of Leana and near Elsmore, and oil wells west of Savonburg. The production of oil in Allen county in 1922 was 549,570 barrels; 1923, 506,896 barrels; 1924, 427,111 barrels; 1925, 556,342 barrels; and in the first half of 1926, 140,264 barrels—a total production for the 4%-year period of 2,180,183 barrels. Records of drilling show that approximately 85 per cent of the test wells in the county have met with success, which means that only a little over one well in ten is a failure.

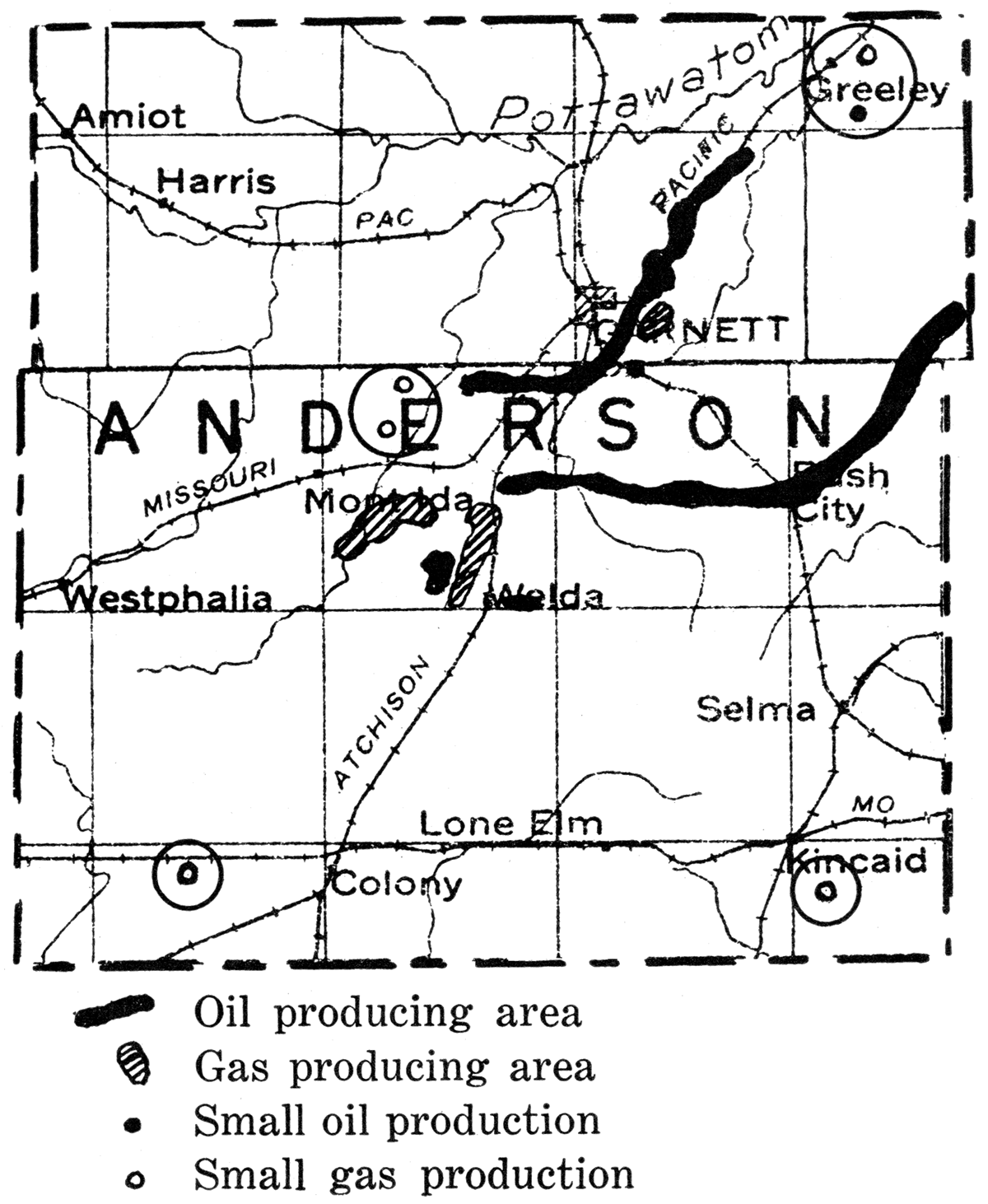

Anderson County

For many years before 1921 a small production of gas and a much smaller yield of oil was obtained in Anderson county, chiefly in the vicinity of Garnett. In 1921 a very important gas field was found in the southern part of the county near Colony, and since 1923 a considerable and steadily increasing production of oil is reported. The total yield for the county in 1925 was 824,039 barrels, or an average of 2,258 barrels a day. This production has increased to more than 3,000 barrels a day.

The oil and gas are confined almost entirely to narrow elongate sand bodies called "shoestrings." These sands are found mainly at three horizons: (1) The first occurring in the Bandera shale and found at depths ranging from 475 to 675 feet below the surface. This sandstone corresponds to the horizon of the Peru sand in southeastern Kansas and northern Oklahoma. It ranges in maximum thickness up to 60 feet, and northwest of Welda, west and east of Garnett, and along Deer creek, east of Colony, it has produced gas in commercial quantities. Part of the oil production in the field east of Greeley probably comes from this sand. (2) A second productive horizon occurs near the top of the Cherokee shale, and is encountered at depths ranging from 600 feet in the east part of the county to about 825 feet in the west. There are two principal shoestring sands which are now known—the Garnett string and the Bush City string. The former is developed for about 4 1/2 miles and the latter for almost 14 miles. These sands appear to be channel-fillings marking the courses of ancient streams which deposited the sand during a time of temporary emergence in the early part of the Pennsylvanian period. (3) At the Bartlesville horizon, in the lower part of the Cherokee shale, and found at depths ranging from 825 to 1,000 feet there are several small gas pools west of Garnett, north of Bush City and south of Greeley. The most important sand at this horizon, however, is the Colony sand which extends for a number of miles north of Colony. It has a maximum thickness of about 100 feet. Wells have produced from 20,000,000 to 32,000,000 cubic feet of gas, initial open flow, and the Colony field is said to have had a total open flow of 1,350,000,000 cubic feet. Below the Bartlesville zone a small amount of oil and gas, but very little commercial production, has been obtained in a sand near the bottom of the Cherokee shale. The Mississippian limestone has not yielded any commercial . production in Anderson county, although low-gravity oil in small quantity has been found in the top of the lime south and east of Kincaid in Linn county.

Figure 58—Anderson county.

Most of the oil wells are small producers, but one well in sec. 8, T. 21 S., R. 21 E., in the Bush City shoestring is reported to have had an initial yield of 500 barrels from a sand encountered at 593 to 620 feet. The oil is 36 gravity. This section is probably the richest productive area in the county, for a number of other wells having production of 200 to 300 barrels a day were found here.

In the Garnett shoestring more than 40 wells have been reported, with an initial production of 200 barrels or more, and, the yield appears to be fairly long lived.

As is characteristic of the shoestring-sand bodies there is little or no structural indication at the surface of the position or trend of these productive areas. Very many dry holes had been drilled before the discovery of the commercially profitable producing pools. At the present there are about 800 oil wells, about 400 gas wells, and something over 600 dry holes in the county. The average cost of drilling in Anderson county is low. Dry holes in the Bush City district have been reported to have been drilled for less than $1,000. Further exploration will undoubtedly result in extending the shoestring production.

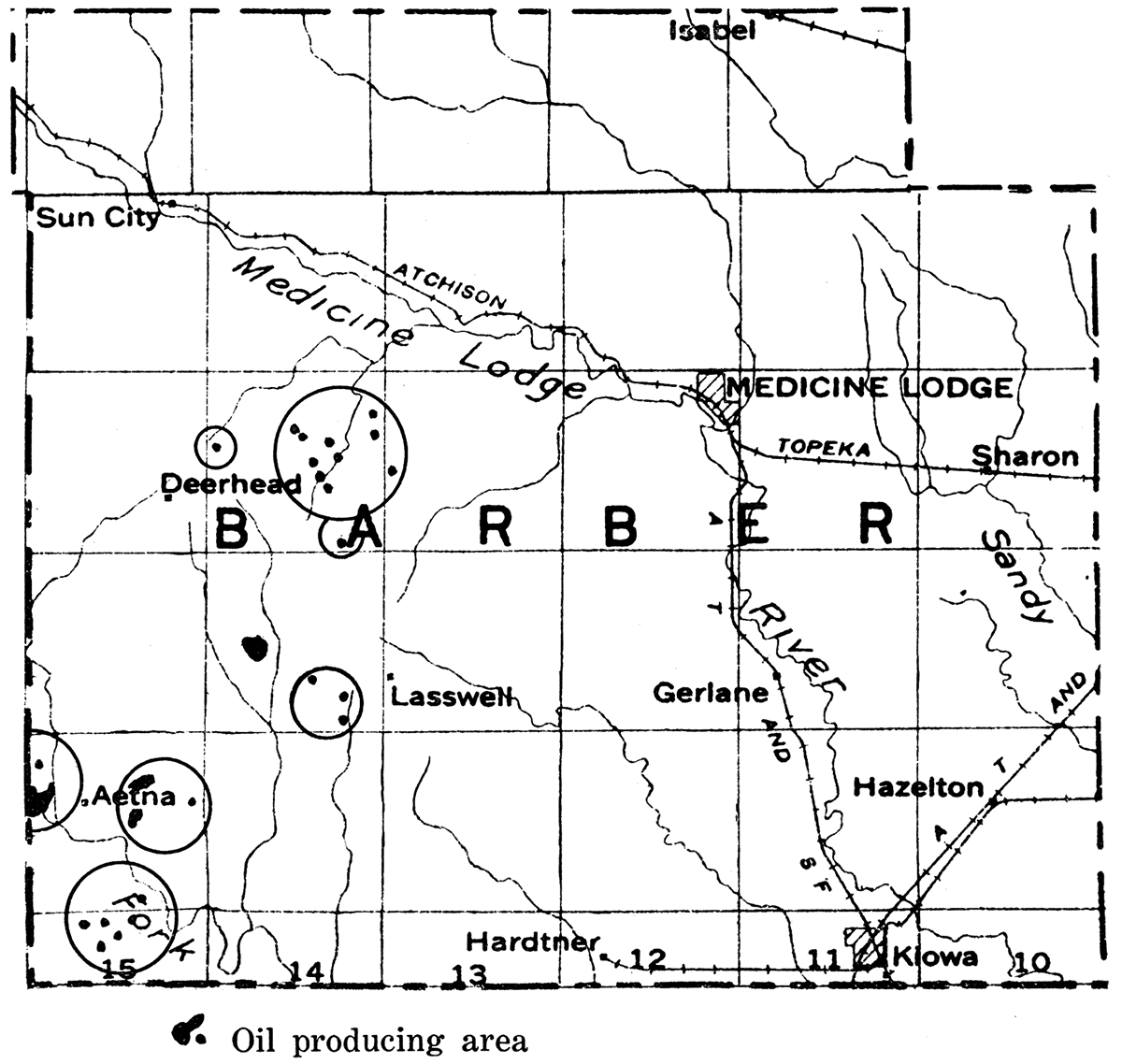

Figure 59—Barber county. Oil and gas in small quantities, but not as yet in commercial amount. have been found in parts of Barber county as here indicated.

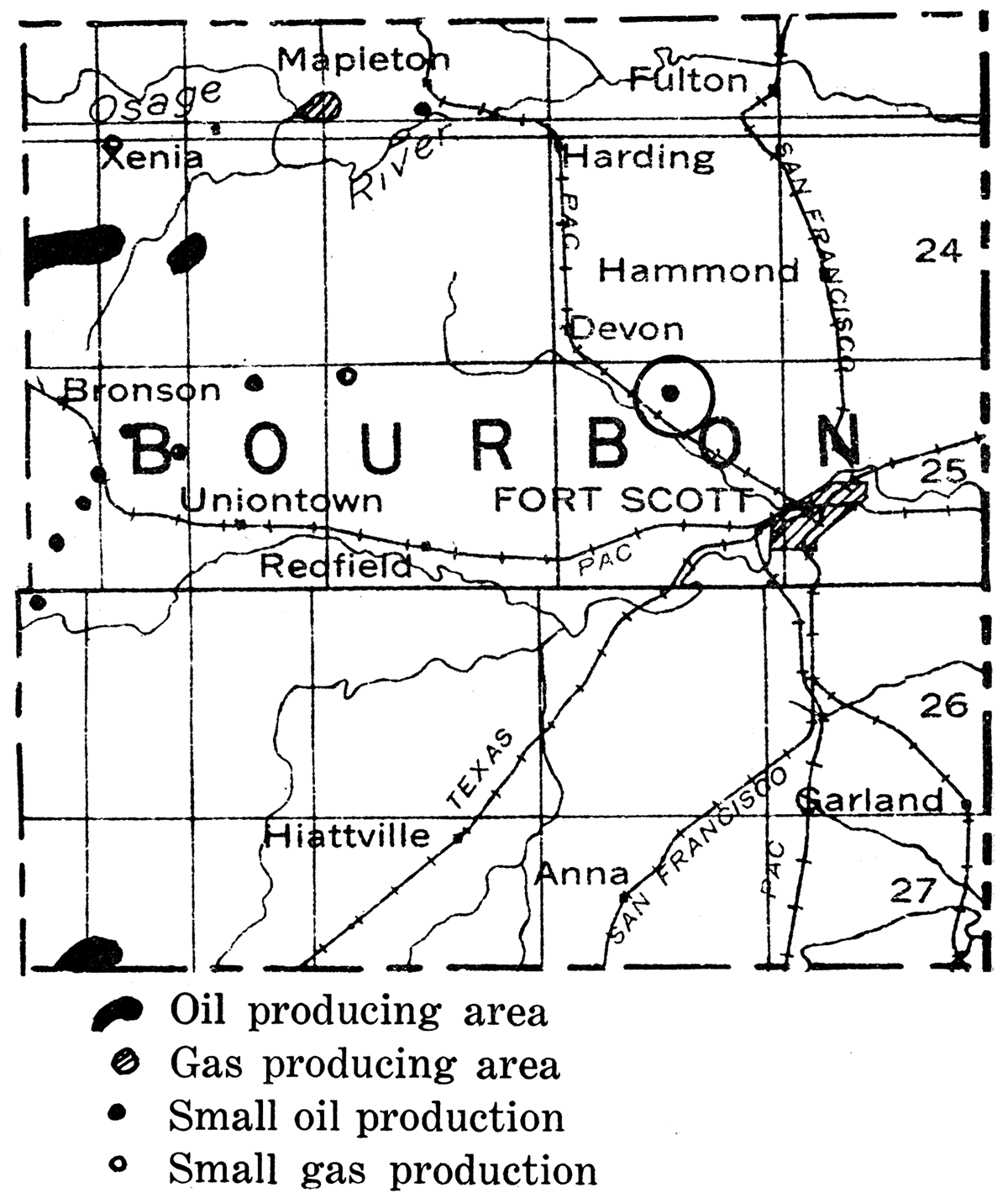

Bourbon County

Some oil and gas have been produced for many years in Bourbon county, but this region has never had the importance of Allen county to the west or Neosho to the southwest. According to available records there were in 1906 eight oil wells and six gas wells in the county. In 1917 the Walnut-Hepler field in southwest Bourbon county was opened by a good producer in sec. 19, T. 27 S., R. 22 E., at a depth of 600 feet. This well had 28 feet of oil sand, and also flowed about a quarter of million cubic feet of gas. A number of good gas wells were drilled in 1918 south of Mapleton, in the southwest part of T. 23 S., R. 23 E., and extending a short distance southward. The following year a small oil field was opened near Bronson, about 2 miles north and a mile east, the oil occurring in a 10-foot sand encountered at 654 feet. Another pool a few miles south of Bronson in T. 25 S., R. 21 E., and extending into Allen county has been developed. The productive area is about 7 miles long by a half mile wide; the oil coming from a 50- to 60-foot sand at depths of 650 to 800 feet. An unusual shallow field has been developed between Hume, Mo., and Fort Scott, extending from south of Hume to within six miles of Fort Scott. About 80 oil wells producing from 3 to 10 barrels a day have been drilled. A well reported to make 1,500,000 cubic feet of gas was brought in a mile east of here. The wells, especially in the Bronson area, are good producers and the oil is exceptionally good for the eastern Kansas shallow fields, averaging around 32 degrees Baumé. Initial production of the wells ranges from 5 to 100 barrels, settling down to 1 to 10 barrels. One well about seven miles southwest of Bronson is reported to produce from the. upper part of the Mississippian limestone at a depth of 830 feet.

Figure 60—Bourbon county. (Modified after map by Oil and Gas Journal.)

In 1924 the production of Bourbon county was 35,231 barrels; in 1925 the production dropped to 13,315 barrels; and in the first half of 1926 the yield was only 3,470 barrels.

Butler County

Butler county contains the most important oil-producing territory in Kansas. Indeed, the total production from this county surpasses that of the entire remainder of the state since the beginning of recorded production in 1889, and this notwithstanding the fact that the first important commercial production in the county was only discovered in December, 1915. More than 200,000,000 barrels of oil have been produced from Butler county fields. This huge quantity of oil exceeds the total production up to the present of any foreign field except Russia, Mexico, Dutch East Indies and Rumania.

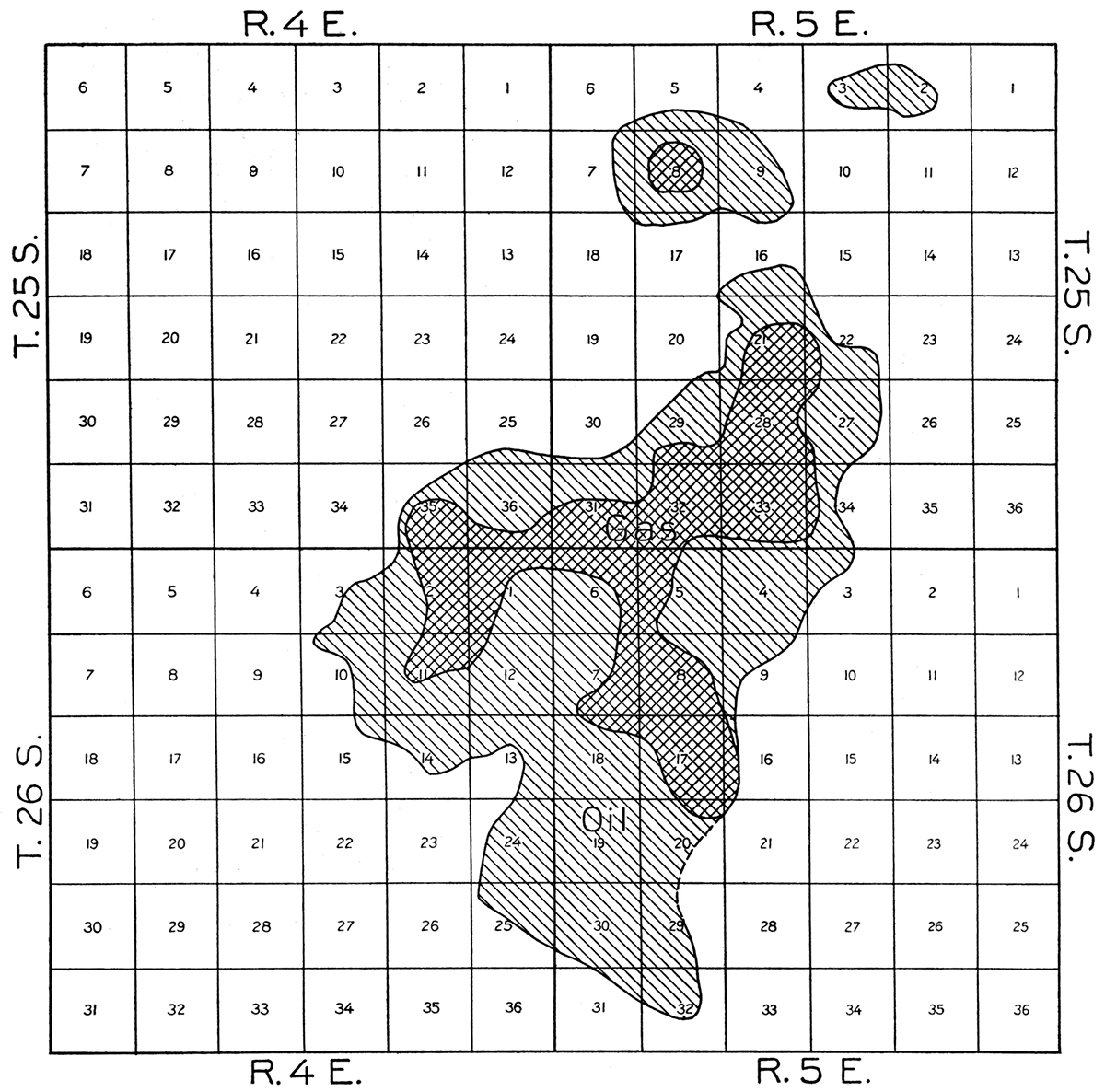

Prior to the year 1916 the largest annual production of oil in Kansas was 4,250,708 barrels-i-in 1904. In 1912 the entire state produced only 1,128,668 barrels. In the first year following the discovery of the deep producing sand in Butler county the state's total production was 8,738,000 barrels, of which about two-thirds were produced in Butler county. In 1917 the Augusta pool produced 11,353,600 barrels and the El Dorado district 19,915,569 barrels, the total production from the state being 36,536,000 barrels. The peak of production was reached the following year, 1918, when the county produced 36,069,670 barrels, or an average of 98,821 barrels per day. Of this amount the El Dorado district produced 29,198,145 barrels. The oil from these fields is a good grade, averaging in gravity from 33 to 35 degrees Baumé,

In May, 1917, the Towanda pool, in T. 26 S., R. 4 E., in the west part of the El Dorado district was discovered. The Trapshooters Oil Company drilling on the Williams farm in the southeast of the west half of the northwest quarter of sec. 11, T. 26 S., R. 4 E., secured a flowing well estimated as high as 20,000 barrels a day. This was undoubtedly one of the largest producers of high grade oil in the world. In September, 1917, the Gypsy Oil Company's No. 5, Shumway, in the same section, started out with 20,000 barrels a day, and produced two and a quarter million barrels before it quit. Other wells in the vicinity had a production of more than 10,000 barrels a day, and one, the Shriver No. 23, started at 23,000 barrels, but stopped after one day's flow. According to records of the Empire Gas and Fuel Company the Shumway lease of the Gypsy Oil Company, 160 acres in extent, averaged over 50,000 barrels per acre. The Empire's Cardey farm, an 80-acre lease, has yielded more than 30,000 barrels to the acre.

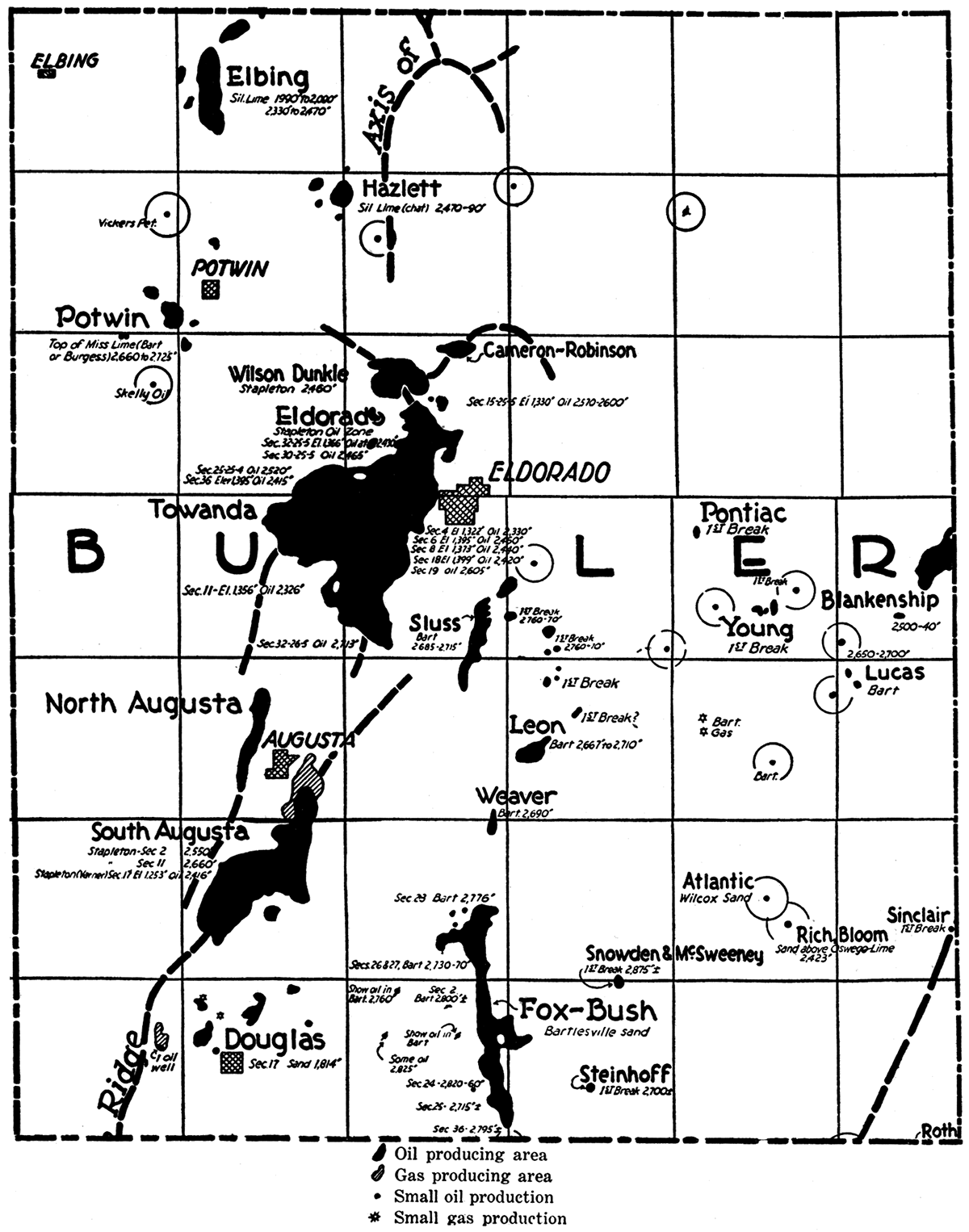

Following the initial development of the great El Dorado and Augusta oil district, exploration has proved the existence of considerable quantities of oil in other parts of the county. The most important of these is the Elbing pool in T. 23 S., R. 4 E. Other important pools are the Potwin pool, in the southeast part of T. 24 S., R. 3 E., the Fox-Bush pool in the east part of T. 28-29 S., R. 5 E., the Sluss pool in T. 26 S., R. 5 E., the Leon pool in T. 27 8., R. 6 E., and the Blankenship pool in T. 26 S., R. 8 E.

The rocks which appear at the surface in Butler county belong in the lower part of the Permian system. They consist of more or less flinty limestone and shale formations. At the east edge of the county and extending into west Greenwood county is the prominent Flint Hills escarpment, formed by the outcrop of hard flinty limestone of Permian age. Most of the remainder of the county is gently rolling, and there are few prominent topographic features. The rock strata have a general slight inclination to the west, amounting on the average to about 30 feet per mile. In the El Dorado and Augusta districts geologic studies before the drilling of the discovery wells showed the existence of a prominent anticlinal fold, trending in a direction slightly east of north and west of south. (Figure 62.) Near El Dorado the eastward dip of the strata is prominent.

Figure 61—Butler county. (Modified after map by Oil and Gas Journal.)

Figure 62—Structure map of El Dorado oil field. Structure contours on top Fort Riley limestone.

Beneath the Permian in the El Dorado and Augusta districts, are a little over 2,000 feet of alternating limestone, shale and sandstone beds, belonging to the Pennsylvanian system.