Prev Page--Geography || Next Page--Mining Systems

Detailed Stratigraphy of Kansas Coals

General Outline of the Stratigraphy

The Coal Measures

The Kansas coals occur in various shale beds, occupying all positions from the Cherokee shales at the base to the Osage shales more than 2000 feet above. In connection with the following descriptions the reader is referred to the generalized geologic section, Plate VI, and to the two maps, Plates VII and VIII.

The Cherokee shales produce vastly larger quantities of coal than any other shale beds in the whole Coal Measures. It is from this horizon that is obtained the coal of Cherokee and Crawford counties, the Fort Scott coal of Bourbon county, nearly all the coal of Labette county, and the coal of Leavenworth county. In addition to these localities it is known that coal could be obtained in other places. The deep borings at Cherryvale, in Montgomery county, show that a bed of coal from 26 to 28 inches in thickness lies near the base of the Cherokee shales at that place. Wells in the vicinity of Pleasanton likewise show that beneath the coal now operated and within the Cherokee shales other coal is found which sometimes may be operated to advantage. Other wells which have penetrated the Cherokee shales at various places within the state likewise show the same conditions, namely, that coal may be found in the Cherokee shales under a large part of southeastern and eastern Kansas. The abundance of coal within these shales seem,s to be so great that it need not be a surprise if heavy beds be found under any part of the eastern fifty or seventy-five miles of the state.

The Labette shales, first in order above the Cherokee shales, have considerable bituminous matter within them, but nowhere does it amount to a good bed of coal. In a few places to the southwest of Fort Scott the coal is heavy enough so that it was formerly mined to a limited extent, but nowhere so far as is known have they produced any considerable amount.

The next shale bed above this, the Pleasanton shales, carries large quantities of coal; particularly in the Lower Pleasanton shales. This is true to so great an extent that a detailed description of the Pleasanton shales is given. in the proper place. Suffice it here to say that next to the Cherokee shales the Pleasanton shales probably carry the largest amount of coal known in the state.

Above the Pleasanton shales the next important shale bed is that of the Thayer shales, a shale bed that likewise carries a considerable amount of coal. This is particularly true in the vicinity of Thayer and to the southwest between Thayer and Neodesha and Independence.

From the Thayer shales upwards the next important shale bed is the Lane shales which as far as is known, is void of coal.

Above this is found the Lawrence shales, a heavy bed carrying a sufficient amount of coal to be of great commercial importance. Coal is mined or has been in these shales in Atchison county at Atchison, in different places in Jefferson county, in scores of places in Douglas county, but most of all in Franklin county, to the west and southwest of Ottawa. Farther south they have produced coal in limited amounts throughout almost the whole area over which the Lawrence shales are exposed, to the southwest entirely to the south part of the state.

The various shale beds above the Lawrence shales seem to be barren of coal, or almost so, until the Osage shales are reached. Here is a formation averaging about 200 feet thick, extending entirely across the state from north to south and which carries a large amount of coal that has been mined in nearly a hundred places. In the northeastern part of the state to the northwest of Atchison a half dozen or more localities have furnished coal from these shales. Southward in the vicinity of Topeka coal has been mined for years near the city and also further west near Sugar Works. And again southward, in the vicinity of Burlingame, Osage City, Carbondale, Scranton, etc., it has been mined to a great extent for more than twenty years. South from the Osage region, the same bed of shales has produced coal in the vicinity of Lebo, in Coffey county; Hilltop, and Virgil and other points in Greenwood county; at different places in Elk county; and at Leeds, in Chautauqua county. The coal of the Osage shales is not uniform in quantity or quality throughout this whole distance, but, it must be confessed, there is a strong similarity between the different samples found at the different places.

Above the Osage shales no coal has been found in the Carboniferous of Kansas of sufficient importance to justify mining, even for local consumption. At different places in the upper parts of the Coal Measures and also in a few places in the Permian rich carboniferous shales exist which somewhat resemble coal and which occasionally are locally called coal.

The only remaining coal in the state that need be noticed is the Cretaceous coal, found in the Dakota area of north central Kansas. The Dakota of Kansas has been divided by Logan (Logan, 1897, p. 206) into two divisions, the "lower" and "upper," the division between the two being provisionally made the sandstone layer which immediately underlies the heavy bed of shale that is the coal producer. Logan's description of the stratigraphy of these western coals may be here included (Logan, 1897, p. 208).

The Upper Group

"Lignite Horizon.-Resting upon the gray or white sandstone, in the last upper layer of the sandstone group, is a thin bed of lignite which is entirely wanting in certain localities. The lignite varies in thickness from 6 to 26 inches. In Republic county it occurs from 80 to 100 feet below the Benton limestone. In Lincoln county it is only 60 feet below that horizon, and in Russell county it is 90 feet. The thickest vein occurs in the mines on Little Timber creek in Lincoln county where the lignite rests between the beds of shale and gray sandstone, the shale adjacent the coal being extremely bituminous in character. In Republic county, near Minersville, two 9-inch veins are intercalated with shales which are argillaceous, and not bituminous in character. Above the lignite bed in Mitchell county rests a thick bed of bituminous shales which seem to pass conformably into lignite. In Coal cañon thin layers of lignite are intercalated with sandstone and shale. The lignite is mined in this locality by tunneling into the drift of the creek bed. Shafts have been sunk to a depth of 80 feet in Republic county and 50 feet in Lincoln county. Lignite is mined and used for fuel in Republic, Mitchell, Lincoln, Russell, and Ellsworth counties. The lignite contains much ash in the form of pyrite, shale, etc. The principal mines are located on Wolf creek and Coal cañon in Russell county; on Coal creek and Elkhorn in Ellsworth county; on Spillman creek, Little Timber creek, Bacon creek, Rattlesnake creek, and Elkhorn creek in Lincoln county; on Rock creek and Solomon river in Mitchell county; on West creek in Republic and Cloud counties.

"The strata adjacent the lignite vary with the locality. In some localities the lignite rests between beds of shale, in others between layers of sandstone, and still in other localities it is found resting upon sandstone and covered with shale. In many places it is entirely wanting. Its place, however, may be occupied by a thin bed of bituminous shale."

The different coal-bearing horizons will now be considered more in detail, beginning at the base of the Coal Measures and progressing upwards.

Cherokee Shales

The position, areal extent, and general characteristics of the Cherokee shales have been given in considerable detail in the first part of this volume, to which the reader is referred in this connection.

Of all coal-bearing horizons in the state the Cherokee shales are by far the most important, as they have produced more than three-fourths of all the coal that has thus far been mined in Kansas. They occupy large surface areas in both Cherokee and Crawford counties and lesser areas in Labette and Bourbon counties. In addition to this they pass westward and northward under the overlying strata to unknown distances, and throughout a considerable part of this. westward extension they are known to carry coal. It is impossible to make any definite statement regarding the amount and position of this deeply buried coal. It is mined extensively at Leavenworth, and has been reached by scores of walls drilled in prospecting for oil and gas. The coal map, Plate VIII, shows in detail the surface area covered by the Cherokee shales and how they pass westward under the overlying formations. Also the gradual decrease westward of the shading illustrates the decreasing probability of finding coal in the Cherokee shales which are there covered by succeeding strata.

It is no vain statement that from every standpoint of geology there is a possibility of finding coal in this covered area. Had not enterprising prospectors sunk the deep wells at Leavenworth we would be in ignorance. of the coal at that place. There is just as much reason a priori for looking for coal in the Cherokee shales anywhere to the east of the outcropping of the Oread limestone as there was at Leavenworth, and no one need be surprised at any time should prospecting develop such coal:

Already the well record at Cherryvale shows that the coal exists there in as great quantity as it does at Leavenworth and it need be no surprise if dozens of other localities are found where similar quantities, may be had.

With the known amount of coal in the Cherokee shales and with the probability of finding other amounts likewise, as jus.t stated, we must look upon them as being one of the greatest coal producing horizons in the Mississippi valley.

For a more detailed account of the Cherokee shales the following extracts are taken from the records of the various deep wells that have gone into or through them:

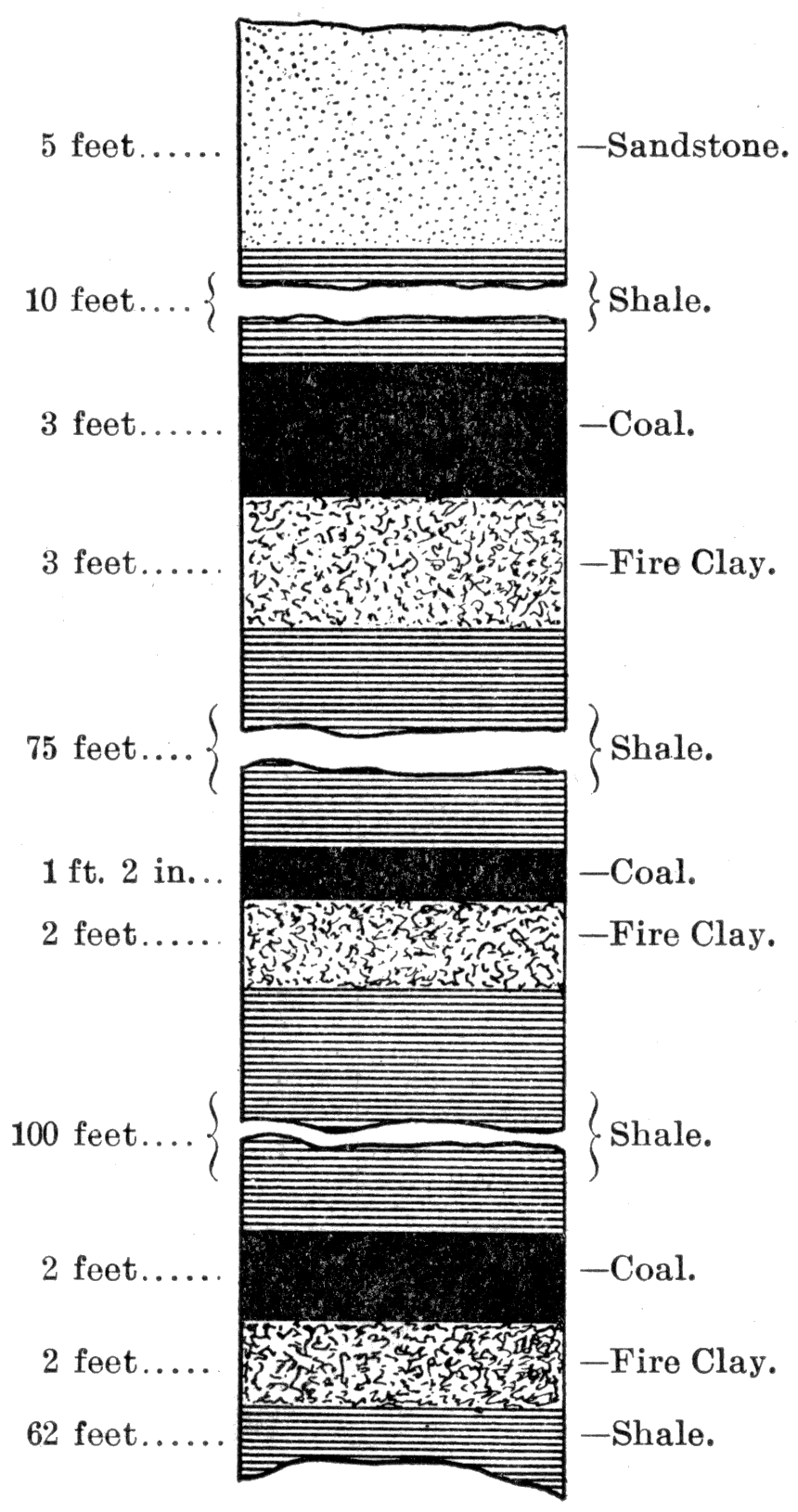

Weir City Water Well

| Reported by A. B. Cockerill, Manager Cherokee-Lanyon Spelter Company | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 15 feet | 15 feet | |

| Sandstone | 5 feet | 20 feet | |

| Shale | 10 feet | 30 feet | |

| Coal | 36 inches | 3 feet | 33 feet |

| Fire clay | 3 feet | 36 feet | |

| Shale | 75 feet | 111 feet | |

| Coal | 14 inches | 1 foot, 2 inches | 112 feet, 2 inches |

| Fire clay | 2 feet | 114 feet, 2 inches | |

| Shale | 100 feet | 214 feet, 2 inches | |

| Coal | 24 inches | 2 feet | 216 feet, 2 inches |

| Fire Clay | 2 feet | 218 feet, 2 inches | |

| Shale | 62 feet | 280 feet, 2 inches | |

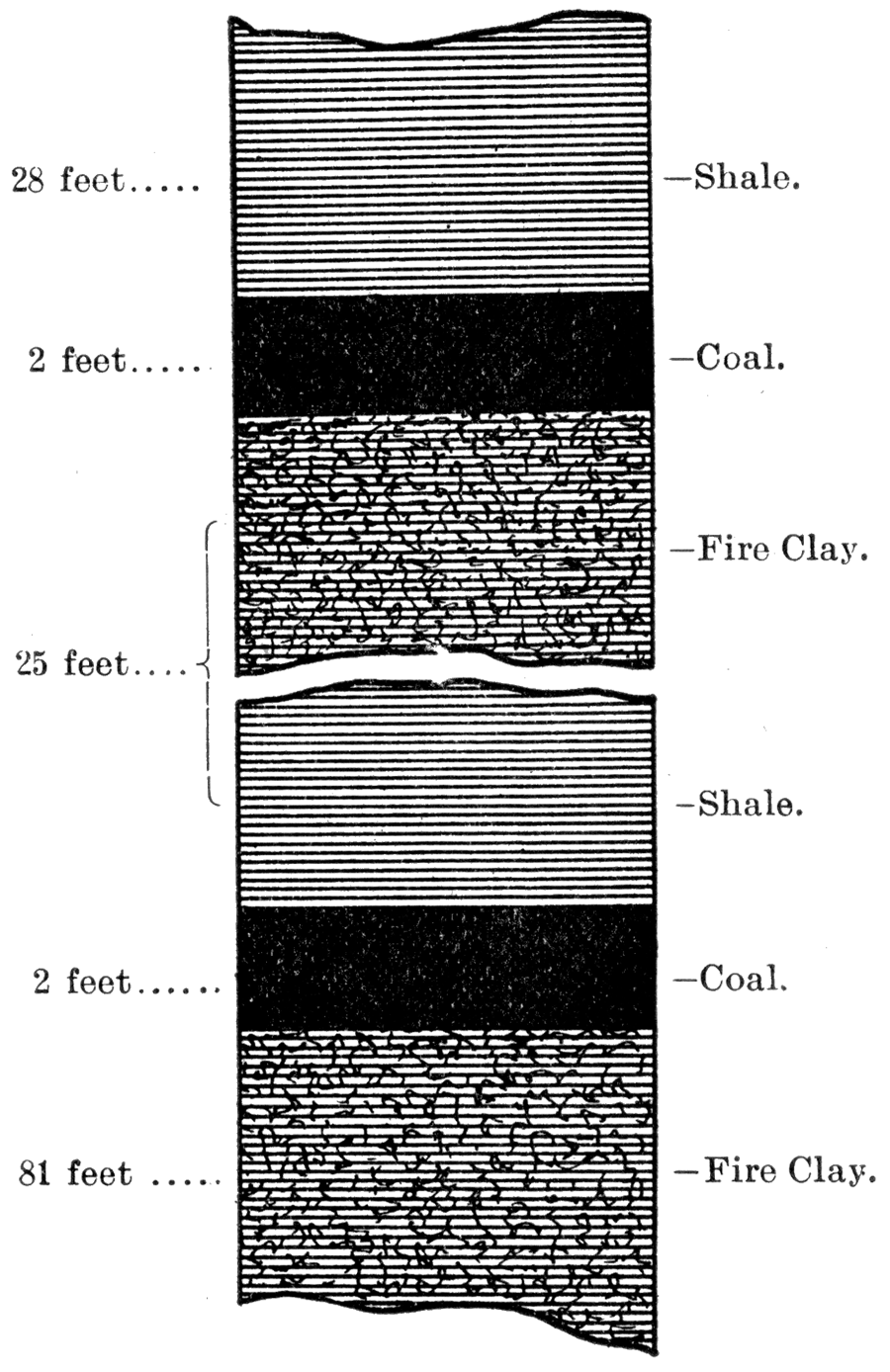

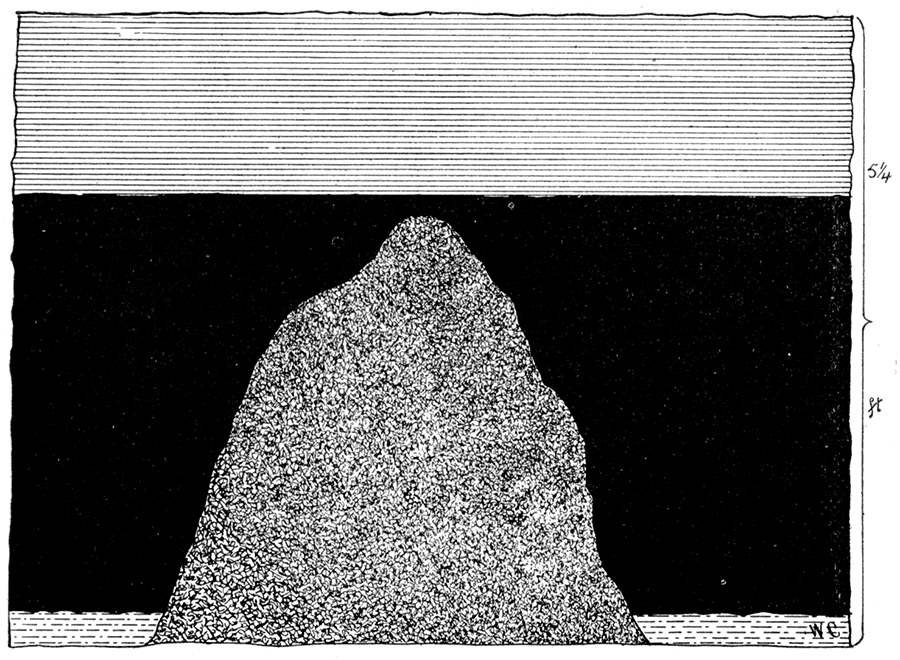

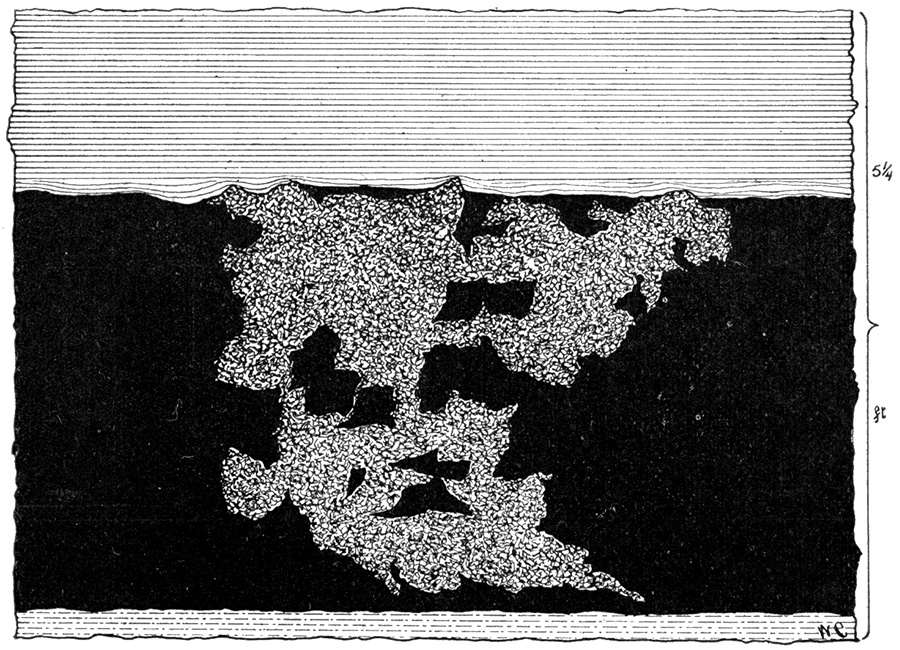

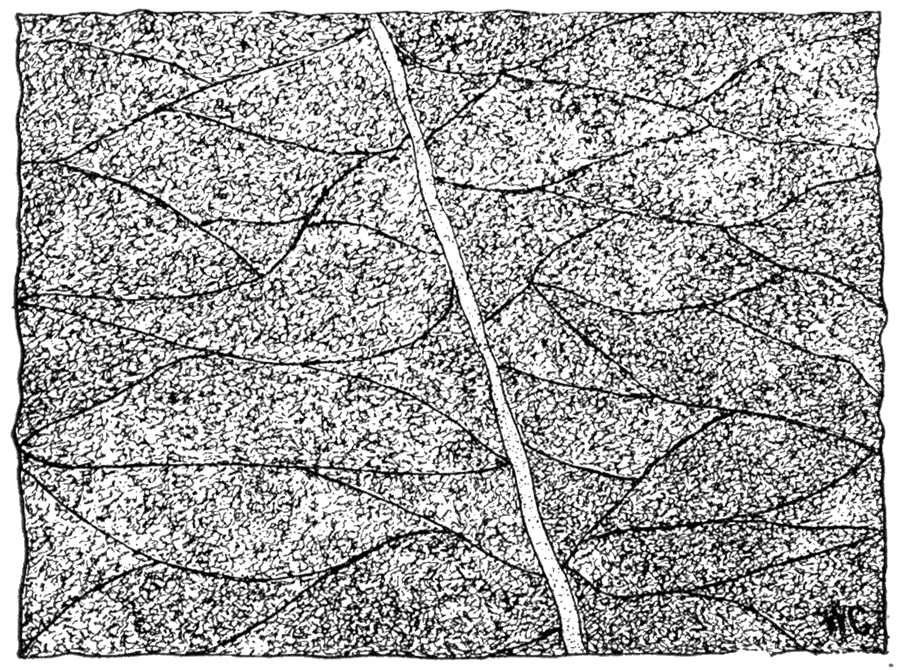

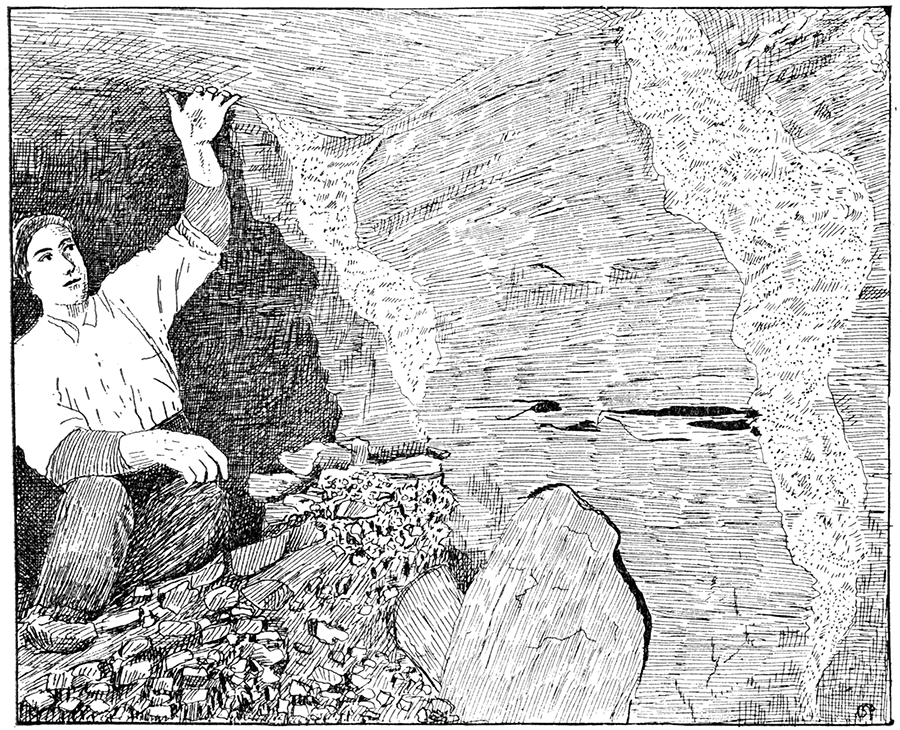

Figure 4—Section of Weir City Well.

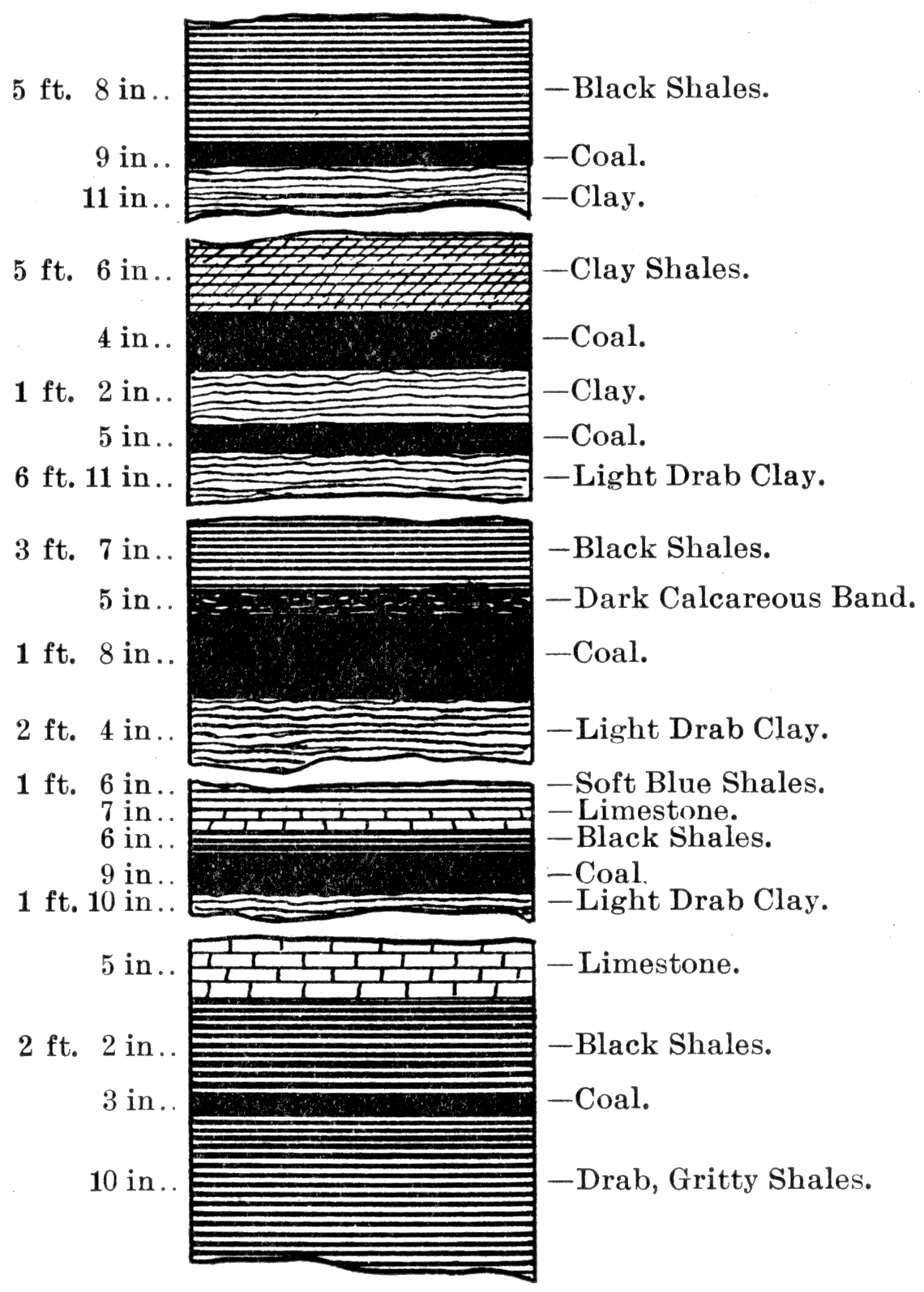

Well near Pittsburg

| Reported by Prof. O. St. John. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Yellow Clay | 5 feet | 5 feet | |

| Soft Drab Shales | 10 feet, 5 inches | 15 feet, 5 inches | |

| Dark Drab Shales | 3 feet, 7 inch | 19 feet | |

| Black Shales | 5 feet, 8 inches | 24 feet, 8 inches | |

| Coal | 9 inches | 9 inches | 25 feet, 5 inches |

| Soft, Light, Drab Clay | 11 inches | 26 feet, 4 inches | |

| Limestone | 2 feet, 4 inches | 28 feet, 8 inches | |

| Black Shales | 2 feet, 9 inches | 31 feet, 5 inches | |

| Limestone | 8 inches | 32 feet, 1 inch | |

| Black Shales | 2 feet, 8 inches | 34 feet, 9 inches | |

| Limestone | 11 inches | 35 feet, 8 inches | |

| Black Shales | 1 foot, 6 inches | 37 feet, 2 inches | |

| Drab Clay Shales | 5 feet, 6 | 42 feet, 8 inches | |

| Coal | 4 inches | 4 inches | 43 feet |

| Drab Clay | 1 foot, 2 inches | 44 feet, 2 inches | |

| Coal | 5 inches | 5 inches | 44 feet, 7 inches |

| Light Drab Clay | 6 feet, 11 inches | 51 feet, 6 inches | |

| Light Drab Gritty Shales | 9 feet, 8 inches | 61 feet, 2 inches | |

| Soft Blue Shales | 4 feet | 65 feet, 2 inches | |

| Black Shales | 3 feet, 7 inches | 68 feet, 9 inches | |

| Dark Calcareous Band | 5 inches | 69 feet, 2 inches | |

| Coal | 20 inches | 1 feet, 8 inches | 70 feet, 10 inches |

| Light Drab Clay | 2 feet, 4 inches | 73 feet, 2 inches | |

| Hard Gray Sandstone | 1 foot, 2 inches | 74 feet, 4 inches | |

| Drab, Slightly Gritty, Shales | 7 feet, 8 inches | 82 feet | |

| Drab Clay Shales | 4 feet | 86 inches | |

| Soft Blue Shales | 1 foot, 6 inches | 87 feet, 6 inches | |

| Limestone | 7 inches | 88 feet, 1 inches | |

| Black Shales | 6 inches | 88 feet, 7 inches | |

| Coal | 9 inches | 9 inches | 89 feet, 4 inches |

| Light Drab Clay | 1 foot, 10 inches | 91 feet, 2 inches | |

| Drab, Gritty Shales | 10 inches | 92 feet | |

| Compact, Gray, Sandy Shales | 7 feet, 10 inches | 99 feet, 10 inches | |

| Dark Clay Shales | 2 feet, 6 inches | 102 feet, 4 inches | |

| Gray, Coarse, Gritty Shales | 6 feet, 6 inches | 108 feet, 10 inches | |

| Dark, Drab, Slightly Gritty Shales | 2 feet, 6 inches | 111 feet, 4 inches | |

| Compact, Drab, Gritty Shales | 1 foot, 6 inches | 112 feet, 10 inches | |

| Soft, Dark, Drab, Shales | 1 foot, 3 inches | 114 feet, 1 inches | |

| Dark Blue Shales | 2 feet, 4 inches | 116 feet, 5 inches | |

| Limestone | 5 inches | 116 feet, 10 inches | |

| Black Shales | 2 feet, 2 inches | 119 feet | |

| Coal | 3 inches | 3 inches | 119 feet, 3 inches |

| Drab, Gritty Shales | 10 inches | 120 feet, 1 inches | |

| Drab, Fine Gritty Shales | 6 feet | 126 feet, 1 inches | |

| Hard Gray Sandstone | 1 foot, 4 inches | 127 feet, 5 inches | |

| Gray, Sandy Shales | 9 feet | 136 feet, 5 inches | |

| Drab, Coarse, Gritty Shales | 2 feet, 10 inches | 139 feet, 3 inches | |

| Gray, Sandy Shales, Coal Streaks | 5 feet, 10 inches | 145 feet, 1 inches | |

| Gray, Coarse Gritty Shales | 1 foot, 1 inch | 146 feet, 2 inches | |

| Soft Drab Shales | 3 inches | 146 feet, 5 inches | |

| Coal | 39 inches | 3 feet, 3 inches | 149 feet, 8 inches |

| Gray, Gritty Clay | 3 inches | 149 feet, 11 inches | |

| Soft, Dark Drab, Clay | 1 foot, 1 inches, 151 feet | ||

| Dark Blue Clay with Coal Streaks | 8 inches | 151 feet, 8 inches | |

| Light Drab Clay | 4 inches | 152 feet | |

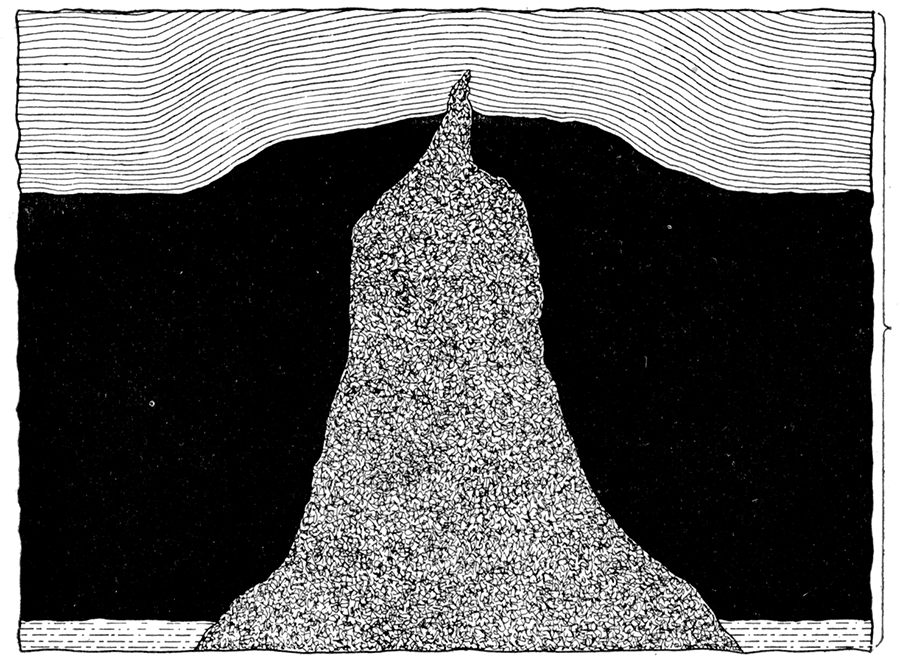

Figure 5—Section of Well near Pittsburg.

McKee's Gas Well. North of Girard.

| Material Beginning 148 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

|---|---|---|---|

| Black Shale | 5 feet | 153 feet | |

| Brown Limestone | 2 feet | 155 feet | |

| Oil Sand | 5 feet | 160 feet | |

| Sand shale | 55 feet | 215 feet | |

| White Shale | 33 feet | 248 feet | |

| Brown Shale | 10 feet | 258 feet | |

| Brown Limestone | 4 feet | 262 feet | |

| Shale | 2 feet | 264 feet | |

| Limestone | 3 feet | 267 feet | |

| Shale | 2 feet | 269 feet | |

| Limestone | 3 feet | 272 feet | |

| Shale | 52 feet | 325 feet | |

| Sandstone | 7 feet | 332 feet | |

| Shale | 26 feet | 358 feet | |

| Black Shale | 2 feet | 360 feet | |

| Lime Shale | 3 feet | 363 feet | |

| White Shale | 17 feet | 380 feet | |

| Brown Shale | 30 feet | 410 feet | |

| Alternate Light and Dark Shale | 79 feet | 489 feet | |

| Sand and Little Gas | 3 feet | 492 feet | |

| Shale | 4 feet | 496 feet | |

| Alternate Sandstone and Shale | 13 feet | 509 feet | |

| Sandstone | 6 feet | 515 feet | |

| Black Shale, Little Coal | 3 feet | 518 feet | |

| Dark Shale | 32 feet | 550 feet | |

| Total | 402 feet |

La Harpe Well.

| Reported by L. C. Beattie, Manager Palmer Oil Company | |||

|---|---|---|---|

| Material Beginning at 637 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Gray Shale | 5 feet | 642 feet | |

| Gray Sandstone | 8 feet | 650 feet | |

| Gray Shale | 8 feet | 658 feet | |

| Dark Shale | 6 feet | 664 feet | |

| Red Flint and Limestone | 3 feet | 667 feet | |

| Black Shelly Sandstone | 10 feet | 677 feet | |

| Dark Shale | 26 feet | 703 feet | |

| Changeable Shale; Light, Dark, Green, Black | 192 feet | 895 feet | |

| Sand Shale, with some Clear Sand | 12 feet | 907 feet | |

| Black Shale | 6 feet | 913 feet | |

| Dark Sand Shale | 8 feet | 921 feet | |

| Black Shale | 61 feet | 982 feet | |

| Total | 345 feet | ||

Girard Well. No. 1.

| Material Beginning at 54 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

|---|---|---|---|

| Soapstone Shale | 104 feet | 158 feet | |

| Limestone | 11 feet | 169 feet | |

| Black Slate Shale | 4 feet | 173 feet | |

| Soapstone Shale | 130 feet | 303 feet | |

| Sand Shale | 97 feet | 400 feet | |

| Soapstone Shale | 75 feet | 475 feet | |

| Coarse Sandstone | 25 feet | 500 feet | |

| Total | 446 feet |

Humboldt Well. No. 1.

| Reported by Guffey & Galey. Location: Section 8, township 26 south, range 18 east. | |||

|---|---|---|---|

| Material Beginning at 635 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Shale—Water bearing | 10 feet | 645 feet | |

| White Shale | 30 feet | 675 feet | |

| Black Shale | 70 feet | 745 feet | |

| White Shale | 15 feet | 760 feet | |

| Black Shale | 36 feet | 796 feet | |

| Sandstone | 2 feet | 798 feet | |

| Black Shale | 96 feet | 894 feet | |

| Sandstone | 5 feet | 899 feet | |

| Shale | 46 feet | 945 feet | |

| Sandstone—Salt Water bearing | 25 feet | 970 feet | |

| Total | 335 feet | ||

Humboldt Well. No. 5.

| Location: Northeast quarter of northwest quarter, section 29, township 25 south, range 18 east. | |||

|---|---|---|---|

| Material Beginning at 650 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Shale | 15 feet | 665 feet | |

| Shale | 147 feet | 812 feet | |

| Sandstone | 4 feet | 816 feet | |

| Shale | 62 feet | 878 feet | |

| Sandstone | 47 feet | 925 feet | |

| Break, White Sandstone and Shale | 17 feet | 937 feet | |

| Total | 287 feet | ||

Toronto Well.

| Reported by Mr. Troxel | |||

|---|---|---|---|

| Material Beginning at 1,080 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Dark Shale | 24 feet | 1,104 feet | |

| Oil Sand | 25 feet | 1,129 feet | |

| Shale | 11 feet | 1,140 feet | |

| Shale | 110 feet | 1,250 feet | |

| Soft Sandstone | 4 feet | 1,254 feet | |

| Shale | 86 feet | 1,340 feet | |

| Soft Sandstone | 7 feet | 1,347 feet | |

| Shale | 83 feet | 1,430 feet | |

| Soft Sandstone | 8 feet | 1,438 feet | |

| Shale | 14 feet | 1,452 feet | |

| Total | 372 feet | ||

Pleasanton Well.

| Location: Section 25, township 21 south, range 24 east | ||||

|---|---|---|---|---|

| Material Beginning at 214 feet |

Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

|

| Shale | 74 feet | 288 feet | ||

| Shale and Sandstone | 20 feet | 302 feet | ||

| Sandstone | 8 | 316 feet | ||

| Black Shale | 22 feet | 338 feet | ||

| Shale-Water Bearing | 10 feet | 348 feet | ||

| Brown Sandstone | 5 feet | 353 feet | ||

| White Shale | 5 feet | 358 feet | ||

| Black Shale | 40 feet | 398 feet | ||

| Black Sandstone | 26 feet | 424 feet | ||

| White Sandstone | 20 feet | 444 feet | ||

| White Shale | 95 feet | 539 feet | ||

| Black Shale | 117 feet | 656 feet | ||

| Sandstone and Limestone (?) | 30 feet | 686 feet | ||

| Sandstone | 6 feet | 692 feet | ||

| Shale and Sandstone | 65 feet | 757 feet | ||

| Total | 543 feet | |||

Coal Beds in the Cherokee Shales

The Cherokee shales have coal at different positions within them. These positions vary both vertically and horizontally. In some localities coal exists near the base. In the southeastern part of Cherokee county coal has been found only a few feet. above the base of the shales. This coal, however, is thin and of little commercial importance. A few farmers mined it years ago to supply their own fires, but beyond this it has never been developed. In the latter sixties coal was mined by stripping in different places on the west side of Brush creek in Cherokee county. Here the coal was heavier than that just mentioned, but was still too light to support mines for commercial purposes. In the early days of the settlement of the country coal was teamed from these mines to the neighboring villages and to a limited extent into Missouri. But of recent years the mines have been entirely abandoned.

Next above this coal is a horizon which still furnishes a considerable quantity of coal for the general markets, particularly when a combination of events favors a slight advance in prices. It lies about 150 feet above the base of the shales. It is capped by a thin layer of shale which in turn rests immediately under a heavy sandstone—the Columbus sandstone—which covers so large an area to the east and southeast of Columbus. Here over an area of many square miles the coal is found outcropping along the bluffs of Brush creek and Shawnee creek and other lesser tributaries, reaching all the way from within a mile of Columbus eastward to the escarpments facing Crestline and the valley to the south. This coal horizon seems not to extend very far west of Columbus, at least its absence is known in many places where wells have penetrated the shales It sufficient depth to have reached it.

The Weir-Pittsburg Beds

Above the Columbus coal lie the Weir-Pittsburg Lower and Upper coals which are the heaviest known in the state, the Lower averaging about 40 inches and the Upper about 30 inches in thickness. The outcroppings of these coal beds form an irregular line extending northeast and southwest by way of Stippville, Scammon, Weir City, Pittsburg, and other points to the northeast.

Development of the Weir-Pittsburg Coals—In 1868, after the sale to the James F. Joy Company of the "Cherokee neutral lands," as they were then called—an area twenty-five by fifty miles in the southeastern part of the state including all of Cherokee and Crawford counties and the south part of Bourbon county—Professor Wilbur of Chicago was sent out by a Chicago company to examine the lands for coal. He reported that coal existed in large quantities along a narrow strip of country from Pittsburg to Weir and farther to the southwest. In some places he found the coal to be about four feet thick, but elsewhere much thinner.

Previous to this time the early settlers had mined coal from the Weir-Pittsburg Lower and Upper beds at a half dozen or more localities. It seems that before the civil war, back in the 'fifties, coal was mined to a limited extent from the Weir-Pittsburg Lower bed by citizens of Missouri who teamed it to Granby and other places where it was used for blacksmithing. During the autumn of 1866 a blacksmith from Granby came over and obtained the assistance of Mr. W. H. Peters, a citizen of the southeast part of Cherokee county and at present a member of the board of county commissioners. The blacksmith led the way to an outcropping of the Weir-Pittsburg Lower at a point near the present eastern suburbs of Weir City. Here with almost no labor at all they stripped a little soil from the upper surface of the coal and loaded their wagons rapidly by the use of pick and shovel. Later in the same autumn Mr. Peters with other neighbors revisited the locality and obtained coal in a similar manner. At that date the wide prairie land between Spring river and Neosho river was not occupied by settlers, so that coal was obtained nearly ten miles from the nearest residence. As the settlements pushed farther west during the summer of 1867 and '68 the coal mining likewise was increased, so that by the time Professor Wilbur visited the area he had the assistance of the partially developed mines to direct his investigations.

Shortly after the Missouri River, Fort Scott & Gulf railroad, now the Kansas City, Fort Scott & Memphis, completed its line to Baxter Springs in 1870, a coal company was formed in Fort Scott for the purpose of mining coal which was sold principally to the railroad company. Mining operations were conducted in the vicinity of Fort Scott and on the Drywood to the south, as elsewhere explained, and also by the same company along the outcroppings of the Weir-Pittsburg Lower in the vicinity of Stilson, now Scammon, from which point coal was teamed to the different railroad stations to supply the demands of the road and for shipment into the general market. The Fort Scott company operated for about two years when it quit the business. During this time a large number of individuals began mining operations at various places by the strip pit process so that in the aggregate a considerable quantity of coal was shipped into the market.

In 1874 Scammon Brothers sank a shaft just north of the old town of Stilson, now Scammon, from which shaft large quantities of coal were obtained. There was considerable opposition to this enterprise by their friends who doubted the expediency of such a method of mining, fearing that the nearness to the surface would cause the roof to break and crumble to such an extent that mining by the room and pillar system could not be employed. But the firm of Scammon Brothers persevered and from the start succeeded admirably, both mechanically arid financially. From a shaft which began with two or three car loads a day they soon had it developed to a capacity of forty cars a day. Upon the success of this new method of mining others imitated them and shafts were sunk in many localities until the development of today was reached.

In 1871 the firm of Keith & Rawlings, of Kansas City, began dealing in coal and conducted- their operations so that they were of great assistance in the development of mining property. After the death of Mr. Rawlings Mr. Keith was associated with a second partner by the name of Borard. In 1872 they began mining by the strip pit process and shipping coal to Kansas City and other markets, as well as supplying the railroad with large quantities of it. Later Mr. Keith was associated with a Mr. Henry, and in 1880 the firm of Keith & Perry was formed, a company which perhaps has exerted as wide an influence on coal mining in Kansas as any other company, largely because they were pioneers in the business.

In 1878 and 1879 Moffet and Sargent, of Joplin, Missouri, built the Joplin & Girard railroad from Joplin to Pittsburg, primarily for the purpose of obtaining coal from the Kansas fields. The city of Pittsburg originated with the road and was purely a coal mining town until the zinc smelters were established there later. It was in 1878 also that the Kansas and Texas Coal Company began their operations in a small way at Weir. Here from a beginning of operating coal mines by the strip pit method on a small scale this company has grown into one of the strongest in the territory. The Santa Fe Company, now changed to the Mount Carmel Coal Mining Company, did not obtain a foothold in these coal fields until March, 1886, and the Missouri, Kansas & Texas Railway Company did not get its mines started at Mineral City until 1895.

In 1897 Cherokee and Crawford counties produced 2,652,029 tons of coal, giving employment to 5540 men part of the year. These figures include the production from the Arcadia area as well as that from the Weir-Pittsburg beds.

The first mining that was done on this Weir-Pittsburg horizon in the early 'seventies was confined to the strip pit processes and therefore the principal mining towns were located along the irregular line of outcropping previously mentioned. As the coal dips to the northwest at a low angle it may be reached by shafting to various depths, dependent upon the distance back from the line of outcropping, and upon the general contour of the surface.

Mining developments have now been carried hr enough to determine the extent of this heavy coal with a tolerable degree of accuracy. It is found that it is limited in extent to the southwest so that it reaches a point opposite Columbus, while to the northwest in transverse direction it does not reach as far as Girard. It therefore is a long elliptical area with the major axis trending northeast and southwest. From the central area the coals gradually grow thinner in every direction.

The extreme southwestern limit, however, is not yet known. Only a few years ago it was thought that the ridge along the line of the Missouri Pacific railroad between Cherokee and Sherwin Junction limited the western extent of these coals. At present, however, it is known that there is a large quantity of coal in the vicinity of Mineral where the M. K. & T. Railroad Company has its mines. Beyond Mineral to the west, northwest, and southwest the limitations are not yet fully determined.

Further to the southwest in the vicinity of Oswego there is a varying amount of coal at about the same horizon as the Weir-Pittsburg coal, although a definite connection between the two areas has not been made. The Oswego coal is by no means so heavy, the thickest bed being from 18 to 24 inches.

Coal above the Weir-Pittsburg

Above the two Weir-Pittsburg horizons are other lesser beds of coal, the outcropping lines of which are farther to the northwest. At some places it would seem there is but one of these, while in others there appear to be two. They are found in northwestern Cherokee county on the east side of Lightning creek, and to a less extent in southwestern Crawford county, and also farther to the northeast towards the state line.

Still higher, at the very summit of the Cherokee shales, is another coal bed which has produced large quantities of coal for the market and has therefore performed all important part in the history of coal mining in the state. This is generally known as the Fort Scott coal. It lies from 6 to 10 feet below the lower member of the Oswego limestone system. In the vicinity of Fort Scott these limestones are cut through by the Marmaton river and by all of its many tributaries. South from Fort Scott the upper tributaries of the Drywood likewise cut through the Oswego limestones in many places. Throughout all of this area, making many miles In linear extent, the Fort Scott coal outcrops along the banks and, bluffs of these various streams and drainage channels. It has been extensively mined, but always by the strip pit process. As the overlying limestone is heavy and difficult to remove the stripping never has been carried back very far from the front surface—the coal thus obtained therefore always has been exposed to the weathering agents and the pyrite it contains has been oxidized into iron rust, giving a reddish color to the coal. In this way the coal from this whole area has been known in the markets as the Fort Scott "red" coal.

The Leavenworth coal is found in the Cherokee shales. It seems that here three horizons exist, the lower one at a depth of 988 feet below the surface, the middle one at 748 feet, and the upper one 720 feet. Each of these three is reported to be a 24 inch bed of coal. It is the upper one that is mined at the present time. If the published drill records can be relied upon either of the other beds would be almost as profitable as the one now mined. Any attempt at correlations between the Leavenworth coals and the coals of Cherokee and Crawford counties would be largely conjectural further than to show that they all belong to the Cherokee shales. The lowermost coal, the one at 88 feet below the surface, is 157 feet above the base of the Cherokee shales, which would place it at about the same position as the Columbus coals already described. The middle horizon is 398 feet above the base of the shales, and the upper one, the one now mined, 425 feet above the base of the shales. It manifestly would be improper to look upon these as an extension of the southern coal beds, but rather it should be considered that during the formation of the Cherokee shales physical conditions were favorable for the production of coal here and there at irregular intervals throughout a wide area and that the southern coals were formed in one basin and the Leavenworth coals in another, with an indefinite number of intermediate areas probably existing.

Weir-Pittsburg Area

Returning now to Cherokee and Crawford counties it may be well to examine the mining territory in more detail.

The two strata of coal known as the Weir-Pittsburg Upper and Lower furnish the greater part of the workable coal of the state. A third stratum makes its appearance between the Upper and Lower and will be called the Intermediate.

The Lower stratum is the thickest and is the one most worked. It is worked at a depth of about 90 feet in the northern part of the county. In the western part the same stratum is worked at a depth of 230 feet, in the central portion it is reached at a depth of 70 to 80 feet, while in the south-central part the same coal is met with at 25 feet from the surface.

The Upper stratum of the Weir-Pittsburg coal is reached at a depth of 96 feet in the western part of the county; in the northern part it is worked at about 50 or 60 feet on the average; in the west-central part it is passed through at a depth of 15 or 20 feet; and in the southern part no trace of the stratum is to be found. The line of outcropping of this stratum lies west of Weir City, passing to the south and west, while on the north it follows quite closely a line parallel to the outcropping of the Lower, maintaining an average vertical distance of 30. feet above it. The line of outcropping of these two strata of coal cannot be traced continuously throughout the county, due to the fact that the covering is shale, which weathers into soil so readily that the coal strata in most cases are covered up. To reach the Weir-Pittsburg coal in the northern part of the county a vertical distance of at least 270 feet would have to be passed through.

Mineral City and Vicinity

The lowest coal stratum is reached at a depth of 229t feet at the southeast corner of the northwest quarter of the south. west quarter of section 9, township 31, range 23, about five miles north of Mineral City. It is 32 inches in thickness, good coal, roofed by 19 1/2 feet of black, bituminous shale, and underlaid by 14 inches of fire clay. A drill hole here shows the following association of strata:

| A—Record of Drill Hole Five Miles North of Mineral City. | ||||

|---|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

|

| Soil and Clay | 12 feet | 12 feet | ||

| Clay and Gravel | 27 feet, 4 inches | 39 feet, 4 inches | ||

| Gray Shale | 5 feet, 4 inches | 44 feet, 8 inches | ||

| Coal | 16 inches | 1 foot, 4 inches | 46 feet | |

| Fire Clay | 2 feet | 48 feet | ||

| Gray Shale | 5 feet | 53 feet | ||

| Black Shale | 14 feet, 6 inches | 67 feet, 6 inches | ||

| Coal | 34 inches | 2 feet, 10 inches | 70 feet, 4 inches | |

| Fire Clay | 2 feet, 2 inches | 72 feet, 6 inches | ||

| Drab Shale | 9 feet, 1 inch | 81 feet, 7 inches | ||

| Coal | 15 inches | 1 foot, 3 inches | 82 feet, 10 inches | |

| Fire Clay | 4 feet, 2 inches | 87 feet | ||

| Sandstone | 4 feet | 91 feet | ||

| Gray Shale | 5 feet, 7 inches | 96 feet, 7 inches | ||

| Coal | 25 inches | 2 feet, 1, inch | 98 feet, 8 inches | |

| Fire Clay, soft | 2 feet, 8 inches | 101 feet, 4 inches | ||

| Drab Shale | 16 feet, 8 inches | 118 feet | ||

| Coal | 9 inches | 9 inches | 118 feet, 9 inches | |

| (?) | 2 feet, 9 inches | 121 feet, 6 inches | ||

| Gray Shale | 33 feet, 6 inches | 155 feet | ||

| Black Jack | 4 feet, 6 inches | 159 feet, 6 inches | ||

| Coal | 11 inches | 11 inches | 160 feet, 5 inches | |

| Gray Shale | 17 feet, 7 inches | 178 feet | ||

| Coal | 41 inches | 3 feet, 5 inches | 181 feet, 5 inches | |

| Black Shale | 1 foot, 5 inches | 182 feet, 10 inches | ||

| Coal | 4 inches | 4 inches | 183 feet, 2 inches | |

| Fire Clay | 1 foot, 7 inches | 184 feet, 9 inches | ||

| Gray Shale | 8 feet, 3 inches | 193 feet | ||

| Black Shale | 8 feet, 2 inches | 201 | feet, 2 inches | |

| Coal | 12 inches | 1 foot | 202 feet, 2 inches | |

| Gray Shale | 7 feet, 10 inches | 210 feet | ||

| Black Shale | 19 feet, 6 inches | 229 feet, 6 inches | ||

| Coal | 32 inches | 2 feet, 8 inches | 232 feet, 2 inches | |

| Fire Clay | ||||

The same stratum was passed through by a drill 400 feet south and 528 feet west Of the northeast corner of the northwest quarter of the northeast quarter of section 24, township 31, range 23. The following is a record of the prospect hole:

| B—Record of a Prospect Hole near Mineral City. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Clay and Shale | 7 feet, 7 inches | 7 feet, 7 inches | |

| Coal | 11 inches | 11 inches | 8 feet, 6 inches |

| Gray Shale | 10 inches | 9 feet, 4 inches | |

| Sandstone | 6 feet, 3, inches | 15 feet, 7 inches | |

| Black Shale | 14 feet, 7 inches | 30 feet, 2 inches | |

| Coal | 24 inches | 2 feet | 32 feet, 2 inches |

| Fire Clay, soft | 5 feet, 5 inches | 37 feet, 7 inches | |

| Drab Shale | 6 feet, 5 inches | 44 feet | |

| Gray Shale | 6 feet, 10 inches | 50 feet, 10 inches | |

| Drab Shale | 10 feet | 60 feet, 10 inches | |

| Coal | 8 inches | 8 inches | 61 feet, 6 inches |

| Fire Clay | 2 feet, 6 inches | 64 feet | |

| Gray Shale | 4 feet, 10 inches | 68 feet, 10 inches | |

| Sandstone | 4 feet, 6 inches | 73 feet, 4 inches | |

| Gray Shale | 5 feet, 2 inches | 78 feet, 6 inches | |

| Drab Shale | 21 feet, 4 inches | 99 feet, 10 inches | |

| Gray Shale, hard | 22 feet, 4 inches | 122 feet, 2 inches | |

| Coal | 47 inches | 3 feet, 11 inches | 126 feet, 1 inch |

| Black Bituminous Clay | 2 inches | 126 feet, 3 inch | |

By comparing these records we see that the black shale roof of the first has changed to a gray shale in the second, which makes a somewhat better roof than the bituminous shale; the fire clay floor of the former has also been replaced by bituminous clay. The coal found in these borings is of fairly good quality and of uniform thickness, but has considerable "black jack" (bituminous shale) and sulphur in the form of pyrite. "Horsebacks" are quite numerous here, but are found most abundant at Mineral City, at which place much of the coal is rendered worthless by the frequent crossing and recrossing of "horsebacks" and, in many instances, the complete cutting out of the coal by them. Ten strata of coal were passed through in the 232 feet drilled, as seen in the record. These vary in thickness from 4 to 41 inches. In the thinner strata the coal merges into bituminous shale. The exceedingly large number of coal strata with accompanying shale shows how very carbonaceous the shales are in this locality. The sandstone and arenaceous shales met with are very characteristic of the Cherokee shales as found further east.

The Upper and Lower strata are represented in A at 96 feet 7 inches and 229 feet 6 inches, respectively, and in B only the Upper was reached, which was found at 122 feet 2 inches. In consequence of the westward dip the Lower stratum lies much deeper at this point. Deeper drilling here—regarding the dip of the strata as uniform—would result in finding the Lower at a depth of 250 odd feet. From both A and B we see a third coal stratum making its appearance at 67 feet 6 inches and 30 feet 2 inches, respectively, from the surface, or at an average of 60 feet above the Upper. One 40-inch stratum appears between the Upper and Lower.

Vicinity of McCune

Passing a short distance northwest to McCune, we find a shaft which was sunk here ten or twelve years ago, but which has not been in operation for several years. No detailed record of the shaft is obtainable, but the following general record shows the position of the coal passed through:

| C—Record of Coal Strata in a Shaft at McCune. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Coal | 18 inches | 85 feet | |

| Coal | 24 inches | 125 feet | |

| Coal | 12 inches | 155 feet | |

| Coal | 12 inches | 185 feet | |

| Coal | 12 inches | 215 feet | |

| Coal | 6 inches | 333 feet | |

| Coal | 14 inches | 400 feet | |

| Coal | 10 inches | ||

According to this record we find eight distinct coal strata in the 400 feet passed through, only one of which strata is of sufficient thickness to warrant mining.

The Upper stratum, as it dips 12 feet to the mile, would be in the neighborhood of 200 feet from the surface at this point. The 24 inch stratum of this record, placed at 125 feet, might possibly be the Upper. The Lower, dipping westward 20 feet to the mile, ought to be found at this point about 350 to 400 feet below the surface. The 14 inch stratum of the above record, at 400 feet, comes the nearest to correlating with the Lower. The extreme thinness might be accounted for by local alteration in the stratum.

Passing east to Cherokee we find a shaft 150 feet deep. The Upper and Lower are quite prominent here. The Upper is reached at 40 feet, showing a 20 to 24 inch stratum; at 150 feet the Lower stratum was reached. The Lower stratum is said to be 36 inches in thickness, but varies from 30 to 48 inches. The coal is of excellent quality with very little or no bituminous shale ("black jack") either above or below. "Horsebacks" are present but not rrumerous. The amount of "sulphur" found in the coal is probably considerably below the average of the coal of the Cherokee shales. A few fossil invertebrates and plants are found. The dip is to the northwest.

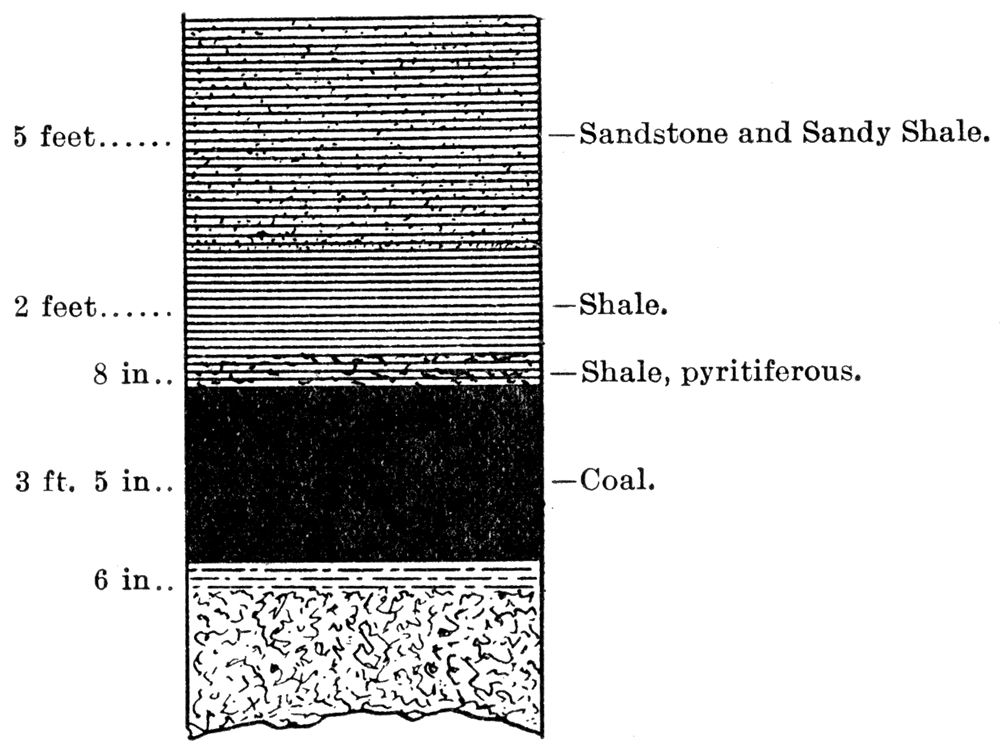

Stippville

About five miles north of Columbus, at Stippville, the first shaft is met with in passing northward into the coal mining regions. Here the coal is 4 feet thick and lies 20 feet below the surface. It is the Weir-Pittsburg Lower and is of extra good quality. The mine was closed when last visited during the summer of 1897. Two or three miles north of Stippville, on the Perry farm, which is two and one-half miles south of Scammon, on the northwest forty of the quarter section, a pros. pect drill hole has been sunk, the record of which is as follows:

| D—Record of a Drill Hole near Stippville. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 8 feet | 8 feet | |

| Shale | 1 foot, 6 inches | 9 feet, 6 inches | |

| Coal Blossom | 6 inches | 6 inches | 10 feet |

| Fire Clay | 2 feet | 12 feet | |

| Sandy Fire Clay | 6 feet | 18 feet | |

| Shale | 2 feet, 6 inches | 20 feet, 6 inches | |

| Sandstone | 5 feet, 3 inches | 25 feet, 9 inches | |

| Ironstone | 2 inches | 25 feet, 11 inches | |

| Sandstone | 1 feet, 1 inches | 27 feet | |

| Sandy Shale | 4 feet | 32 feet | |

| Blue Shale, soft | 1 foot | 33 feet | |

| Shale, pyritiferous | 8 inches | 34 feet, 8 inches | |

| Coal | 41 inches | 3 feet, 5 inches | 38 feet, 1 inch |

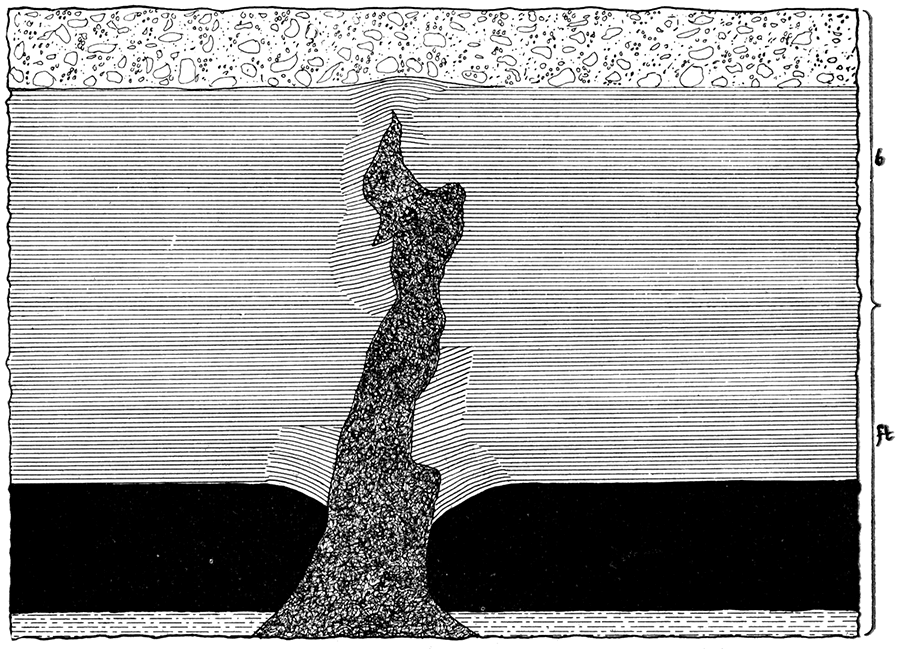

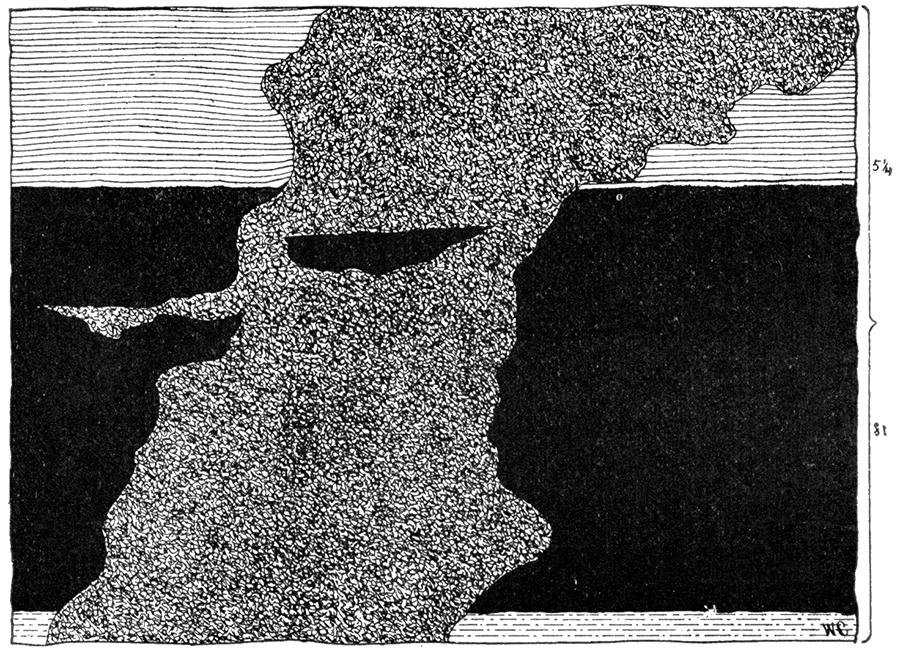

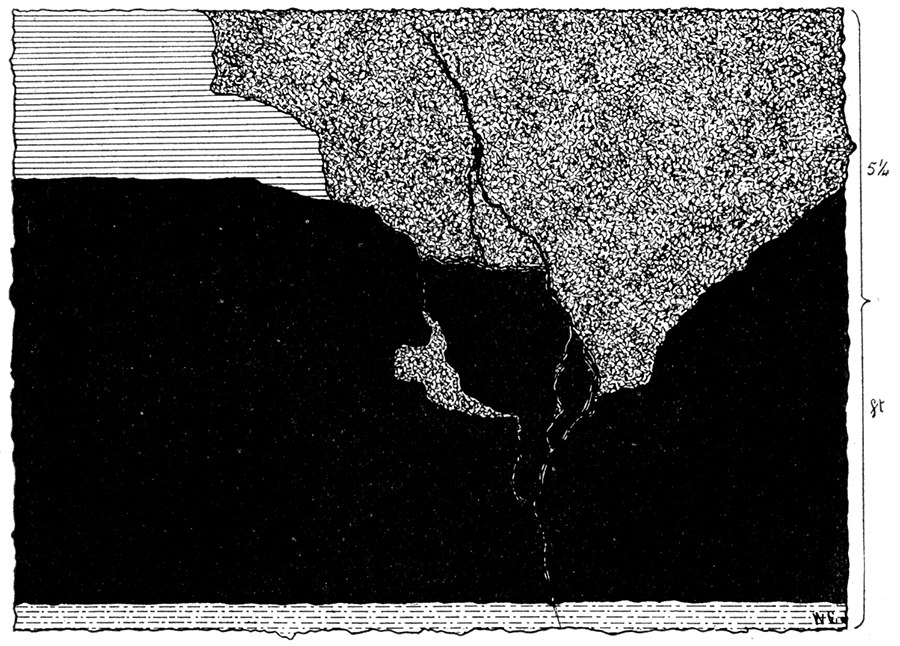

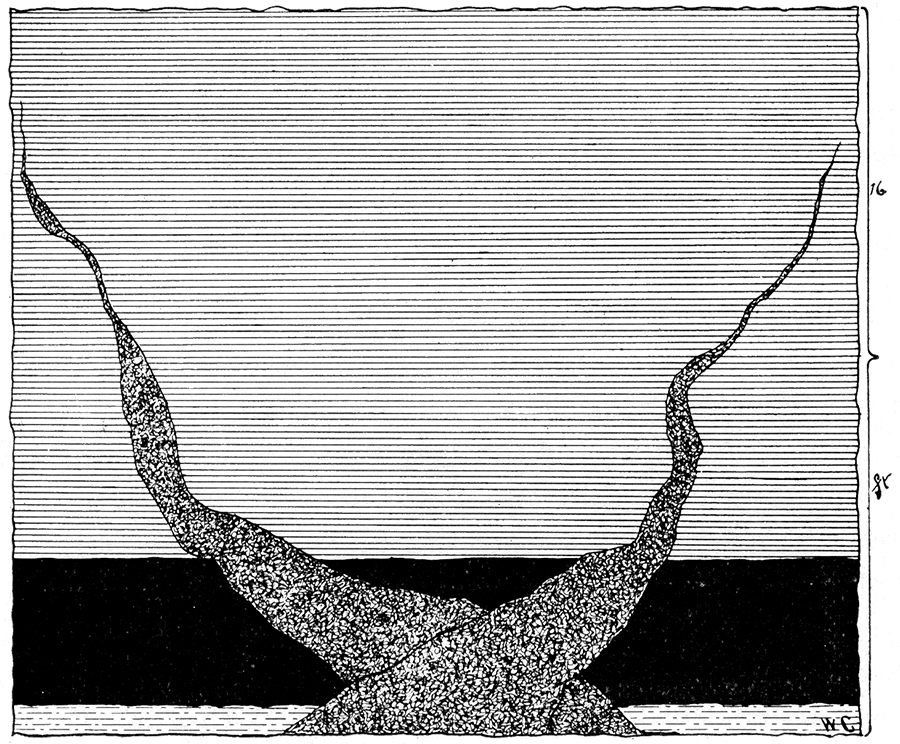

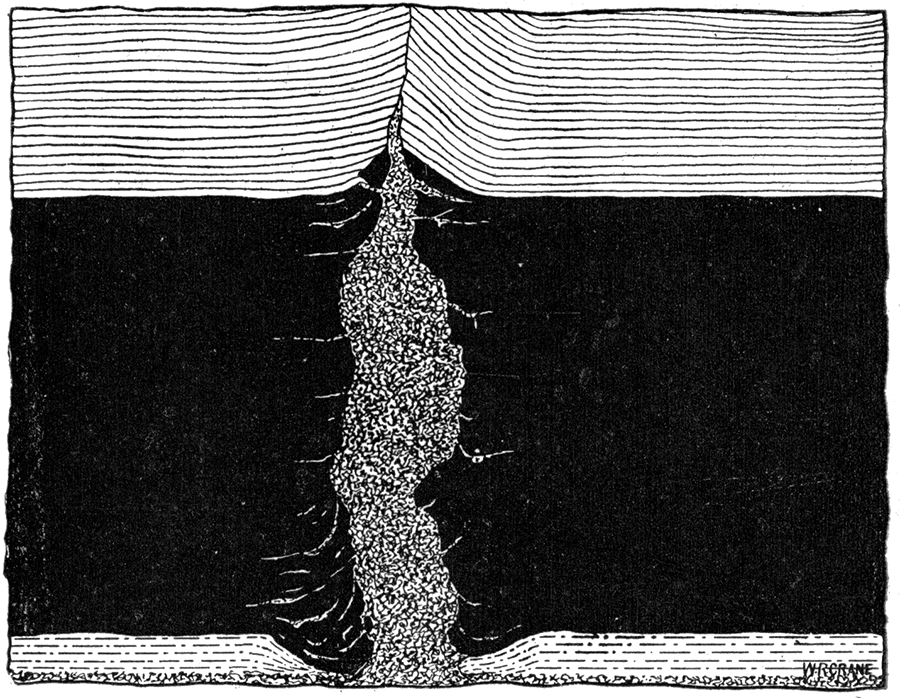

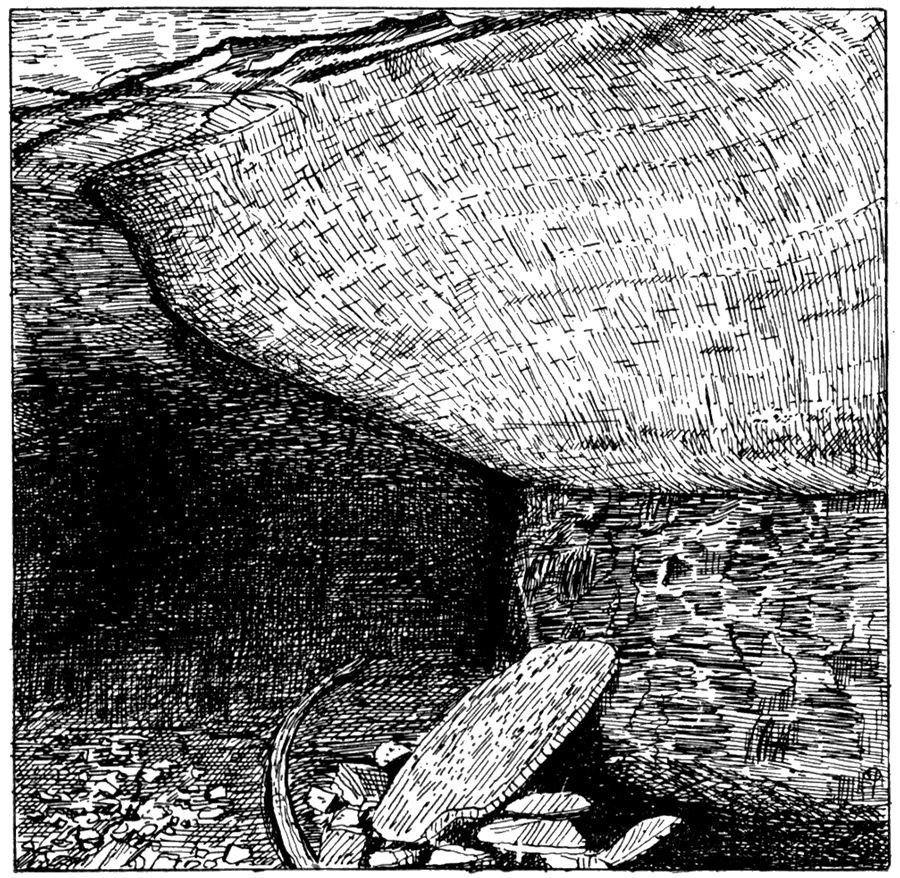

Figure 6—Section of Well South of Scammon, on Perry Farm.

On the same farm, in the center of the south half, is another prospecting drill hole, which gives the following section:

| E—Record of a Drill Hole near Stippville. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 9 feet | 9 feet | |

| Sandstone | 6 feet | 15 feet | |

| Streaks of Sand and Shale | 7 feet, 6 inches | 22 feet, 6 inches | |

| Soft Blue Shale | 1 foot, 7 inches | 24 feet, 1 inch | |

| Hard Blue Shale | 1 foot, 1 inch | 25 feet, 2 inches | |

| Coal | 45 inches | 3 feet, 9 inches | 28 feet, 11 inches |

The coal reached here at 34 feet 8 inches and at 25 feet 2 inches in D and E respectively is of the same quality as that found at Stippville. The roofing of the former is pyritiferous shale, which makes a fairly good roof, in the latter a good working roof of hard blue shale is found. The floor is a good quality of fire clay. "Horsebacks" occur occasionally. Sulphur in the form of balls and thin laminae of pyrite in the coal is often met with. The workable stratum found here is the Lower.

A stratum intermediate between the Upper and the Lower averaging 6 inches in thickness is passed through here in D, just on the southeast limit, the "blossom" being reached at a depth of 9 feet 6 inches: In E it short distance to the south of D no trace of this "blossom" is found.

Scammon and Vicinity

Two prospecting drill holes on the Scammon farm, designated here as F and G respectively, give the depth of coals with accompanying strata, as passed through in shaft No. 7, northeast quarter of section 4; township 32, range 24.

| F—Record of a Drill Hole at Scammon. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Clay and Soil | 12 feet | 12 feet | |

| Shale | 4 feet | 16 feet | |

| Coal | 12 inches | 1 foot | 17 feet |

| Fire Clay and Shale | 13 feet | 30 feet | |

| Gray Shale | 13 feet | 43 feet | |

| Sandstone | 3 inches | 43 feet, 3 inches | |

| Blue Shale | 5 feet, 6 inches | 48 feet, 9 inches | |

| Sandstone and Ironstone | 1 feet, 3 inches | 50 feet | |

| Blue Shale | 1 feet, 6 inches | 51 feet, 6 inches | |

| Coal | 6 inches | 6 inches | 52 feet |

| Fire Clay | 8 feet | 60 feet | |

| Sandy Shale, gray | 15 feet | 75 feet | |

| Sandy Shale | 5 feet, 6 inches | 80 feet, 6 inches | |

| Coal | 6 inches | 6 inches | 81 feet, 6 inches |

| Sandstone, gray | 1 feet, 9 1/2 inches | 82 feet, 9 1/2 inches | |

| Coal | 13 1/2 inches | 1 foot, 1 1/2 inches | 83 feet, 1 1/2 inches |

The second well, G, located about 300 feet southwest of the shaft, shows the following sequence of strata:

| G—Record of Drill Hole at Scammon. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 11 feet | 11 feet | |

| Shale | 2 feet | 13 feet | |

| Coal | 6 inches | 6 Inches | 13 feet, 6 inches |

| Fire Clay | 3 feet | 16 feet, 6 inches | |

| Sandstone | 2 feet, 6 inches | 19 feet | |

| Shale | 6 feet | 25 feet | |

| Shale, gray | 15 feet, 11 inches | 40 feet, 11 inches | |

| Sandstone | 1 inch | 41 feet | |

| Blue Shale | 6 inches | 41 feet, 6 inches | |

| Ironstone | 2 inches | 41 feet, 8 inches | |

| Blue Shale | 3 feet, 10 inches | 45 feet, 6 inches | |

| Ironstone | 5 inches | 45 feet, 11 inches | |

| Blue Shale, | 6 inches | 46 feet, 5 inches | |

| Ironstone | 5 inches | 46 feet, 10 inches | |

| Blue Shale | 1 foot, 6 inches | 48 feet, 4 inches | |

| Coal | 4 inches | 4 inches | 48 feet, 8 inches |

| Fire Clay, sandy | 6 feet, 4 inches | 55 feet | |

| Sandstone, gray | 20 feet | 75 feet | |

| Sandy Shale | 4 feet, 11 inches | 79 feet, 11 inches | |

| Coal | 42 inches | 3 feet, 6 inches | 85 feet, 5 inches |

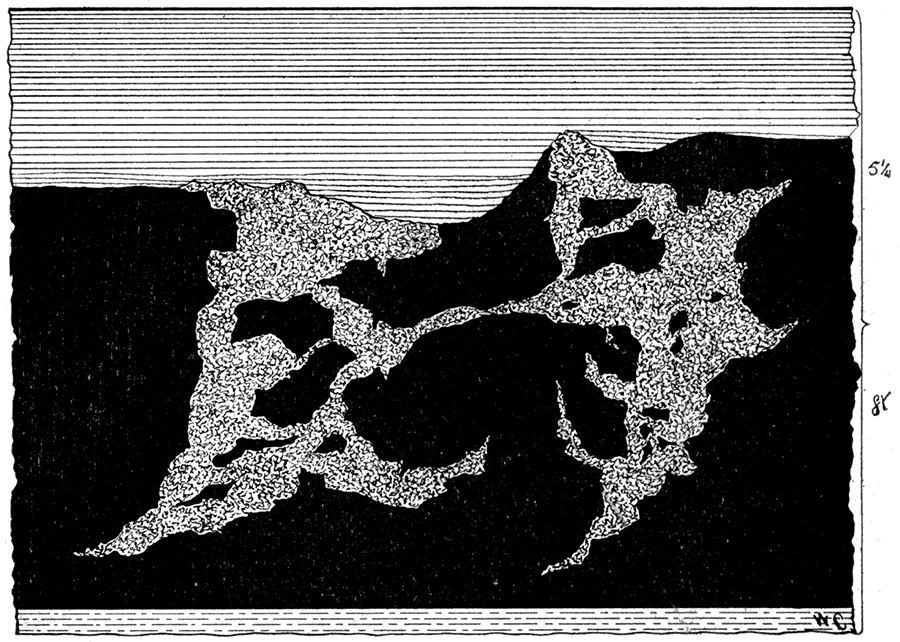

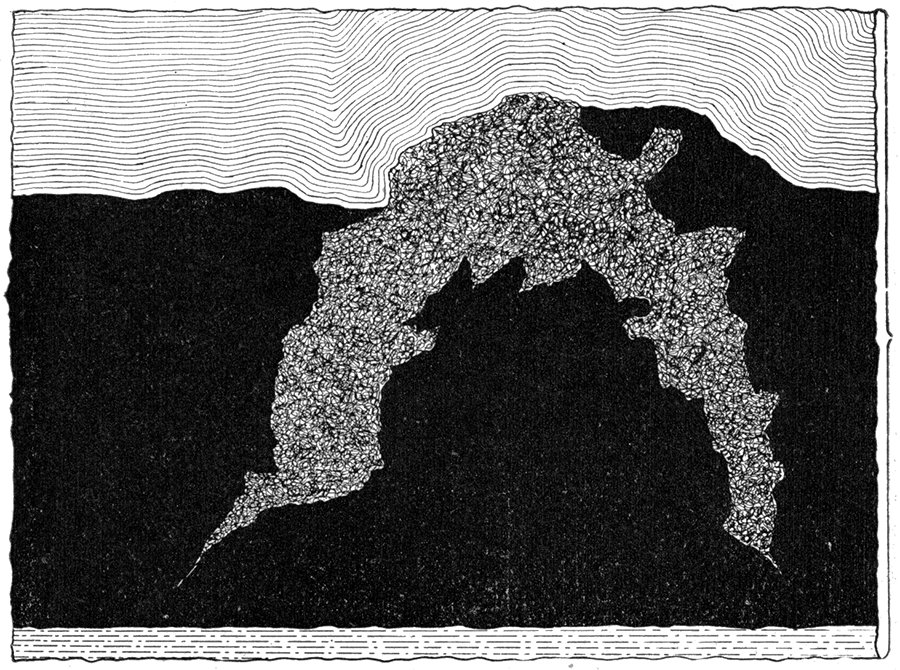

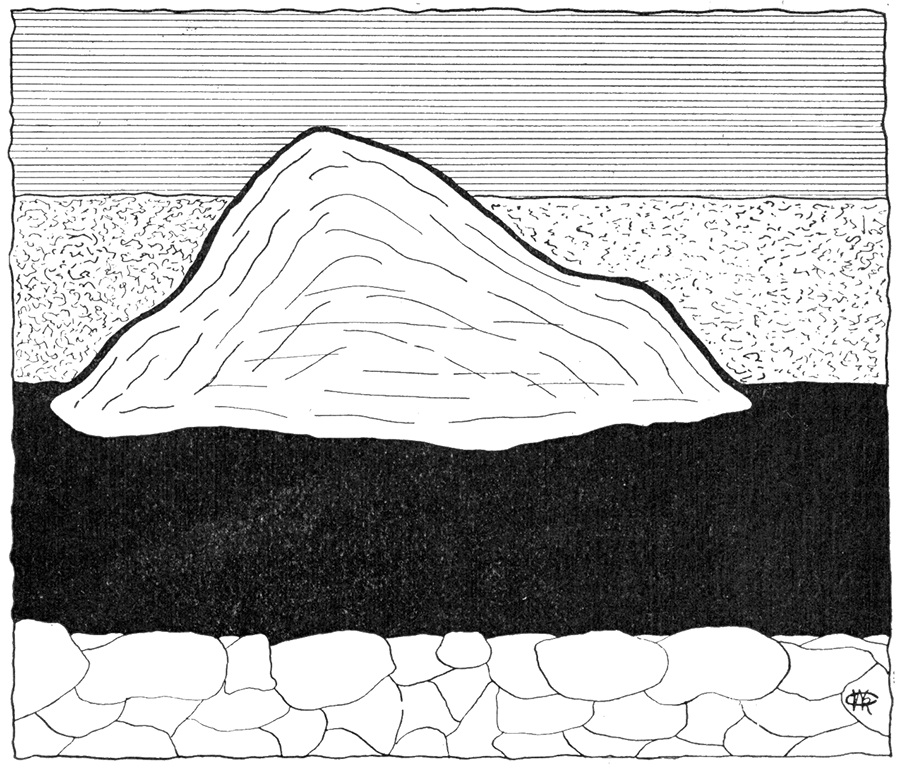

Figure 7—Section of Well at Scammon.

In F and G the Upper is reached at 16 feet and 13 feet respectively from the surface. The coal in this stratum averages 9 inches, and is poor in quality, carrying much pyrite or "sulphur" and "black jack." The floor and roof are good. The Lower stratum, reached at a depth of 82 feet 10 inches and 79 feet 11 inches, respectively, is found to vary considerably in thickness, in G maintaining its usual thickness of 42 inches, while in F it has shrunk to 13 inches. This is simply a local thinning out, a phenomenon which is not of infrequent occurrence. The roof in the above mentioned mine is composed principally of sandstone and arenaceous shales, forming a brittle, unreliable covering to the coal. Fire clay and occasionally a little "black jack" comprise the floor of the mine. The coal is a very good quality, but is somewhat pyritiferous.

As will be seen in examining F a new coal stratum makes its appearance still lower than the one mentioned in D. It is not found in G.

Weir City and Vicinity

A section on the Lewis farm about 300 yards northwest of No. 8 shaft gives a fair record.

| H—Record of a Well near Weir City. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 10 feet | 10 feet | |

| Shale | 6 feet | 16 feet | |

| Sandstone | 1 foot | 17 feet | |

| Blue Shale | 3 feet, 6 inches | 20 feet, 6 inches | |

| Coal | 5 inches | 5 inches | 20 feet, 11 inches |

| Fire Clay | 9 feet, 1 inch | 30 feet | |

| Shale, gray | 6 feet | 36 feet | |

| Sandstone, gray | 11 feet | 47 feet | |

| Sandy Shale | 10 feet, 1 inch | 57 feet, 1 inch | |

| Coal | 39 inches | 3 feet, 3 inches | 60 feet, 4 inch |

The Weir-Pittsburg has dropped out at this place. The Intermediate coal stratum, mentioned in connection with the record D, still occurs at approximately the same hight above the Lower, having a thickness of 5 inches. At 57 feet 1 inch the Lower stratum is mined. The coal is of a good quality, although considerable "sulphur" and "black jack" are found in spots. The roof is made up of arenaceous shale, the same as that noted in G, with a floor made up of fire clay. "Horsebacks" are quite numerous.

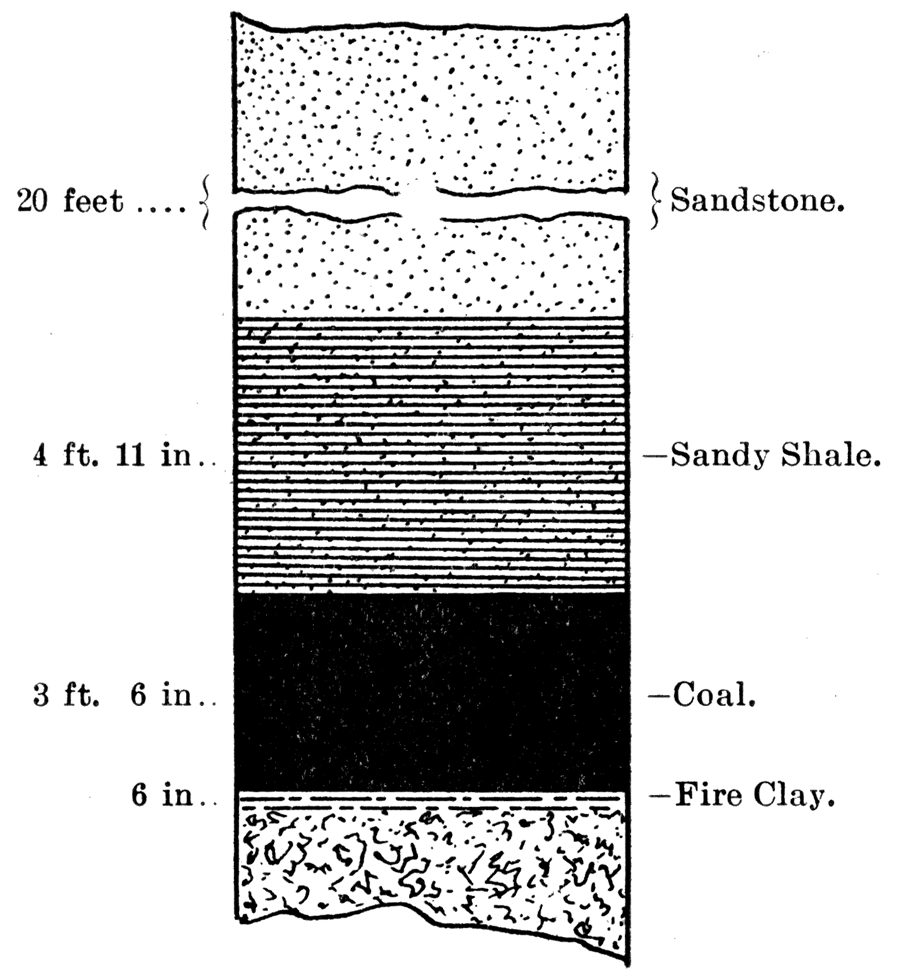

On the Kepple farm; near shaft No. 5, a drill hole record shows the strata assuming the following order:

| I—Record of a Drill Hole near Weir City. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Clay and Sandstone | 13 feet | 13 feet | |

| Shale, hard and soft | 3 feet, 6 inches | 16 feet, 6 inches | |

| Blue Sandy Shale, hard | 7 feet, 6 inches | 24 feet | |

| Blue Shale | 3 feet | 27 feet | |

| Blue Black Shale, soft | 3 feet | 30 feet | |

| Coal | 6 inches | 6 inches | 30 feet, 6 inches |

| Fire Clay | 3 feet | 33 feet, 6 inches | |

| Fire Clay, sandy | 4 feet | 37 feet, 6 inches | |

| Sand and Shale | 10 feet | 47 feet, 6 inches | |

| Fire Clay | 2 feet | 49 feet, 6 inches | |

| Sandy Shale | 6 feet | 55 feet, 6 inches | |

| Coal | 48 inches | 4 feet | 59 feet, 6 inches |

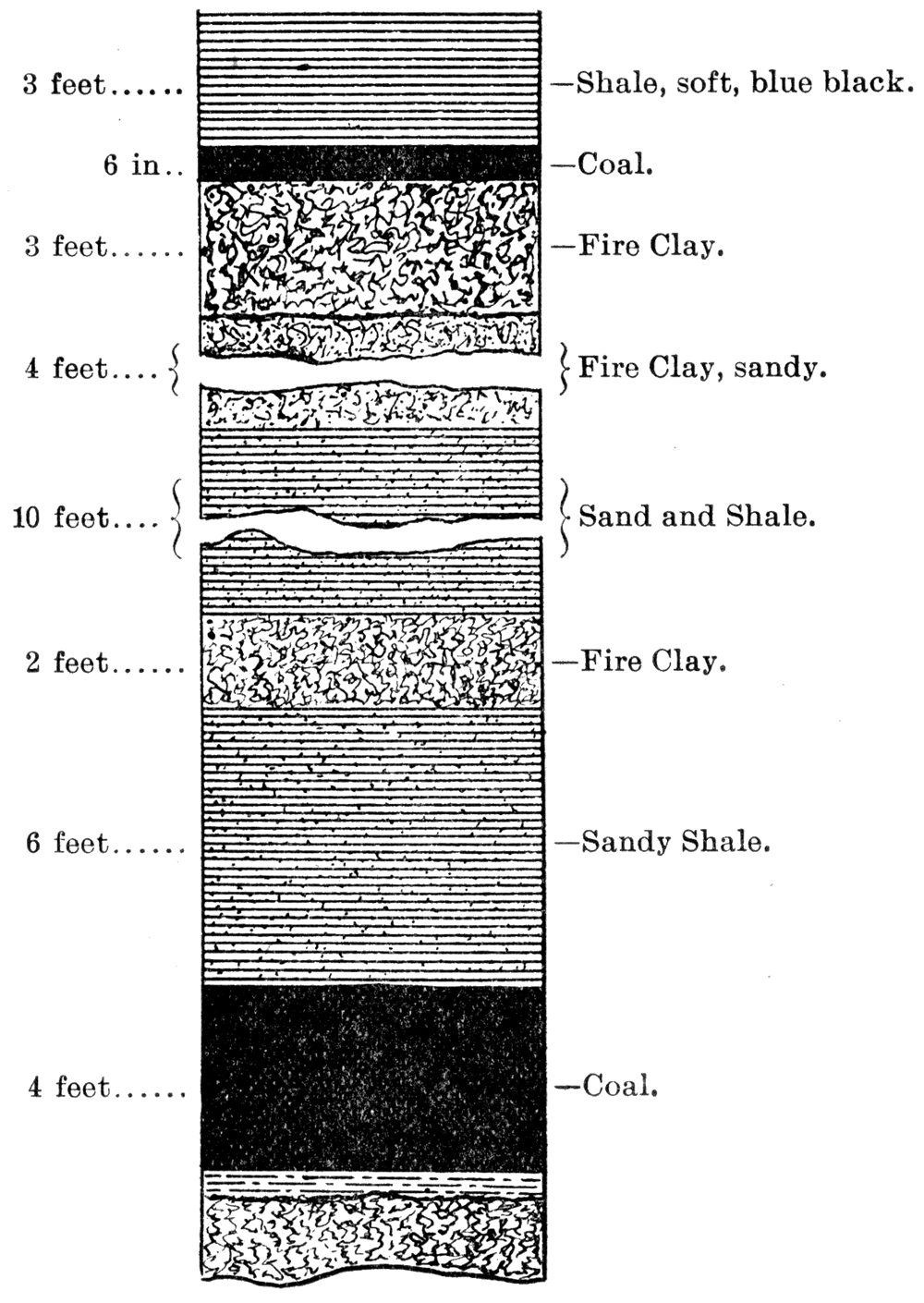

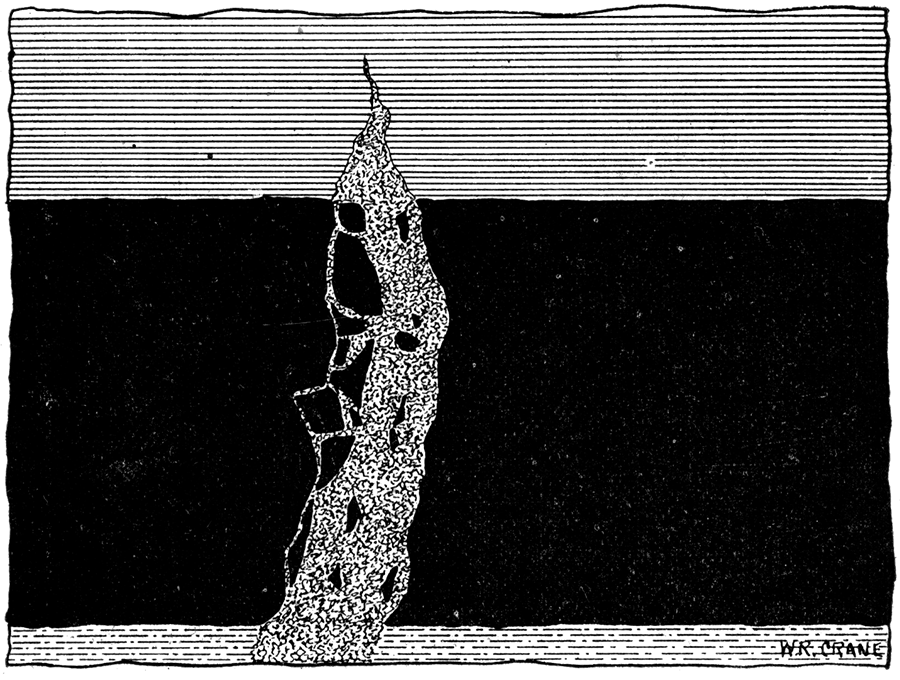

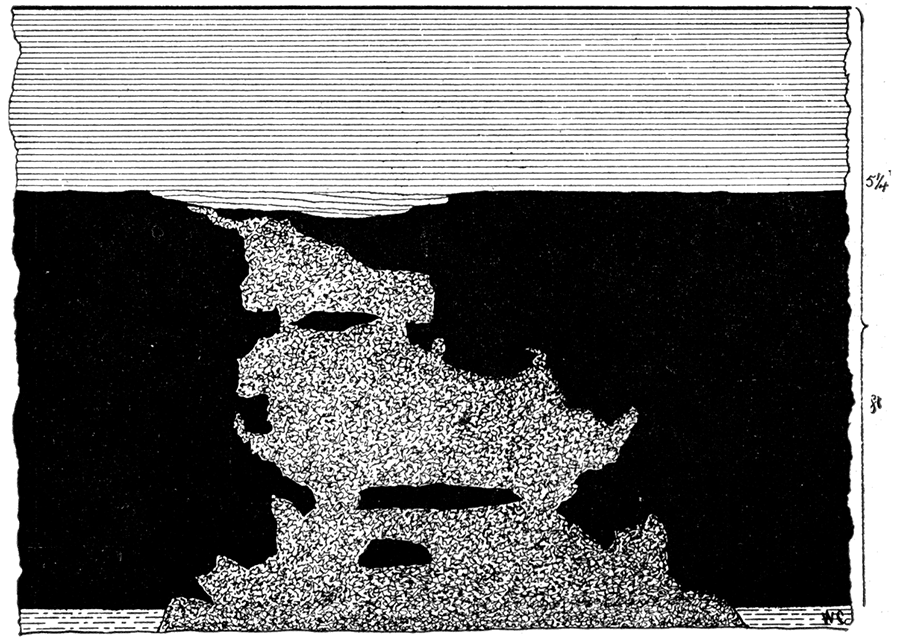

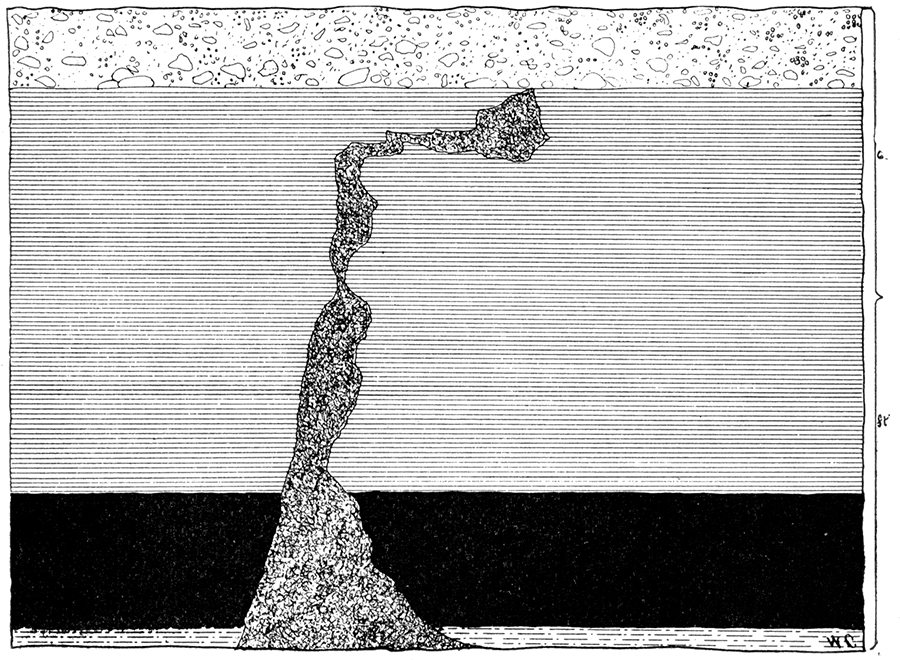

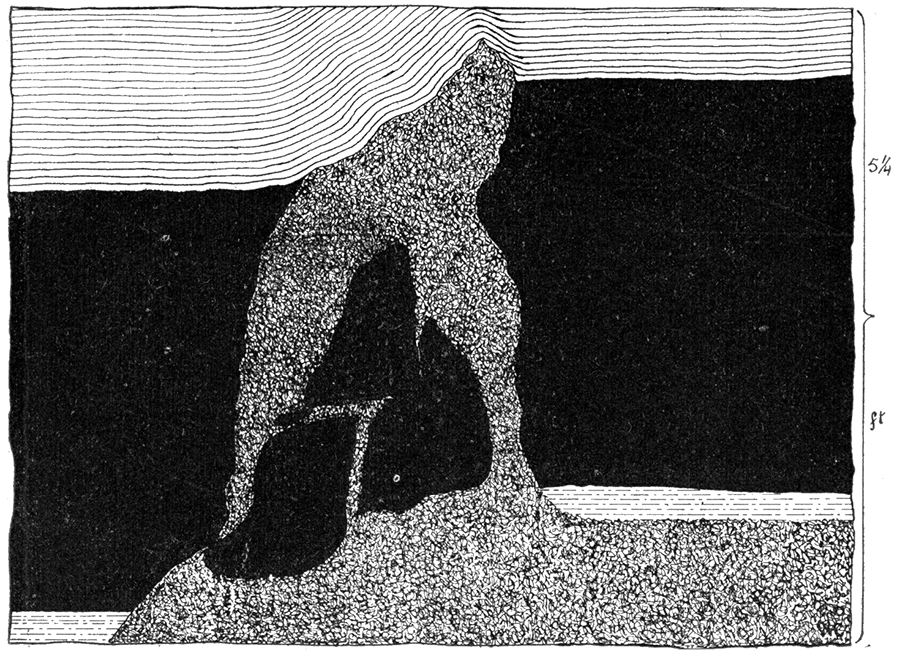

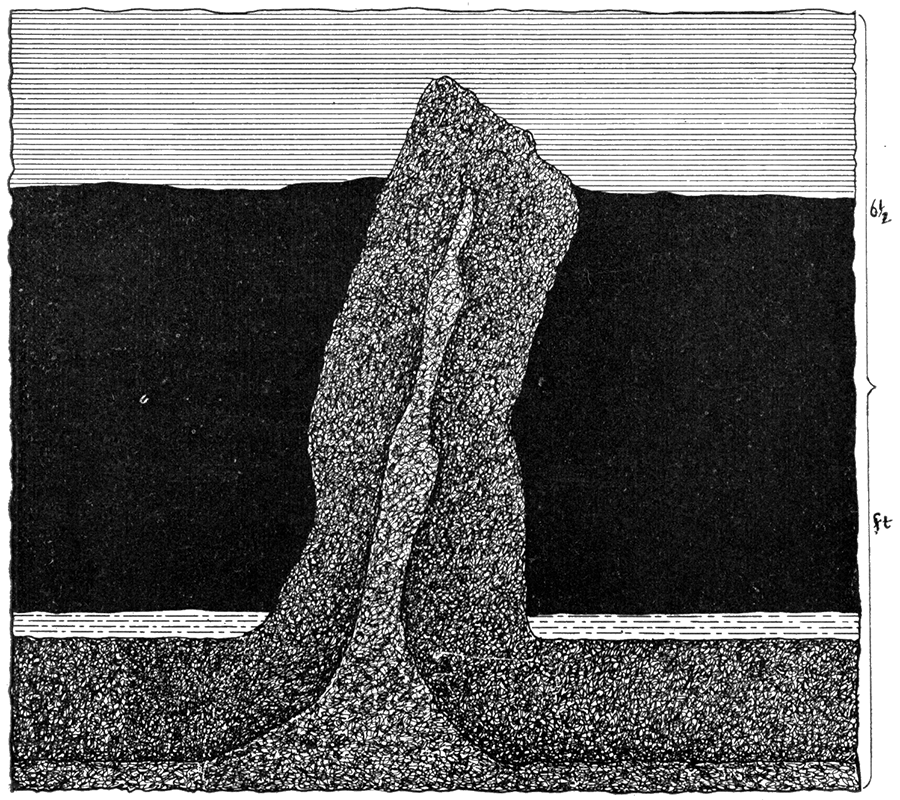

Figure 8—Section of Drill Hole on the Kepple Farm near Weir City.

The Intermediate 6 inch stratum is still persistent. The Lower is found here at a depth of 59 feet 6 inches, with a thickness of 4 feet. The coal is good, although containing some "sulphur" and "black jack." The roof is breaking down into a soft bituminous shale. The floor is of fire clay and "black jack" and is fairly good. "Horsebacks" are numerous.

One and a half miles north of Weir City on the Daisy farm, a prospect hole was sunk within about 250 yards of the Daisy shaft. From the record of this hole the following sequence of strata was noted:

| J—Record of Prospect Hole on the Daisy Farm. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Soil and Clay | 8 feet, 6 inches | 8 feet, 6 inches | |

| Sandstone | 10 feet | 18 feet, 6 inches | |

| Shale, gray and soft | 6 feet, 6 inches | 25 feet | |

| Coal | 2 inches. 2 inches | 25 feet, 2 inches | |

| Clay, black | 2 feet, 2 inches | 27 feet, 4 inches | |

| Shale, bluish gray | 6 feet, 6 inches | 33 feet, 10 inches | |

| Ironstone | 4 inches | 34 feet, 2 inches | |

| Blue Black Shale | 3 feet | 37 feet, 2 inches | |

| Coal | 4 inches | 4 inches | 37 feet, 6 inches |

| Fire Clay | 1 foot, 8 inches | 39 feet, 2 inches | |

| Gray Sand | 1 foot, 10 inches | 41 feet | |

| Fire Clay | 10 feet | 51 feet | |

| Dark Sand | 10 feet, 6 inches | 61 feet, 6 inches | |

| Shale, soft | 3 feet | 64 feet, 6 inches | |

| Gray Sandy Shale | 5 feet, 10 inches | 70 feet, 4 inches | |

| Sandstone, blue | 3 feet, 8 inches | 74 feet | |

| Coal | 4.2 inches | 3 feet, 6 inches | 77 feet, 6 inches |

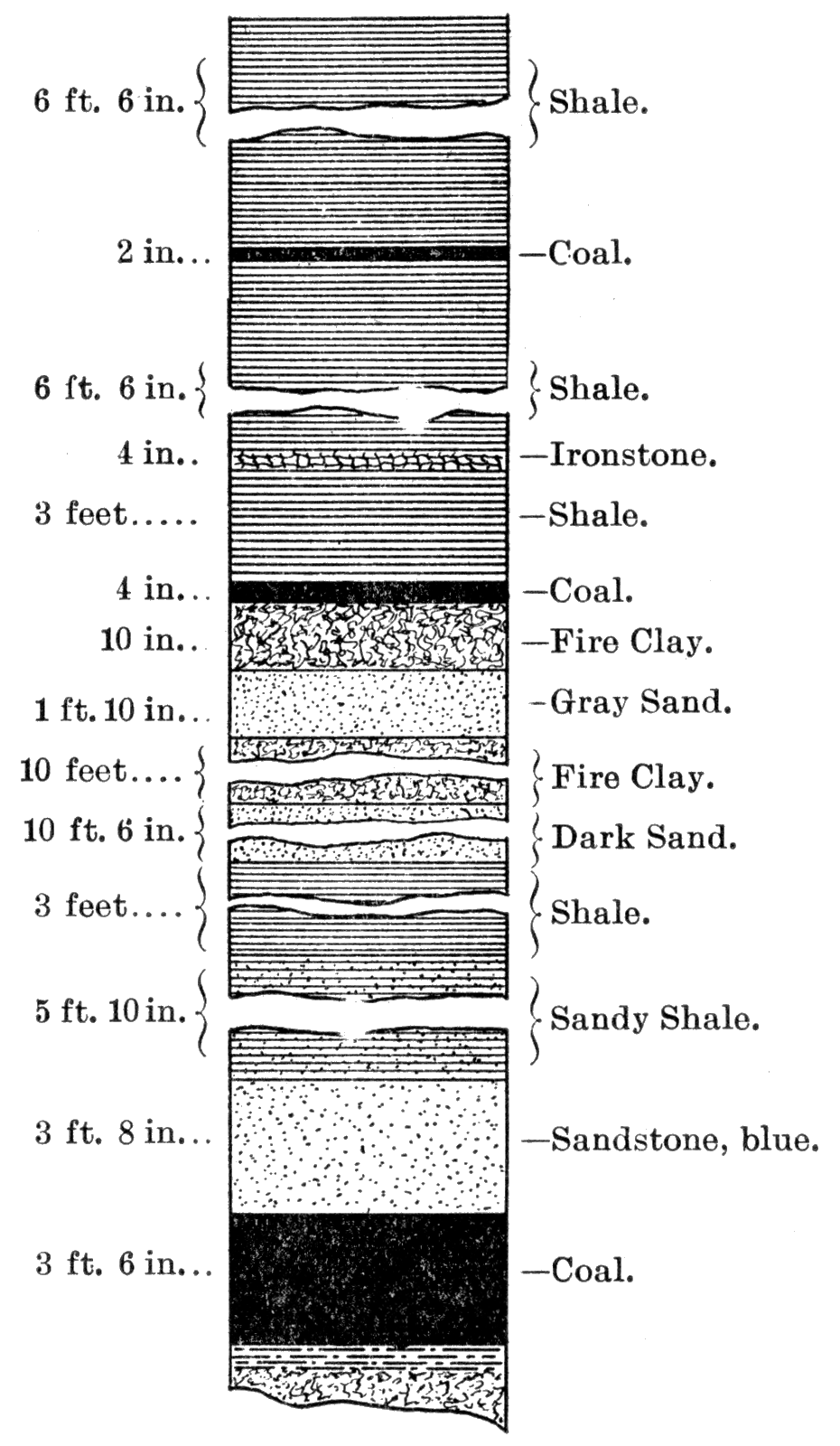

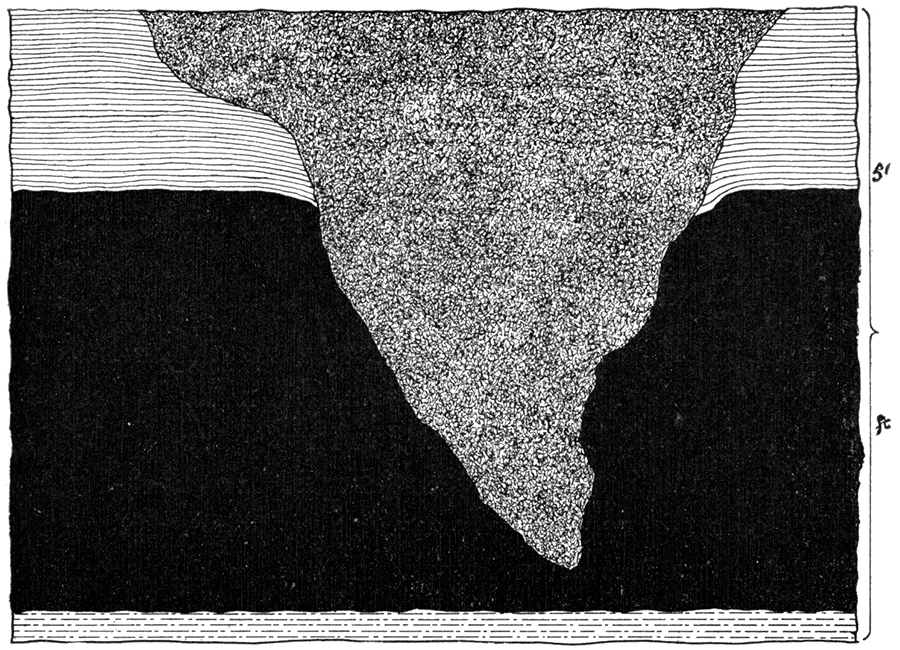

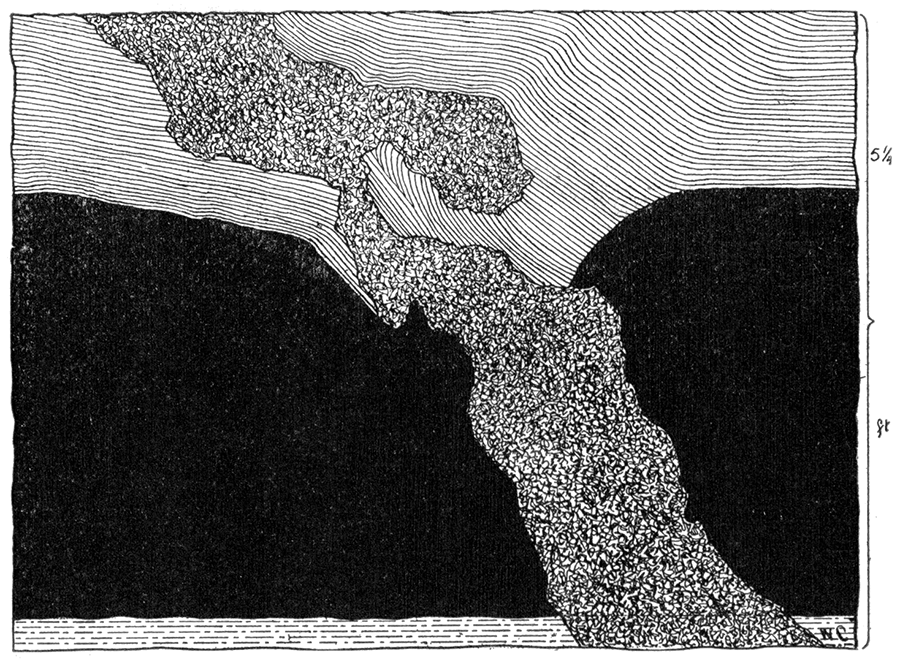

Figure 9—Section of Drill Hole on Daisy Farm near Weir City.

The Weir-Pittsburg Upper is here represented by a 2-inch stratum of coal and "black jack" or bituminous shale. The roof is soft shale and is weak. The floor is bituminous clay. The Intermediate stratum occurs 36 feet above the Lower and has a thickness of only a few inches at this point. The roof is bituminous and blue shale; the floor is fire clay. The Lower stratum, reached at a depth of 74 feet has a blue sandstone roof which is bituminous. The coal if of good quality and of average thickness, 3 feet 6 inches. The floor is fire clay; "horsebacks" are quite numerous; "sulphur" and "black jack" are quite abundant, with the "sulphur" occurring in balls or in rounded masses in the seams of the coal. A 4-inch stratum of ironstone, or "bastard rock," as called by the miners, is found 32 feet from the surface. This form of rock occurs quite frequently throughout the Cherokee shales, especially to the north. The bituminous, carbonaceous, and arenaceous shales are still found to merge back and fourth in rapid succession.

On Mr. Scranton's estate, in the southern part of Weir City, about a half mile from the main street, a shaft has been in operation for several years. The lower stratum of coal is worked here at a depth of 30 odd feet. The Upper stratum was passed through not as coal but bearing close resemblance to soft charcoal, a soft, black, bituminous, and carbonaceous earth. The 6 inch stratum before mentioned as lying between the Upper and the Lower is found at this point. To the east of this shaft about a half mile the Lower stratum comes to the surface in a ravine.

Starting from a point a few rods south of this shaft and passing around to the east and north of Weir from one-half mile to a mile and a half of the city strip pits are numerous. These strippings are located on or near the outcropping of the Lower stratum, the Upper cropping out further to the west. The average thickness of material removed in these strippings is 10 feet, although varying from 6 to 16 feet. The coal thus obtained is of a fairly good quality but, on account of its nearness to the surface, has been so thoroughly saturated by surface waters that it is badly slacked and therefore rendered soft and difficult to handle. For several years it has been mined quite extensively by stripping in the northern part of the city to supply the smelters located near by, but recently less has been stripped than formerly. The covering of the coal is, as a rule, light blue shale, often merging into arenaceous shales and sandstone. The floor is fire clay; "horsebacks" are quite numerous and troublesome.

About a mile and a half northeast of Scammon considerable mining by stripping has been done in times past. Coal is still removed at this point by Mr. Clemens, and there is demand for it. The coal in this neighborhood is in better condition than that stripped further east. The reason for this is that it is farther from the outcroppings and is generally at a greater depth and is therefore less affected by weathering, but it is also more expensive to work. "Horsebacks" occur quite frequently in these strippings.

Chicopee

Three prospect drill holes in the vicinity of Chicopee will serve to show the association of strata at this point. The reoord of hole No. 1, located on section 27, township 30, range 24, reads as follows:

| K—Record of a Prospect Well near Chicopee | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

|||||||

| Soil | 13 feet | 13 feet | ||||||||

| Gray Shale | 4 feet, 6 inches | 17 feet, 6 inches | ||||||||

| Dark Shale | 4 feet, 6 inches | 22 feet | ||||||||

| Gray Shale | 10 inches | 22 feet, 10 inches | ||||||||

| Coal | 10 1/2 inches | 10 1/2 inches | 23 feet, 8 1/2 inches | |||||||

| Gray Shale | 7 feet | 30 feet, 8 1/2 inches | ||||||||

| Black Shale, hard | 5 feet, 1 inch | 35 feet, 9 1/2 inches | ||||||||

| Coal | 7 inches | 7 inches | 36 feet, 4 1/2 inches | |||||||

| Gray Shale | 10 inches | 37 feet, 2 1/2 inches | ||||||||

| Black Shale | 5 feet, 1 inch | 42 feet, 3 1/2 inches | ||||||||

| Coal | 6 1/2 inches | 6 1/2 inches | 42 feet, 10 inches | |||||||

| Gray Shale, hard | 22 feet | 64 feet, 10 inches | ||||||||

| Gray Sandstone, hard | 9 feet, 7 inches | 74 feet, 5 inches | ||||||||

| Coal | 32 inches | 2 feet, 8 inches | 77 feet, 1 inch | |||||||

| Black Shale | 1 foot | 78 feet, 1 inch | ||||||||

| Gray Shale, soft | 6 feet, 4 inches | 84 feet, 5 inches | ||||||||

| Total depth of well, 95 feet 7 inches. | ||||||||||

Hole No. 2, on section 27, township 30, range 24, gives the following sequence of strata:

| L—Record of a Prospect Well near Chicopee. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Clay and Gumbo | 17 feet, 3 inches | 17 feet, 3 inches | |

| Black Shale, hard | 5 feet, 5 inches | 22 feet, 8 inches | |

| Coal | 32 inches | 2 feet, 8 inches | 25 feet, 4 inches |

| Gray argillaceous Shale | 6 feet | 31 feet, 4inches | |

| Limestone, blue, fossiliferous | 8 inches | 32 feet | |

| Gray argillaceous Shale | 8 feet, 6 inches | 40 feet, 6 inches | |

| Black Shale | 3 feet, 8 inches | 44 feet, 2 inches | |

| Coal | 14 inches | 1 foot, 2 inches | 45 feet, 4 inches |

| Gray argillaceous Shale | 4 feet | 49 feet, 4 inches | |

| Gray Shale | 22 feet, 2 inches | 71 feet, 6 inches | |

| Black Shale | 6 feet | 77 feet, 6 inches | |

| Coal | 6 inches | 6 inches | 78 feet |

| Gray arenaceous Shale | 12 feet, 6 inches | 90 feet, 6 inches | |

| Gray arenaceous Shale | 2 feet | 92 feet, 6 inches | |

| Gray arenaceous Shale | 6 feet | 98 feet, 6 inches | |

| Coal | 39 inches | 3 feet, 3 inches | 101 feet, 9 inches |

| Black Shale | 1 foot, 1 inch | 102 feet, 10 inches | |

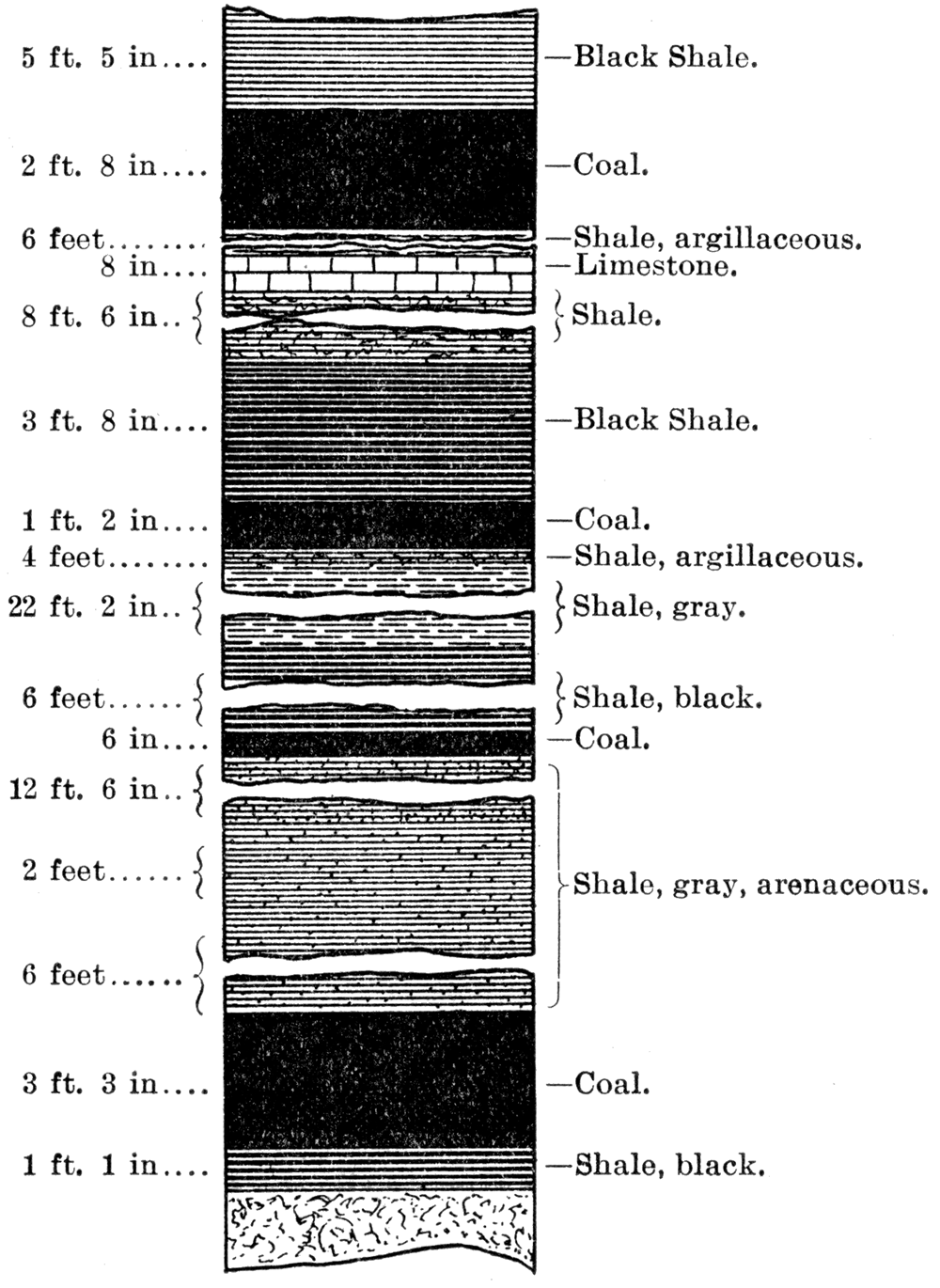

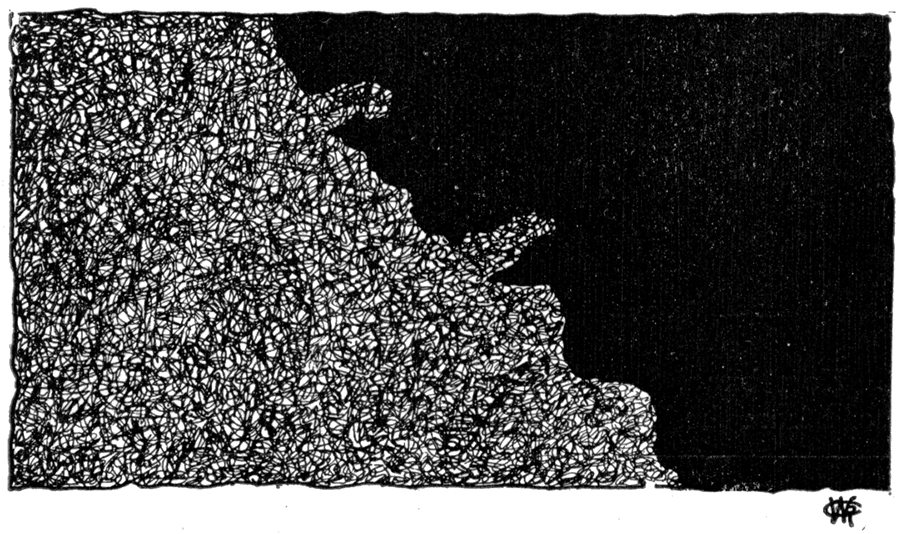

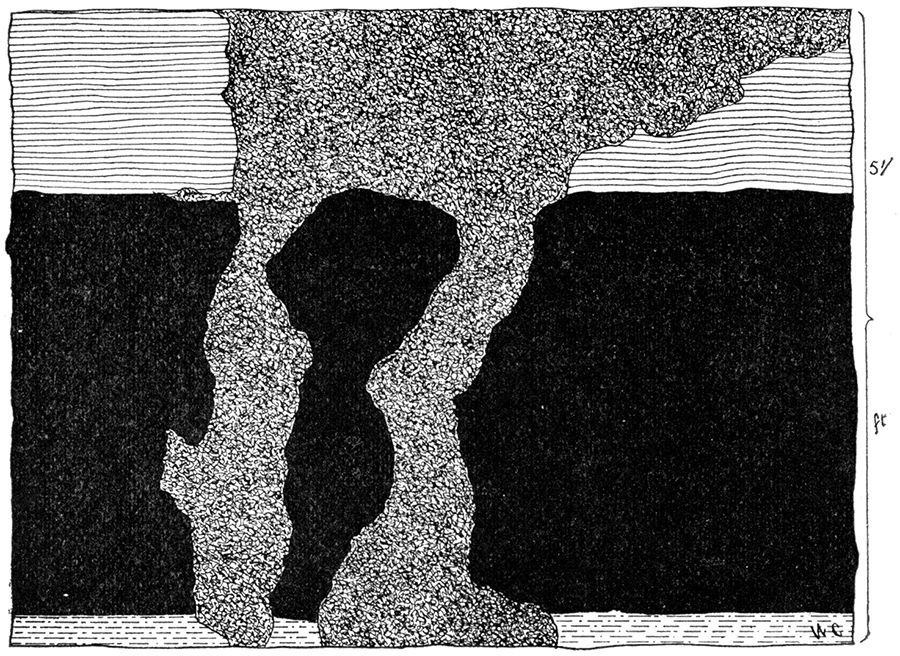

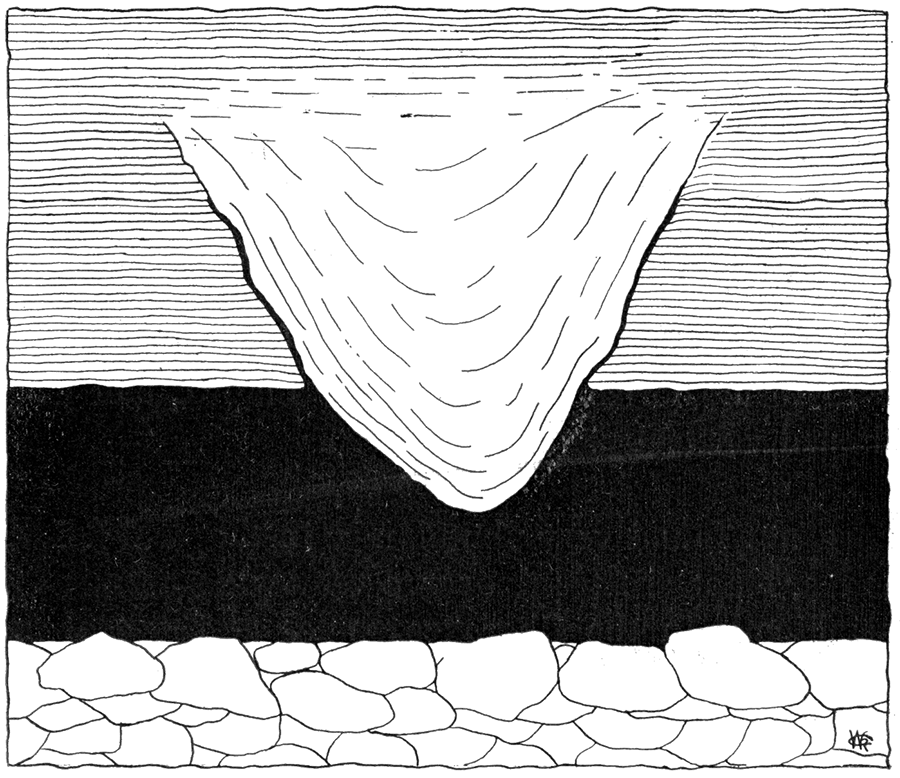

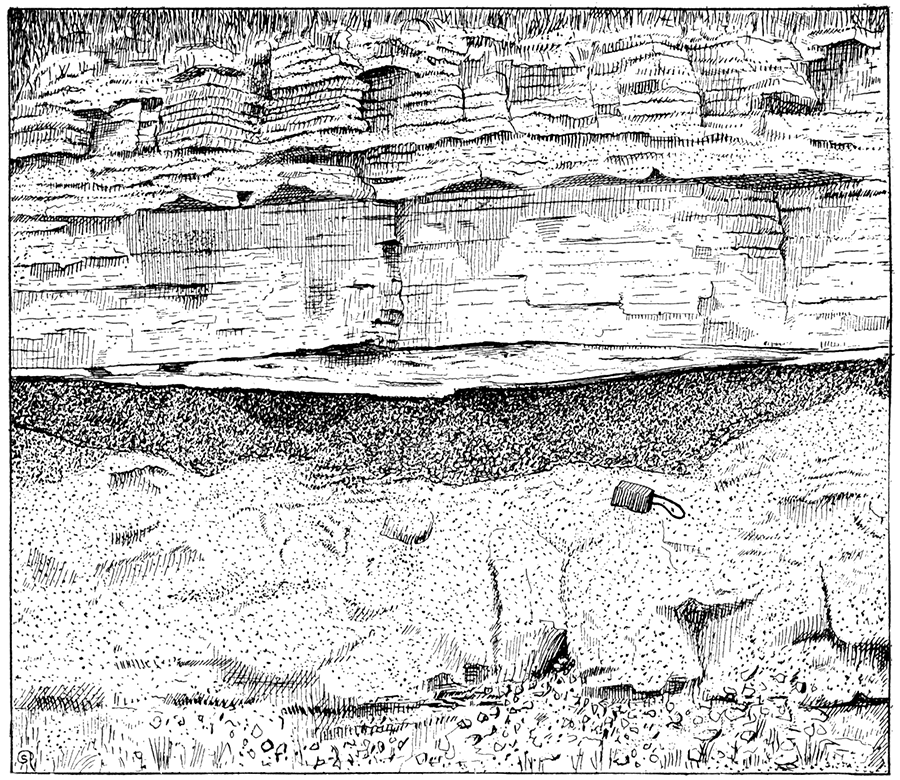

Figure 10—Section of Drill Hole near Chicopee.

Hole No. 3, located on section 27, township 30, range 24, although a trifle deeper than either 1 or 2—K or L—shows the same association of strata at this locality. The record is as follows:

| M—Record of a Prospect Well near Chicopee. | |||

|---|---|---|---|

| Material | Thickness of Coal |

Thickness of Strata |

Depth to Bottom of Strata |

| Clay and Gumbo | 12 feet, 8 inches | 12 feet, 8 inches | |

| Black Clay | 2 feet | 14 feet, 8 inches | |

| Coal | 28 inches | 2 feet, 4 inches | 17 feet |

| Argillaceous Shale, gray | 11 feet | 28 feet | |

| Blue Limestone | 6 inches | 28 feet, 6 inches | |

| Argillaceous Shale, gray | 4 feet, 6 inches | 33 feet | |

| Dark Shale | 10 inches | 33 feet, 10 inches | |

| Gray Limestone | 1 foot, 2 inches | 35 feet | |

| Dark Shale | 4 inches | 35 feet, 4 inches | |

| Coal | 9 inches | 9 inches | 36 feet, 1 inch |

| Argillaceous Shale, gray | 5 feet, 7 inches | 41 feet, 8 inches | |

| Gray Shale | 19 feet, 9 inches | 61 feet, 5 inches | |

| Black Shale | 2 feet | 63 feet, 5 inches | |

| Blue Limestone | 4 inches | 63 feet, 9 inches | |

| Black Shale | 4 feet, 4 inches | 68 feet, 1 inches | |

| Coal | 5 inches | 5 inches | 68 feet, 6 inches |

| Gray Shale | 9 feet | 77 feet, 6 inches | |

| Gray Sandstone | 1 foot, 6 inches | 79 feet | |

| Shale, hard | 1 foot, 6 inches | 80 feet, 6 inches | |

| Blue Limestone | 7 inches | 81 feet, 1 inch | |

| Gray Shale, hard | 10 feet | 91 feet, 1 inch | |

| Gray Sandstone | 3 feet, 4 inches | 94 feet, 5 inches | |

| Gray Shale, hard | 1 foot, 8 inches | 96 feet, 1 inches | |

| Coal | 25 1/2 inches | 2 feet, 1 1/2 inch | 98 feet, 2 1/2 inches |

| Dark argillaceous Shale | 1 foot | 99 feet, 2 1/2 inches | |

The Upper stratum is reached in K, L, and M at 21, 22, and 14 feet, respectively. The roof of this coal is argillaceous and bituminous shale, in some places weak, but as a general rule making a fairly good supporting roof. The floor material is similar to that of the roof, being argillaceous shale.

The Intermediate stratum increases a trifle in thickness as it passes to the north, having here an average thickness of 7 inches. The bituminous shale here makes a very good covering and is quite persistent. The floor is a good quality of hard, gray shale and is tolerably level, making a good working floor.

The Lower stratum is reached at a depth of 83 feet 7 inches, 93 feet 6 inches, and 96 feet 1 inch, in K, L, and M, respectively. The roof merges from hard blue shale in M to arenaceous shale in L, then to hard sandstone in K. The floor consists of a very bituminous hard shale, yet in M an argillaceous shale is met with, making a poor working floor.

The large amount of bituminous (black) shales and clays found in these drill hole records, as well as the arenaceous shales and sandstone, are very characteristic of these shale beds as noted farther south.

The Area North of Pittsburg and Chicopee

A smaller number of records of wells and shafts have been obtained from the area lying north of Chicopee and Pittsburg than have already been given for the southern portion of the country, but from observations taken covering the greater part of the above mentioned district it is found that the coal strata continue to dip gradually deeper beneath the surface to the north and west at an angle which does not differ materially from that already observed farther south. The Weir-Pittsburg Lower outcrops in the vicinity of Pittsburg and has been stripped quite extensively on the south, west, and north of the city. At present it is taken from the clay pits at the clay factory at which place it is found at a depth of from 16 to 20 feet below the surface, being overlaid with arenaceous and argillaceous shales. The line of outcrop passes northeastward from Pittsburg to the state line -eight to ten miles from Pittsburg. The outcropping is seen only in the ravines, consequently on the higher ground to the north and west the coal is mined by shafting.

Details of Stratigraphy in the Mines

To give a more definite idea of the depth of the workable strata of coal, their thickness, and the character of the associated strata, the exact data will be given as obtained directly from the operators of the various mines. The mines from which the following data were obtained are located principally in Cherokee county.

- 1. The Western Coal Mining Company, Mine No. 3. Fleming. The mine is 100 feet deep. Thickness of coal is 3 feet 3 inches. The roof is blue shale, merging into sandy shale. Considerable gas is found here. The floor is generally fire clay, but quite frequently pyritiferous "black jack." The Lower coal stratum is mined.

- 2. The Western Coal Mining Company, Mine No. 2. Fleming. The mine is 100 feet deep. Coal is 3 feet 2 to 4 inches in thickness. The floor is level and composed of fire clay and pyritiferous "black jack," which makes mining difficult as the force of the charge in blasting is lost in the elastic "black jack." The roof is shale, sometimes sandy. The Lower coal stratum is mined here.

- 3. The Schaub Coal Company. The J. H. Durkee Coal Company, lessee, Mine No. 3. The mine is located on the southwest quarter of section 6, township 32, range 24. The mine is 50 .feet deep and the coal is 3 feet 6 inches in thickness. Very little "black jack" is found associated with roof or floor. Little or no iron pyrite or "sulphur" occurs. The floor is level and smooth and composed of fire clay. The roof is blue shale and a trifle arenaceous in places. The Lower coal stratum is mined.

- 4. Hamilton and Grant Coal Company, Mine No. 3. Weir City. The mine is 30 feet deep. Coal is 3 feet 6 inches thick. "Horsebacks" are numerous and "black jack" is troublesome. The roof is composed of shale and sandy shale. The floor is "black jack" and fire clay. The Lower coal stratum is the one mined.

- 5. Kansas and Texas Coal Company, Mine No. 47. North of Weir three miles. The mine is 30 feet deep and the coal 3 feet 4 to 6 inches in thickness. The floor dips to the northwest, is quite smooth, and is composed principally of fire clay with a little "black jack" intermixed. Roof is shale—fairly good. Lower coal stratum is mined.

- 6. Kansas and Texas Coal Company, Mine No. 23. North of Weir three miles. The mine is 42 feet deep. Coal is 3 feet 6 to 8 inches in thickness. The floor is rather uneven and is composed of fire clay and "black jack." The roof is shale and sandy shale. The Lower stratum is mined.

- 7. Kansas and Texas Coal Company, Mine No. 18. North of Weir nearly three miles. The mine is 76 feet deep and the coal is 3 feet 6 inches in thickness. The roof is arenaceous shale and sandstone—poor. The floor is composed of shale and "black jack," 3 to 4 inches in thickness, then fire clay—poor. "Horsebacks" are numerous. The Lower stratum is mined.

- 8. Hamilton and Braidwood, Mine No. 2, In the vicinity of Weir. The mine is 73 feet deep. Coal is 3 feet 3 to 6 inches thick. The roof is arenaceous shale and sandstone-poor. There are 6 inches of "black jack" under the coal, then fire clay. At this point the drill hole, 110 feet deep, shows two other coal strata -10 and 8 inches in thickness, respectively. The depths at which these two strata were reached were not known to the operator. The roof is arenaceous shale. "Horse. backs" are of frequent occurrence. The Lower stratum is worked.

- 9. The Central Coal and Coke Company, Mine No. 5. In the vicinity of Weir. Mine is 60 feet deep. Coal is 3 feet 6 inches thick. A strip of faulty coal, several rods wide, passes through this neighborhood trending northeast and southwest. "Horsebacks" are very numerous. The roof is arenaceous shale and shale. The floor is fire clay and "black jack." "Black jack" is not very troublesome. Lower stratum is worked.

- 10. Durkee Coal Company, Mine No. 1. Location: East half of the northeast quarter of section 33, township 31, range 24. The mine is 50 feet deep, and coal is 3 feet 8 inches in thickness, and dips very perceptibly to the northwest. The roof is shale and sandy shale. The floor is fire clay and "black jack," but there is very little of the latter. Lower stratum is mined.

- 11. John Bennett Coal Company, Mine No. 5. In the vicinity of Weir. Mine is 55 feet deep. Coal is 3 feet 6 inches in thickness. The roof is shale: The floor, composed of "black jack" and fire clay, dips to the northwest. "Horsebacks" are numerous. The stratum mined is the Lower.

- 12. Central Coal and Coke Company, Mine No. 8. West of Weir. The mine is 75 feet deep. The coal is 3 feet 4 to 6 inches thick. The floor is almost level, dipping to the west slightly, and is composed of fire clay and "black jack," with very little of the latter. The roof is shale, fairly good. "Horsebacks" are of frequent occurrence. The stratum mined is the Lower.

- 13. Weir Brothers Coal Company, Mine No. 2. Weir City. Mine is 96 feet deep. The coal is 3 feet 4 to 8 inches thick. The floor is fire clay and "black jack." The roof is shale and sandy shale. Some gas is found here. "Horsebacks" are met occasionally. The stratum worked is the Lower.

- 14. Central Coal and Coke Company, Mine No. 6. West of Weir. Mine is 72 feet deep. Coal is 3 feet 8 inches thick. Floor is fire clay and "black jack." Roof is blue shale. n Horsebacks" are numerous. Lower stratum is worked.

- 15. Davis Coal Company, Mine No. 3. The mine is, located on the northeast quarter of section 19, township 31, range 24. Cherokee. Depth of mine is 150 feet. Two strata are found here. The first is reached at a depth of 40 feet where the coal is 2 feet thick; the second at a depth of 150 feet where the coal is 3 feet 3 to 6 inches thick. The floor is fire clay with a thin stratum of "black jack" next to. the coal. "Horsebacks" are not numerous. The Lower stratum is mined.

- 16. Norton's Works, Mine No. 2. Durkee Coal Company, lessee, Mine No. 3. Scammon. The mine is 67 feet deep, and the coal is 4 feet in thickness. .Floor strata as shown in "sump" are as follows: "black jack" 2 to 3 inches in thickness; blue shale 18 to 20 inches; coal 2 to 3 inches; and fire clay 2 to 3 feet in thickness. The roof is arenaceous shale and sandstone, fossiliferous. The floor is rough and wavy and dips to the northwest. "Horsebacks" are numerous. The stratum mined is the Lower.

- 17. The Durkee Coal Company, Mine No. 4. Location is on the northeast half of section 16, township 31, range 24. The mine is 60 feet deep. Coal is 3 feet 6 inches to 4 feet thick. The roof is blue shale. The floor is "black jack," shale, and fire clay, similar to that found in No. 16. "Horsebacks" are quite numerous. The Lower stratum is worked.

- 18. Southwestern Coal and Improvement Company, Mine No. 6. Mineral City. The mine is 125 feet deep. The coal is 3 feet 8 to 10 inches in thickness. "Horsebacks" are very troublesome. The roof is blue shale and is fairly good. The floor is "black jack" and pyritiferous fire clay. The coal carries considerable pyrite in the nature of fine seams and bands. The floor is wavy and dips to the northwest. Gas is found here. The Mineral City Lower is mined here,

- 19. The McCune Coal Company. McCune. This company's mine is 400 feet deep. There are six strata of coal. One is 6 inches in thickness; three are 1 foot each in thickness; one is 2 feet; and one is 18 inches. Both the 18 inch and the 2 foot strata have been worked. The 24 inch strata is probably the Weir-Pittsburg Upper. The roof is shale and sandstone. The floor is fire clay and "black jack."

- 20. Columbus Coal Company, Mine No. 4. This mine is located at the southeast corner of the northwest quarter of section —, township 32, range 24, and is 25 feet deep. The coal is 4 feet thick. The roof is blue shale and sandy shale. The floor is fire clay and "black jack." "Horsebacks" occur here. The stratum worked is the Lower.

Inclination of Coal Beds

It is desirable to determine the inclination of the coal beds. The practical question for the miner being the distance below the surface at which the coal is found the inclination of the coal beds with reference to the surface rather than with reference to a level will be sought after. But as the whole of the coal mining area in Cherokee and Crawford counties is almost level the figures obtained will not differ materially from figures obtained showing the dip referred to the horizontal.

The Weir-Pittsburg Lower may be traced from its outcrop. ping three-fourths of a mile east of Weir westward to the limit of mining operations at Mineral City, by noticing its position in the records of the strip-pits, shafts, and drill holes located between these two points. The Lower occurs here as follows:

- 1. In the strip-pits east of Weir at a depth of from 10 to 16 feet.

- 2. At Mr. Scranton's mine in the southeastern part of Weir at a depth of 30 odd feet.

- 3. In the Daisy shaft at a depth of 75 feet.

- 4. In prospect hole No. 2 as seen in record G at a depth of 79 feet.

- 5. At Cherokee at a depth of 150 feet.

- 6. In prospect hole, record A, five miles north of Mineral City, at 229 feet 6 inches.

This makes an average westward dip below the surface of 20 feet to the mile.

The Weir-Pittsburg Lower may be traced to the north from its outcropping near Columbus, but as the exact location of the outcrop is uncertain, due to the covering of soil, it would probably be best to use the locality where the exact depth of the stratum is known as the initial point in the correlation on the south.

- 1. A shaft at Stippville, a few miles north of Columbus, reached the Lower stratum at a depth of 25 feet.

- 2. On the Perry farm two and a half miles south of Scammon, in prospect hole No. 2, record D, it was found at a depth of 24 feet 8 inches.

- 3. On the Scammon farm, near Scammon, in hole No. 2, record G, the Weir-Pittsburg Lower was reached at a depth of 79 feet 11 inches.

- 4. Still farther north at the Daisy shaft, on the Daisy farm, it was met with at a depth of 75 feet.

- 5. At the M. K. & T. mine No. 18, a few miles north of Weir, it is reached at a depth of 75 feet.

- 6. At Fleming the same stratum is worked at a depth of 100 feet.

From the above it will be seen that the dip to the north is on the average 4 feet to the mile below the surface.

The Weir-Pittsburg Upper stratum may be traced as follows:

- 1. It is first noted in records F and G at 16 and 13 feet, respectively.

- 2. In the Daisy shaft the Upper occurs at a depth of 20 odd feet.

- 3. At Fleming this stratum is reached at 18 or 20 feet.

We thus see that this coal stratum is dipping below the surface on an average of 3 feet to the mile, in passing northward.

Passing westward from Weir to Mineral City and vicinity the following points may be noted at which the Upper stratum can be found:

- 1. The "blossom" of the Upper appears on the Scranton farm one-half mile south of Weir at a few feet from the surface.

- 2. On the Daisy farm, one and one-half miles north of Weir (see record J) , the Upper is reached at a depth of 24 feet from the surface.

- 3. Near Scammon, in hole No. 2, record F, it is reached at a depth of 16 feet.

- 4. At Cherokee it was reached at a depth of 40 feet.

- 5. North of Mineral City, see records A and B, it was reached at 96 feet 7 inches and 122 feet 2 inches, respectively.

This gives for the Upper an average westward dip beneath the surface of 12 feet to the mile.

This difference in westward inclination of the two main coal beds is somewhat surprising and at the same time interesting. It implies that throughout this area there was a more rapid accumulation of shale forming material to the west during the interval between the production of the two coal beds. This excessive westward thickening averages 8 feet to the mile, the difference between the dip of the two coal beds. The general westward inclination of the Cherokee shales as a whole along the south line of the state, as shown in Plates I and II, is about 20 feet to the mile. The westward inclination of the Lower or principal coal bed is therefore about the same as that of the Cherokee shales, while the position of the Upper coal bed is such that it is inclined to the general bedding planes of the Cherokee shales.

The dip of the Cherokee shales to the north and west, in Cherokee county, is therefore quite marked, which dip soon carries them below the higher geological formations to the north and west, and to such a depth that in a comparatively short distance beyond the upper line of outcrop the accompanying coal strata become, for the present, unworkable.

The Intermediate coal stratum is as persistent in the constancy of its thickness and extent of occurrence as well as in its dip as are the Upper and Lower.

Arcadia Area

At Arcadia three strata are found from which considerable coal is removed. The upper stratum comes within a few feet of the summits of Bunker Hill and Coal Mound, at which places it is mined. It resembles the Fort Scott "red" and is much used as a domestic fuel. The second stratum is stripped just east of town, and is also drifted for on the creek bank south of Arcadia. At Coalvale, about four miles south of Arcadia, a third stratum is shafted for in the creek valley. These coal strata average probably 20 inches in thickness and produce large quantities of good coal which is put on the market in competition with Weir-Pittsburg coals to the south. These strata belong to the Cherokee Shales, but are higher than those to the south. Plate XXXI shows the association of strata found here.

Fort Scott Area

Near the top of the Cherokee shales in the vicinity of Fort Scott coal has been mined for over thirty years. Here there are two beds of coal, one from 6 to 10 feet below the lower Oswego limestone, and the other 60 feet or more still further below. The former is mined in many places around Fort Scott, while the latter is mined to a lesser extent near the state line along the Drywood and along the Marmaton.

Coal mining was first begun in the Fort Scott vicinity about the close of the war, in 1865. The upper bed of coal outcropped in a thousand places along the banks of the ravines, and larger tributaries of the Marmaton. Here exposed to the weathering agents the iron sulphide within it became oxidized, producing iron rust which gave the coal a rusty appearance from which the name "red coal" was derived. Being so close to the overlying Oswego limestone the escarpments and steep bluffs produced on account of the protective action of the limestone made it possible for the coal to be oxidized completely along the surface and to be practically unaffected only a few feet back in the bank. The contrast between this condition and the conditions in the vicinity of Weir City and Pittsburg, where there is no protective limestone overlying, is very great. In the latter place such a weathering and such a production of "red" coal extends many times as far back from the line of outcropping while this outcropping line is concealed almost entirely by the overlying soil so plentifully produced by the decomposition of the shales.