Permeability

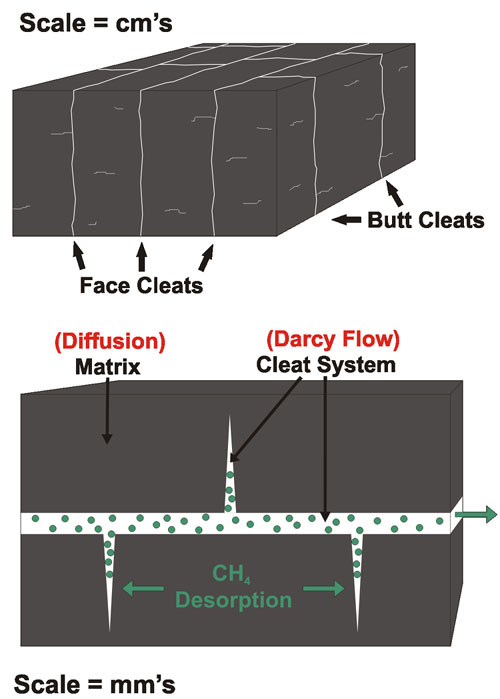

One of the most important factors governing the producibitlity of CBNG is permeability. Coalbeds are considered to be dual-porosity, dual-permeability systems, represented by the cleats and matrix. Cleats are naturally occurring, regularly-spaced fractures that occur nearly perpendicular to bedding. A cleat system consists of an orthogonal set of fractures: the face cleats, which are the dominant through-going fracture set, and butt cleats, which terminate upon their intersection with the face cleats or any dull band in the coal. Cleating is mainly a function of rank, ash content, and geological structural.

Flow within the cleat system can be described by Darcy’s Law. It is important to note that permeabilities can be significantly different depending if the flow is in the direction of the face cleats or butt cleats. The coal matrix, where most of the gas is stored, is characterized by diffusion of gas through the matrix, which is controlled by concentration gradient, and modeled by Flick’s Law.

During the initial production of a CBNG well, the rates of fluid and free gas are mainly a function of the permeability of the cleat system. As dewatering continues and the drop in reservoir pressures leads to gas desorption, the rate of gas production becomes more of a function of the rate of diffusion of the coal matrix rather than the permeability of the cleat system. For these reasons diffusion rates and cleat spacing can be critical controls on the producibility of CBNG.

Gas Content

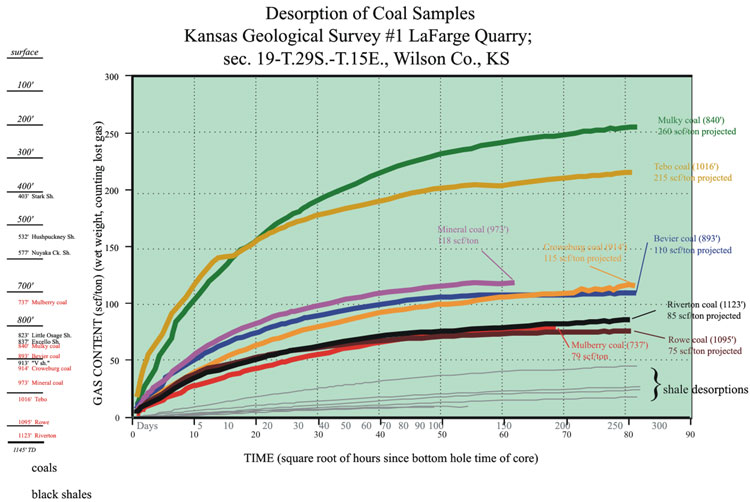

Coal gas content is a critical variable needed for setting the initial conditions of the reservoir model. It can easily be determined through simple desorption experiments. Coal samples from the LQ #1 core were collected and allowed to desorb for a sufficient length of time to obtain an accurate gas content for each coal.

Gas content is also important for determining whether a coal is saturated or under saturated with respect to gas, at reservoir conditions. Understanding gas saturations can help to predict the gas production characteristics during pressure drawdown. The shape of the desorption curves can also be used to estimate the rate of diffusion, by analyzing the time it takes to desorbe 63.7 percent of the maximum gas content.

Coals from the LQ #1 core had gas contents ranging from 75 scf/ton up to 260 scf/ton, which are consistent with gas contents values from core and cuttings data from the surrounding region.

http://www.kgs.ku.edu/PRS/publication/2006/2006-13/p2-03.html

Last Modified May 2006