Kansas Geological Survey, Mineral Resources Circular 8, originally published in 1937

Originally published in 1937 as Kansas Geological Survey Mineral Resources Circular 8. This is, in general, the original text as published. The information has not been updated. An Acrobat PDF version (6 MB) is also available.

By Kenneth K. Landes

The State Geological Survey of Kansas published Mineral Resources Circular 5, "Rock wool resources of Kansas," in March 1937 [available online]. In this report is a description of rock wool, details of the apparatus and procedure for blowing rock wool in the experimental laboratory at the University of Kansas, the results of tests made on samples collected in twenty-two scattered localities in the state, and economic considerations pertinent to the rock-wool industry. As a result of this investigation, one rockwool plant is now operating south of Neodesha, and other plants are planned.

The distribution of Circular 5 resulted in so many requests for tests of raw materials from other localities that it was decided to continue the project during the field season of 1937, and to publish an appendix. In the recent investigation samples were obtained and tested from thirteen additional localities. The experimental plant has been dismantled, as practically the entire stratigraphic range of rock formations in Kansas has been tested. The results obtained from a given formation in one locality can be successfully applied to other exposures of the same formation.

The subject matter covered by this appendix is confined to a description of the stratigraphic position of the rock samples recommendations for a rock-wool mix, and the results of the blowing tests for each locality. A brief description of the new rock-wool plant at Neodesha is appended. For more detailed information in regard to the rock-wool industry and for a description of the results obtained from other localities, the reader is referred to Mineral Resources Circular 5, copies of which are still available for distribution from the offices of the State Geological Survey at Lawrence, Kansas.

The Kansas Geological Survey is again grateful to Prof. E. D. Kinney, chairman of the Department of Chemical Engineering at the University of Kansas, for the use of the electric furnace; to the Department of Machine Construction, and its chairman. Prof. A. H. Sluss, for the use of Fowler Shope in which the experimental plant was erected; and Mr. V. M. Smith, who worked with Mr. Plummer in blowing the rock wool from the samples collected. Mr. Norman Plummer collected the samples, put them through a preliminary calcining, prepared the mixtures, helped run the tests, and wrote the following appendix. The Survey is also grateful to the various individuals who aided in making the collection of samples in the field, and to Mr. C. M. Laird. Superintendent of the Verdigris Valley Vitrified Brick Company of Neodesha, for his courtesy in supplying essential data regarding the rock-wool plant which was erected and is operated under his supervision.

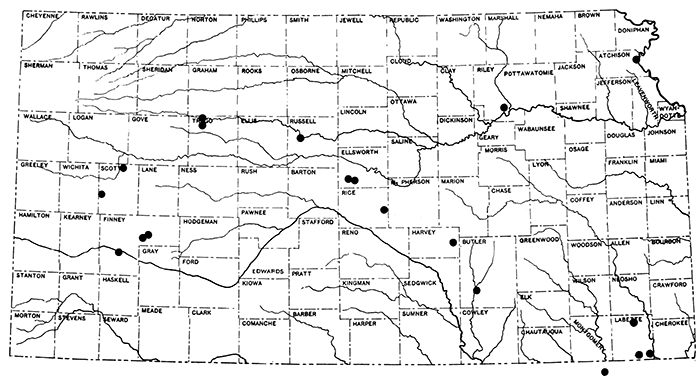

Geographically, the area covered by this report extends over almost the entire state, ranging from Scott and Finney counties in the western half of the state, to Atchison and Labette counties on the east. (See Fig. 1).

Figure 1--Index map of Kansas, showing location of outcrops sampled for testing for rock wool.

The stratigraphic range extends from the Cherokee shale in the lower Pennsylvanian series, and upward through the Permian, Cretaceous, Tertiary, and Quaternary rocks.

Kereford quarry at the south edge of the city of Atchison in the NW sec. 18, T. 6 S., R 21 E., Atchison County.

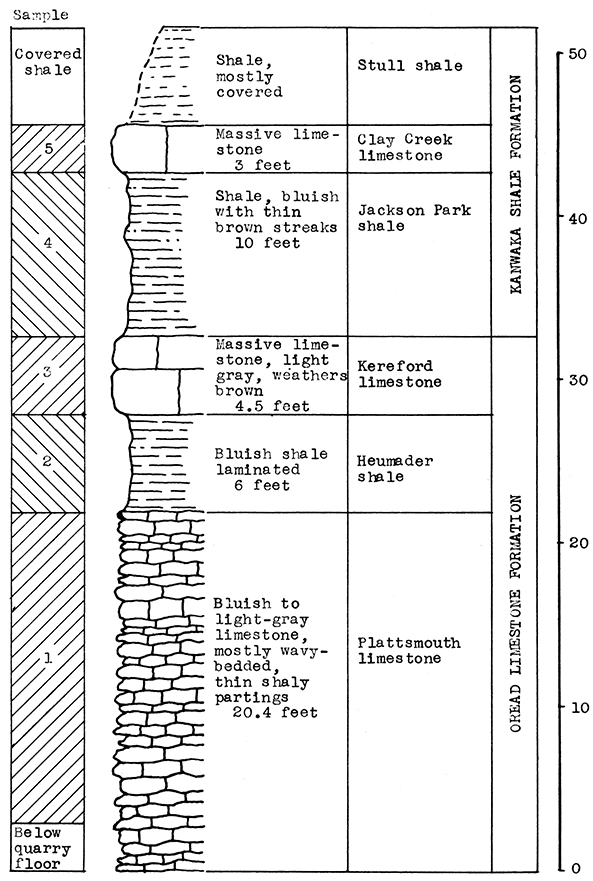

The rocks exposed in the Kereford quarry are in Shawnee group in the Pennsylvanian series. From the floor of the quarry upward the Plattsmouth limestone, the Heumader shale and the Kereford limestone, members of the Oread formation, are exposed. Resting on the Kereford. limestone is the Kanwaka formation, containing the Jackson Park shale, the Clay Creek limestone, and the Stull shale members. The Stull shale is partially covered at this exposure by glacial drift, and was, therefore, not sampled.

Each of the limestone and shale members sampled were ~s~for carbon-dioxide content, and the entire section included in a rock-wool mixture, in proportion to the thickness of the members sampled. The vertical section of 43 feet is composed of 19.5 feet of Plattsmouth limestone, 6 feet of Heumader shale, 4.5 feet of Kereford limestone, 10 feet of Jackson Park shale, and 3 feet of Clay Creek limestone. The average carbon-dioxide content of the mixture is 27.38 per cent. A fine wool with slight lavender tint was produced in the blowing test, with a pouring temperature of approximately 1500° C., and steam pressure at 65 pounds.

U.S. Highways 59 and 73, and Kansas Highway 7, pass through Atchison. Three railroads, the Missouri Pacific, the Santa Fe, and the Burlington, serve this area. Gas is piped in from the south. Several years ago a good grade of coal was mined a short distance from the Kereford quarry.

Figure 2--Stratigraphic section of quarry south of Atchison showing locations of samples No. 1 (CO2 37.9 per cent), No. 2 (CO2 12.25 per cent), No. 3 (CO2 39.50 per cent), No. 4 (CO2 8.08 per cent), and No.5 (CO2 35.26 per cent). All samples were included in the wool-rock mixture. Measured by R. C. Moore.

Limestone quarry about one mile south of the town of Parsons, in the W2 sec. 30, T. 31 S., R. 20 E., Labette County.

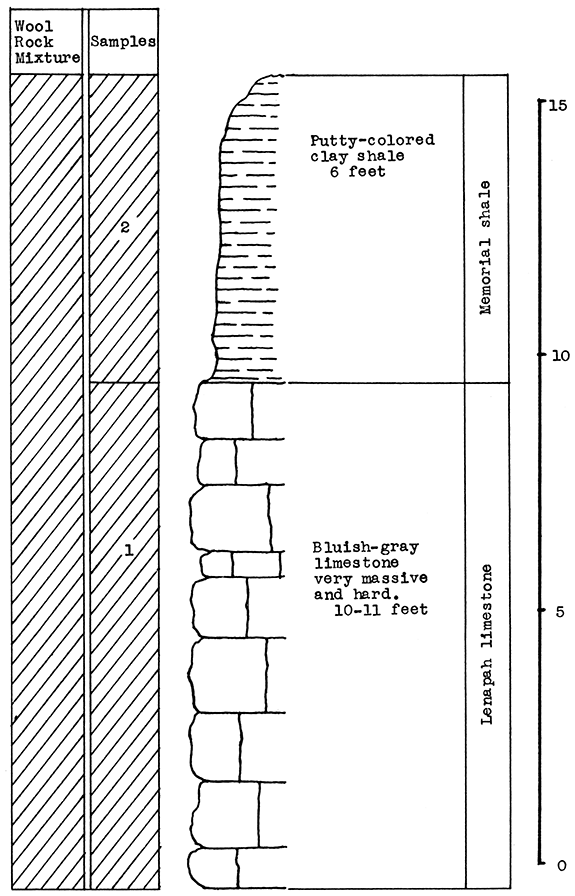

At this outcrop two samples were taken in the Marmaton group in the Des Moines subseries. Ten to 11 feet of the upper Lenapah limestone was sampled from the quarry face, and 6 feet of the Memorial shale immediately above the limestone. This putty-colored clay shale comprised the greater part of the overburden at the quarry.

The calcination tests indicated a carbon-dioxide content of 41.12 per cent for the Lenapah limestone (sample No. 1) and 6.72 per cent for the Memorial shale (sample No. 2). The entire section of 16 feet was used in the mixture for the blowing test. This mixture, in percentage by weight, is approximately 62.5 per cent limestone and 37.5 per cent shale; and has an average carbon-dioxide content of 28.22 per cent. Fine white wool was produced in the blowing test at 1500° C. with only 52 pounds steam pressure.

Figure 3--Stratigraphic section at quarry south of Parsons showing location of samples No. 1 (CO2 41.12 per cent) and No. 2 (CO2 6.72 per cent).

An abundance of gas and oil is available in this area. Transportation facilities include the Frisco and the Missouri, Kansas and Texas railroads, and U.S. Highways 59 and 160.

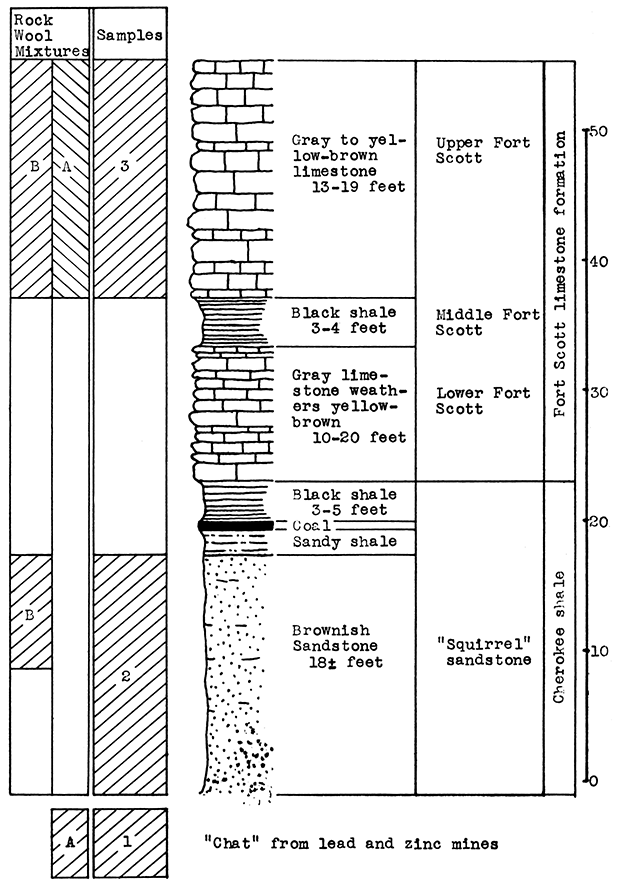

Sample No. 1, "chat" from lead and zinc mine, Cherokee County, Kansas. Sample No. 3, from a stone quarry west of Chetopa in SW sec. 30, T. 34 8., R. 20 E., Labette County. Sample No. 2 from sec. 26, T. 34 S., R. 21 E., Labette County, northeast of Chetopa.

Sample No. 1 is composed of chert which comprises the matrix of the lead and zinc ores in the Tri-State district. Enormous piles of this material are stored in the district. Sample No. 3 is from a quarry in the upper Fort Scott limestone. Twenty-eight feet of this limestone were logged in a well near the quarry. Sample No. 2 is an 18-foot sandstone in the upper Cherokee shale. The sample used was taken from beneath the surface, but the sandstone is exposed nearby.

The sample of "chat" (No. 1) lost 1.54 per cent of its weight by calcination. Probably only a portion of this small percentage represents carbon dioxide. The upper Fort Scott limestone (sample No. 3) contains 39.61 per cent carbon d1oxide. The Cherokee sandstone (sample No. 2) has a carbon-dioxide content of 2.35 per cent.

Two mixtures were prepared from these samples for the blowing test. Rock wool A contains 30 per cent of sample No. 1 and 70 per cent of sample No. 3. This mixture has an average carbon-dioxide content of 28.19 per cent, and produced a rather short-fibered, very fine white wool at 1500° C. with 60 pounds per square inch steam pressure. The results indicate that the temperature used was too high, or that not enough of the "chat" was used in the mixture. A mixture containing slightly more than the usual amount of silica is indicated because of the low alumina content. A mixture with a carbon-dioxide content of 27 per cent would probably produce a wool with longer and slightly coarser fibers. Possibly the fusion temperature could be dropped to 1450° C. or 1400° C.

Rock wool B is composed of 66.67 per cent of sample No. 3 and 33.33 per cent of sample No. 2. The carbon-dioxide content of the mixture is 27.21 per cent. A large amount of fine white wool was blown from this mixture at a temperature of 1500° C. Sixty-five pounds steam pressure was used.

The Missouri Pacific railroad passes within a short dIstance of outcrop No. 3. Both the Missouri Pacific and the Missouri, Kansas and Texas railroads pass through Chetopa. Other transportation facilities include U.S. Highways 59 and 166. An abundance of both gas and oil are available in this area.

Figure 4--Stratigraphic section of outcrops near Chetopa, showing locations of samples No. 1 (CO2 1.54 per cent), No. 2 (CO2 2.35 per cent), and No. 3 (CO2 39.61 per cent).

Quarry on east side of U.S. Highway 169 at Bells Spur about 12 miles south of Coffeyville, Kansas, in the NW of NE sec. 30, T. 28 N., R. 16 E., Nowata County, Oklahoma.

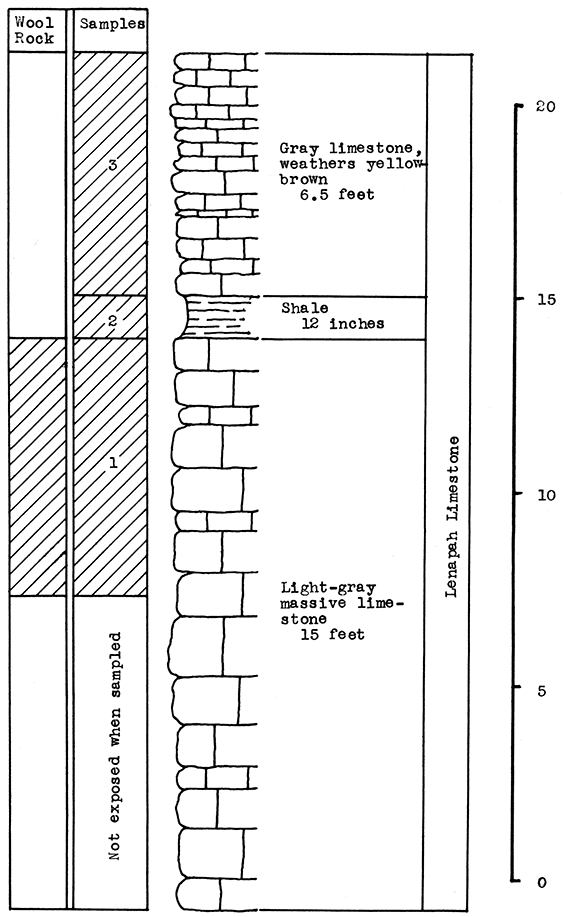

The Lenapah limestone of the Marmaton group is made up of three beds where sampled. The lower 15 feet is a light-gray, massive limestone (sample No. 1). Above this is a 1-foot bed of blue-gray shale (sample No. 2), and above the shale approximately 6 feet of light-gray limestone which weathers gray and light yellowish-brown (sample No. 3). An excellent exposure of the Lenapah limestone occurs about 4 miles west of Coffeyville in the SE of the SW sec. 7, T. 35 S. R. 17 E., in the east bluff of the Verdigris River, Montgomery County, Kansas. [Measurements and other data on Lenapah limestone by R. C. Moore, "Guide Book, Eleventh Annual Field Conference", 1937.]

The carbon-dioxide content of the samples tested follows: No: 3, 38 per cent; No. 2, 8.4 per cent, and No. 1, 21.37 per cent. The carbon-dioxide content of sample No. 1 is within the limits for a natural wool rock, and was subjected to the blowing test without mixing with other material. Although this sample is quite close to the lower limit of 20 per cent carbon dioxide for a wool rock, it proved to be easily fusible in the blowing test, producing an excellent quality of white wool at slightly over 1500° C. with 60 pounds steam pressure.

No successful wools were produced using samples No. 2 and No. 3, but if the carbon-dioxide content were correctly adjusted by the addition of a siliceous rock to the upper limestone and the thin middle shale, it would be possible to use the entire 20 feet of the Lenapah limestone.

The Bells Spur quarry is on U.S. Highway 169, and the Union Traction Company electric railroad. This railroad is now used to haul the limestone taken from the quarry to Coffeyville. Other transportation facilities available at Coffeyville include the Missouri Pacific and the Missouri, Kansas and Texas railroads, and U.S. Highway 166. Gas and oil are available from both the southeastern Kansas and the northern Oklahoma fields.

At the time of sampling the east quarry at Bells Spur was opened into but 7 feet of the lower Lenapah limestone, and samples could not be taken in the west quarry because of water.

Figure 5--Stratigraphic section at Bells Spur, 12 miles south of Coffeyville, showing location of samples No. 1 (CO2 21.37 per cent), No. 2 (CO2 8.4 per cent), and No. 3 (CO2 38 per cent).

Road cut in escarpment on the north side of U. S. Highway 24, 3 1/2 miles west of Kansas State College, in the S2 sec. 10, T. 10 S., R. 7 E., Riley County.

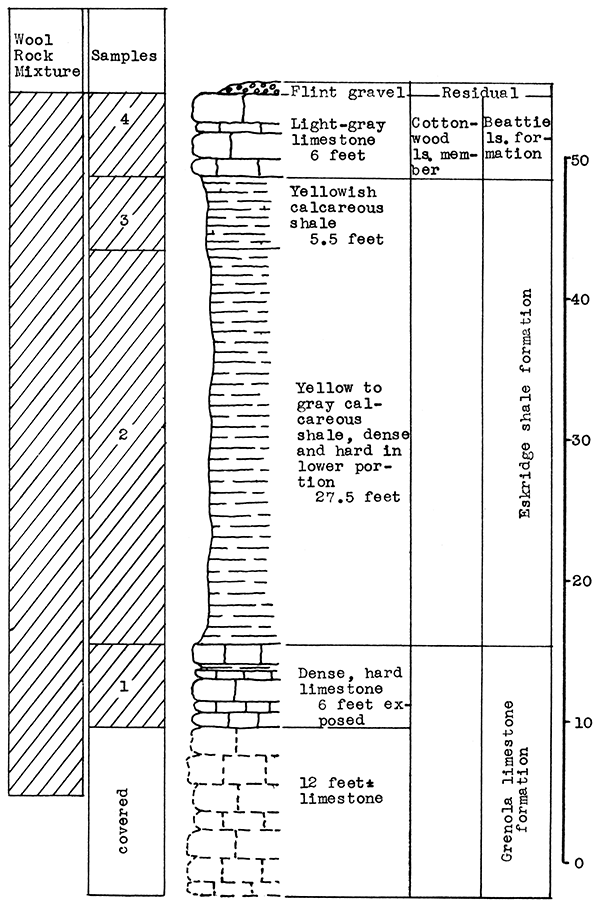

The lowermost memer of the Beattie formation, the Cottonwood limestone, caps the escarpment at the outcrop sampled. This limestone rests on the Eskridge formation. a highly calcareous shale. Below this 6 feet of the Neva limestone member of the Grenola formation is exposed. Approximately 12 feet of this limestone is below the road level. All the rocks exposed are in the Council Grove group of the Big Blue series of the Permian system.

For the carbon-dioxide determination test the rocks sampled were divided into four groups. No. 4 is the Cottonwood limestone; No. 3 includes the upper 5.5 feet of the Eskridge shale; No. 2, the lower 27.5 feet of the Eskridge shale; and No. 1 the Neva limestone. The table below gives the carbon-dioxide content of each group, the percentage by weight of each in the wool-rock mixture tested, and the percentage of carbon dioxide which each group contributed to the mixture.

| Wool Rock Data | ||||

|---|---|---|---|---|

| Group | Vertical depth included |

Per cent by weight included |

Per cent carbon dioxide |

Per cent carbon dioxide contributed |

| 4 | 6 | 11.54 | 38.57 | 4.45 |

| 3 | 5.5 | 10.57 | 22.96 | 2.43 |

| 2 | 27.5 | 52.88 | 16.37 | 8.66 |

| 1 | 13 | 25.00 | 39.00 | 9.75 |

| Average carbon-dioxide content of the wool rock mix, 25.29 per cent. | ||||

The above wool rock is made up of the entire section from the top of the escarpment to 7 feet below the road level. A very high-grade white wool was blown from this mixture at a pouring temperature of 1500°-1525° C with steam at 65 pounds pressure.

It will be noted that the 5.5 feet of Eskridge shale represented by group 3 on the table has a carbon-dioxide content (22.96 per cent) within the limits of a wool rock. A separate blowing test was not made of this sample because of the thinness of the deposit and the nature of the overburden.

Transportation facilities in this area include U.S. Highways 40 and 24, Kansas Highways 13 and 29, and the Union Pacific and Rock Island railroad lines. Gas is piped in from the southwest.

Figure 6--Stratigraphic section at outcrop west of Manhattan, showing location of samples No. 1 (CO2 39 per cent), No. 2 (CO2 16.37 per cent), No. 3 (CO2 22.96 per cent), and No. 4 (CO2 38.57 per cent).

Limestone quarry south of Augusta, operated and owned by Mr. E. W. Young; Butler County.

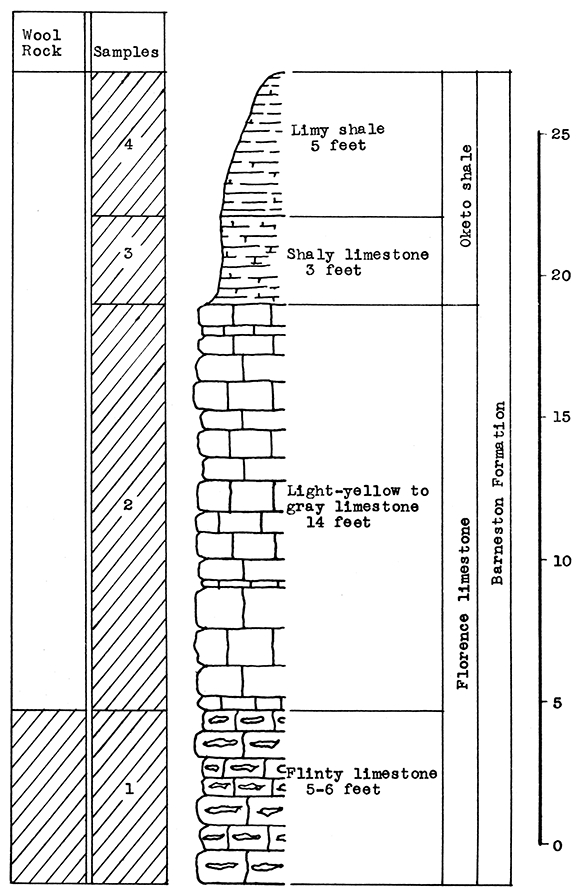

Samples were taken from the Barneston formation at this outcrop. From bottom to top the samples included: 5 to 6 feet of the lower flint-bearing Florence limestone (No. 1); 14 feet of the upper Florence limestone (No. 2); 3 feet of shaly limestone (No. 3); and 5 feet of limy shale (no. 4). Samples No. 3 and 4 are from the Oketo shale member.

The percentage of carbon dioxide in the samples, as determined by the calcination test, are as follows: No. 1, 26.89 per cent; No. 2, 40.55 per cent; No. 3, 35.65 per cent; No. 4, 36.04 per cent.

Sample No. 1, the Florence "flint" limestone, is a natural wool rock, with a carbon-dioxide content very close to the optimum percentage. This sample was fused and blown into rock wool at 1500° C., producing a fine, white wool. Very wet steam at 60 pounds per square inch pressure caused shot to be formed in the blowing test. This material fused readily at the temperature used, and was quite fluid when poured. A rock wool of similar quality was produced in the blowing test during the summer of 1936 from a sample of the Florence limestone taken southwest of Junction City. Since the Junction City sample contained 25 per cent in comparison to the 26.89 per cent of the Augusta sample, it nay be concluded that the Florence "flint" limestone is a satisfactory wool rock of fairly uniform quality over a wide area. This limestone has a thickness of at least 20 feet within a few miles of the outcrop sampled at Augusta.

Sample No. 2 is the limestone quarried and was not considered as a rock-wool material.

Sample No. 3 and sample No. 4 might be very profitably used in the production of rock wool by the addition of a siliceous material such as shale or sand. It constitutes the overburden in the quarrying operation.

Augusta is on the Frisco and the Missouri Pacific railroads, and also on U.S. Highways 54 and 77. The area is an important one in the production of gas and oil.

Figure 7--Stratigraphic section at the E. W. Young quarry south of Augusta, showing location of samples No. 1 (CO2 26.89 per cent), No. 2 (CO240.55 per cent), No. 3 (CO2 35.05 per cent), and No. 4 (CO2 36.04 per cent).

Five and one-half miles east of Newton and one-fourth mils south of oiled road, on creek bank in the N2 sec. 21, T. 23 S., R. 2 E., Harvey County.

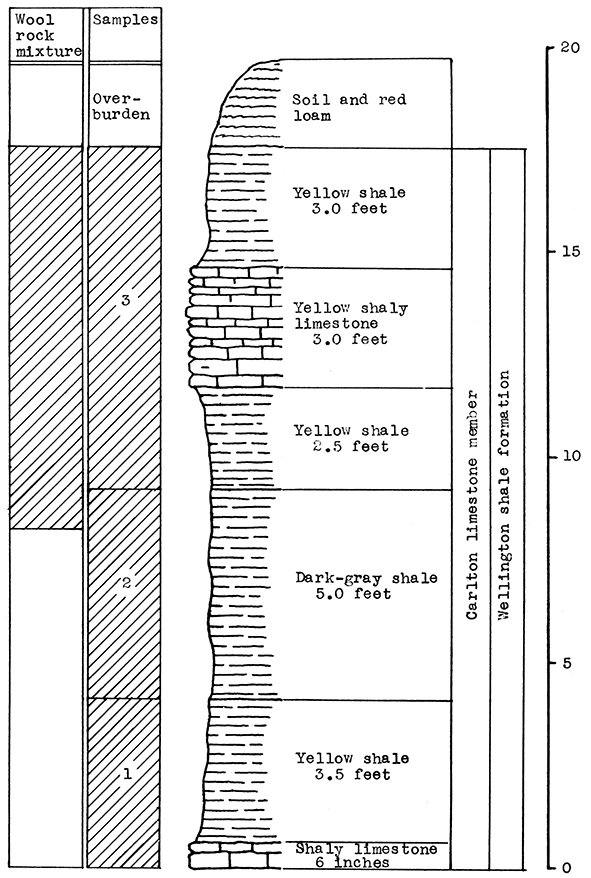

The Newton sample was taken from the Carlton limestone member of the Wellington shale formation, in the upper Permian system. The outcrop from top to bottom includes 3 feet of reddish loam (overburden); 3 feet of yellow shale; 3 feet of shaly limestone; 2 1/2 feet of yellow shale; and 5 feet of dark-gray shale. A total of 9 1/2 feet of limestone and shale were included in the wool-rock mixture used for a blowing test. It is possible that a greater thickness of usable rock can be found a short distance from this outcrop, particularly at the exposures along the creek bank on the north side of the road in the SE sec. 17, T. 23 S., R. 2 E. This exposure was not sampled because of its weathered condition, and the accumulation of slumped material.

The limestone and shale used for the blowing test have an average carbon-dioxide content of 27.5 per cent. A large amount of fine white wool was blown from this material. The fusion temperature was 1500° C.; steam pressure, 60 pounds.

The city of Newton is on Kansas Highway 15 and U.S. Highways 50 S. and 81; and on the Santa Fe and Missouri Pacific railroads. There is an abundant supply of both gas and oil in this area.

Figure 8--StratigraphiC section of outcrop east of Newton showing location of samples No. 1 (CO2 16.14 per cent), No. 2 (CO2 12.81 per cent), and No. 3 (CO2 29.14 per cent). The wool rock mixture (CO2 27.5 per cent) includes the upper one foot of sample No. 2.

Quarry operated by Cleo C. Ely, 5 miles south and 2 1/2 miles east of Little River in the SE sec 11, T. 20 S., R. 6 W., Rice County.

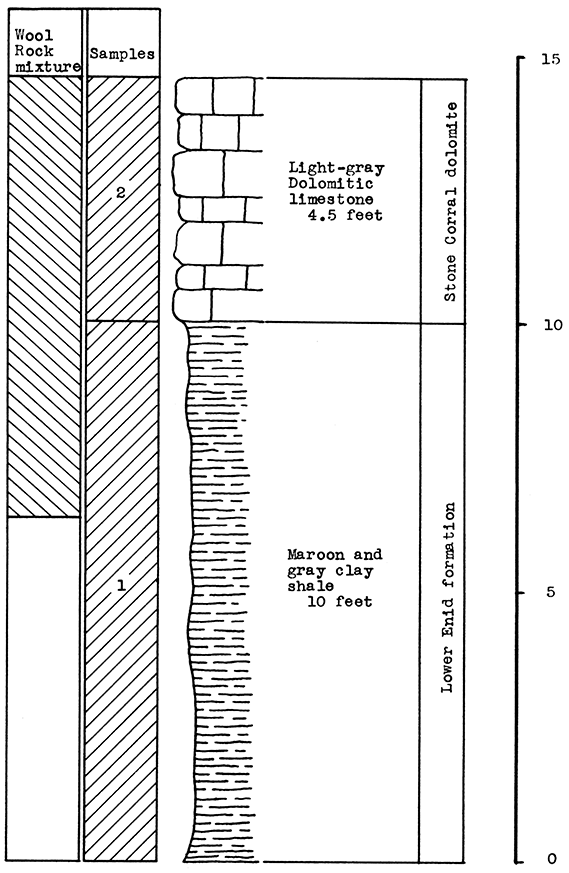

The rocks sampled at Little River include 4 1/2 feet of the Stone Corral dolomite, and 10 feet of red to gray clay shale upon which the dolomite rests. The Stone Corral dolomite caps the escarpments west of Little Arkansas River in the area from which the samples were taken. This dolomite outcrops as close as 2 1/4 miles south and 1 1/2 miles east of Little River. The overburden is negligible at the outcrop sampled.

The Stone Corral dolomite (sample No. 2) tested 44.36 per cent for carbon-dioxide content. The underlying shale (sample No. 1) had a carbon-dioxide content of 6.62 per cent. A mixture containing 55 per cent dolomite and 45 per cent shale was prepared for the blowing test. The average carbon-dioxide content of the mixture was 27.4 per cent. The mixture produced a white fluffy wool of good quality at a fusion temperature of 1500° C. A steam pressure of 60 pounds was used. The shot in the wool was a light-lavender color.

If it should prove more economical to do so, other siliceous materials closer to Little River could be substituted for the shale in the wool-rock mixture. Alluvium from the flood plain of Little Arkansas River is suggested.

Little River is on U.S. Highway 50 N., and on the Santa Fe railroad. Gas is available for fuel.

Figure 9--StratigraphiC section at quarry operated by Cleo C. Ely, southeast of Little River, showing location of samples No. 1 (CO2 6.62 per cent) and No. 2 (CO2 44.36 per cent).

Location A: about 4 miles north or Lorraine in road cut on highway in the SE sec. 28, T. 16 S., R. 9 W. This is the first road cut in the breaks south and west of Smoky Hill River. Location B: 2 miles due east of location A, in the SE sec. 26, T. 16 S., R. 9 W., Ellsworth County.

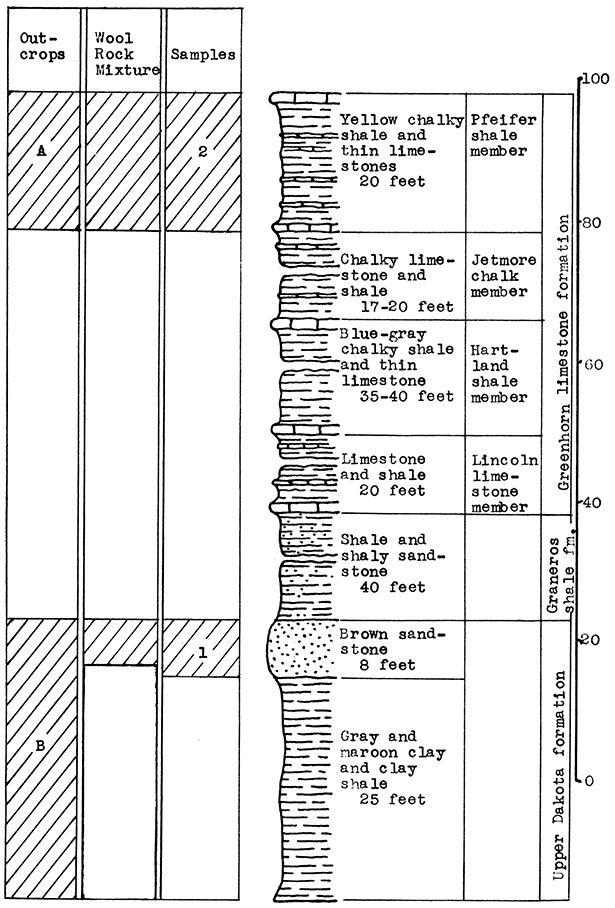

The rock sampled at location A is the Pfeifer shale In the Greenhorn formation. Fifteen feet of chalky shale and thin limestones were sampled at this locality. The Greenhorn limestone includes 75 to 100 feet of rock which is a suitable ingredient for a wool-rock. Sample B is an 8-foot brown sandstone from the Dakota formation. This sandstone caps the escarpments west of the location sampled, and nearer location A, but these outcrops are not well exposed. The sandstone rests on 25 feet of plastic clay.

The Pfeifer shale at location A has a carbon-dioxide content of 36.98 per cent (sample No. 1). The Dakota sandstone at location B has a carbon-dioxide content of 1.72 per cent (sample No. 2). A mixture of 73 per cent Pfeifer shale and 27 per cent Dakota sandstone was used in the blowing test. The carbon-dioxide content of the mixture is 27.46 per cent. The wool produced was of good quality and white. The fusion temperature was 1500° C., the steam pressure 65 pounds.

The materials used for the test can be quarried over a fairly wide area surrounding the locations given. The top mantle of sandy clay loess could be used as a substitute for the sandstone if it should be more economical to do so.

Gas and oil are available for fuel in this area. The highways most accessible to the outcrop are Kansas Highways 4 and 14. Kansas Highway 14 joins U.S. Highway 40 at Ellsworth and U.S. 50 N, at Lyons. The Frisco railroad from Lorraine to Ellsworth passes within one-half mile of outcrop A. Ellsworth is also on the Union Pacific railroad, and Lorraine on the Santa Fe.

Figure 10--Stratigraphic section at outcrops north and northeast of Lorraine, showing location of samples No. 1 (CO2 1.72 per cent) and No. 2 (CO2 36.98 per cent).

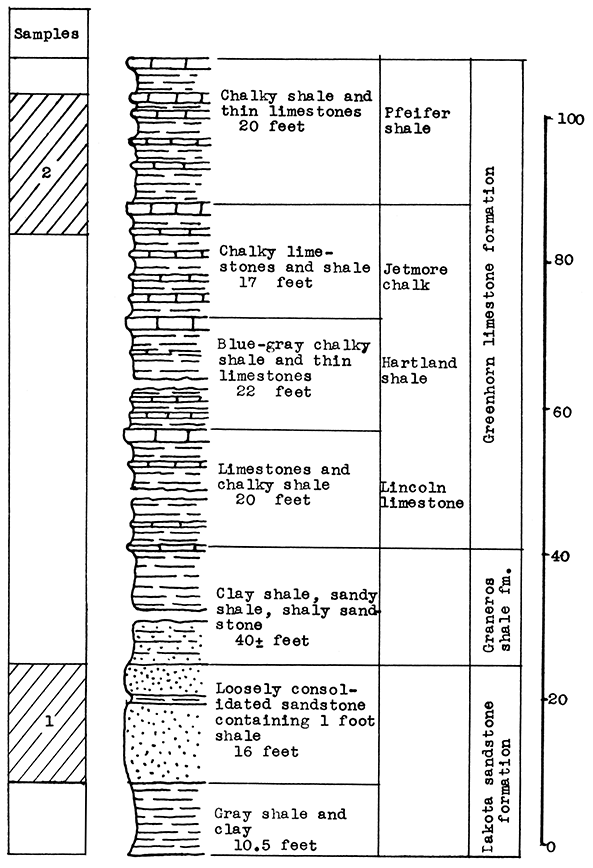

Sample No. 2: road cut in escarpment south or the Saline River, about 3 1/2 miles north of Russell. Sample No. 1: about three-fourths of a mile north of location of sample No. 2. and approximately 50 yards east of Saline River bridge. Both samples were taken in the W2 sec. 3, T. 13 S., R. 14 W., Russell County.

The rocks exposed in the immediate vicinity of the locations sampled include the Carlile shale, the Greenhorn limestone and the upper Dakota formation. The Greenhorn formation is made up almost entirely of thin limestones and chalky shales containing a high percentage of calcium carbonate. The "fencepost" limestone occurs at the top of the Greenhorn formation. The Fairport shale, a member of the Carlile formation, is lithologically simIlar to the Greenhorn for a few feet above the "fencepost" limestone. Sample No. 2 includes all but the upper 5 feet of the Pfeifer shale member and a portion of the Jetmore chalk member. A vertical section of 19 feet was sampled. Sample No. 1, which was taken in upper Dakota sandstone formation, includes 16 feet of loosely consolidated sandstone. The overburden at both localities consists of a few feet of material weathered from the underlying rocks.

Sample No. 2 (Greenhorn limestone) has a carbon-dioxide content of 37.49 per cent; sample No. 1 contains 10.78 per cent carbon dioxide. A mixture was prepared for the blowing test containing 65 per cent No. 2 and 35 per cent No. 1, having an average of 28.14 per cent carbon dioxide, indicating a calcium-carbonate content of 63.9 per cent. In the blowing test this mixture produced a fine white wool. Some shot resulted from the extremely wet steam at 58 pounds pressure. The glass was poured at 1500° C.

The outcrops sampled are on a gravelled highway 2 miles west of Kansas Highway 8. Russell, the county seat of Russell County, is on U.S. Highway 40, and on the Union Pacific railroad.

Figure 11--Stratigraphic section of outcrops north of Russell showing location of samples No. 1 (CO2 10.78 per cent) and No. 2 (CO2 37.49 per cent).

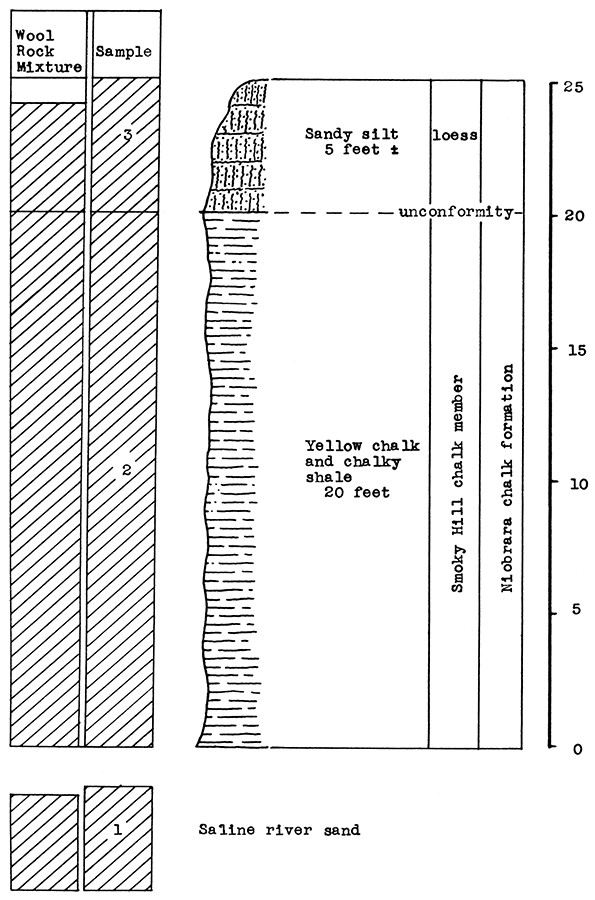

Samples No. 2 and No. 1, two miles south of Saline river, and one-fourth of a mile west of Kansas Highway 21, in chalk "badlands" south of road near the north section line in the NE sec. 28, T. 11 S., R. 23 W. Sample No. 3, sand from bed of Saline River near bridge on Kansas Highway 21, Trego County.

Twenty feet of buff-colored chalky shale was sampled from the Smoky Hill member of the Niobrara chalk formation in the Upper Cretaceous (sample No. 1). This member has a maximum thickness of about 700 feet where none of the original deposit has been removed by erosion. Resting on the Smoky Hill chalk is a surface mantle of red-brown to yellow loess of varying thickness (sample No. 2). Five feet of loess covers the Smoky Hill chalk at the location sampled.

The sand sampled from the Saline River bed contains a small amount of chalky shale flakes from the Smoky Hill member. The sample includes portions taken over a horizontal range of about 50 feet, and a vertical range of 5 feet.

Sample No. 1, the Smoky Hill chalk has an average carbon-dioxide content of 35.75 per cent. The loess (sample No. 2) contains 6.57 per cent carbon dioxide, and the river sand (sample No. 3) 2.52 per cent carbon dioxide. A wool-rook mixture was made containing 75 per cent of sample No. 1, 15 per cent of sample No. 2, and 10 per cent of sample No. 3. The carbon-dioxide content of the mixture averaged 28.05 per cent. At a pouring temperature of 1500° to 1525° C. a white, fine-fibered wool was produced. A steam pressure of 60 pounds was used.

The outcrops sampled are on or near Kansas Highway 21 Which passes through Wakeeney. Wakeeney is on U.S. Highway 40, and on the Union Pacific railroad. Gas has been piped into this town within the past year.

Figure 12--Stratigraphic section of outcrops north of Wakeeney, showing location of samples No. 1 (CO2 2.52 per cent), No. 2 (CO2 35.75 per cent), and No. 3 (CO2 6.57 per cent).

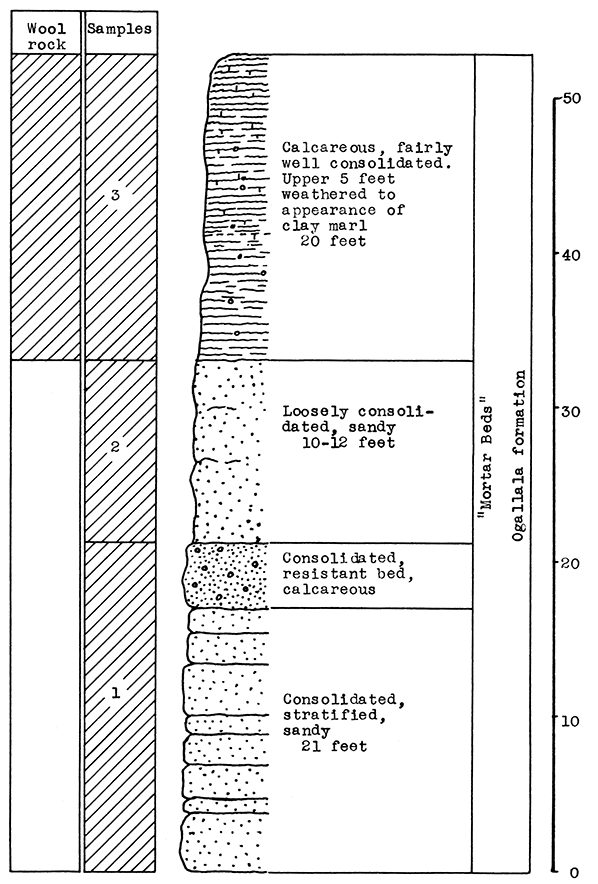

Samples No. 1, No. 2, and No. 3: escarpment on east edge of the Scott County State Park in road cut, on highway which runs east from the park to U.S. Highway 83. Sample No. 4: On the John Kittle farm about 300 yards east of the Wichita-Scott county line, and 3 1/2 miles south of Kansas Highway 96, in sec. 6, T. 19 S., H. 34 W., Scott County.

Both of the outcrops sampled are from the "mortar beds" beds in the Ogallala formation. The "mortar beds" are composed of sand, gravel and clay cemented by calcium carbonate. The proportion of the constituent materials varies widely. Out of a vertical distance of 53 feet which was sampled at the State Park, only the upper 20 feet contained sufficient calcium carbonate to be classed as a wool rook (sample No. 3). Twelve feet of material underlying this portion contained less than 2 per cent calcium carbonate. Sample No. 3 includes the upper 20 feet of the State Park outcrop; the upper 5 feet of which is composed of weathered material having the appearance of a clay marl. The overburden consists only of a few inches of clay and soil.

The "mortar bed" from which sample No. 4 was taken is 10 feet thick at the outcrop. The overburden is negligible.

Sample No. 3 has a carbon-dioxide content of 26.6 per cent, and sample No. 6 contains 28.58 per cent carbon dioxide. In the blowing test sample No. 3 produced a fine white wool which contained a large proportion of shot because of excessively wet steam. The glass was poured at 1500° C. and a steam pressure of 55 pounds used. Sample No. 6 produced an excellent quality of white wool at a pouring temperature of 1525° C. with the steam pressure varying from 50 to 55 pounds.

The outcrop from which No. 3 was sampled is on the gravel road leading east from the Scott County State Park to U.S. Highway 83. The outcrop for sample No. 6 is on a dirt road about 3 1/2 miles south of U.S. Highway 96. Scott City is on the Missouri Pacific and the Union Pacific railroads. Gas is available from the Hugoton field by pipe line.

An outcrop of the "mortar beds" similar to sample No. 6 was observed 8 miles west of Scott City, a short distance south of Kansas Highway 96 on the banks of Stony Creek.

Figure 13--Stratigraphic section at Scott County State Park, north of Scott City, showing location of samples No. 1 (CO2 10.97 per cent), No. 2 (CO2 1 per cent), and No. 3 (CO2 26.60 per cent). Sample No. 3 produced rock wool.

Sample No. 2 is algal limestone taken from an outcrop about 17 miles northeast of Garden City near the center of the south line of sec. 28, T. 22 S., R. 30 W. Sample No. 1 was taken from the Churchill quarry, about 18 miles northeast of Garden City, in the W2 sec. 22, T. 22 S., R. 30 W; sample No. 3, from the G. E. Smith sand pit south of the Arkansas River, Garden City; No. 4, dune sand 1 1/2 miles south of Garden City on U.S. Highway 83. All outcrops sampled are in Finney County.

The rocks sampled from this area were taken from the Ogallala formation in the Tertiary system, and from the Fort Hays chalk member in the Upper Cretaceous system. The 2-foot algal limestone is a local phase of the Ogallala "mortar beds" which rests disconformably on Fort Hays chalk in the area sampled.

The sand sampled at the south edge of the flood plain of the Arkansas River (No. 3) is from old river terrace deposits. Sample No. 4 is dune sand, a recent deposit which covers the surface over a wide area south of the Arkansas River.

The algal limestone (sample No. 2) has a carbon-dioxide content of 41.89 per cent, indicating a calcium-carbonate content of approximately 95 per cent. The Fort Hays chalk contains 41.17 per cent carbon dioxide, or approximately 93.6 per cent calcium carbonate. The two sand samples were not tested for carbon dioxide after treatment with hydrochloric acid indicated no carbonates were present. Both samples (No. 3 and No. 4) were assumed to be 100 per cent silica and alumina.

Two wool-rock mixtures were prepared for the blowing test. Wool rock A contained 65 per cent of sample No. 2 (algal limestone) and 35 per cent of sample No. 4 (dune sand). The carbon-dioxide content of the mixture averaged 27.23 per cent.

A fine white wool was blown at approximately 1525° C. with a steam pressure of 55 pounds. Wet steam at low pressure produced a large amount of shot and reduced the quantity of wool, but under normal conditions the mixture would be satisfactory.

Wool rock B contained 65 per cent of sample No. 1 (Fort Hays chalk) and 35 per cent of sample No. 3 (sand). The carbon-dioxide content of the mixture was 26.76 per cent. At 1525° C. and with slightly drier steam at 65 pounds pressure, a good quality of white wool was produced in the blowing test. The amount of shot was not excessive.

Garden City is located at the junction of U.S. Highways 50 N. and 50 S., and on 83. The Santa Fe railroad serves this area. Gas is obtained from the Hugoton field.

A few inches of the Fort Hays chalk is exposed at Twin Springs in the W2 sec. 10, T. 23 S., R. 30 W. The depth of the chalk at this exposure was not determined. An outcrop of "mortar beds" occurs south of U.S. Highway 50 N., in sec. 15, T. 23 S., R. 30 W.

As a result of the rock-wool investigation conducted by the Kansas Geological Survey in 1936, a plant has been constructed and rock wool is being produced, on a commercial scale by the Verdigris Valley Vitrified Brick and Tile Company at their plant, located south of Neodesha.

Mr. Charles Laird, superintendent of the brick plant, has designed and supervised the construction of the equipment now in use. The raw materials, a mixture of limestone and shale, are fused in a reverberatory, gas-fired furnace. The molten rock is blown into wool by a blast of air at 100 pounds pressure. The wool is removed from the receiving room by a drag conveyor, and is sacked by hand. The furnace has a capacity of two tons of raw material per charge. Three tons of rock wool a day can be blown when the plant is operating at full capacity. The only serious problem encountered in the operation of this plant is the selection of satisfactory refractory lining for the furnace, as ordinary fire-clay bricks are corroded by the molten glass. However, Mr. Laird is confident that a slight improvement in design, and the use of a different type of refractory, will solve this problem.

Previous to the construction of the present commercial scale equipment, Mr. Laird built a smaller furnace to determine a suitable design, and to test the possibilities of fusing a wool-rock mixture in a gas-fired furnace. He has experimented with mixtures ranging from nearly pure shale to nearly pure limestone, and has varied the fusion temperature from 2450° F. to 3000° F. Mr. Laird's experience has demonstrated very clearly the advisability of this preliminary phase in the development of a commercial plant.

Kansas Geological Survey, Rock Wool Resources of Kansas, Appendix

Placed on web July 12, 2015; originally published Dec. 15, 1937.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/MRC8/index.html