Kansas Geological Survey, Bulletin 199, pt. 1, originally published in 1970

Originally published in 1970 as part of Kansas Geological Survey Bulletin 199, pt. 1, p. 9-10. This is, in general, the original text as published. The information has not been updated. An Acrobat PDF version of the complete bulletin (5 MB) is also available.

Calvert volcanic ash (Pliocene) has been expanded, producing a low-density closed cellular structure similar to that produced in Pearlette volcanic ash (Pleistocene). Expanded bulk density is somewhat higher than that of the Pearlette ash.

It was previously reported (Carey, et al., 1952, p. 38) that Calvert ash does not expand. The easily expanded Pearlette ash and the reportedly nonexpandable Calvert ash have similar physical and chemical characteristics (Table 1). The comparative properties would indicate that Calvert ash should expand. Ceramic slips containing Calvert ash require more water for fluidity, just as do slips containing Pearlette ash, indicating that approximately the same internal pore structure exists in the shards.

Table 1--Comparative properties of Pliocene (Calvert, NNV-1A) and Pleistocene (Pearlette, JV-6) volcanic ash*.

| Chemical analysis | Particle-size analysis | Particle geometry | Index of refraction, ave. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| NNV-1A | JV-6 | NNV-1A | JV-6 | Typical Pliocene ash |

Typical Pleistocene ash |

NNV-1A | JV-6 | ||

| SiO2 | 73.44% | 73.32% | 20 mesh | 5.40% | 0.02% | Shards flat and thin |

Shards curved |

1.501 ± .001 | 1.499 ± .002 |

| Range: 1.503-1.498 | |||||||||

| Al2O3 | 11.36 | 10.76 | 60 mesh | 1.31 | 0.20 | ||||

| Fe2O3 | 2.01 | 1.66 | 150 mesh | 3.52 | 2.51 | ||||

| TiO2 | 0.39 | 1.36 | 200 mesh | 17.48 | 20.40 | ||||

| CaO | 0.61 | 0.53 | pan | 72.27 | 76.87 | ||||

| MgO | 0.08 | 0.23 | |||||||

| K2O | 5.23 | 5.30 | |||||||

| Na2O | 2.33 | 2.27 | |||||||

| L.O.I.† | 3.93 | 3.93 | |||||||

| * Data taken from Carey, J.S., et al., 1952. † L.O.I. = loss on ignition. |

|||||||||

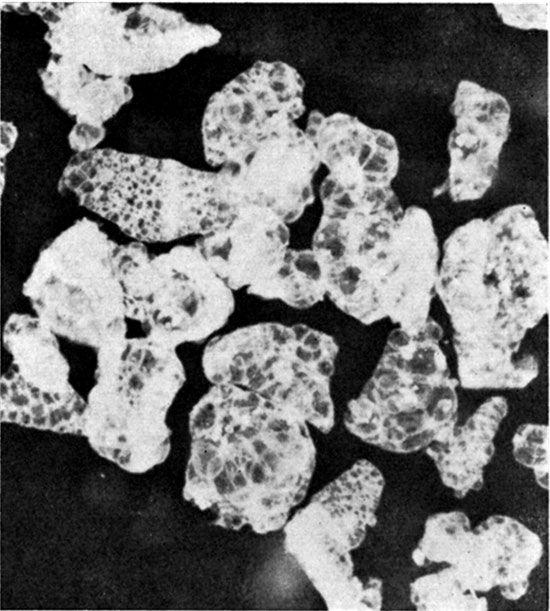

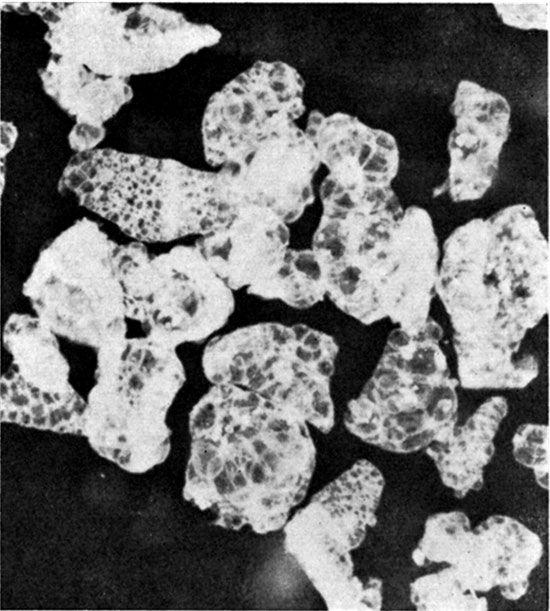

Using the same expansion procedure and equipment as used with Pearlette ash, a sample of Calvert ash (NNV-1A) was expanded to a structure similar to that produced in Pearlette ash. It required a higher flame temperature to produce cellular expansion. The temperature observation is strictly qualitative, based on the amount of gas input. Actual temperature measurement of a flame with glowing insulative particles in suspension is difficult. Microscopic examination (Fig. 1) shows good expansion of many shards. However, many shards show only partial expansion, hence the reported bulk densities (Table 2) are higher than Pearlette ash. (Commercially expanded Pearlette ash has a bulk density of 6-7 pounds per cubic foot).

Figure 1--Cellulated structure in expanded Calvert volcanic ash, X35. Picture made by direct projection of ash image onto enlarging paper.

Table 2--Comparison of vibration-compacted bulk densities of Calvert and Pearlette cellulated volcanic ash.

| Particle size | Bulk density (lbs per cu ft) | |

|---|---|---|

| Calvert ash | Pearlette ash | |

| +24 mesh | 6.6 | 4.9 |

| -24 + 60 mesh | 2.3 | 2.1 |

| -60 mesh | 8.3 | 6.0 |

I do not think the higher bulk density problem is unsolvable. A careful study of burner design, rate of feeding, and air classification should produce an expanded Calvert ash that is indistinguishable from an expanded Pearlette ash.

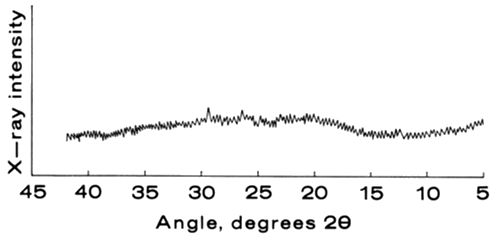

It is often asked if there is a health hazard accompanying the handling of expanded volcanic ash because it has such a low density and easily floats in the air. A search of books on occupational diseases reveals no reference to volcanic ash as a hazardous material. The X-ray pattern of crushed expanded ash (Fig. 2) is that of a typical amorphous material and shows no crystalline quartz. It is crystalline quartz that causes silicosis. Small amounts of expanded ash floating in the air are quite irritating to most people; they will not remain exposed to it any longer than necessary without protective breathing masks. As far as we know, there is no danger of silicosis from the expanded volcanic ash. It is recommended that the usual normal, established health requirements for handling dusty material be followed, as too much of any dust can cause temporary irritations.

Figure 2--X-ray diffraction pattern for crushed expanded volcanic ash. (Cu radiation, 100 counts/sec.)

The above remarks refer only to the volcanic ash after it has passed through the expansion process or to an ash deposit that is completely free of crystalline silica (sand). If the ash deposit contains small particles of sand, normal safeguards against silicosis must be taken in the mining operation and handling of the ash in the pre-expansion stages in the plant. Any sand present will drop out of the air stream immediately upon leaving the burner as the sand does not change its density and will be too heavy to be carried in the air stream used to move the expanded ash.

Even though there is strong geological evidence that there are at least two distinct ash falls in Kansas separated in geological time, many of the physical and chemical properties of the ashes are similar, suggesting that the source area for each was from the same general volcanic area. Lava chemistry must have been similar. The best expansion behavior seems to be associated with the "fresh" ash, i.e., ash that has not started to alter to montmorillonitic clay minerals.

Carey, J. S., Frye, J. C., Plummer, Norman, and Swineford, Ada, 1952, Kansas volcanic ash resources: Kansas Geol, Survey Bull. 96, pt. 1, p. 1-68. [available online]

Kansas Geological Survey, Expansion Characteristics of Calvert Volcanic Ash (Pliocene) in Kansas

Placed on web Oct. 4, 2016; originally published in March 1970.

Comments to webadmin@kgs.ku.edu

The URL for this page is http://www.kgs.ku.edu/Publications/Bulletins/199_1B/index.html