|

HELP: Quantitative Analysis Equations - Fluid DST |

NOTE: Much of this web page is taken from the lecture notes "Modern Concepts in Drillstem Testing Part 2 Quantitative Analysis"2 by Hugh W. Read, Author & Instructor.

For a disccussion of the theory of pressure buildup interpretaton and the derivation of the pertinent equations the reader is referred to the original now classical paper by Horner(1).

90% of all quantitative Drill Stem Test analysis is based on Horner's method of analysis which assumes the following ideal conditions:

i) Radial flow

Radial flow is flow into the well bore equally from all directions in the formation. By and large

condition is met by most DST's through linear systems such as fractures, narrow channel sands etc.

are obvious exceptsion which may be handled separately.

ii) a homogeneous reservoir

Homogeneity in a reservoir denotes constant characteristics throughout the length and thickness.

Any values calculated from test data then becomes averages over the length and/or thickness.

iii) "steady-state" conditions of flow

"Steady-state" flow condiitions imply a rate and pressure drawdown (which is responsible for the flow)

which is constant.

iv) infinite reservoir

An infinite reservoir is one in which there are no finite limits or depletion. All DST's in wildcat

wells can be considered to test infinite reservoirs, except those testing very small local

porosity or fracture developments which in any event deplete rapidly and are not commercial.

v) single phase flow

Single phase flow assumes that only one phase is entering the well bore. Thus for example any gas

produced with oil is considered as solution gas and any liquids in a gas test are considered as

condensation of gases in the pipe or immediate well bore vicinity.

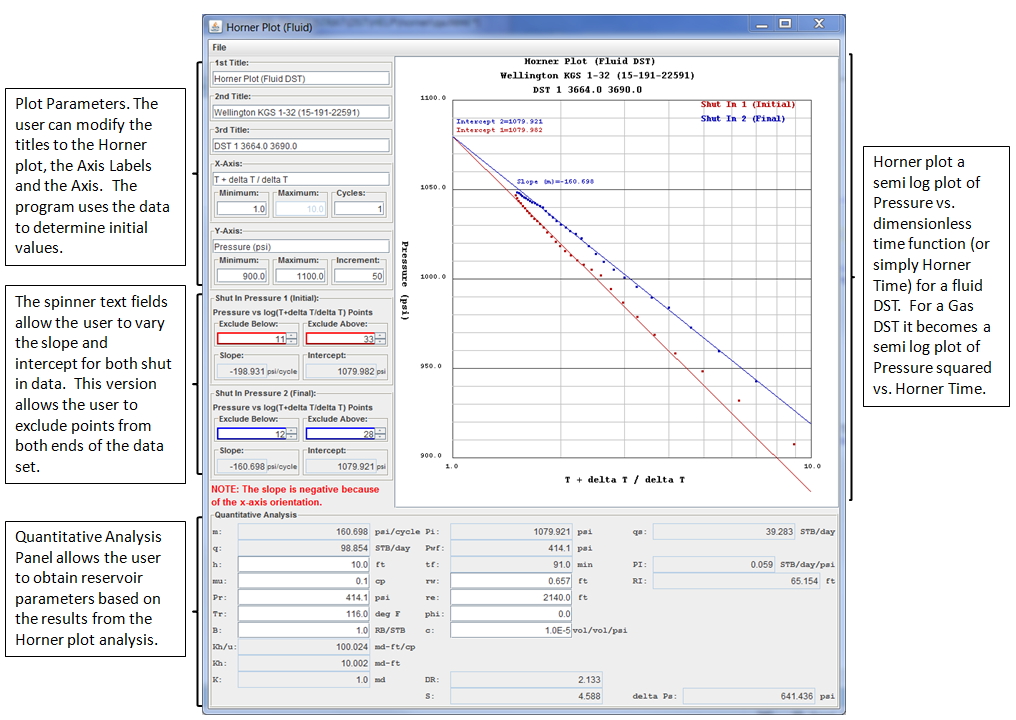

This example is from the Wellington KGS 1-32; DST 1 in the Mississippian from 3664.0 ft to 3690.0 ft dst-fluid.las. The Recovery and Pressure Summary Data will be needed in performing the horner plot and quantitative analysis and is listed as follows,

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(1) The data necessary for this plot is a set of detailed readings of pressures and times during each shut in period plus the total amount of time spent flowing the well.

(2) Arrange the data in tablular form where,

T = Cumulative flowing time (minutes)

ΔT = Times during shut in that each pressure is read (minutes)

P = Pressure read during shut in time (psig)

| Table 3 Tabular Listing of Shut In Data for Horner Plot Calculation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

From the Pressure Summary Table (a) Shut-in 1 Time - Open to Flow 1 Time { 44.0 - 12.0 = 32.0 minutes } (b) Shut-in 2 Time - Open to Flow 2 Time + Total Flow Time from (a) { 168.0 - 109.0 + 32.0 = 91.0 minutes } |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In the table note that the Shut In 1 (Initial) period was broken down into 4 minute intervals while only 8 minute increments was considered sufficient for the Shut In 2 (Final) period.

The Pressure Summary Table gives a summary of the DST Pressure-Temperature-Time Readings at specific points. This DST had a 32.0 minute preflow and a 59.0 minute main flow. Thus 'T' for the Shut In 1 (Initial) period = 32.0 minutes since there was a total of 32 minutes flow time prior to Shut In 1 (Initial). T for the Shut In 2 (Final) period becomes 91 minutes ( 32 minutes preflow + 59 minutes mainflow since T is the cumulative flow time prior to shut in.

The quantity (T + ΔT)/ΔT is mathematically the same as 1 + (T/&DeltaT) thus for the Shut In 2 (Final) period example the (T + ΔT)/ΔT for the first increment = (91+8)/8 = 12.38, which is the same as 1 + (91/8) = 1 + 11.38 = 12.38.

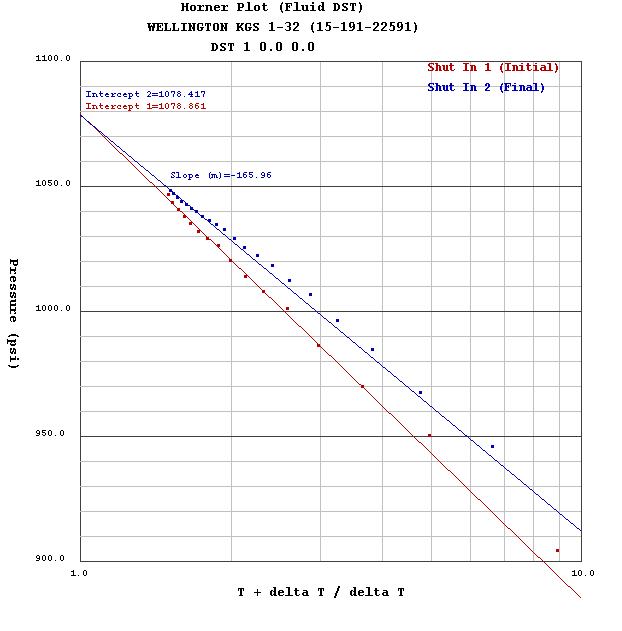

(3) The Horner plot is then constructed by plotting log10[(T+ΔT)/ΔT] vs P

for each point.

(4) In Figure 1 both Shut In Pressure-Time curves have been plotted. In order to determine the static reservoir pressure the linear portion is extrapolated to the left hand margin where the value of the time function (T + ΔT)/ΔT = 1. Since the logarithm of 1 is zero the log10[(T + ΔT)/ΔT ] = 0 (or infinity) at this point. Thus we are extrapolating the Horner straight line to a 'infinite' shut in time where completely static pressure prevails. In the example here the static pressure ~ 1078.0 psig. Both Shut In intervals extrapolations yield this value. In cases where the Shut In 2 (Final) extrapolation is substantially less than the Shut In 1 (Initial) depletion is indicated. ( If the depletion factor 100.0 * Shut In [(Initial)-(Final))/(Initial) ] is greater than 4%, then the idications of depletion can be considered serious or sustantial.

(5) The final piece of information which is obtained form the Horner plot is the "slope" (m) of the striaght line segment. Numerically this is the difference between the pressure at log10[(T + ΔT)/ΔT ]=0 and at log10[(T + ΔT)/ΔT ]=1. where the slope is simply the change in pressure over one complete log cycle. The slope in this example using the Shut In (Final) slope m=165.96 psi/cycle. The slope is used in the calculations to derive permeability and other reservoir parameters.

The well known equation describing pressure build-up characteristics of a well is expressed as

Theoretically, the plot of Pressure Po vs. log10[(T+ΔT)/ΔT] will result

in a straight line; Po = Pf - m * log10[(T+ΔT)/ΔT] where

Pf is the extrapolation of log10[ (T+ΔT)/ΔT ] to zero or formation pressure and

m is the slope of the line.

m = 162.6 * q * μ * B / (K * h) [psi] / [log cycle]

q = flow rate [STB] / [day]

μ = viscosity [cp]

B = Formation Volume Factor [RB] / [STB]

h = vertical thickness of continuous porosity [ft]

K = average effective permeability [md]

This states that the slope of the buildup is representative of a given fluid having physical properties

μ, B flowing at a rate q through a formation having physical properties K * h.

Note: the flow rate (q) is computed by using the total fluid volume in the recovery table and the total flow time computed from the pressure summary table and converting to days, i.e. q = (Total Fluid Volume [bbls] / Total Flow Time [min] ) * ( 60 [min] / [hr] ) * ( 24 [hr] / [day] ).

Transmissibility can be found my rearranging the slope as follows,

| Transmissibility: | K * h / μ = 162.6 * q * B / m | [md]-[ft]/[cp] | ||||

| Permeability Thickness: | K * h = ( Transmissibility ) * μ | [md]-[ft] | ||||

| Permeability: | K = ( Permeability Thickness ) / h | [md] |

| Pi - Pwf | ||

| DR = | ------------------------------------------------ | - 2.85 |

| m * log { [ k * To / ( φ * μ * c * rw2 ) ] } |

where,

| Pi | = Initial static reservoir pressure | [psig] |

| Pwf | = Bottom Hole Flowing Pressure (FFP) | [psig] |

| m | = slope from the Horner plot | [psi] / [log cycle] |

| K | = Permeability ( K ) | [md] |

| To | = Flow Time | [min] |

| φ | = Porosity | |

| μ | = viscosity | [cp] |

| c | = compressibility | [vol]/[vol]/[psi] |

| rw | = well bore radius | [ft] |

If K, φ, μ, c and rw are not known then the Damage Ratio can be estimated by,

| Pi - Pwf | ||

| EDR = | ----------------- | + 2.65 |

| m * log { To } |

Skin factor (S) - A numerical quantity which attempts to describe the amount of damage or improvement. The numerical value of skin is so defined that a positive value for the skin factor indicates a damaged condition and a negative skin factor indicates improvement over the natural condition. The skin factor is zero when neither skin damage nor improvement are present i.e. no alterations to natural condition.

| - | - | |||||

| | | Pi - Pwf | K * To | | | |||

| S = 1.1515 * | | | ----------- | - log | ------------------ | + 5.01 | | |

| | | m | φ * μ * c * rw2 | | | |||

| - | - |

where,

| Pi | = Initial static reservoir pressure | [psig] |

| Pwf | = Bottom Hole Flowing Pressure (FFP) | [psig] |

| m | = slope from the Horner plot | [psi] / [log cycle] |

| K | = Permeability ( K ) | [md] |

| To | = Flow Time | [min] |

| φ | = Porosity | |

| μ | = viscosity | [cp] |

| c | = compressibility | [vol]/[vol]/[psi] |

| rw | = well bore radius | [ft] |

If φ, μ, c and rw are not known then the Skin factor (S), assuming average values of φ=0.15, μ*c=0.00000955 [cp]/[psi] and for siplicity assume rw=0.333 [ft], can be estimated by,

| - | - | |||||

| | | Pi - Pwf | | | ||||

| S = 1.1515 * | | | ----------- | - log | (K * To) | + 1.80 | | |

| | | m | | | ||||

| - | - |

Pressure Drop Across a Damage Zone ΔPskin The additional pressure drop during flow caused by the presence of skin (ΔPskin) may be calculated as follows,

ΔPskin = 0.87 * S * m

where,

| S | = Skin factor | |

| m | = slope from the Horner plot [psi] / | [log cycle] |

Productivity Index (PI) Productivity Index is a measure of a zone's ability to flow at a particular drawdown ( reservoir pressure - flowing pressure). It may be formally defined as the flow rate [STB]/[day] per unit [psi] of pressure differential between the well bore at the formation face and the static reservoir pressure in the zone.

| K * h | 1 | ||

| PI = 0.00708 | ----- | * | ---------------------- |

| μ * B | ln(re/rw) - 0.75 + S |

| K | = average effective permeability | [md] |

| h | = vertical thickness of continuous porosity | [ft] |

| μ | = viscosity | [cp] |

| B | = Formation Volume Factor | [RB] / [STB] |

| re | = drainage radius | [ft] |

| rw | = well bore radius | [ft] |

| S | = Skin factor |

Stabilized Production Rate (qs) Once the stable PI has been derived the stable flow rate at any pressure may be calculated simply by multiplying the chosen drawdown by the PI.

qs = PI * ( Pi - Pwf )

where,

| Pi | = Initial static reservoir pressure | [psig] |

| Pwf | = Bottom Hole Flowing Pressure (FFP) | [psig] |

| PI | = Productivity Index |

Radius of Investigation (RI) The radius of investigation is the radial distance from the well bore which the pressure disturbance from the DST has investigated ( in other words "how far out into the zone the DST has looked").

RI = 2.6408 * √( K*To / ( φ * μ * c ) )

where,

| K | = Permeability ( K ) | [md] |

| To | = Flow Time | [min] |

| φ | = Porosity | |

| μ | = viscosity | [cp] |

| c | = compressibility | [vol]/[vol]/[psi] |

If φ, μ, and c are not known then the Radius of Investigation (RI) is as follows,

For Water: RI = 6.83 * √( K*Tf );

For Oil: RI = 4.63 * √( K*Tf );

References:

(1) Pressure Build-Up in Wells, by D.R. Horner,

3rd World Petroleum Congress, May 28 - June 6, 1951 , The Hague, the Netherlands

http://www.onepetro.org/mslib/servlet/onepetropreview?id=WPC-4135&soc=WPC

(2) Drillstem Test Interpretation Seminar, Author & Instructor: H.W.Reid

(3) Recent Developments in the Interpretation and Application of DST Data, by L.F.Maier

Journal of Petroleum Technology Volume 14, Number 11, November 1962, pgs 1213-1222

http://www.onepetro.org/mslib/servlet/onepetropreview?id=00000290